You face significant risks when you deploy robots in hazardous or specialized environments. Relying on generic battery solutions exposes your operations to failures such as fires and thermal runaway. For example, robots have caught fire due to faulty battery packs and charging units, with incidents lasting several days and causing major disruptions.

In 2018, a robot fire started from a faulty battery.

In 2019, a warehouse fire lasted four days after a battery charging malfunction.

In 2021, battery defects led to a major recall.

You need customized battery requirements to ensure safety, compliance, and reliability. Custom lithium battery packs provide advanced protection and tailored performance to meet the unique demands of special custom AGV and inspection robots.

Key Takeaways

Custom battery solutions enhance safety and reliability for robots in hazardous environments. Tailor battery packs to meet specific operational needs.

Follow strict certification standards like ATEX, IECEx, and UL to ensure compliance and safety. Verify all certifications before deploying battery systems.

Monitor battery performance with advanced Battery Management Systems (BMS). These systems provide real-time diagnostics and prevent overheating.

Implement effective thermal management strategies to avoid hazards like thermal runaway. Use insulation and cooling technologies to maintain safe operating temperatures.

Choose suppliers with strong quality control measures. Look for proven practices to ensure battery reliability and safety in demanding applications.

Part1: Custom Battery Requirements

1.1 Certification Standards

You must follow strict certification standards when selecting batteries for special inspection and explosion-proof robots. These standards ensure safety and compliance in hazardous environments. The most recognized international standards include ATEX, IECEx, and UL. Each standard addresses unique aspects of battery safety and performance.

Certification Standard | Description |

|---|---|

ATEX | Equipment and protective systems intended for use in explosive atmospheres must comply with this standard. |

IECEx | International standard for equipment used in explosive atmospheres, ensuring safety and compliance. |

UL | Safety standard for battery-operated appliances, ensuring safe operation in various environments. |

Note: ExRobotics holds 27 ex certificates, including Quality Assurance ATEX and IECEx Certificates. UL 2593 is a key safety standard for battery-operated appliances in explosive environments.

Regional standards also play a crucial role:

In the EU, you must comply with the Machinery and EMC Directive, following EN ISO 10218-1 and EN ISO 10218-2.

In North America, ANSI/RIA R15.06 outlines safety requirements for industrial robots and robot systems.

You can find more about international certification standards in scientific publications such as Nature.

Custom battery requirements demand that you verify all certifications before deployment. This step reduces risk and ensures your robots meet global safety expectations.

