You need reliable Battery Solutions to keep inspection robots working around the clock in substations and transmission lines. Lithium battery packs and intelligent battery monitoring systems protect inspection robots from extreme temperatures, dust, and moisture. The table below highlights how these systems boost reliability in harsh environments:

Feature | Reliability Benefit |

|---|---|

Real-time voltage, current, and temperature data | Prevents thermal runaway and ensures safety |

Adaptive charging and hardware interlocks | Avoids hazardous charging issues |

Dust, shock, and moisture resistance | Maintains dependable operation |

Key Takeaways

Choose lithium battery packs with long cycle life to reduce downtime and replacement costs for inspection robots.

Select batteries that can withstand extreme temperatures and environmental conditions to ensure reliable operation in harsh settings.

Utilize advanced battery monitoring systems to detect issues early, maximizing battery lifespan and maintaining operational efficiency.

Consider solid-state and sodium-ion batteries for improved safety and energy density in demanding applications.

Implement predictive maintenance strategies to lower costs and extend the life of batteries used in inspection robots.

Part 1: Inspection Robots Requirements

1.1 Durability and Cycle Life

You need batteries that last through thousands of charge and discharge cycles to keep inspection robots running efficiently. Long cycle life reduces downtime and replacement costs. For example, Boeing’s omnidirectional AGVs have used 48V 200Ah lithium-ion batteries since 2018. These batteries still hold over 80% of their original capacity after more than 3,500 cycles, far exceeding the initial 1,000-cycle rating. This kind of durability ensures your inspection robots can operate 24/7 with minimal interruptions.

Long cycle life means fewer battery replacements.

Consistent performance supports continuous inspection schedules.

High-quality lithium battery packs deliver reliable energy for demanding tasks.

1.2 Temperature and Environmental Tolerance

Inspection robots often work in harsh environments. You need battery solutions that withstand extreme temperatures, dust, and moisture. The table below shows the typical temperature ranges required for these applications:

Temperature Type | Range |

|---|---|

Operating Temperature | -20°C to +55°C |

Storage Temperature | -20°C to +60°C |

Batteries must maintain performance in both hot substations and cold outdoor settings. Robust sealing and protective casings help prevent damage from dust and moisture.

1.3 Energy Density and Weight

You want batteries that provide high energy density while keeping weight low. This balance allows inspection robots to operate longer without frequent recharging and move easily through complex environments.

Feature | Description |

|---|---|

Energy Density | These compact battery packs hold a considerable amount of energy, ensuring uninterrupted operation of robotics. |

Lightweight Design | Designed to be as light as possible without compromising performance or safety. |

Safety Features | Includes protections against overcharging, overheating, and short-circuiting. |

High energy density lets you fit more power into smaller spaces.

Lightweight batteries improve robot mobility and efficiency.

1.4 Safety and Maintenance

Safety is critical when inspection robots operate near high-voltage equipment. Batteries must meet strict standards, such as UL 2593, which covers protection against fire, electric shock, and overheating. You should look for features like flame-retardant housings and touch-proof interfaces.

Use chargers with auto-cutoff to prevent overcharging.

Store batteries at 40–60% state of charge in cool, dry places.

Avoid deep discharges and high-rate charging in hot conditions.

Regularly check battery health using monitoring systems and replace worn components as needed.

Tip: Regular maintenance and real-time monitoring help maximize battery lifespan and keep your inspection robots safe and reliable.

Part 2: Battery Solutions and Technologies

2.1 Li-ion and LiFePO4 Packs

You need battery solutions that deliver consistent performance for inspection robots in demanding environments. Lithium-ion (Li-ion) and Lithium Iron Phosphate (LiFePO4) packs stand out as field-proven options. These batteries power robots in medical, industrial, security, and infrastructure sectors. You can rely on them for routine power line inspections and other critical tasks.

