Digital twin batteries reshape the safety and intelligence of medical devices by leveraging virtual models for health monitoring and prediction. Lithium-ion battery reliability directly affects device performance and patient safety. Traditional battery management often lacks real-time data and predictive capabilities. With digital twin technology, manufacturers gain accurate health prognostics and predictive maintenance strategies, enabling safer and smarter operations.

Key Takeaways

-

Digital twin batteries create virtual models of lithium-ion batteries, allowing real-time monitoring and predictive maintenance. This enhances safety and performance in medical devices.

-

Real-time data from digital twins helps detect potential battery failures early. This proactive approach minimizes downtime and ensures uninterrupted patient care.

-

Predictive maintenance strategies reduce unexpected failures and extend battery life. Hospitals can allocate resources more effectively, improving overall efficiency.

-

Digital twin technology supports compliance with safety standards. Manufacturers can simulate battery behavior, ensuring devices meet regulatory requirements before deployment.

-

Implementing digital twin batteries requires careful planning. Start with pilot projects, integrate real-time data, and train staff to maximize benefits and ensure successful adoption.

Part 1: Digital Twin Batteries

1.1 Definition

Digital twin batteries represent a virtual replica of a physical lithium-ion battery system. This digital model mirrors the real-time status, performance, and aging characteristics of the battery. Engineers use advanced algorithms and sensor data to update the digital twin continuously. The model incorporates standardized battery chemistries such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. Each chemistry offers unique platform voltages, energy densities, and cycle lives. For example, LiFePO4 typically provides a platform voltage of 3.2V, energy density around 90-160 Wh/kg, and cycle life exceeding 2000 cycles. The digital twin tracks these metrics and predicts future performance.

Note: Digital twin batteries enable manufacturers to simulate battery behavior under various conditions without physical testing. This approach reduces development time and improves reliability.

1.2 Role in Medical Devices

Medical devices rely on lithium battery packs for consistent power delivery. Digital twin batteries play a critical role in ensuring device safety and operational intelligence. They allow manufacturers to monitor battery health, predict failures, and optimize charging cycles. Hospitals and device makers benefit from real-time insights into battery status, which supports preventive maintenance and reduces downtime.

-

Key Functions in Medical Devices:

-

Real-time monitoring of battery temperature, voltage, and state-of-charge.

-

Simulation of battery performance during emergency scenarios.

-

Prediction of cycle life and energy density degradation.

-

A table below highlights how digital twin batteries support different medical device applications:

|

Application Scenario |

Battery Chemistry |

Platform Voltage |

Energy Density (Wh/kg) |

Cycle Life (cycles) |

|---|---|---|---|---|

|

Portable monitors |

NMC |

3.7V |

150-220 |

1000-2000 |

|

Infusion pumps |

LCO |

3.6V |

140-200 |

500-1000 |

|

Surgical robots |

LiFePO4 |

3.2V |

90-160 |

2000+ |

Digital twin batteries help medical device manufacturers meet strict safety standards and regulatory requirements. They also support integration with IoT platforms for smarter device management.

Part 2: Safety Benefits

2.1 Real-Time Monitoring

Digital twin batteries provide a new standard for safety in medical devices by enabling real-time monitoring of lithium-ion battery systems. These digital replicas of physical systems collect and analyze data from sensors embedded in the battery pack. The system integrates real-time and historical data, which enhances the accuracy of life prediction and reliability evaluation. This approach supports continuous feedback between the virtual model and the physical battery, ensuring that device operators receive up-to-date information on battery health and performance.

-

Digital twin technology collects design data, operation data, and real-time feedback data.

-

The framework supports real-time interaction between virtual and physical spaces, which is crucial for maintaining battery health in medical devices.

-

Real-time monitoring improves the efficiency of battery management and supports remote patient monitoring, especially in critical care and chronic disease management scenarios.