1.2 Voltage and Capacity

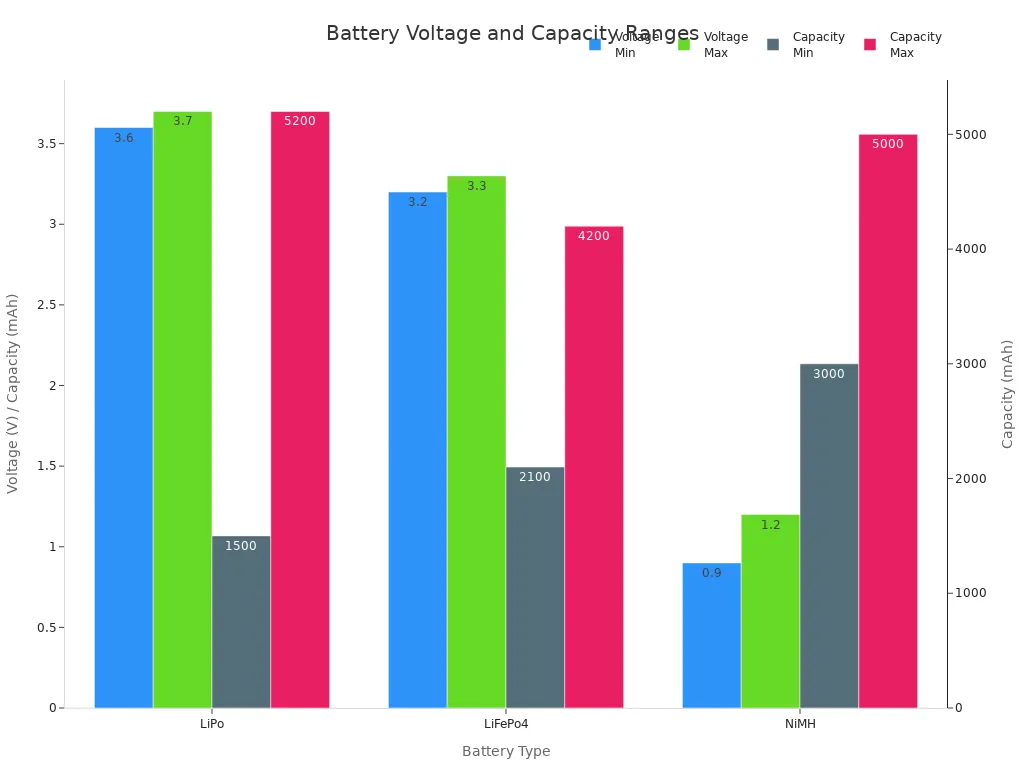

Choosing the right voltage and capacity for your lithium-ion batteries is essential for optimal battery performance. Different robot applications require specific voltage and capacity ranges. The table below compares the most common battery chemistries used in special inspection robots:

Battery Type | Voltage Range (V) | Capacity Range (mAh) |

|---|---|---|

Lithium Polymer (LiPo) | 3.6-3.7 (nominal) | 1500 – 5200 |

Lithium Iron Phosphate (LiFePO4) | 3.2-3.3 (nominal) | 2100 – 4200 |

Nickel Metal Hydride (NiMH) | 1.2 – 0.9 (nominal) | 3000 – 5000 |

You must match the battery pack to your robot’s operational needs. High energy density increases operational time, while long cycle life ensures reliability. The table below shows how battery capacity impacts performance:

Feature | Impact on Robots’ Performance |

|---|---|

High energy density | Increases operational time by providing more energy storage. |

Long cycle life | Ensures reliability and longevity of power supply in operations. |

High current discharge capability | Supports high-intensity operations without performance drops. |

Safety design | Prevents accidents, ensuring safe operation in hazardous environments. |

A battery capacity test helps you verify that your robots can operate for the required duration. You should always consider both voltage and capacity when specifying customized battery requirements for your application.