Battery Type | Safety Features | Energy Density | Cycle Life | Application Scenarios |

|---|---|---|---|---|

Li-ion | Advanced protection circuits, flame-retardant casing | High energy density | 1,000–3,500 cycles | Robotics, medical, security systems |

LiFePO4 | Excellent thermal stability, robust casing | High energy density, long cycle life | 2,000–5,000 cycles | Industrial, infrastructure, robotics |

LiFePO4 packs offer superior thermal stability. You can use them in harsh conditions without worrying about overheating. Li-ion packs provide high energy density, which means your inspection robots can operate longer between charges. Both chemistries support automatic recharging and battery monitoring, which helps you maintain operational efficiency during power line inspection.

Tip: Choose LiFePO4 packs for environments with extreme temperatures or high safety requirements. Select Li-ion packs when you need maximum energy density and lightweight design.

2.2 Solid-State and New Chemistries

You can explore new battery solutions to enhance safety and energy density for inspection robots. Solid-state batteries and sodium-ion batteries represent the latest advancements. These chemistries offer unique benefits for power line inspection and other industrial applications.

Battery Type | Safety Features | Energy Density |

|---|---|---|

Lithium Iron Phosphate (LiFePO4) | Excellent thermal stability, safer under harsh conditions | High energy density, long cycle life |

Solid-State Batteries | Non-flammable solid electrolytes, reduced fire risk | Potentially up to 2.5 times that of Li-ion |

Sodium-Ion Batteries | Less prone to dendrite formation, safer than Li-ion | Lower cost, potentially higher energy density |

Solid-state batteries improve safety by using non-flammable solid electrolytes. You reduce fire and explosion risks in your inspection robots.

Sodium-ion batteries are safer than traditional lithium-ion batteries. You avoid dendrite formation, which can cause short circuits and fires.

The fire hazard in lithium batteries comes from dendrite formation. Sodium-ion batteries lower this risk, making them a promising choice for applications with strict safety standards.

You can use these new chemistries in robotics, medical devices, and security systems. Solid-state batteries may soon offer up to 2.5 times the energy density of current Li-ion packs, which means longer operation for your inspection robots during routine power line inspections.