The measurable outcomes of implementing real-time monitoring through digital twin batteries in healthcare settings include:

|

Description |

|

|---|---|

|

Improved Patient Care |

Enhances patient care through real-time data integration and personalized insights. |

|

Diagnostic Accuracy |

Supports precise and timely diagnoses, reducing errors and enabling earlier interventions. |

|

Proactive Interventions |

Enables early detection of deterioration, allowing for timely interventions and optimized care. |

|

Resource Optimization |

Reduces the need for frequent hospital visits, optimizing healthcare resources and management. |

|

Patient Engagement |

Empowers patients to manage their health actively, leading to better adherence to treatment. |

|

Predictive Analytics |

Forecasts disease progression and treatment outcomes, improving patient safety and long-term care. |

Note: Real-time monitoring not only increases efficiency but also supports personalized medicine by providing tailored insights for each patient.

2.2 Predictive Maintenance

Predictive maintenance stands as a key advantage of digital twin batteries in medical devices. The technology enables proactive remote monitoring of equipment, allowing operators to identify potential problems or technical issues before they escalate. Maintenance can be scheduled during planned downtime, which helps maintain the continuity of care and saves valuable resources. This strategy improves efficiency and battery optimization, reducing unexpected failures and extending the operational life of lithium battery packs.

Medical device manufacturers benefit from predictive maintenance by minimizing device downtime and ensuring uninterrupted service. Hospitals can allocate resources more effectively, while patients experience fewer disruptions in their care. Predictive analytics, powered by digital twin models, also support personalized medicine by forecasting battery performance and maintenance needs based on individual usage patterns.

2.3 Risk Detection

Safety remains a top priority in medical device design and operation. Digital twin batteries enhance risk detection by continuously analyzing battery data for early warning signs of failure. The system can detect a range of risks associated with lithium-ion batteries used in medical devices:

-

Fires caused by thermal runaway, leading to uncontrollable heat and potential ignition.

-

Leaks that release toxic chemicals, posing severe health risks.

-

Fumes from off-gassing of combustible and toxic substances, which may require evacuation.

-

Blasts or explosions resulting from thermal runaway, which can be catastrophic, especially for patients with implantable devices.

By identifying these risks early, digital twin batteries enable rapid intervention and corrective action. This proactive approach supports safety and efficiency in battery management, ensuring that medical devices operate reliably in critical environments. The integration of digital twin technology also accelerates drug discovery by providing accurate simulations of battery behavior in new device prototypes, supporting faster and safer innovation.

Tip: For organizations seeking to improve safety and efficiency, digital twin batteries offer a robust solution for risk detection and battery management across a range of medical and industrial applications.

Part 3: Smarter Device Management

3.1 Performance Optimization

Medical device manufacturers rely on advanced management systems to maximize the performance of lithium battery packs. Digital twin technology enables engineers to simulate real-world operating conditions, optimizing charging cycles and discharge rates for each battery chemistry. For example, LiFePO4 batteries deliver stable platform voltages and long cycle life, making them suitable for surgical robots and critical care devices. NMC batteries offer higher energy density, which benefits portable monitors and consumer electronics. The table below compares battery management systems across various sectors:

|

Sector |

Battery Chemistry |

Platform Voltage |

Energy Density (Wh/kg) |

Cycle Life (cycles) |

Management System Type |

|---|---|---|---|---|---|

|

Medical |

LiFePO4 |

3.2V |

90-160 |

2000+ |

Digital Twin |

|

Robotics |

NMC |

3.7V |

150-220 |

1000-2000 |

Digital Twin |

|

Security Systems |

LCO |

3.6V |

140-200 |

500-1000 |

Traditional BMS |

|

Infrastructure |

LTO |

2.4V |

70-110 |

7000+ |

Digital Twin |

|

Consumer Electronics |

Solid-State |

3.8V |

250-400 |

1000-2000 |

Digital Twin |

|

Industrial |

Lithium Metal |

3.6V |

400+ |

500-1000 |

Traditional BMS |

Tip: Manufacturers can achieve higher reliability and longer service life by selecting the optimal battery chemistry and management system for each application.

