Smart bms technology transforms the safety and reliability of lithium battery-powered power inspection devices. You benefit from features that provide continuous data streams and immediate insights into battery health.

Real-time monitoring of temperature, voltage, and current supports predictive analytics.

Proactive maintenance ensures fast response to issues, reducing operational risks and downtime.

These advancements in safety make your inspection equipment more dependable, which matters for every B2B professional seeking reliable solutions.

Key Takeaways

Smart BMS technology enhances safety by providing real-time monitoring of battery health, reducing risks of overcharging and overheating.

Predictive maintenance features allow you to identify issues early, helping to avoid costly repairs and downtime.

Advanced cell balancing ensures all battery cells work together, extending battery life and improving overall performance.

Smart BMS systems support remote monitoring, giving you control and insights into battery status from anywhere.

Choosing devices with Smart BMS leads to better reliability and efficiency, making them essential for critical applications in various industries.

Part1: Smart BMS Overview

1.1 What Is a Smart BMS

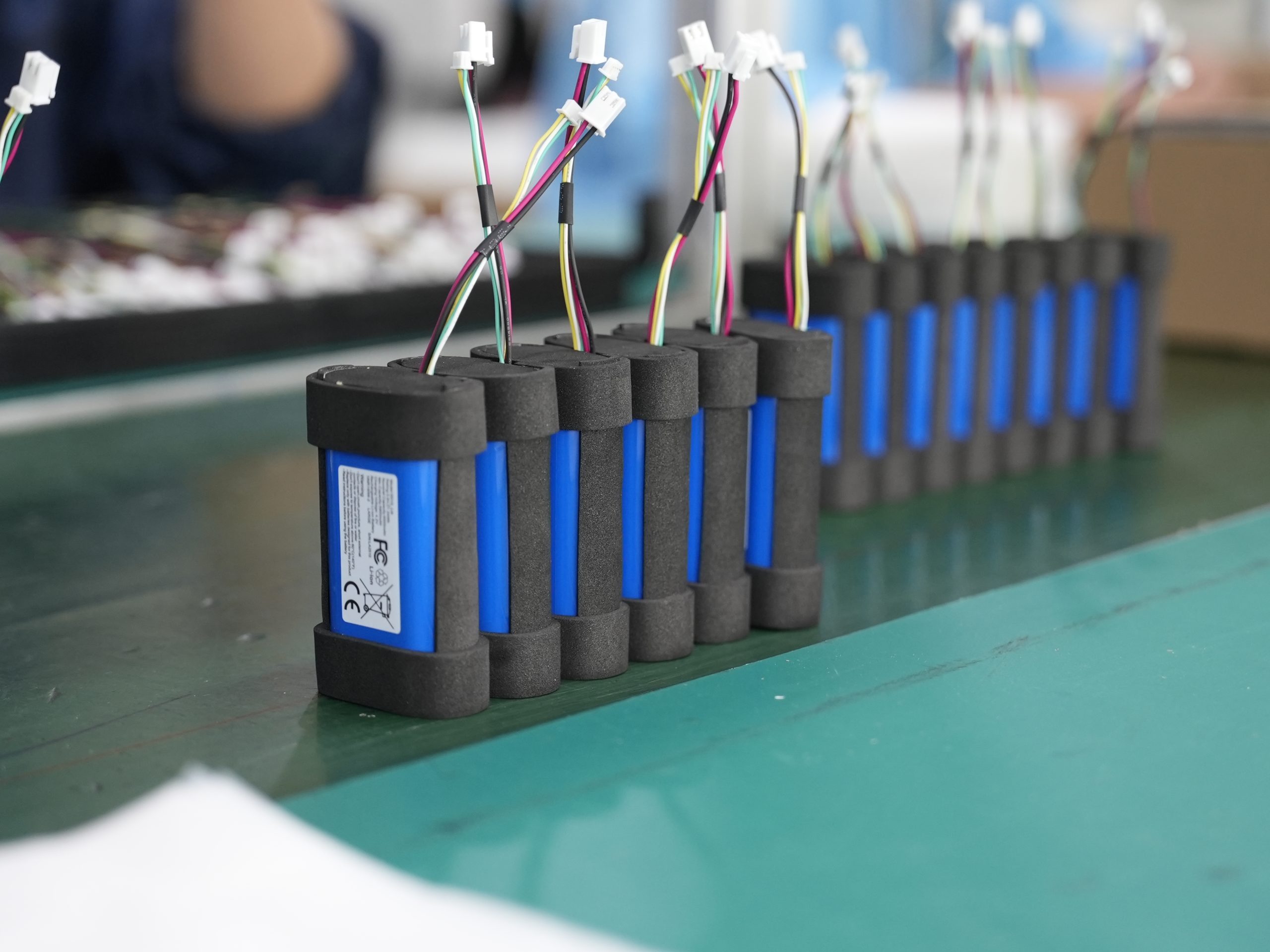

You rely on lithium battery packs for power inspection devices in many industries. A smart bms acts as the electronic control unit for these battery packs. It serves as the brain of your lithium batteries, managing performance and ensuring optimal operation.

A smart bms differs from traditional systems by using advanced technology to monitor and control every aspect of the battery. You benefit from features such as:

AI-driven optimization and predictive analytics for battery management.

Real-time assessment of battery capacity and performance, including State of Charge (SOC) and State of Health (SOH).

Advanced communication protocols like CAN bus, SMBus, and I2C for efficient data transmission.

Multiple temperature sensing points for thermal monitoring.

Active cell balancing to prevent degradation and extend battery life.

Intelligent power management algorithms that optimize usage.

Tip: Smart bms technology supports lithium chemistries such as LiFePO4, NMC, LCO, LMO, and LTO, each offering unique platform voltages, energy densities, and cycle lives.

