You see future trends in robotics batteries shaping how robots work in industries. Higher energy density lets robots run longer and carry more advanced tools. Lithium-ion batteries, including LiFePO4 and NMC, now hold over 85% of the market. The global robot battery market grows at 15% yearly, reaching $12 billion by 2028. Faster charging and smarter management improve operational efficiency and reliability. Testing new battery technology, like lithium metal, boosts safety and sustainability. These advances support robots in manufacturing, logistics, and healthcare, making your operations more productive and efficient.

Key Takeaways

Higher energy density in batteries allows robots to operate longer and carry heavier tools, enhancing productivity.

Fast charging technology reduces downtime, enabling robots to recharge in minutes and maintain continuous operation.

Sustainable battery production focuses on recyclability and reduced environmental impact, supporting eco-friendly practices.

Smart battery management systems optimize charging and extend battery life, ensuring safe and efficient robot operations.

Emerging battery technologies, like graphene and solid-state batteries, promise significant improvements in performance and safety.

Part1: Future Trends in Battery Technology

1.1 Energy Density

You see rapid progress in robots battery technology, especially in energy density. High energy density means robots can operate longer and carry heavier payloads without increasing weight. Over the past five years, several advancements have transformed the field:

The F.03 battery achieved a 94% increase in energy density. You can now integrate this battery directly into a robot’s torso, which improves design efficiency and saves space.

Lithium-ion batteries, such as LiFePO4 and NMC, remain the preferred choice for robotics. These batteries offer high energy density and long cycle life, which means robots spend less time charging and more time working.

Solid-state batteries are emerging as a promising technology. They provide increased energy density and improved safety, which is critical for industrial robots.

Recent developments in graphene chemistry have also changed the landscape. When you apply a graphene coating to lithium-ion battery cathodes, you double the cycle life and expand the temperature range. This improvement is vital for robots that must perform in demanding environments. Graphene batteries deliver high energy densities, fast charging, and lighter weight, which allows robots to work longer and more efficiently.