3.2 Data-Driven Decisions

Digital twin batteries empower manufacturers to make informed decisions using real-time data. They detect anomalies early, which is essential for maintaining safety and performance. Predictive maintenance becomes possible by calculating metrics such as state of charge and state of health. Simulations ensure batteries meet safety standards before deployment in medical and industrial devices. These capabilities support fault diagnostics and performance optimization, reducing operational risks.

-

Early anomaly detection

-

Predictive maintenance scheduling

-

Pre-deployment safety validation

3.3 AI and IoT Integration

The combination of AI, IoT, and digital twin batteries transforms healthcare device management. Continuous real-time monitoring allows virtual models to reflect changes in vital signs and health metrics, which is vital for chronic disease management. IoT technologies enable compact devices to transmit data, helping healthcare professionals respond to emergencies quickly. AI-driven digital twins simulate scenarios, optimize resource allocation, and improve patient flow. Hospitals benefit from better utilization of staff and equipment, leading to enhanced operational efficiency.

For further reading on battery management systems, visit Battery Management System (BMS).

Part 4: Digital Twin Technology in Testing

4.1 Virtual Testing

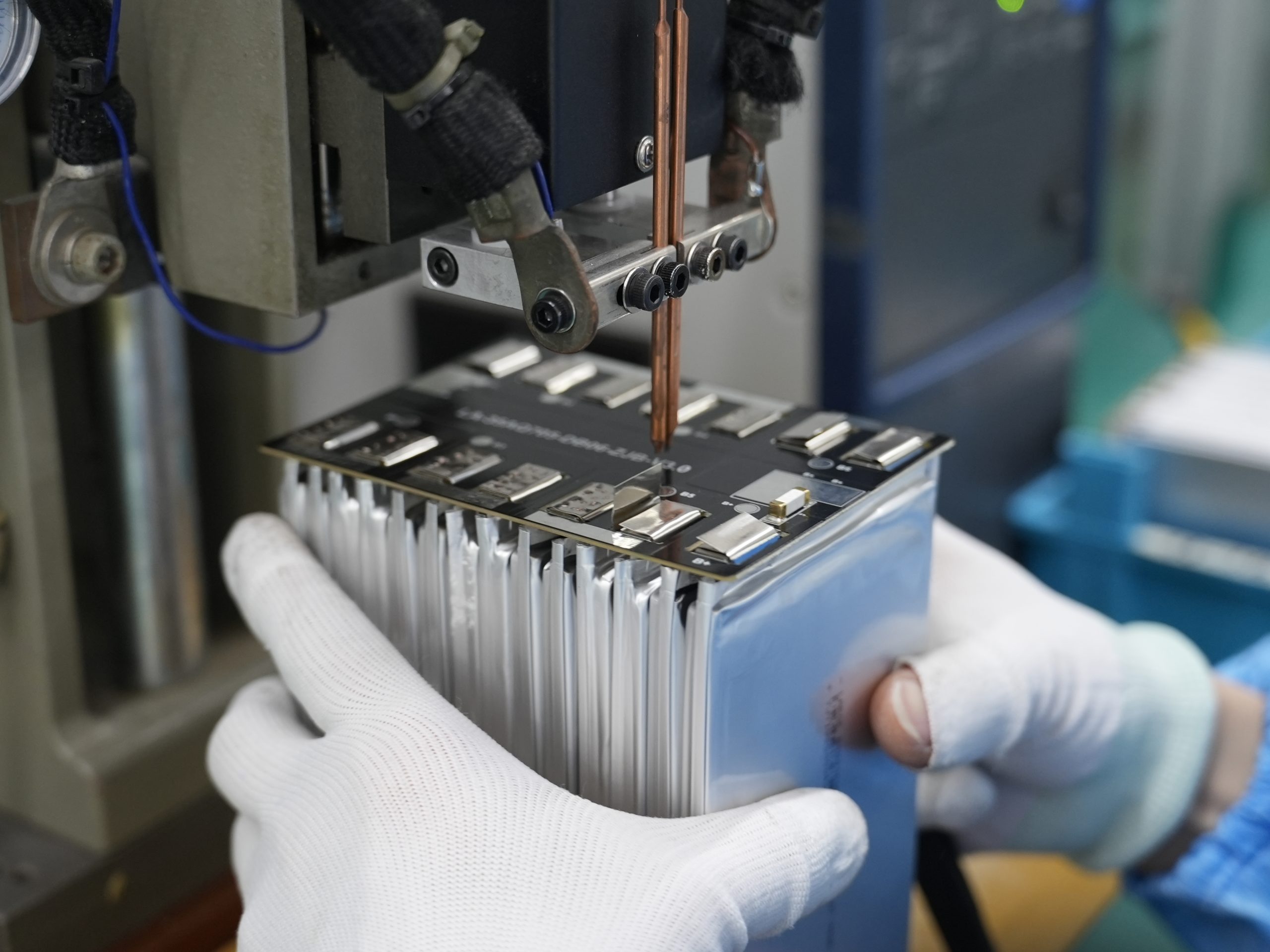

Digital twin technology transforms the way manufacturers test lithium-ion battery packs in medical devices. By creating a virtual replica of the battery system, engineers can simulate real-world conditions and predict performance, safety, and aging mechanisms. This approach reduces the need for multiple physical prototypes and accelerates the development process.

A notable example is the THOR European project, which uses digital twins in healthcare to simulate battery behavior and enable predictive analysis. The table below summarizes its impact:

|

Aspect |

Description |

|---|---|

|

Project Name |

THOR European project |

|

Purpose |

Facilitate the development of next-gen European batteries |

|

Role of Digital Twin |

Simulates battery behavior, enabling predictive analysis of performance, safety, and aging mechanisms |

|

Benefits |

Speeds up testing processes and reduces the need for extensive physical tests |

Manufacturers benefit from digital twins in healthcare by enhancing performance monitoring, improving collaboration among battery state estimation techniques, and enabling optimal operation of battery storage units. Virtual testing also leads to significant cost and time savings. For example:

