Imagine building an educational robot for a classroom or a companion robot for a care facility. You need a battery solution that supports lightweight design and long runtime, but every choice affects performance, safety, and usability. Industry studies show that heavier batteries restrict mobility and limit dynamic tasks, making operational efficiency a challenge. Manufacturers often struggle with battery weight, energy density, and safety risks like thermal runaway. Choosing the right lithium battery and custom solutions helps you balance these needs while supporting advanced robot features.

Key Takeaways

Lightweight battery design enhances robot mobility and usability, allowing for longer operation and more complex tasks.

Custom lithium battery packs optimize weight and capacity, fitting the robot’s design while maximizing energy efficiency.

Implementing advanced battery management systems (BMS) ensures safety and extends battery lifespan through real-time monitoring.

Regular maintenance and proper storage of batteries can significantly improve their cycle life and overall performance.

Part 1: Lightweight Design in Robot Batteries

1.1 Mobility and Usability

You need to focus on lightweight design when developing educational and companion robots. A lighter robot moves more easily and interacts better with users. Lightweight battery solutions play a key role in this process. They allow you to increase energy density, so your robot can carry more energy without adding extra weight. This means your robot can perform more tasks and move around classrooms, care facilities, or even medical environments with greater efficiency.

Lightweight battery design improves energy density, which lets your robot work longer and do more.

Robots with high energy density batteries can handle more complex activities, making them more useful in educational and companion roles.

Some battery structures serve as both energy storage and part of the robot’s frame, which boosts both mobility and stability.

When you use a lithium battery, you get the benefit of high energy density and reduced weight. This makes your robot easier to handle and safer for users, especially in environments like schools or hospitals where safety and usability matter most.

1.2 Weight vs. Capacity Trade-offs

You must balance battery weight and capacity to achieve the best results. If you choose a battery with high capacity, you might increase the weight, which can limit your robot’s mobility. On the other hand, a lighter battery may reduce runtime. Custom lithium battery packs help you solve this problem. These packs are lightweight and compact, with high energy density, making them ideal for robots where space is limited.

Custom lithium battery packs also let you shape the battery to fit your robot’s design. This flexibility means you can use every bit of space inside the robot, which is important for educational and companion robots that need to be small and efficient. By optimizing battery size and weight, you can create robots that look good and perform well.

Tip: Always consider both the battery’s capacity and its weight when designing your robot. The right lithium battery pack can help you achieve the perfect balance between runtime and mobility.

Battery Chemistry | Energy Density (Wh/kg) | Typical Application Scenarios |

|---|---|---|

LiFePO4 | 90-160 | Robotics, medical, infrastructure |

NMC | 150-220 | Consumer electronics, security |

LCO | 150-200 | Consumer electronics |

LMO | 100-150 | Industrial, robotics |

LTO | 70-80 | Industrial, infrastructure |

Part 2: Lithium Battery Technologies

2.1 High Energy Density Options

You need to select the right lithium battery technology to achieve both lightweight design and long runtime for your robot. Lithium-ion and lithium-polymer batteries are the most common choices in robotics. Both offer high energy density, but they have different strengths.

Battery Type | Energy Density (Wh/kg) |

|---|---|

Lithium-ion | 150 to 250 |

Lithium-polymer | 100 to 200 |

Lithium-ion batteries provide higher energy density, which means you can store more energy in a smaller, lighter package. This feature is critical for robots that need to operate for long periods without increasing weight. Lithium-polymer batteries offer more flexible shapes and sizes, making them suitable for custom designs where space is limited. You can use lithium-polymer batteries to fit unique robot forms, but you may sacrifice some energy density.

When you compare these options, think about your robot’s application. For example, medical robots and security systems often require maximum runtime and reliability. Industrial robots may need robust battery packs with a long lifespan. Consumer electronics and educational robots benefit from lightweight, compact batteries that do not compromise safety.

Here is a comparison of popular lithium battery chemistries used in robotics and related fields:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 | Robotics, medical, infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Consumer electronics, security |

LCO | 3.7 | 150-200 | 500-1000 | Consumer electronics |

LMO | 3.7 | 100-150 | 500-1500 | Industrial, robotics |

LTO | 2.4 | 70-80 | 7000-20000 | Industrial, infrastructure |

Solid-State | 3.7 | 250-400 | 1000-5000 | Medical, robotics, security systems |

Lithium Metal | 3.7 | 350-500 | 500-1000 | Advanced robotics, aerospace |

If you want to learn about responsible sourcing, see our conflict minerals statement. For sustainability practices, visit our sustainability approach.