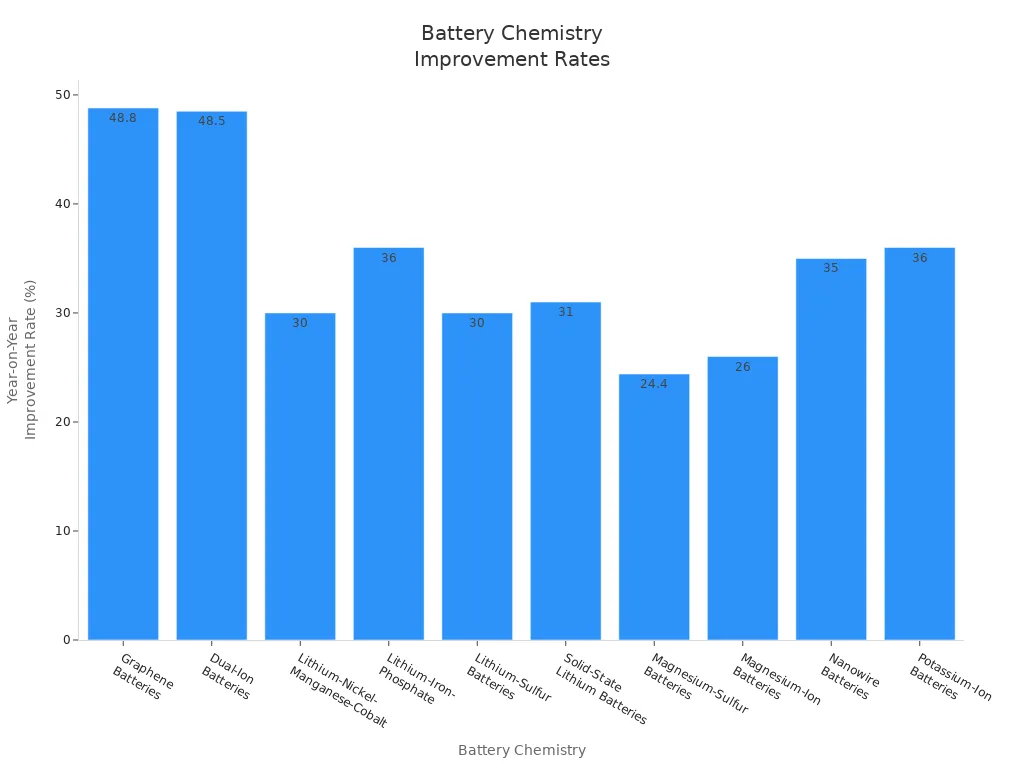

You can compare the year-on-year improvement rates and benefits of different battery chemistries in the table below:

Battery Chemistry | Year-on-Year Improvement Rate | Key Benefits |

|---|---|---|

Graphene Batteries | 48.8% | High energy densities, increased cycle life, fast charging, potential for lighter robots. |

Dual-Ion Batteries | 48.5% | Significant improvement rates, potential for enhanced performance. |

Lithium-Nickel-Manganese-Cobalt (NMC) | 30% | Current dominant chemistry, improving but slower than graphene. |

Lithium-Iron-Phosphate (LiFePO4) | 36% | Steady improvements, reliable for industrial use. |

Lithium-Sulfur Batteries | 30% | Limited disruption potential compared to graphene. |

Solid-State Lithium Batteries | 31% | Slow improvement, unlikely to disrupt current technologies. |

Magnesium-Sulfur Batteries | 24.4% | Emerging technology, slower improvement rate. |

Magnesium-Ion Batteries | 26% | Similar to magnesium-sulfur, limited disruption potential. |

Nanowire Batteries | 35% | Emerging technology, potential for future improvements. |

Potassium-Ion Batteries | 36% | Similar to magnesium technologies, slower than graphene. |

You benefit from these advancements because robots can now operate for longer periods and handle more complex tasks. Graphene batteries, in particular, promise a future where robots work more efficiently and require less downtime for charging. Lithium-based batteries continue to improve, but graphene chemistry may soon set a new standard for robots battery technology.

1.2 Sustainability

Sustainability in battery production has become a top priority for robotics manufacturers. You want batteries that not only perform well but also minimize environmental impact. Sustainable production processes now focus on recyclability, use of recycled materials, and waste reduction.

Aspect | Detail |

|---|---|

Battery Recyclability | 99% recycled (more than aluminum cans) |

Use of Recycled Materials | Roughly 80% recycled materials used |

Waste Reduction | On-site equipment refines materials |

Sustainable battery production reduces waste and environmental impact.

Improved recyclability means less harm to the environment.

Many manufacturers now use renewable energy in battery manufacturing.

You can learn more about sustainable battery practices in robotics by visiting our approach to sustainability.

Battery management strategies now include design-for-disassembly principles. These principles make it easier to recycle and repurpose battery components at the end of their life. However, you must also consider the challenges of non-standardized battery designs and the hazards of handling battery materials. Companies like Posh Robotics lead the way by automating battery recycling with robotics and computer vision. Everledger tracks the lifecycle of batteries with digital passports, which helps you ensure responsible sourcing and recycling.

Company | Focus Area | Year Founded | Funding Amount |

|---|---|---|---|

Posh Robotics | Automating EV battery recycling using robotics and computer vision | 2021 | $3.8 million |

Everledger | Digital passports for tracking battery lifecycle | N/A | N/A |

IonQ | Quantum computing for optimizing battery development | N/A | N/A |

Group14 Technologies | N/A | N/A | N/A |

Northvolt | N/A | N/A | N/A |

You should also pay attention to the sourcing of raw materials. Responsible sourcing helps avoid conflict minerals, which can harm both people and the environment. For more information, see the conflict minerals statement.

By choosing sustainable battery solutions, you support both operational efficiency and environmental responsibility in robotics. These practices help you meet regulatory requirements and improve your company’s reputation in the industry.

