You face a critical challenge when you design batteries for medical applications. You must optimize energy density while maintaining strict safety standards. Recent advancements in battery technology drive significant changes:

Higher energy density allows you to create smaller medical devices.

Miniaturization supports portability and enables minimally invasive procedures.

Lithium-ion and solid-state batteries enhance device functionality.

You improve patient outcomes when you balance usability, reliability, and safety in every medical project.

Key Takeaways

Prioritize user-centric design in medical battery projects to enhance usability and safety.

Implement advanced battery management systems to monitor performance and prevent failures.

Stay updated on regulatory standards to ensure compliance and protect patient safety.

Part 1: Medical Device Battery Design Challenges

1.1 Energy Density vs. Device Usability

You encounter a constant trade-off between energy density and usability in medical device battery design. High energy density enables miniaturization, allowing you to create portable medical device solutions that improve patient comfort and mobility. However, increasing energy density can introduce thermal management issues and impact device stability. For wearable medical devices, battery pack design must accommodate bending and flexing while maintaining chemical stability and durability. Enhanced graphical interfaces in medical devices may increase energy consumption, but efficient design can reduce overall power usage. You must balance high power density with practical usability, ensuring that innovation does not compromise safety features or patient protection.

Tip: Prioritize user-centric design and monitor battery health to optimize both energy density and device usability.

