You see security robots working nonstop in airports, warehouses, and hospitals. Reliable power keeps these robots alert and ready to respond. Smart batteries deliver consistent energy, advanced management, and high-energy density for safe and uninterrupted operation. Recent improvements in lithium-ion battery packs reduce safety risks and boost reliability. B2B clients benefit from longer runtime, efficient performance, and greater operational reliability.

Key Takeaways

Smart batteries provide reliable power for security robots, ensuring they remain active and ready to respond in various environments.

Advanced Battery Management Systems (BMS) enhance safety by monitoring battery conditions and preventing issues like overheating and overcharging.

Custom lithium battery solutions optimize runtime and efficiency, allowing security robots to operate longer and more effectively in demanding tasks.

Remote diagnostics enable real-time monitoring of battery health, helping to detect issues early and schedule preventive maintenance.

Future advancements in battery technology, such as AI-driven systems and graphene batteries, promise even greater efficiency and safety for security robots.

Part1: Smart Batteries and Security Robots

1.1 Battery Technology Overview

You rely on smart batteries to keep your security robot active and alert. These batteries use advanced lithium chemistries to deliver reliable power for long periods. You see them in medical devices, industrial equipment, and security systems. Each chemistry offers unique benefits for your application.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-5000 | Robotics, medical, infrastructure |

NMC | 3.7 | 150-220 | 1000-2000 | Security robots, consumer electronics |

LCO | 3.7 | 150-200 | 500-1000 | Consumer electronics |

LMO | 3.7 | 100-150 | 700-1500 | Industrial, security systems |

LTO | 2.4 | 70-110 | 7000-20000 | Medical, industrial |

Solid-state | 3.7 | 250-400 | 1000-5000 | Robotics, security, medical |

Lithium metal | 3.7 | 350-500 | 500-1000 | Advanced robotics, infrastructure |

You choose the chemistry that matches your robot’s needs for runtime, safety, and reliability.

1.2 Key Features of Smart Batteries

Smart batteries give your robot consistent power and protect it from unexpected shutdowns. You benefit from features that keep your operations running smoothly:

Battery Management System (BMS) monitors and regulates state of charge, health, and power.

BMS prevents overcharging and overdischarging, reducing failures and improving safety.

BMS maintains charge between 20% and 80%, boosting battery longevity and performance.

You notice fewer interruptions and safer operation when your robot uses smart batteries.