Part2: Charging Innovations for Robots

2.1 Fast Charging

You see fast charging technology transforming how robots operate in industrial environments. When you use lithium battery packs with advanced chemistries like LiFePO4 and NMC, you unlock rapid charging performance that keeps robots working longer and reduces downtime. Fast charging allows you to restore significant battery capacity in under 30 minutes. Production-line robots and AGVs benefit from high-current DC charging systems. These systems enable opportunity charging during scheduled pauses, so robots spend less time idle and more time productive.

Fast charging reduces the need for manual battery swaps and centralized charging rooms. You streamline factory logistics and keep robots operating continuously in smart production environments.

LiFePO4 batteries support fast charging, which is crucial for AGVs in warehouses and manufacturing plants. You can quickly return these vehicles to operation after recharging, minimizing downtime and maximizing operational efficiency. High energy density and robust chemistry ensure that batteries maintain performance even after repeated fast charging cycles.

You can compare the latest fast charging solutions for robotics batteries in the table below:

Fast Charging Solution | Charging Time | Benefits |

|---|---|---|

Nyobolt Ultra | 6–10 minutes | Increases robot uptime, reduces fleet size by 30-40% |

Nyobolt Xtreme | 1–5 minutes | Enables rapid recharge cycles for 24/7 operations |

EV Prototype | 4 minutes 37 seconds | Charges from 10% to 80%, providing 120 miles of range |

You gain a competitive advantage by adopting fast charging strategies. Robots equipped with advanced lithium battery packs and optimized charging strategy can handle more tasks without interruption. You improve operational efficiency and reduce costs associated with battery maintenance and replacement.

2.2 Ultra-Fast Solutions

Ultra-fast charging technology pushes the boundaries of robotics battery performance. You can now charge batteries from 10% to 80% in under 5 minutes. Nyobolt’s ultra-fast charging technology is ideal for high-demand robotics applications, where every minute counts. You achieve rapid recharge cycles that support 24/7 operations and minimize downtime.

TYVA Energie’s Ultrion technology offers even faster charging rates. You can charge batteries at 50 C in just one minute or at 100 C in only 30 seconds. These batteries deliver high energy density and maintain a lifespan exceeding 10 years, making them suitable for intensive industrial use.

Technology | Charge Time (at 20°C) |

|---|---|

TYVA Energie Ultrion | 50 C – 1 minute |

TYVA Energie Ultrion | 100 C – 30 seconds |

TYVA Energie Ultrion | 10 C – 5 minutes |

You benefit from ultra-fast charging by reducing the number of robots needed in your fleet. When you recharge batteries quickly, you keep robots available for more tasks and improve overall efficiency. You also support advanced robotics design by integrating batteries with high energy density and robust chemistry.

Testing new battery technology remains essential. You must evaluate charging performance, cycle life, and energy density to ensure reliability. Lithium battery packs with solid-state, lithium metal, and advanced graphene chemistry offer promising results in both fast and ultra-fast charging scenarios. You see these innovations driving the future of robotics and enabling smarter, more efficient operations.

Part3: Smarter Battery Management

3.1 Predictive Systems

You rely on intelligent battery management systems (BMS) to keep robots running safely and efficiently. These systems use real-time monitoring and predictive analytics to optimize battery charging and discharging. The BMS adapts charging rates based on battery conditions, which helps prevent overheating and extends battery life. You can use predictive energy management to plan robot routes and tasks, reducing unnecessary power consumption and maximizing uptime.

Modern BMS features include:

Feature | Description |

|---|---|

State of Charge (SOC) | Estimates the current charge level of the battery. |

State of Health (SOH) | Assesses the overall health and lifespan of the battery. |

Thermal management | Regulates temperature to prevent overheating and ensure optimal performance. |

Cell balancing | Ensures uniform charging and discharging of battery cells. |

Communication protocols | Supports CAN, UART, RS485 for data transfer. |

Real-time diagnostics | Provides immediate feedback on battery status and detects faults. |

You see predictive systems like Model Predictive Control (MPC) and Predictive Dynamic Window Approach (P-DWA) in action. These technologies help optimize energy use and robot path planning. For example, AGVs use predictive models to minimize both transport distance and energy consumption. This approach improves efficiency and reduces operational costs.