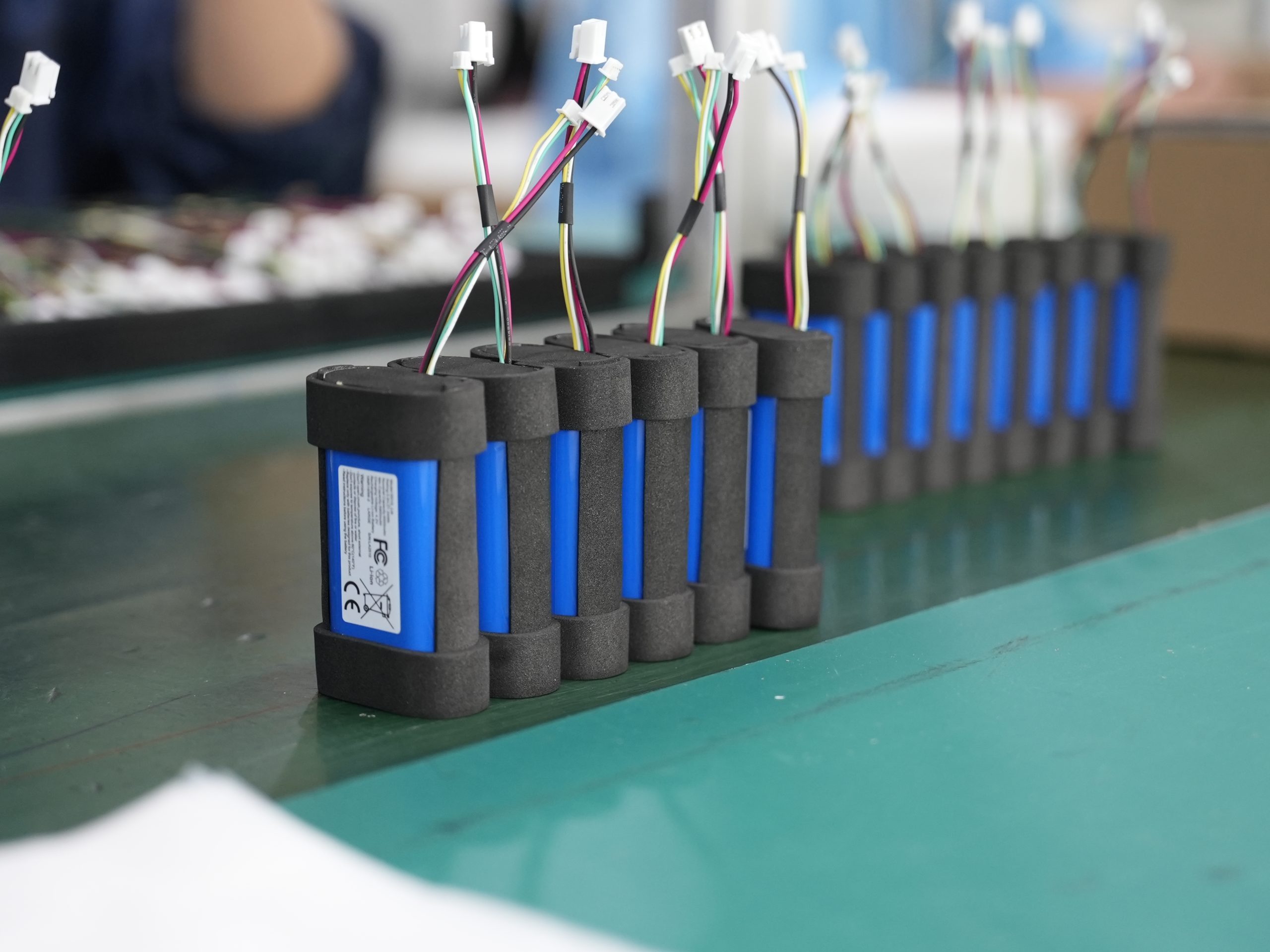

1.2 Reliability and Longevity in Medical Applications

Reliability is essential for medical device battery design. You must select lithium-ion batteries and solid-state batteries that meet strict standards for performance and reliability. Battery capacity must match the operational needs of each device, especially for critical applications like pacemakers and infusion pumps. Advanced battery management systems enhance reliability by monitoring battery status, preventing overcharging, and supporting short-circuit protection. Environmental testing chambers simulate real-world conditions, helping you identify design flaws and ensure compliance with international standards. Longevity reduces maintenance costs and improves health outcomes for patients relying on portable medical device solutions.

1.3 Battery Safety and Patient Protection

Battery safety remains a top priority in medical device battery design. Overheating, fire hazards, leakage, and power loss are frequent risks in lithium battery packs. You must integrate protection features such as thermal management systems, current fuses, and short-circuit protection to safeguard patients. Compliance with ANSI/AAMI ES 60601-1 and IEC 62133 standards is mandatory to prevent incidents like thermal runaway and internal degradation. The table below highlights common health risks associated with battery failures in medical devices:

Health Risks | Description |

|---|---|

Chronic respiratory illnesses | May develop or be exacerbated, such as asthma or bronchitis. |

Heavy metal accumulation | Can cause neurological problems. |

Increased cancer risk | Potential long-term consequence of exposure. |

Cardiovascular strain | Resulting from repeated inhalation of fine particulate matter. |

Skin and eye damage | Possible recurring rashes or corneal damage. |

You must monitor device operation and ensure compliance with all safety standards to protect patients and maintain device reliability.

Part 2: Strategies for Energy Density and Battery Safety

2.1 Advanced Chemistries: NMC, LiFePO4, and SSbD Materials

You drive innovation in medical device battery design by selecting advanced chemistries that balance energy density, reliability, and safety. The most widely used lithium chemistries include NMC, LiFePO4, and solid-state battery materials. Each chemistry offers unique benefits and trade-offs for portable medical device applications.

Battery Type | Energy Density | Cycle Life | Safety | Thermal Runaway Risk |

|---|---|---|---|---|

LiFePO4 | Lower | Longer | Safer | Lower |

NMC | Higher | Shorter | Less Safe | Higher |

Highest (potential) | Longest | Safest (potential) | Lowest (potential) |

NMC batteries deliver high energy density, supporting miniaturization and high power density in compact medical devices. You benefit from lightweight battery pack design and extended device runtime. However, NMC chemistries present higher thermal runaway risks and shorter cycle life, which can impact reliability and safety features.

LiFePO4 batteries offer unmatched safety, chemical stability, and longevity. You achieve lower costs (about 30% less than NMC) and reduced risk of overheating. The lower energy density may limit miniaturization in some medical applications, but the enhanced protection and reliability make LiFePO4 ideal for critical devices.

Solid-state batteries promise the highest energy density and chemical stability, with minimal thermal risks. Although still emerging, these materials could transform medical device battery design by combining miniaturization, safety, and long-term reliability.

Note: Always evaluate the trade-offs between energy density and safety features when selecting a chemistry for your medical device. For custom consultation on chemistry selection, contact Large Power.