1.3 Discharge Rate and BMS

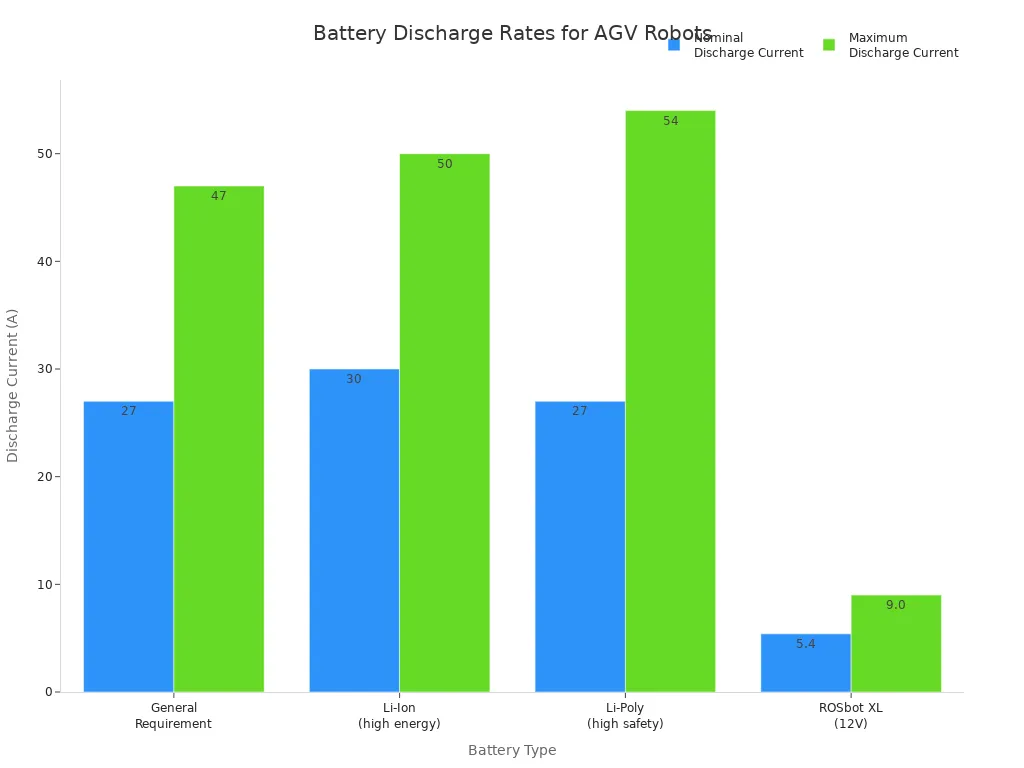

Discharge rate is a critical factor in battery performance, especially for high-performance AGV robots. Lithium-ion batteries must deliver high current safely and efficiently. The table below summarizes the discharge rates required for different battery types:

Battery Type | Nominal Discharge Current | Maximum Discharge Current |

|---|---|---|

General Requirement | >= 27A | >= 47A |

Li-Ion (high energy) | 30A | 50A |

Li-Poly (high safety) | 27A | 54A |

ROSbot XL (12V) | >= 5.4A | >= 9.0A |

You need a robust battery management system (BMS) to monitor and control lithium-ion batteries. Modern BMS advancements include intelligent communication protocols, adaptive charging, and structural designs that resist dust, shocks, and moisture. These features enhance safety, reliability, and operational efficiency. You can learn more about BMS technology at Large Battery BMS and PCM.

Advancement | Description |

|---|---|

Intelligent BMS | Enhances safety, reliability, and operational efficiency by establishing communication protocols and balancing techniques. |

Adaptive Charging | Regulates charging rates to avoid hazardous situations during operation. |

Structural Design | Ensures battery packs are resistant to dust, shocks, and moisture, enhancing reliability in hazardous environments. |

Safety Testing | Prototypes undergo rigorous testing to meet safety standards before mass production. |

You must also ensure your batteries pass rigorous performance testing. This includes altitude simulation, vibration resistance, impact testing, and IP68 waterproofing. The following table outlines the main custom-battery testing protocols:

Test Code | Description |

|---|---|

T1 | Altitude Simulation: Low pressure simulating unpressurized cargo hold at 15,000 meters. |

T2 | Thermal Test: Temperature extremes by keeping batteries for 6h at -40°C and +75°C. |

T3 | Vibration: Test simulates vibration during transportation at 7Hz to 200Hz for up to 3 hours. |

T4 | Shock: Test simulates impact during transportation at given G-forces relating to battery size. |

T5 | External Short Circuit: With fusing, apply a short circuit at 50°C. Case cannot exceed +170°C. |

T6 | Impact: >20mm cylindrical cell tested for impact; all <20mm cell types tested for crushing. |

T7 | Overcharge: Charge at twice the recommended current for 24 hours (secondary batteries only). |

T8 | Forced Discharge: Same as T7, forced discharge with primary and secondary cells. |

Tip: IP68 waterproofing is essential for underwater and hazardous robots. It ensures the battery remains sealed against water ingress, which prevents short circuits and thermal issues. This design increases the mean time between failures and supports safe operation in marine environments.

You should always include an emergency stop test and other safety testing protocols to meet battery safety standards. These steps guarantee that your customized battery requirements align with both performance and safety expectations.

Part2: Safety Features

2.1 Thermal Management

You must address thermal management as a top priority when designing lithium battery packs for explosion-proof robots. Temperature fluctuations create serious safety concerns and can lead to hazards such as thermal runaway or short circuits. Cold temperatures may cause lithium plating, which forms dendrites and increases the risk of internal short circuits. High temperatures accelerate battery aging and can trigger thermal runaway, posing safety hazards in environments with hazardous materials.