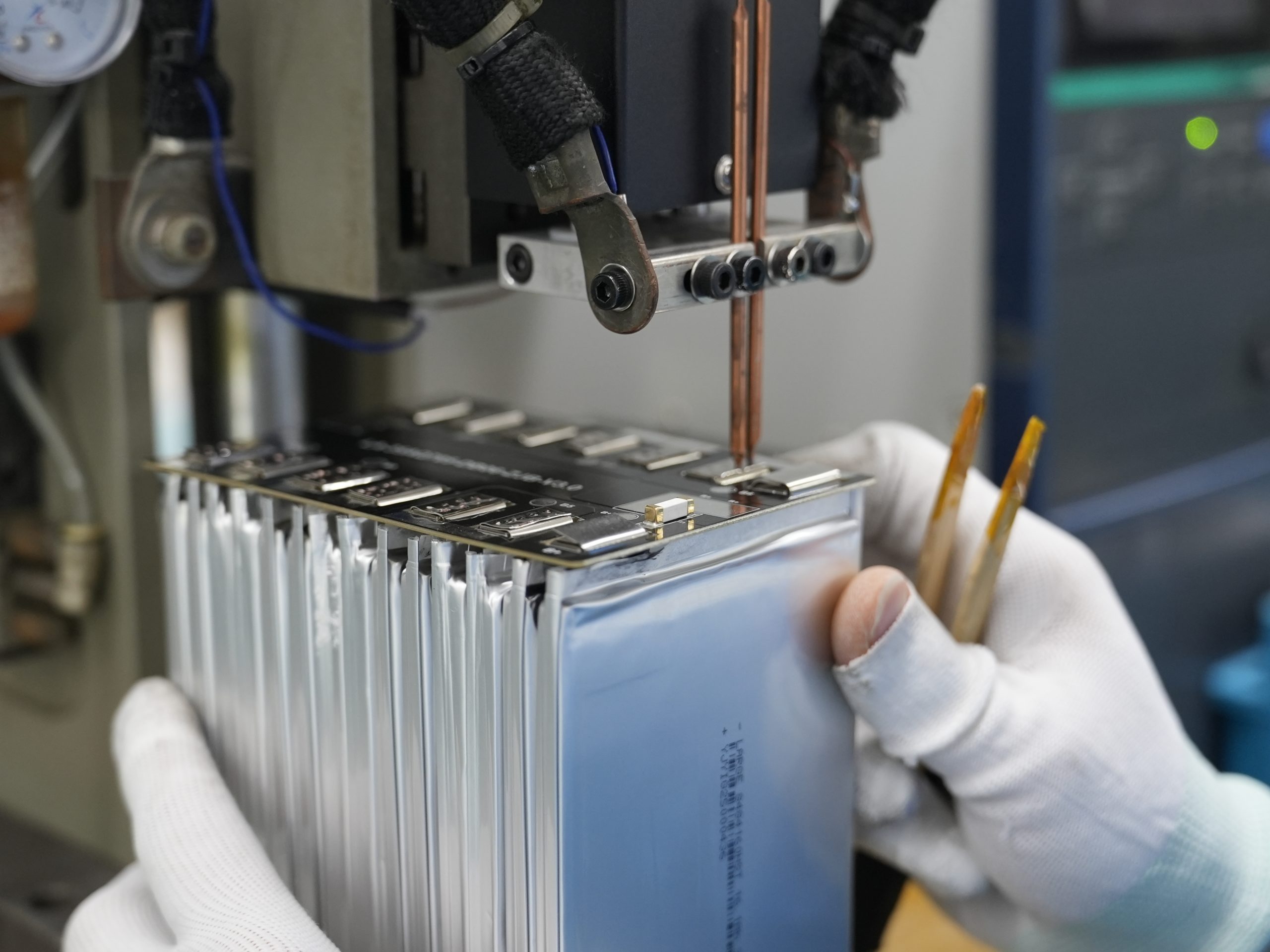

2.2 Custom Battery Packs

Custom battery packs help you optimize both weight and runtime for your robot. You can design these packs to fit the exact shape and size of your robot, making the most of every available space. This flexibility is especially important for educational and companion robots, where compact design and long runtime are top priorities.

Efficient power management extends runtime by using energy-efficient components and circuits.

Optimal battery selection, such as high-capacity lithium-ion cells, increases both runtime and battery lifespan.

Regular maintenance, including monitoring battery health and timely replacements, prevents unexpected shutdowns.

You can also choose fast-charging custom battery packs. These packs reduce downtime and keep your robot available for more tasks. Fast-charging batteries use special designs to handle higher currents safely. However, you should know that frequent fast charging may reduce battery lifespan over time.