Tip: Explore more about BMS and protection circuit modules for lithium battery packs at BMS and PCM.

3.2 Safety and Efficiency

Safety remains a top priority in robotics battery management. The BMS integrates multiple safety features to protect both robots and your operations. Overcurrent protection prevents currents above 300A, while short-circuit detection responds within microseconds. Overcharge and over-discharge prevention keep each cell within safe voltage limits. Thermal runaway prevention monitors temperature, reducing the risk of fires or explosions.

Safety Feature | Description |

|---|---|

Overcurrent Protection | Prevents currents exceeding 300A, avoiding overheating and fires. |

Short-Circuit Detection | Detects short circuits within 50–150µs, ensuring rapid response. |

Overcharge Prevention | Stops charging above 4.25V per cell, protecting battery health. |

Over-Discharge Prevention | Prevents discharge below 2.5V per cell, avoiding battery failure. |

Thermal Runaway Prevention | Monitors temperature to prevent dangerous conditions. |

You benefit from advanced battery management systems by maximizing power efficiency and performance. State monitoring and cell balancing extend battery life and reduce replacement costs. Predictive maintenance alerts you before failures occur, minimizing downtime. These features support intelligent energy management and help you maintain high productivity in robotics applications.

BMS enables robots to perform complex tasks with consistent power delivery.

Real-time monitoring ensures immediate response to any battery issue.

Intelligent management supports fast charging cycles without sacrificing safety.

You see these advancements in lithium battery packs using chemistries like LiFePO4, NMC, and solid-state technology. Smarter battery management gives you the confidence to deploy robots in demanding environments, knowing that safety, efficiency, and performance are always protected.