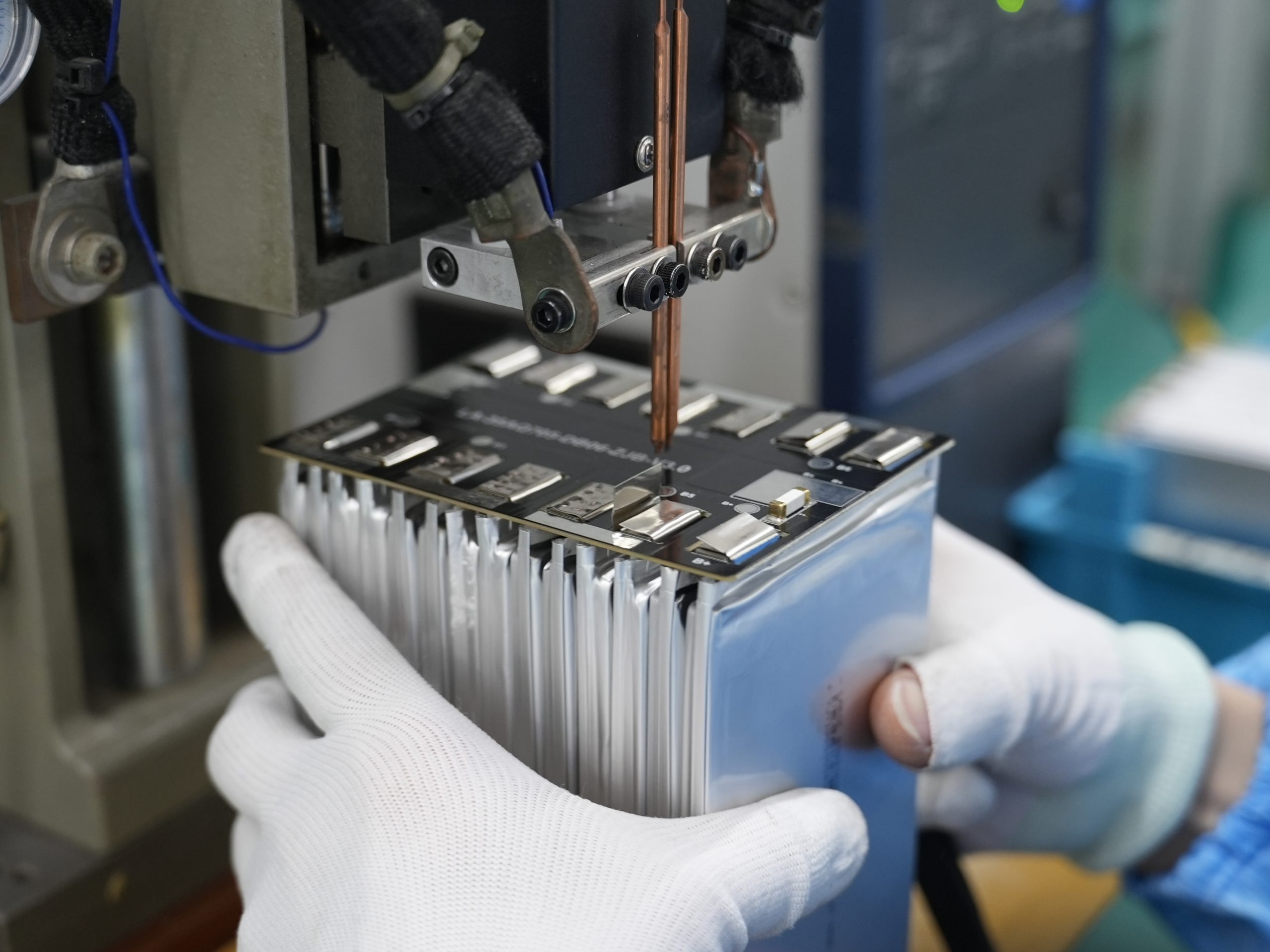

2.2 Cell Balancing and Battery Management Systems

You ensure peak performance and reliability in lithium-ion batteries by implementing advanced cell balancing and battery management systems (BMS). Cell balancing addresses cell mismatch, which can cause uneven aging, voltage differences, and premature failure in medical battery packs. Active cell balancing improves energy storage potential, reduces cell stress, and maintains chemical stability.

Aspect | Description |

|---|---|

Energy Storage Potential | Active balancing increases capacity and health by reducing overcharging stress. |

Energy Transfer Speed | Enables faster energy transfer among cells, vital for large battery packs. |

Energy Efficiency | Transfers energy efficiently, minimizing heat in compact or sensitive devices. |

Voltage Regulation | Maintains safe voltage, reducing over- and undervoltage risks. |

Application Importance | Essential for medical and aerospace applications with strict safety requirements. |

You prolong battery life and maintain reliability by keeping voltages uniform and preventing hazards like thermal runaway.