1.3 Custom Lithium Battery Solutions

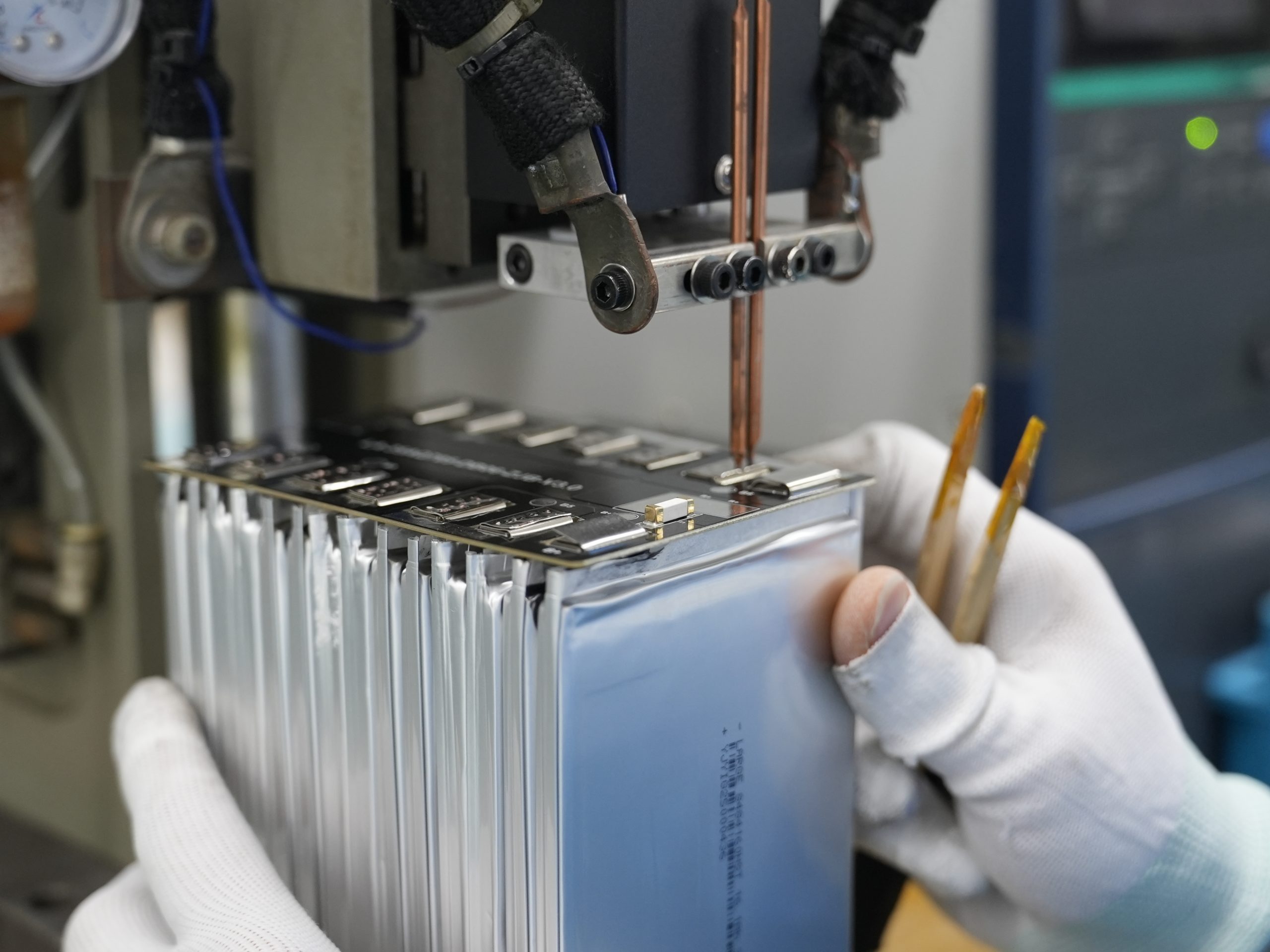

Custom lithium battery solutions help you optimize your robot’s runtime and efficiency. You get batteries designed for your specific needs, not just standard options. The table below shows how custom lithium battery packs outperform standard batteries:

Aspect | Custom Lithium Batteries | Standard Batteries |

|---|---|---|

Design Flexibility | Tailored shapes and sizes for optimal fit in robots | Limited to standard sizes |

Voltage and Current Delivery | Precise voltage and current for specific applications | Generic voltage options |

Battery Management System | Advanced BMS for monitoring and predictive maintenance | Basic monitoring capabilities |

Runtime and Efficiency | Enhanced runtime and efficiency in high-demand environments | Reduced performance in demanding tasks |

You achieve longer runtime, better safety, and higher efficiency with custom lithium battery solutions. Your robot stays active and reliable, even in challenging environments.

Part2: Safety and Reliability

2.1 Battery Management Systems

You depend on advanced battery management systems to keep your security robot safe and reliable. These systems constantly monitor the battery’s condition and protect against hazards. You see the BMS working in real time, checking voltage, temperature, and current. If the system detects abnormal levels, it sends alerts and takes action to prevent accidents. You benefit from these key functions:

Continuous monitoring of voltage and temperature to detect safety risks.

Real-time alerts for abnormal conditions, allowing you to respond quickly.

Protection against overcharging, deep discharging, overcurrent, short-circuits, and overheating.

Automatic disconnect of the charging circuit if a cell’s voltage exceeds safe limits.

You can learn more about battery management systems and their role in lithium battery packs. These features ensure safety by design and help your robot maintain optimal power and runtime.

2.2 Safety Features

You rely on safety features built into lithium battery packs to protect your robot and its environment. The BMS safeguards the battery and system against harmful conditions. It performs protective actions to counteract scenarios that could present safety hazards. You see these features in action:

Thermal management prevents overheating and keeps the battery within safe temperature ranges.

Fail-safes automatically shut down the system if dangerous conditions arise.

Cell balancing maximizes efficiency and longevity, reducing the risk of failure.

Real-time monitoring allows you to track battery health and performance.

Tip: When you choose lithium battery packs for your security robot, you support responsible sourcing. Learn about conflict minerals and their impact on safety here.