Part4: Applications in Robotics

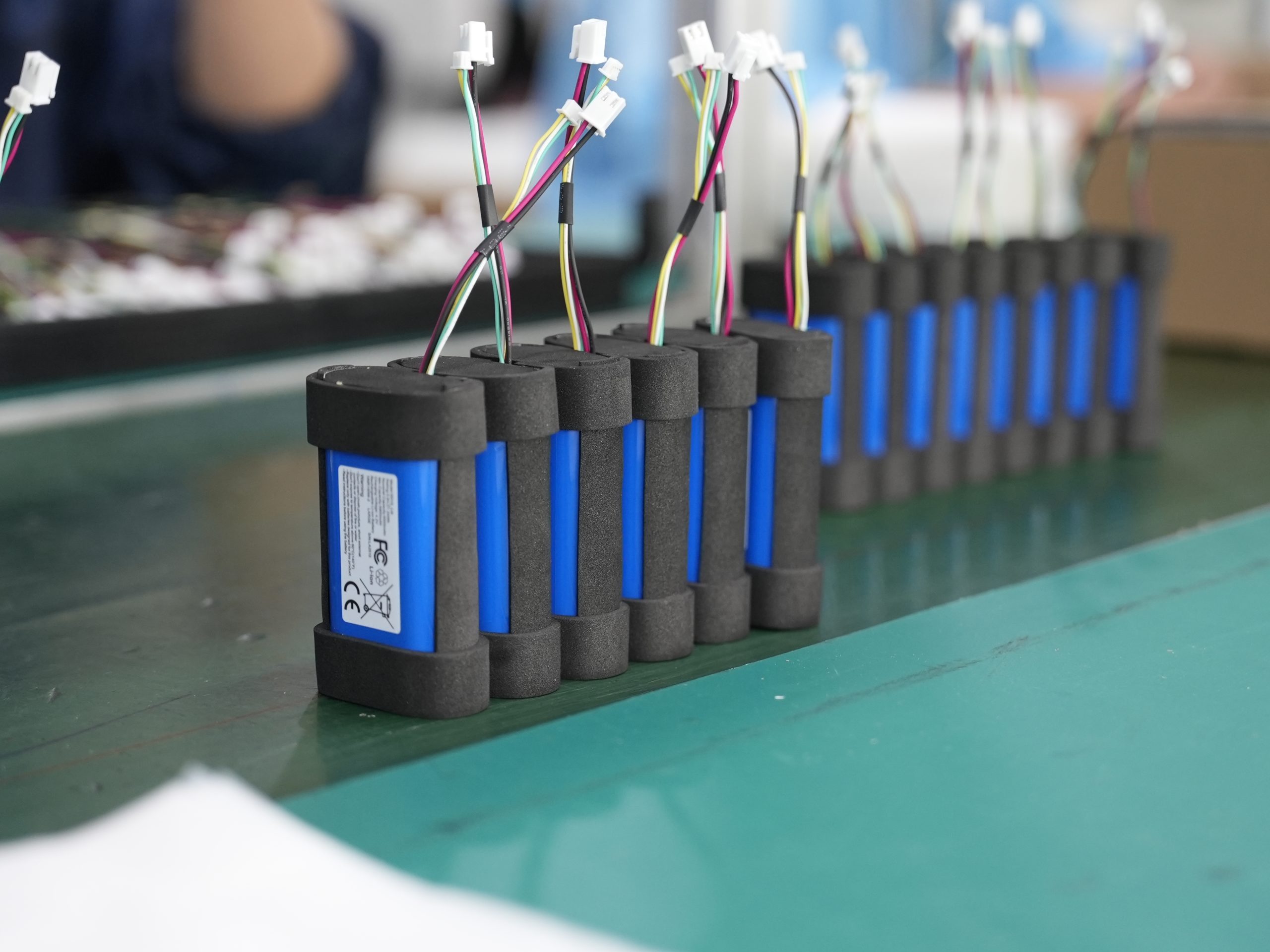

4.1 Industrial Robots

You see industrial robots leading the way in battery and charging innovation. Custom lithium battery solutions, including LiFePO4 and NMC chemistries, deliver high performance and safety for production-line robots, robotic arms, and AGVs. These batteries offer design flexibility, allowing you to fit battery packs into unique robot shapes. You benefit from advanced power delivery, meeting high peak current demands and preventing operational failures. Smart battery management systems (BMS) provide real-time monitoring and predictive maintenance, improving uptime and efficiency.

Custom lithium battery packs enhance performance and safety.

Design flexibility supports unique robot configurations.

Smart BMS enables predictive management and reduces downtime.

Robotic arms and AGVs now use lithium-ion batteries that charge in one to two hours. You achieve longer-lasting energy, with up to 20 hours of continuous operation. Lower maintenance needs mean higher productivity and less downtime.

Shorter charging times increase operational flexibility.

Reliable energy capacity supports continuous work.

Lower maintenance boosts overall efficiency.