Battery management systems monitor voltage, current, temperature, and state of charge. They detect abnormalities, trigger alarms, and disconnect circuits to prevent overcharging, over-discharging, and short-circuit events.

BMS ensures lithium-ion batteries operate within the Safe Operating Area (SOA), maximizing energy extraction and battery safety.

In portable medical device applications, BMS and cell balancing are critical for maintaining high energy density, reliability, and protection.

Tip: Use BMS with real-time monitoring and communication features to enhance device reliability and safety.

2.3 Thermal Management and Short-Circuit Protection

You protect medical devices from overheating and electrical faults by integrating robust thermal management and short-circuit protection systems. Effective thermal management maintains chemical stability and extends battery life.

Cooling Method | Efficiency Characteristics | Complexity and Maintenance |

|---|---|---|

Passive Cooling | Natural heat dissipation; less effective in high-heat environments | Simple, low maintenance, cost-effective |

Active Cooling | Uses fans or liquid cooling for efficient heat extraction | Complex, energy-consuming, requires upkeep |

Thermocouples and infrared sensors provide accurate temperature monitoring, ensuring batteries remain within optimal thermal ranges.

Consistent cooling prevents damage from sudden temperature changes and maintains device performance and reliability.

Mechanical design features, such as robust casings and thermal insulation, add layers of protection against impacts and heat transfer.

Short-circuit protection is vital for lithium battery packs in medical devices. Circuit breakers and fuses automatically interrupt current flow during faults, preventing battery failure and minimizing downtime. Unlike fuses, circuit breakers reset quickly, ensuring continuous device operation and reliability.

You must implement short-circuit protection at both the cell and system level to safeguard patients and maintain compliance with medical standards.

Alert: Never compromise on thermal management or short-circuit protection. These safety features are essential for every portable medical device.

2.4 Regulatory Compliance and Emerging Technologies

You navigate a complex landscape of standards and compliance requirements in medical device battery design. Regulatory bodies enforce strict guidelines to ensure energy density, reliability, and protection in every device.

Medical devices must comply with ISO 13485, UL-60601-1, IEC 62133, and other international standards. These standards address battery safety, biocompatibility, and performance.

Integration of protection circuitry—over-voltage, under-voltage, thermal, and short-circuit protection—is mandatory for all lithium and solid-state battery packs.

Regulatory agencies conduct risk assessments, postmarket surveillance, and require detailed documentation for new battery technologies.

Future trends include requirements for user-removable batteries, extended producer responsibility, and clear safety markings.

Standard | Description |

|---|---|

IEC 62133 | Safety requirements for secondary cells and batteries, including biocompatibility. |

UL 2054 | Safety standard for household and commercial batteries, applicable to medical devices. |

ISO 13485 | Quality management system requirements for medical device manufacturers. |

IEC 60601-1 | General requirements for safety and performance of medical electrical equipment. |

ISO 10993-1 | Guidelines for evaluating biological safety of medical devices, including batteries. |

You must stay updated on evolving standards and compliance requirements to ensure your medical device battery design meets global expectations.

Advanced chemistries and innovative packaging solutions may increase initial costs, but they deliver long-term savings through improved reliability and reduced maintenance.

For guidance on compliance or custom battery solutions, contact Large Power for consultation.

Note: Always verify your battery design with the latest standards and regulatory updates to maintain market access and patient safety.

You strengthen medical device safety and energy density by prioritizing monitoring, redundancy, and compliance with strict standards.

Integrate advanced battery management systems and temperature monitoring tools.

Ensure device protection features meet medical standards.

Continuously review standards and compliance for every medical device.

Focus on monitoring and usability in every medical battery design.

FAQ

What is the most important safety feature for lithium battery packs in medical devices?

You should prioritize thermal management systems. These systems prevent overheating and protect patients from battery failure in every medical application.

How do you ensure biocompatibility in battery design?

You select materials that meet international biocompatibility standards. Testing ensures batteries do not cause adverse reactions when used in direct or indirect contact with patients.

Where can you get custom lithium battery pack solutions for medical devices?

You can contact Large Power for custom consultation and tailored battery solutions.