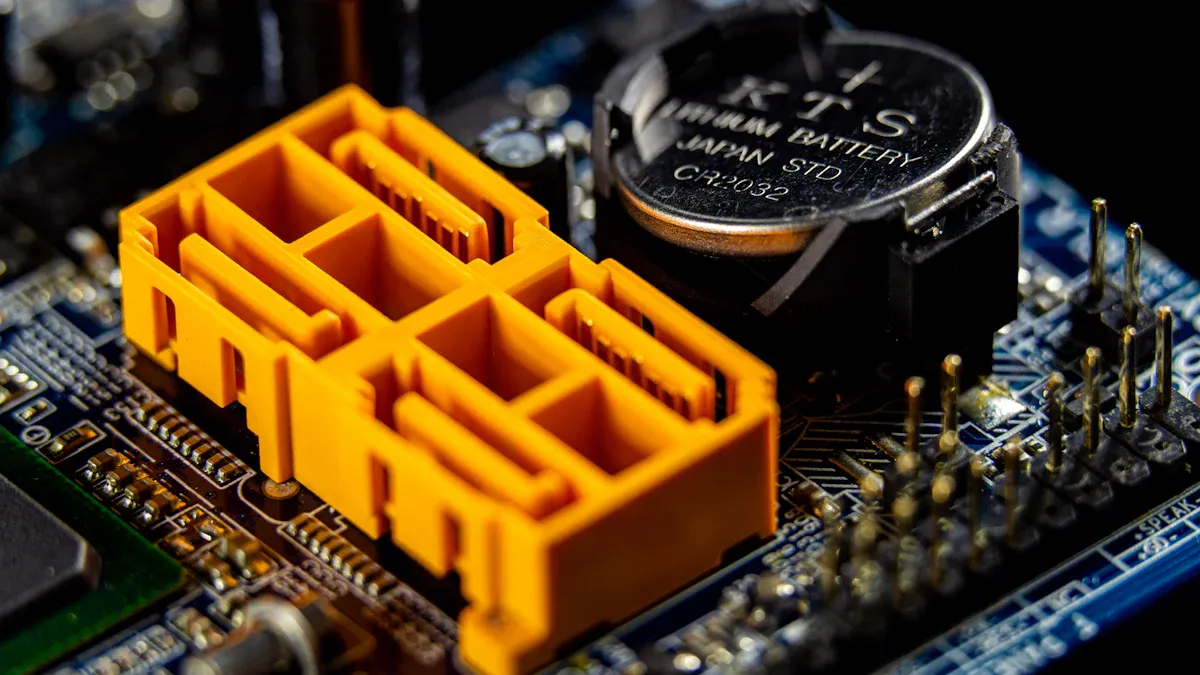

2.3 Battery Monitoring Systems

You need advanced battery monitoring systems to ensure reliability and early fault detection in inspection robots. These systems analyze real-time data and alert you to potential issues before they affect operations. You can learn more about battery management systems and protection circuit modules on our BMS and PCM page.

Predictive monitoring capabilities help you identify problems early by analyzing battery performance data.

Alert systems provide yellow and red warnings, so you can intervene before faults disrupt power line inspection.

Mission delegation allows your robots to reassign tasks if a battery issue arises, maintaining operational continuity.

Direct internal current imaging visualizes electric current distribution inside batteries. You can spot non-uniformities that signal early fault detection.

Non-destructive testing lets you inspect battery cells without causing damage.

Visualization of internal electric current density helps you detect issues that could lead to faults.

Highly accurate inspections support quality control and failure analysis.

Ignition risk prediction gives you early warnings, improving safety and reliability.

Note: Early fault detection keeps your inspection robots running safely and efficiently. You minimize downtime and extend battery lifespan with proactive monitoring.

Part 3: Power Line Inspection Case Studies

3.1 Substation Applications

You can see inspection robots making a difference in substation environments. These robots use lithium battery packs with high cycle life and robust safety features. In one example, robots swim through transformer oil to inspect internal components. The battery packs must resist oil exposure, high voltage, and temperature swings. You benefit from batteries with flame-retardant casings and IP-rated protection. These features keep robots running safely during autonomous inspection tasks. In medical and industrial sectors, similar battery solutions support robots in hazardous areas, showing the versatility of lithium chemistries.

Note: You should select batteries with built-in protection circuits and long cycle life to reduce maintenance and downtime in substations.

3.2 Transmission Line Deployments

You can deploy inspection robots along transmission lines for extended missions. These robots rely on lithium battery packs with self-recharging systems. The robots autonomously locate and land on powerlines. A gripping mechanism lets the robot grasp the cable, providing stability and a way to recharge the battery. The mission autonomy system cycles between inspection and recharging, so you get continuous coverage. This approach works well in infrastructure and security systems, where robots must operate for long periods without human intervention.

Self-recharging systems allow robots to work longer.

Gripping mechanisms provide stability and enable battery recharging.

Mission autonomy systems manage inspection and charging cycles.

3.3 Operational Outcomes

You achieve strong results by using advanced battery solutions in autonomous inspection robots. The accuracy rate for defect recognition has reached 85%. Robots use sensors, artificial intelligence, and machine learning to detect faults, wear, and tear in electrical infrastructure. This technology supports predictive maintenance and helps prevent costly power outages.

Factor | Impact on Cost-Effectiveness |

|---|---|

Battery Voltage/Capacity | Matches robot needs for runtime |

Size and Weight | Improves mobility and fits space constraints |

Discharge Current | Handles peak energy demands |

Lifespan | Reduces maintenance and downtime |

Environmental Compatibility | Ensures reliable operation in harsh settings |

Safety Features | Prevents overheating and short-circuits |

Communication Protocol | Supports robot integration |

You lower costs and improve reliability by choosing the right lithium battery packs for your inspection robots. Autonomous inspection robots help you maintain infrastructure efficiently.

Part 4: Best Practices and Future Trends

4.1 Overcoming Field Challenges

You face many challenges when deploying inspection robots in the field. Extreme weather, dust, and electromagnetic interference can disrupt operations. You can address these issues by selecting lithium battery packs with robust sealing and advanced protection circuits. Utility teams often operate in remote areas, so you need batteries that withstand temperature swings and moisture. You also rely on sensor feedback to monitor battery health and environmental conditions. By using real-time sensor data, you can detect early signs of battery stress and prevent failures. Utility operators in the industrial and infrastructure sectors benefit from these strategies, ensuring reliable performance for inspection robots.