These safety features help you avoid unexpected shutdowns and keep your robot operating smoothly.

2.3 Reliability Enhancements

You want your security robot to deliver consistent performance and minimize downtime. Smart batteries provide reliability enhancements that boost operational uptime. The table below shows how these features contribute to your robot’s efficiency:

Feature | Contribution to Uptime |

|---|---|

State of Charge (SOC) | Ensures optimal energy levels for continuous operation. |

State of Health (SOH) | Monitors battery condition to prevent failures. |

Thermal management | Prevents overheating, ensuring safe operation. |

Cell balancing | Maximizes battery efficiency and longevity. |

Real-time diagnostics | Allows for immediate fault detection and response. |

Predictive maintenance | Alerts users before failures, reducing unexpected downtime. |

Safety | Prevents hazardous conditions that could lead to downtime. |

Performance Optimization | Maximizes runtime and power delivery for tasks. |

Longevity | Extends battery life through intelligent management. |

Reduced Downtime | Fewer disruptions lead to higher operational efficiency. |

You see these reliability enhancements in real-world operations. For example, a security robot in a hospital uses predictive maintenance to alert staff before a battery failure. This proactive approach prevents interruptions and keeps the robot on duty. You experience higher efficiency and safety and reliability in every shift.

Part3: Autonomy and Efficiency

3.1 Extended Runtime

You need your security robot to operate for long hours without interruption. High-energy density in modern lithium battery packs gives you this advantage. These batteries store more power in a compact form, which means your robot can patrol larger areas or work longer shifts before needing a recharge. You see a direct impact on operational schedules and resource allocation.

The table below shows how smart battery features extend runtime and reduce the frequency of charging cycles:

Feature | Description |

|---|---|

Lifespan | Up to 10x longer lifespan than lead-acid batteries |

Runtime | 2x longer runtime compared to conventional batteries |

Charging Speed | Lightning-fast charging with up to 1C continuous charging current |

Maintenance | Maintenance-free for maximum operational reliability |

Energy Efficiency | 100% usable capacity without loss of performance |

Communication | Intelligent communication via SoC, voltage & temperature |

Expandability | Expandable capacity – up to 20 batteries can be used in parallel |

You benefit from a longer cycle life, which means fewer battery replacements and lower costs. Your robot spends more time on duty and less time out of service. Custom lithium battery solutions further optimize runtime by matching the exact power requirements of your robot. This approach ensures you get the most out of every charge.

3.2 Adaptive Power Management

You want your robot to use energy efficiently during every task. Advanced power management systems in lithium battery packs help you achieve this goal. These systems monitor real-time conditions and adjust power delivery based on the robot’s workload. For example, when your robot faces a demanding task, the battery increases output. During idle periods, it conserves energy.

You see several benefits from adaptive power management:

Improved performance during high-demand operations.

Reduced energy waste during low-activity periods.

Consistent power delivery, even as the battery ages.

Custom lithium battery packs allow you to fine-tune these management systems. You can set parameters that match your robot’s unique operational profile. This flexibility leads to higher efficiency and longer battery life. You notice fewer interruptions and smoother transitions between tasks.

3.3 Remote Diagnostics

You need to keep your robot running with minimal downtime. Remote diagnostics in smart batteries give you real-time insights into battery health and performance. You receive alerts and data uploads during charging cycles, which help you detect issues early. AI-driven analysis of this data allows you to schedule preventive maintenance before problems occur.

Here are the key advantages you gain from remote diagnostics:

Real-time monitoring of battery health and operational metrics.

Health telemetry upload during charging cycles for early issue detection.

AI analysis of trends for proactive maintenance scheduling.

Notifications for preventive service to minimize costly repairs.

You see these benefits in real-world applications. For example, Smart Robotics systems can detect anomalies that human workers might miss. This capability leads to faster responses and improved safety. Another case study shows that combining remote diagnostics with control systems, such as the Olis platform, provides 24/7 access to robot cells. You can troubleshoot and correct errors quickly, which reduces downtime and boosts operational efficiency.

Tip: Use remote diagnostics to maximize uptime and protect your investment in security robots. Early detection and proactive maintenance keep your operations running smoothly.