Effective thermal management strategies help you maintain battery performance and safety. The table below compares the most effective technologies for explosion-proof robots:

Category | Technologies/Strategies |

|---|---|

Prevention | Battery Management Systems (BMS), robust mechanical design, thermal insulation |

Early Detection | Gas detection systems, thermal sensors, voltage monitoring, acoustic sensors with AI |

Suppression | Specialized suppression agents (Novec 1230, FM-200), flooding systems |

Containment | Fire-resistant battery compartments, thermal barriers, ventilation systems |

You should also consider phase change cooling and liquid cooling. These techniques inhibit thermal runaway and reduce battery temperature, improving fire protection and overall safety.

Tip: Always use fire extinguishing devices and suppression agents in battery compartments to minimize hazards from explosion or fire.

2.2 Monitoring Systems

You need advanced monitoring systems to track battery health in hazardous environments. Real-time diagnostics allow you to detect safety hazards before they escalate. Key monitoring features include:

State of Charge (SOC) and State of Health (SOH) estimation

Thermal management and cell balancing

Communication protocols (CAN, UART, RS485)

Real-time diagnostics and fault detection

Industrial automation robots require long-lasting, high-current battery power with precision control. Healthcare robots must be fail-safe and reliable to avoid safety concerns. Military and rescue robots demand advanced safety features and long battery endurance to operate in hazardous conditions.

You can learn more about battery management systems.

2.3 Protection Mechanisms

You must follow strict safety test standards to protect against explosion and other hazards. Regulatory bodies mandate several protection mechanisms for lithium battery packs in hazardous environments. The table below outlines key safety requirements:

Test Type | Safety Requirements |

|---|---|

External Short Circuit Test | Battery must not ignite or rupture during external short circuits. |

Forced Internal Short Circuit | Battery must not ignite or rupture due to internal contamination. |

Overcharge Test | Battery must not ignite or rupture when overcharged. |

Forced Discharge Test | Battery must not ignite or rupture during reverse polarity charging. |

Cycle Life Test | Battery must maintain minimum capacity after repeated cycles. |

Crush Test | Battery must not ignite or rupture under physical deformation. |

Integrated protection systems, such as thermal barriers and active cooling, reduce the risk of thermal runaway. You should always verify compliance with international safety standards like ATEX, IECEx, and UL. These standards ensure your battery packs meet the highest safety expectations for explosion-proof robots. For more details, refer to Nature.