1.2 Role in Power Inspection Devices

You need reliable power inspection devices to maintain critical infrastructure and systems. The battery management system in these devices ensures safety and efficiency by constantly monitoring voltage, current, and temperature. It balances cells and manages power flow, reducing energy waste and preventing incidents.

Function | Description |

|---|---|

Voltage Monitoring | Tracks each cell’s voltage to prevent overcharge or over-discharge. |

Current Management | Monitors and controls current flow to avoid overheating. |

Temperature Regulation | Manages thermal conditions using NTC sensors. |

Cell Balancing | Equalizes cell voltages to extend battery life. |

Safety Protections | Guards against overvoltage, undervoltage, overcurrent, and short circuits. |

Communication | Supports real-time data and remote diagnostics through various interfaces. |

Smart bms integration in lithium battery-powered inspection devices provides high-resolution data acquisition and sophisticated algorithms for accurate state estimation. Built-in protections detect overvoltage, short circuits, and overheating, responding automatically to maintain system reliability. IoT and cloud compatibility enable remote monitoring, giving you better oversight and control.

You see these benefits in medical equipment, robotics, and security systems, where uninterrupted operation and safety matter most. Smart bms technology reduces downtime and extends battery life, making your inspection devices more dependable.

Part2: Battery Management System Safety Functions

2.1 Real-Time Monitoring and Diagnostics

You depend on real-time monitoring to keep your power inspection devices safe and reliable. A smart bms gives you a constant stream of data about your lithium battery packs. This data includes voltage, current, temperature, and impedance. You can spot problems early and plan predictive maintenance before small issues become big failures.

Decentralized bms systems let you handle alerts and alarms remotely.

You can track battery state of charge, energy consumption, and energy harvesting.

The system provides automatic control of generators and disconnections.

You receive history graphs and detailed reports for predictive diagnostics.