Part4: Future Trends in Battery Technology

4.1 Lithium-Ion Advancements

You see rapid progress in lithium-ion battery technology for security robots. Companies now develop batteries that last longer, charge faster, and work in more extreme environments. Graphene batteries stand out as a major innovation. They help your robots operate for longer periods and add more features without sacrificing reliability.

Feature | Traditional Lithium-Ion Batteries | Graphene Batteries |

|---|---|---|

Capacity Retention | Degrades over time | Retains 80% through 1,400 cycles |

Charging Speed | Slower | Charges faster than alternatives |

Operational Temperature | Limited range | Operates at extreme temperatures |

Duration Between Charges | Shorter for robots | Longer operational time |

Versatility for Features | Limited by battery life | More features can be added |

You notice that the global market for lithium batteries in service robots is growing. This growth comes from the need for automation in logistics, healthcare, and security. Manufacturers now focus on lightweight, high-capacity lithium battery packs that improve battery performance and energy efficiency. Smart battery systems with real-time monitoring are becoming standard in security robotics.

4.2 AI-Driven Battery Systems

You benefit from AI-driven battery systems that make your security robots smarter and safer. These systems analyze data from your robot’s battery in real time. They predict when maintenance is needed and adjust power use to match the robot’s workload. This technology helps you avoid unexpected downtime and keeps your robots running at peak efficiency.

You see AI systems working with charging modules that enable rapid charge cycles. Tamper-resistant designs and surveillance-integrated charging stations add extra layers of safety and oversight. Charging intelligence supports fleet tracking and deployment, making your robots more autonomous.

4.3 Customization for Security Needs

You can customize smart batteries to fit the exact needs of your security robots. Custom battery packs match your voltage, capacity, and discharge rate requirements. Built-in safety features, such as thermal cutoffs and overcharge protection, keep your robots safe in demanding environments.

Customization Aspect | Description |

|---|---|

Voltage | Custom battery packs are designed to match the specific voltage requirements of security robots. |

Capacity | Tailored to meet the energy needs of the robot for optimal performance. |

Discharge Rate | Configured to provide the necessary discharge rates for various operational tasks. |

Safety Features | Includes built-in thermal cutoffs and overcharge protection to enhance safety. |

Monitors charge/discharge cycles and maintains battery health, ensuring longevity and efficiency. |

You also benefit from features like high-wattage AC-DC charging, tamper-resistant charging stations, and surge protection. These options help you minimize downtime and improve both safety and autonomy for your robot fleet.

For more on sustainability and future battery trends, visit Our Approach to Sustainability.

Smart batteries and custom lithium battery packs help you solve safety and autonomy challenges in security robots. You gain higher reliability, longer runtime, and safer operation for your fleet. For B2B clients, these solutions deliver:

Enhanced safety through advanced battery management and real-time monitoring

You also see future gains as AI-driven systems optimize battery health and charging cycles.

Challenge | Problem Description | BMS Solution |

|---|---|---|

Cell Imbalance | Uneven voltages reduce capacity and cause early failure. | Balancing equalizes voltages, extending battery life. |

Thermal Runaway | High-power tasks risk overheating or fires. | Triple-layer monitoring and cooling keep batteries safe. |

Smart battery technology will continue to advance security robotics, making your operations safer and more autonomous.

FAQ

What makes lithium battery packs safer for security robots?

You benefit from advanced battery management systems in lithium battery packs. These systems monitor temperature, voltage, and current. They prevent overheating and overcharging. You see fewer risks and more reliable operation in security and industrial environments.

How do custom lithium battery packs improve runtime in robotic applications?

You choose custom lithium battery packs for precise voltage and capacity. These packs match your robot’s workload. You get longer runtime and fewer interruptions. This advantage supports robotic applications in medical, security, and industrial sectors.

Can iot-integrated smart batteries help with remote monitoring?

You use iot-integrated smart batteries to track battery health and performance. These batteries send real-time data to your management system. You detect issues early and schedule maintenance. This feature reduces downtime and improves operational efficiency.

Why should you consider lithium battery packs for medical and industrial robots?

You select lithium battery packs for high energy density and long cycle life. These packs deliver consistent power in demanding medical and industrial settings. You experience fewer replacements and lower maintenance costs.

What are the main benefits of cell balancing in lithium battery packs?

You rely on cell balancing to keep voltages equal across all cells. This process extends battery life and prevents early failure. You see improved safety and reliability in your robot fleet.