Part3: Special Custom AGV Applications

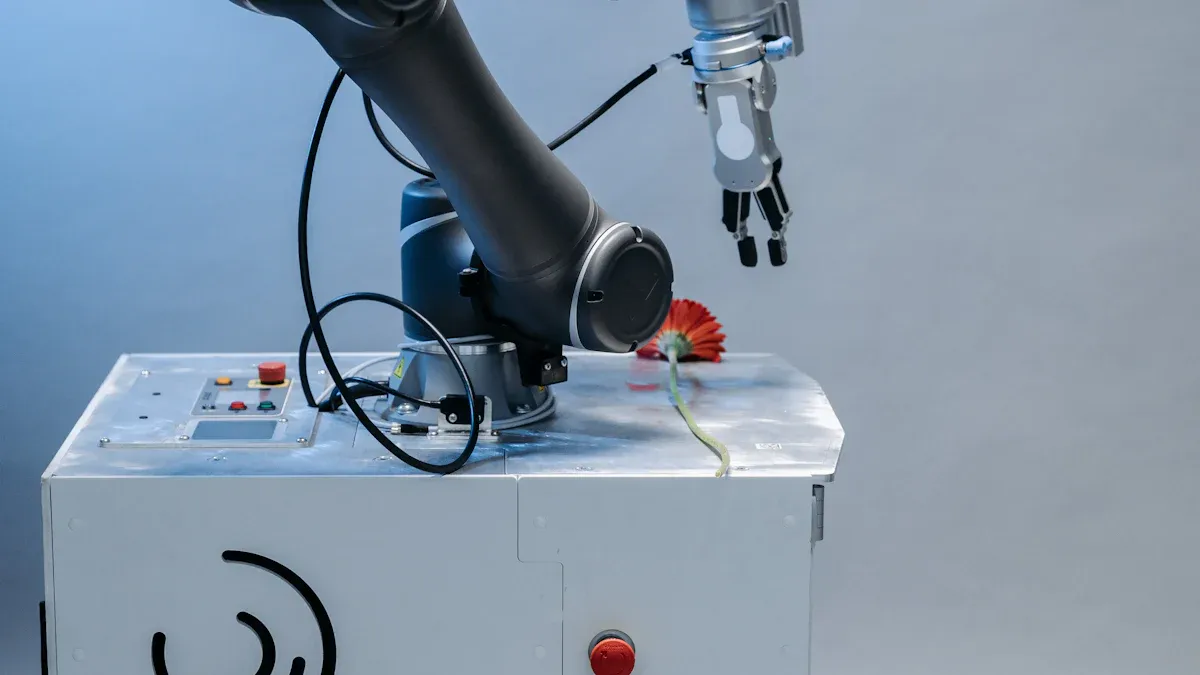

Customized battery solutions play a vital role in supporting different types of agv robots across challenging environments. You need to match the right battery technology to each application to ensure safety, reliability, and compliance. Let’s explore how special custom agv battery packs address the unique needs of firefighting, medical, underwater, and industrial robots.

3.1 Firefighting and Medical Robots

You face strict requirements when deploying agv robots in firefighting and emergency medical environments. Firefighting robots must operate in high-temperature zones and withstand exposure to fire, smoke, and water. You need battery packs that deliver stable power and resist thermal runaway, even during intense fire suppression tasks.

Medical robots, especially those used in surgery or emergency response, require high-precision battery solutions. You benefit from custom lithium battery packs that:

Ensure reliable power for surgical robots, reducing the risk of fire during critical procedures.

Enhance operational efficiency and minimize downtime in emergency scenarios.

Use solid-state batteries for advanced safety, lowering fire hazards and extending lifespan.

Power defibrillators for up to 7 years, as seen in the Defibtech DBP-2800 model, which outperforms older models with only 4 years of battery life.

Tip: LiFePO4 battery customization offers improved thermal stability and safety, making it ideal for both firefighting and medical agv robots.

3.2 Underwater and Survey Robots

Underwater agv robots demand battery systems that can withstand pressure, prevent fire, and deliver long operational times. You see several battery chemistries used in these robots:

Battery Chemistry | Energy Density | Power Density | Characteristics |

|---|---|---|---|

Lead-acid | Low | High | Inexpensive, long cycle life, suitable for short-duration, high-power applications. |

Nickel-cadmium (NiCd) | Higher than lead-acid | Lower than lead-acid | More expensive, longer cycle life, wider temperature range. |

Nickel-metal hydride (NiMH) | Higher than NiCd | Lower than NiCd | More expensive, longer cycle life, environmentally friendly. |

Lithium-ion (Li-ion) | Highest | Highest | Most expensive, safety concerns due to high reactivity and fire risk. |

You benefit from battery customization that improves operational depth and duration. Major manufacturers now partner with ocean technology firms to create hybrid battery systems. These innovations allow agv robots like the HUGIN Endurance to operate at depths of 6000 meters and run for up to 15 days without recharging, using pressure-tolerant lithium batteries. This advancement opens new possibilities for underwater infrastructure inspection and maintenance.

For more on sustainable battery solutions, visit Our Approach to Sustainability.

3.3 Industrial and Explosion-Proof Robots

Industrial and explosion-proof agv robots must operate safely in hazardous areas where fire and explosions are real risks. You face challenges such as short runtime, thermal risks, and space constraints. The table below highlights the main challenges:

Challenge | Description |

|---|---|

Safety | Preventing fire and explosions in industrial settings. |

Thermal Management | Managing heat to avoid fire hazards and performance loss. |

Regulatory Compliance | Meeting strict safety standards for industrial agv robots. |

Short runtime limits operational efficiency.

High-frequency discharging increases fire risk due to overheating.

Compact designs restrict battery size, affecting both capacity and weight.

You can address these challenges with custom lithium battery packs, especially LiFePO4, which offer enhanced safety and thermal management. These solutions help your special custom agv robots meet regulatory requirements and operate reliably in the most demanding environments.