Feature | Description |

|---|---|

Digital Twin BMS | Cloud-based platform for real-time monitoring and analysis of lithium-ion battery performance. |

Advanced Data Processing | Improves battery performance and prediction accuracy. |

Error Correction | Addresses sensor errors and adjusts estimations dynamically. |

Performance Metrics | Achieves high coulombic efficiency, showing effective battery health monitoring. |

You use these features in medical, robotics, and security systems, where device uptime is critical. Real-time monitoring helps you avoid costly emergency repairs by letting you schedule maintenance during planned downtimes. You maintain the health and security of your operational technology networks with continuous monitoring, which keeps your energy storage applications running smoothly.

Note: Predictive maintenance based on real-time monitoring reduces downtime and increases reliability for your lithium battery-powered inspection devices.

2.2 Overcharge, Over-Discharge, and Short Circuit Protection

You face risks like overcharging, over-discharging, and short circuits in lithium battery-powered inspection devices. These events often result from improper charging, manufacturing defects, or harsh environments. Overcharging can cause overheating and thermal runaway, which may lead to bulging, cracking, or even venting of gases. Over-discharging can damage cells and reduce battery life. Short circuits can cause immediate failure or fire.

A battery management system protects you by monitoring state of charge and state of health. The bms uses sensors to track voltage and temperature. It manages charging cycles and alerts you to abnormal conditions. You avoid hazards because the bms can disconnect the battery or shut down the device if it detects unsafe conditions. Over-discharge protection ensures your battery never drops below safe voltage levels, preserving its lifespan.

The bms monitors voltage and current to prevent overcharging.

It avoids leaving devices plugged in overnight, reducing risk.

The system provides protection features that guard against overvoltage, undervoltage, overcurrent, and short circuits.

You see these protections in infrastructure, industrial, and consumer electronics sectors, where safety and reliability are essential.

2.3 Thermal Management and Cell Balancing

Thermal monitoring is vital for lithium battery packs. High temperatures can shorten battery life, while low temperatures reduce usable capacity. The bms cuts off power flow when the battery is fully charged and shuts down the battery if temperatures become too high or too low. This protects your devices from damage.

Advanced bms systems use active or passive balancing to keep all cells at similar charge levels. This balancing maximizes battery capacity and lifespan. The bms monitors individual cells and uses algorithms to prevent overheating. It can activate heaters or coolers to maintain safe temperature limits. Cooling systems like fans or liquid cooling help keep batteries within the optimal range of 20°C to 30°C.

The bms regulates charging and discharging rates to control temperature.

It uses sensors for thermal monitoring and algorithms for predictive maintenance.

Passive and active balancing ensure all cells work together, improving reliability.

Factor | Impact on Battery Longevity and Reliability |

|---|---|

Effective Cell Balancing | Optimizes performance and extends lifespan by equalizing charge levels. |

Temperature Management | Best performance at 20°C to 30°C; high temperatures speed up aging, low temperatures lower efficiency. |

Aging Mechanisms | Capacity fade and impedance rise affect state-of-charge and state-of-health estimations. |

You benefit from these features in every sector, from medical to industrial, where lithium battery packs power critical inspection devices. Predictive maintenance and advanced protection features keep your equipment safe and reliable for the long term.

Tip: For more details on bms technology and its role in lithium battery packs, visit Battery Management System (BMS).

Part3: Reliability and Identification of Advanced BMS

3.1 Risks of Non-Smart BMS Devices

You face significant risks when using inspection devices without a smart bms. Traditional systems often lack advanced protection mechanisms and real-time monitoring. This can lead to undetected overcharging, overheating, or cell imbalance. These issues increase the chance of device failure, safety incidents, and costly downtime. In sectors like medical, robotics, and industrial, even a short interruption can disrupt operations or compromise safety.

Risk Factor | Non-Smart BMS Devices | Smart BMS Devices |

|---|---|---|

Real-time Monitoring | Not available | Available |

Predictive Maintenance | Not supported | Supported |

Protection Features | Basic | Advanced |

Reliability | Lower | Higher |

Downtime | Frequent | Rare |

You see that non-smart systems often miss early warning signs. This makes predictive maintenance impossible and increases the risk of sudden failures in energy storage solutions and energy storage applications.