4.2 Battery Selection and Integration

You must choose batteries that match your robot’s mission profile and utility requirements. Integration strategies play a key role in maximizing performance and reliability.

The integration strategies employed in the AERIAL-CORE project significantly enhance battery performance and robot reliability during power line inspections. The use of multi-robot teaming and autonomous battery charging features allows for extended-range inspections with minimal human intervention. Additionally, the ability of aerial robots to perch on power lines for recharging and maintenance tasks directly impacts their operational efficiency and reliability.

You should select lithium battery packs with the right voltage, capacity, and sensor compatibility. Utility teams in medical, security, and infrastructure sectors use these packs for their high energy density and safety features. Proper integration with sensor systems ensures accurate monitoring and seamless operation.

4.3 Maintenance and Lifecycle Management

You can extend battery life and reduce costs by adopting predictive maintenance. Battery monitoring systems use sensor data to track performance and predict failures before they occur.

Benefit | Description |

|---|---|

Reduced Downtime | Systems remain online longer with fewer interruptions due to battery faults. |

Extended Battery Lifespan | Preventing overcharge and thermal damage leads to longer battery cycles. |

Lower Maintenance Costs | Fewer emergency repairs and optimized replacement schedules save time and budget. |

Predictive maintenance minimizes unexpected breakdowns, allowing robots to work consistently.

This leads to increased throughput and lower operating costs, directly reducing downtime.

Utility operators rely on these practices to keep inspection robots and sensor networks running efficiently.

4.4 Innovations Ahead

You will see rapid advances in lithium battery technology for utility applications. Solid-state batteries and sodium-ion chemistries promise higher energy density and improved safety. Utility teams will benefit from batteries that support longer missions and faster recharging. Sensor integration will become more advanced, enabling real-time diagnostics and smarter energy management. You can learn more about our sustainability approach as the industry moves toward greener solutions. These innovations will help you meet the growing demands of utility inspection robots in medical, security, and industrial sectors.

You can boost the reliability of inspection robots by choosing lithium battery packs with advanced monitoring systems. These solutions support grid monitoring and electric grid health in industrial, medical, and security sectors. Next-generation solid-state batteries now deliver 8–12 hours of operation, while wireless charging enables 24/7 emergency line inspection. Drone-mounted sensors help you maintain infrastructure and respond quickly to faults. Stay informed about new battery technologies to keep your robots ready for future challenges.

FAQ

What battery features help drones inspect power transmission lines in harsh environments?

You need lithium battery packs with high energy density and robust casings. These batteries support drones during automated drone inspection of power transmission line infrastructure. You get reliable operation in substation, industrial, and medical sectors. Advanced monitoring systems help you maintain grid stability.

How do battery monitoring systems improve drone safety during power transmission line inspections?

Battery monitoring systems track voltage, temperature, and current. You receive alerts before faults occur. Drones use these systems for automated drone inspection of power transmission line networks. You reduce downtime and improve grid reliability in robotics, security, and infrastructure applications.

Why should you choose lithium iron phosphate batteries for power transmission line drones?

Lithium iron phosphate batteries offer excellent thermal stability and long cycle life. You use them in drones for power transmission line inspection in medical, industrial, and grid sectors. These batteries resist overheating and provide safe, reliable energy for continuous drone operation.

How do drones recharge during extended power transmission line inspections?

Drones use autonomous landing and gripping mechanisms to perch on power transmission lines. You enable automated drone inspection and recharging cycles. This approach supports grid monitoring in infrastructure and security systems. You extend drone mission duration and reduce manual intervention.

What factors affect battery selection for power transmission line drone inspections?

You consider voltage, capacity, weight, and safety features. Drones require batteries that match power transmission line inspection needs. You select lithium battery packs for grid monitoring in robotics, medical, and industrial sectors. Proper integration ensures reliable drone performance.