Part4: Manufacturer Evaluation

4.1 Supplier Qualification

You must evaluate suppliers carefully when sourcing lithium battery packs for hazardous environment robots. Not all suppliers meet the strict standards required for explosion-proof and inspection robots. You should check if suppliers follow recognized classification systems for hazardous locations. The table below compares the main systems:

System | Classification Type | Description |

|---|---|---|

HAZLOC | Class and Division | Based on the presence of gases, dust, or fibres. |

IECEx | Zone-based | Classified by numerical zones for hazards. |

ATEX | Zone-based | Requires evaluation by location. |

You should also confirm that suppliers comply with ethical sourcing policies. Responsible suppliers publish a conflict minerals statement to show transparency in their supply chain. This step helps you avoid legal and reputational risks.

4.2 Quality Control

You need strong quality control to ensure battery reliability and safety. Effective quality control measures help you avoid failures in hazardous environments. The table below outlines the most effective practices:

Quality Control Measure | Description |

|---|---|

Control and inspection planning | Plan and optimize the management of quality inspections. |

Root-cause analysis | Use standardized tools to solve problems and prevent recurrence. |

Quality action management | Deliver corrective actions on time and manage escalations. |

Audit and assessment | Streamline processes by removing redundant activities. |

Rigorous inspection techniques | Test batteries for environmental, thermal, and electrical performance. |

Automation for efficiency | Use advanced manufacturing systems to reduce errors. |

Advanced technology integration | Apply vision AI for real-time inspection and monitoring. |

Continuous improvement with data analytics | Analyze trends to find bottlenecks and improve processes. |

You must watch for common quality control failures in battery manufacturing. These include:

Contamination from dust or humidity during assembly.

Misalignment of electrodes, which reduces performance.

Variation in electrode thickness, affecting lifespan.

Seal failures that cause leaks or air exposure.

Capacity mismatch between cells, leading to imbalance.

You can reduce these risks by choosing suppliers with proven quality systems and regular audits.

4.3 Support and Maintenance

You need reliable support and maintenance for your lithium battery packs. Good suppliers offer technical support, fast response times, and clear documentation. You should look for:

Training for your staff on safe battery handling.

Scheduled maintenance and performance checks.

Spare parts availability and warranty services.

Remote diagnostics and software updates for battery management systems.

Tip: Choose suppliers who provide ongoing support and transparent communication. This ensures your robots operate safely and efficiently throughout their service life.

Customized lithium battery packs give your robots the safety, reliability, and compliance needed in hazardous environments. You benefit from application-specific solutions that address unique operational demands. To maximize battery performance and lifespan, follow these best practices:

Use the recommended charger and avoid overcharging.

Store batteries at 40–60% charge in a cool, dry place.

Inspect batteries regularly for damage or swelling.

Monitor battery health with smart systems.

Prioritize compliance, reliability, and technical due diligence when selecting suppliers and maintaining your battery systems.

FAQ

What certifications do you need for lithium battery packs in hazardous environments?

You need ATEX, IECEx, and UL certifications for lithium battery packs. These standards ensure safety and compliance in explosive or hazardous locations. Always verify certification before deployment.

How do you select the right lithium battery chemistry for your robot?

You should compare battery chemistries based on voltage, capacity, and safety. The table below shows key differences:

Chemistry | Voltage (V) | Capacity (mAh) | Safety Level |

|---|---|---|---|

LiFePO4 | 3.2–3.3 | 2100–4200 | High |

LiPo | 3.6–3.7 | 1500–5200 | Moderate |

NiMH | 1.2–0.9 | 3000–5000 | Moderate |

Why is a Battery Management System (BMS) important for AGV robots?

A BMS monitors battery health, balances cells, and prevents overheating. You gain real-time diagnostics and improved safety. This system helps you avoid failures and extend battery life.

What maintenance practices help you maximize lithium battery pack lifespan?

You should inspect batteries regularly, store them at 40–60% charge, and use the recommended charger. Scheduled maintenance and remote diagnostics also help you prevent failures and ensure safe operation.

How do you ensure lithium battery packs meet quality standards?

You must choose suppliers with strict quality control. Look for root-cause analysis, audit processes, and advanced inspection techniques. Reliable suppliers provide documentation and support for ongoing compliance.