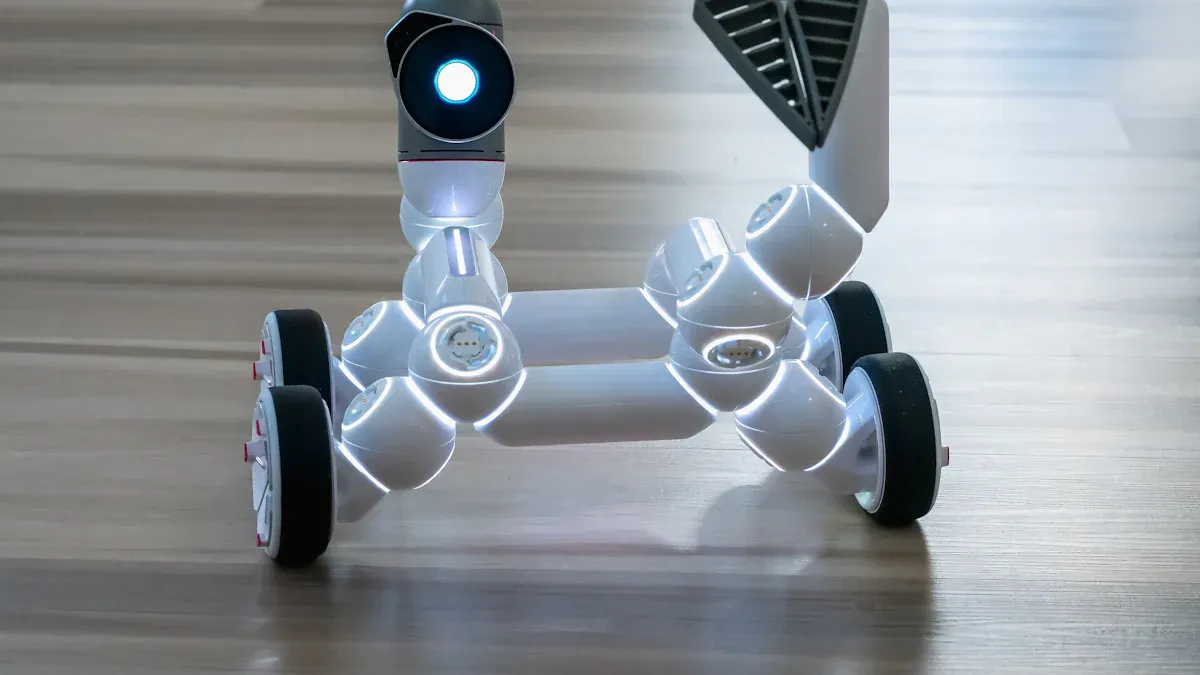

4.2 Humanoid Robots

You see future trends in battery technology shaping humanoid robots. The latest version of Agility’s Digit robot uses a battery housed in a backpack, running for 90 minutes and recharging in just 9 minutes. Most humanoid robots operate for about two hours per charge. Innovations like swappable batteries and fast charging are essential for extending operational time. Achieving an eight-hour shift without recharging may take up to a decade due to slow improvements in energy density.

Dynamic charging systems power robots during operation, improving autonomy and efficiency. The Walker S2 robot features a dual-battery system for autonomous swapping, enabling 24/7 operation. Inductive charging allows robots to receive power while working, eliminating downtime and enhancing mobility.

Tip: Dynamic power delivery and advanced BMS are crucial for safe, efficient, and autonomous humanoid robots in industrial and medical sectors.

4.3 Service Robots

You rely on service robots in commercial environments, including medical, security, infrastructure, and consumer electronics sectors. These robots require batteries with fast charging capability, wide temperature range, long cycle life, high discharge rates, and superior safety. LTO batteries can recharge in 6 to 10 minutes and operate from -30°C to 55°C. Long cycle life reduces replacements, supporting continuous operation.

Feature | Description |

|---|---|

Fast Charging Capability | LTO batteries recharge at rates up to 10C in 6–10 minutes. |

Wide Temperature Range | Operate from -30°C to 55°C for reliability in extreme conditions. |

Long Cycle Life | Fewer replacements needed, enabling uninterrupted service. |

High Discharge Rates | Maintains performance for AGVs and mobile robots. |

Safety | Superior safety features for demanding environments. |

Recent battery innovations provide up to six times more energy capacity, 40% lower weight, and ten times longer cycle life than standard lithium-ion batteries. Ultra-fast charging and compatibility with existing systems enable 24/7 operation. These advancements set new standards for speed, efficiency, and reliability in robotics.

Smarter, more durable robots optimize operational efficiency.

Enhanced battery management supports continuous uptime.

Fast charging and safety features drive productivity in service applications.

Part5: Industry Outlook

5.1 Market Implications

You see future trends in robotics batteries driving major changes in the industry. The market for robot batteries reached about USD 1.5 billion in 2023. Projections show growth to USD 4.3 billion by 2032. Growth rates vary by region and application:

The robot battery market is expected to grow at a CAGR of 6.2% from 2025 to 2032.

The global robot battery market may reach a CAGR of 12.7% from 2025 to 2033.