3.2 Identifying Advanced BMS Features

You need to verify advanced features before selecting a battery management system for your inspection devices. Look for real-time monitoring, accurate state-of-charge and state-of-health estimation, and robust cell balancing. Advanced bms testing and bms validation help confirm these features.

Feature | Description |

|---|---|

Temperature Sensor Support | Simulates various thermal conditions for testing. |

CAN Communication | Allows direct interface with the BMS firmware for accurate testing. |

Real-time Monitoring | Provides ongoing assessment of BMS performance during tests. |

Command-based Communication | Enables precise testing protocols for thorough validation of BMS units. |

You should also check for adaptive charging algorithms and integration with IoT systems. These features improve reliability and make predictive maintenance easier.

3.3 Real-World Impact on Device Reliability

You benefit from smart bms-equipped devices in real-world conditions. These systems use wireless communication and advanced analytics to deliver higher reliability and lower costs. You can deploy more sensors and gather better data for bms testing and predictive maintenance. In contrast, traditional systems rely on older protocols and offer limited sensor deployment.

Feature | Smart BMS (SBMS) | Traditional BMS (BMS) |

|---|---|---|

Communication Method | Wireless communication methods | CAN-bus and I2C/SPI protocols |

Reliability | Improved reliability | Believed to have unreliability |

Cost | Lower costs | Higher costs |

Sensor Deployment Feasibility | High feasibility | Limited feasibility |

Challenges | Latency and fading issues | N/A |

You see these advantages in medical, security, and industrial inspection devices. Smart bms technology ensures your equipment stays operational, safe, and efficient, reducing downtime and supporting long-term success.

You gain essential advantages when you choose inspection devices with smart BMS. These systems deliver continuous monitoring, strict safety protocols, and real-time adjustments to keep your lithium battery packs safe. You benefit from advanced diagnostics, dynamic cell balancing, and temperature management, which extend battery lifespan and support energy storage applications. Organizations report improved performance, functional safety, and cost reduction. To upgrade, you should assess your current system, plan the schedule, and seek expert advice. Predictive maintenance becomes easier, helping you avoid downtime and ensure reliable operations.

Benefit Type | Description |

|---|---|

Performance & Range | Optimal battery performance and cell balancing. |

Life Span & Reliability | Longevity and consistent operation. |

Diagnostics & Communication | Efficient monitoring and data sharing. |

FAQ

What makes smart BMS essential for lithium battery packs in power inspection devices?

You need smart BMS to ensure safe and reliable power delivery. It monitors lithium battery packs in real time. You get protection against overcharge, over-discharge, and short circuits. This keeps your power inspection devices running smoothly in medical, robotics, and industrial sectors.

How does cell balancing improve power reliability in inspection devices?

You benefit from cell balancing because it keeps all cells in your lithium battery pack at similar charge levels. This process prevents weak cells from reducing overall power output. You see longer battery life and consistent power performance in security systems and infrastructure applications.

Can smart BMS help reduce downtime in power inspection devices?

You avoid unexpected downtime when you use smart BMS. It provides real-time diagnostics and predictive maintenance for your lithium battery packs. You receive alerts before power failures occur. This helps you maintain continuous power in consumer electronics and industrial inspection devices.

Which lithium battery chemistries offer the best power for inspection devices?

You choose from LiFePO4, NMC, LCO, LMO, and LTO chemistries. Each provides different platform voltages, energy densities, and cycle lives. You match the chemistry to your power needs in medical, robotics, and infrastructure sectors for optimal performance and reliability.

How does smart BMS support remote power monitoring for inspection devices?

You use smart BMS to access remote power monitoring. It connects your lithium battery packs to IoT platforms. You track power status and health from anywhere. This feature supports efficient power management in security systems and industrial inspection devices.