Custom lithium battery packs allow you to balance energy density, weight, and safety features. You can select the right chemistry, such as NMC for high energy density or LiFePO4 for a long lifespan and stable performance. This approach supports robots in medical, industrial, and security applications, where reliability and safety features are essential.

2.3 Safety and Reliability

You must prioritize safety and reliability when you use lithium battery technologies in robots. Lithium-ion batteries can age and sometimes fail unexpectedly. These failures may cause serious incidents, such as fires or explosions. Monitoring battery safety is crucial, especially in educational robots where user safety is a top concern.

Lithium-ion batteries are susceptible to aging and unexpected failures.

These failures can lead to severe incidents such as explosions or fires.

Monitoring battery safety is crucial for reliability in educational robots.

Various methods are being explored to predict battery failures.

Manufacturers use several strategies to address thermal runaway risks in lithium battery packs:

Strategy | Description |

|---|---|

Advanced Thermal Management | Systems monitor temperature changes and provide cooling mechanisms to maintain optimal conditions. |

Battery Management Systems (BMS) | Continuously monitor and control battery operating conditions, regulating charging and discharging. |

Innovative Battery Cell Designs | Design improvements minimize heat buildup and thermal propagation risks. |

You should use a battery management system (BMS) to monitor and control charging and discharging. BMS balances cell voltages and implements protective measures for abnormal conditions. Advanced BMS can even use machine learning to predict potential thermal events before they happen.

To further improve safety, you can use proper spacing between cells, thermal insulation materials, and heat dissipation mechanisms. A comprehensive fire protection strategy includes prevention, detection, suppression, and containment. This involves using robust casings, thermal insulation, and effective monitoring through BMS.

Note: Always select lithium battery packs with built-in safety features and proven reliability. This ensures your robot operates safely in any environment, from classrooms to hospitals and industrial sites.

By focusing on energy density, custom battery pack design, and advanced safety features, you can achieve a long lifespan and reliable runtime for your robot. This approach supports the demands of modern robotics in medical, industrial, and educational settings.

Part 3: Long Lifespan and Runtime

3.1 Battery Management Systems

You need a battery management system (BMS) to maximize the lifespan and runtime of your robot. A BMS monitors charging, discharging, and temperature, protecting the battery from damage. Advanced BMS solutions use AI-driven technology to optimize usage patterns. These systems analyze charge and discharge cycles, ensuring safe operation and minimizing wear. You can expect robots with a 24V lithium iron phosphate battery to achieve about 4 hours of runtime per charge. Most educational robots operate for 1–3 hours before needing a recharge. For more details on BMS technology, visit BMS and PCM solutions.

AI algorithms predict battery cycles with high accuracy, supporting reliable performance.

Initial cycle analysis allows AI to categorize battery life expectancy with up to 95% accuracy.

Precision management extends battery life, reducing replacement costs and improving energy efficiency.

3.2 Maintenance and Cycle Life

Proper maintenance practices help you extend the cycle life of lithium batteries in companion and educational robots. Regular cleaning of the device removes dirt and debris, ensuring optimal performance. Inspect battery housing and connections for cracks or corrosion to prevent safety risks. Clean and dry filters and battery compartments after each use to avoid mold and mildew. Store the robot in a cool, dry place and use silica gel packs to absorb humidity. Routine inspections maintain safety and reliability.

Lithium batteries offer a longer lifespan than traditional batteries. Research from Fudan University shows that novel repair technology can enhance cycle life by 2.3 times. This improvement reduces the need for replacements and supports sustainability by decreasing waste. Using manufacturer-approved chargers is crucial for maximizing battery longevity.

Chemistry | Cycle Life (cycles) | Application Scenarios |

|---|---|---|

LiFePO4 | 2000–7000 | Robotics, medical, infrastructure |

NMC | 1000–2000 | Consumer electronics, security |

LCO | 500–1000 | Consumer electronics |

LMO | 500–1500 | Industrial, robotics |

LTO | 7000–20000 | Industrial, infrastructure |

3.3 Certification and Safety Standards

You must select lithium battery packs that meet strict certification and safety standards for educational and companion robots. These standards ensure safe operation in medical, industrial, and consumer environments.

IEC 62133 covers safety and performance, including overcharging and thermal runaway.

UN38.3 addresses safety during transport, meeting international shipping criteria.

UL2054 focuses on household and commercial battery reliability.

Standard battery packs meet international shipping approvals, reducing costs and time to market. Custom battery designs require extensive testing and can be expensive, making standard options practical for most educational and companion robots.