Advancements in battery technology, such as solid-state batteries and lithium metal, improve energy density and safety. These improvements boost the performance of robots in manufacturing, logistics, and healthcare. You notice a shift toward energy-efficient robots with longer operational periods. Wireless charging and energy harvesting support uninterrupted operation in dynamic environments. Collaborative efforts between research institutions and technology developers accelerate innovation in battery chemistry and charging solutions. Policy incentives encourage manufacturers to invest in sustainable battery production and management. Continuous improvements in battery cost efficiency make adoption easier for commercial robotics platforms.

Note: Integration of smart monitoring systems and IoT-enabled BMS enhances operational efficiency and safety for robots in industrial settings.

5.2 Strategic Planning

You prepare your business for future developments in robotics battery and charging technology by focusing on strategic planning. Advanced lithium battery packs, including LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal, offer higher energy density, longer cycle life, and improved safety. You optimize fleet management by using AI-driven routing and task allocation, which assigns tasks based on robot availability and battery levels. Real-time performance tracking monitors battery health, motor temperature, and usage patterns. Automated charging schedules adjust based on task completion and remaining runtime.

Feature/Benefit | Description |

|---|---|

AI-driven routing and task allocation | Allocates tasks based on robot availability and battery levels. |

Real-time performance tracking | Monitors battery health, motor temperature, and usage patterns. |

Automated recharging schedules | Adjusts charging based on task completion and remaining runtime. |

Predictive maintenance | Uses historical data to forecast maintenance needs. |

Reduces downtime | Identifies potential failures proactively. |

Increases fleet utilization | Enhances energy efficiency and operational costs. |

Enables 24/7 operation | Allows for minimal human oversight. |

You reduce downtime and increase fleet utilization by adopting predictive maintenance and smart BMS. These strategies enable 24/7 operation and minimal human oversight. You stay competitive by investing in battery management, charging infrastructure, and safety protocols. You monitor future trends and adapt your robotics strategy to leverage new battery technology and charging innovations.

You see future trends in robotics battery technology driving major improvements for robots. Advancements in battery capacity, charging speed, and smarter management help you achieve greater efficiency, reliability, and sustainability in your operations.

You can boost operating profits by up to 60% through supply chain optimization.

Tracking carbon emissions and using sustainable batteries reduces costs and increases customer commitment.

Innovation Type | Description |

|---|---|

Solid-State Batteries | Higher energy density and safety for robots. |

Advanced Battery Management Systems | Better thermal management and safety protocols for robotics. |

Wireless Charging | Convenient and efficient charging for robots. |

You should consider how new battery chemistries, fast charging, and smarter management will shape your business strategy. The rise of collaborative robots, eco-friendly batteries, and advanced charging systems will help you stay competitive in the robotics industry.

FAQ

What are the main benefits of using advanced lithium battery chemistries in robotics?

You gain longer operational time, higher energy density, and improved safety. Chemistries like LiFePO4, NMC, and solid-state batteries support demanding industrial tasks. These batteries also offer better cycle life and reliability for your robotics fleet.

How do fast charging solutions impact robot productivity?

You reduce downtime with fast charging. Robots equipped with advanced battery packs can recharge in minutes. This allows you to keep production lines moving and minimize idle time. Fast charging also supports 24/7 operations in logistics and manufacturing.

Why is battery management important for industrial robots?

You rely on battery management systems to monitor state of charge, temperature, and health. These systems prevent failures and extend battery life. Smart management ensures safe operation and helps you avoid costly interruptions in your workflow.

What role does sustainability play in future trends for robotics batteries?

You see sustainability as a key driver in future trends. Manufacturers now use recycled materials and design batteries for easy recycling. Sustainable battery production reduces waste and supports your company’s environmental goals.

How do you select the right battery for your robotics application?

You consider energy density, cycle life, safety, and charging speed. Evaluate chemistries like LiFePO4, NMC, LTO, and solid-state batteries. Match battery specifications to your robot’s power needs and operational environment for best results.