Certification | Focus Area | Application Scenarios |

|---|---|---|

IEC 62133 | Safety, performance | Robotics, medical, consumer |

UN38.3 | Transport safety | Industrial, infrastructure |

UL2054 | Household, commercial reliability | Consumer electronics, security |

Tip: Always choose certified lithium battery packs to ensure safety, reliability, and compliance in every robot application.

Part 4: Design Strategies for Robots

4.1 Energy-Efficient Hardware

You can boost robot performance by selecting energy-efficient hardware. The right components help you reduce battery weight and extend runtime. Low-power processors, energy-efficient sensors, and brushless DC motors all contribute to better energy conversion and lower power consumption. These choices support robots in medical, industrial, and security systems where reliability matters. The table below compares hardware options for optimizing robot performance and battery life:

Component Type | Description | Benefits |

|---|---|---|

Low-Power Processors | ARM-based CPUs with reduced power draw | Improves overall performance, saves energy |

Energy-Efficient Sensors | LiDAR sensors with sleep modes | Lowers baseline energy use |

Brushless DC Motors | Efficient actuators for motion | Enhances performance, reduces battery load |

Lithium-Ion Batteries | High energy density cells | Extends runtime, supports best robot battery |

Hybrid Power Sources | Batteries plus supercapacitors | Delivers extra power for peak performance |

Power is everything for evolvable robot design—the system as a whole can only ever be as capable as the limits of its power system.

You should consider lithium-sulfur and metal-air batteries for future upgrades. These chemistries offer higher energy densities and may become the best robot battery options for advanced applications.

4.2 Smart Power Management

Smart power management techniques help you optimize robot performance and battery efficiency. You can use sleep mode to reduce power consumption when the robot is inactive. Monitoring battery indicators lets you track health and usage, while avoiding extreme temperatures protects battery life. Regular firmware updates improve charging and overall performance. Efficient motors, regenerative braking, and dynamic voltage scaling further enhance energy savings.

Sleep mode and periodic rest extend battery runtime.

Monitoring and firmware updates improve charging cycles.

Efficient motors and optimized duty cycles boost performance.

These strategies support robots in consumer electronics, infrastructure, and industrial settings. You can learn more about sustainable design at our sustainability approach.

4.3 Modular Battery Solutions

Modular battery designs make maintenance and upgrades easier for your robot. You can replace individual battery modules without changing the entire pack. This approach improves serviceability and allows for quick battery swapping, which is vital for medical and industrial robots. Targeted maintenance extends the useful life of the best robot battery and supports consistent performance.

Modular packs simplify charging and replacement.

Service teams can maintain robots with less downtime.

Extended battery life reduces waste and supports sustainability.

You should prioritize modular lithium battery packs for robots in security systems, infrastructure, and consumer electronics. This strategy ensures high performance and easy maintenance for every application.

You can achieve lightweight design and long runtime in educational and companion robots by following these strategies:

Select lithium battery chemistry (LiFePO4, NMC) for high energy density and long cycle life.

Use custom battery packs tailored to your robot’s geometry for optimal weight and runtime.

Implement intelligent battery management systems (BMS) for real-time monitoring and safety.

Custom battery solutions and advanced BMS give you a competitive edge by improving reliability and efficiency in robotics for medical, security, and industrial applications.

The robotics battery market is growing at a CAGR of 15.5% through 2030. Forward-thinking design with eco-friendly, fast-charging lithium batteries supports future robot applications and sustainability.

FAQ

What makes lithium battery packs ideal for a robot companion in educational settings?

Lithium battery packs offer high energy density and long cycle life. You can use them in a robot companion to support longer lessons and interactive activities. These batteries keep the robot companion lightweight and safe for students.

How do custom lithium battery packs improve the performance of a robot companion?

Custom lithium battery packs fit the unique shape of your robot companion. This design maximizes available space and reduces weight. You can achieve longer runtime and better mobility for your robot companion applications.

What safety features should you look for in lithium battery packs for a robot companion?

You should select lithium battery packs with advanced battery management systems (BMS). These systems monitor temperature and voltage. They protect your robot companion from overcharging, overheating, and short circuits. Safety features are critical for robot companion use in hospitals and schools.

How does modular battery design benefit a robot companion in security systems or infrastructure?

Modular battery packs allow you to swap out batteries quickly. This feature keeps your robot companion operational with minimal downtime. You can maintain and upgrade your robot companion easily in security systems or infrastructure projects.

Can you compare lithium battery chemistries for a robot companion in consumer electronics?

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenario |

|---|---|---|---|

90-160 | 2000-7000 | Robot companion, medical | |

NMC | 150-220 | 1000-2000 | Robot companion, electronics |

LCO | 150-200 | 500-1000 | Robot companion, consumer |

Tip: Choose the chemistry that matches your robot companion’s needs for runtime and safety.