-

Digital twin technology can reduce electric powertrain development time, cost, and risk by enabling up-front design analysis.

-

Integrating digital twins in healthcare can lead to cost savings of up to 80% and improve development efficiency by 25%.

-

Virtual testing helps reduce costs by 15% compared to traditional methods and shortens time to market.

4.2 Simulation and Analysis

Simulation and analysis play a crucial role in digital twins in healthcare, especially for lithium battery packs. Real-time sensor data integration ensures accurate monitoring and predictive maintenance. The process involves several steps:

-

Sensors collect parameters such as temperature, voltage, and current.

-

The simulation engine aligns with experimental behaviors and generates synthetic datasets.

-

Calibrated simulations synchronize operating profiles, ambient conditions, and aging states.

-

The model outputs time series data, enhancing health indicators and reliability.

-

Real-time calibration against experimental measurements ensures data accuracy.

Multiphysics analysis further strengthens digital twins in healthcare. This technique integrates heat, stress, and flow modeling, allowing engineers to predict both normal and runaway scenarios. The digital twin connects processes from materials development to design validation, streamlining battery development for medical devices.

Note: Real-time sensor data and advanced simulation techniques help manufacturers identify potential issues early, optimize battery design, and ensure compliance with strict safety standards.

Part 5: Digital Twins in Healthcare Applications

5.1 Case Studies

Digital twin batteries have improved safety and intelligence in several healthcare settings. Hospitals use digital twins to monitor LiFePO4 battery packs in surgical robots. These systems predict battery failures before they affect patient care. For example, the Mayo Clinic partnered with Siemens Healthineers to implement digital twin technology for imaging devices. The project reduced downtime and improved maintenance scheduling.

In another case, a European hospital used NMC battery packs with digital twins in portable monitors. The system tracked energy density and cycle life, ensuring reliable operation during emergencies. Robotics companies also use digital twins to simulate battery performance in LCO-powered surgical tools, reducing the risk of unexpected shutdowns.

|

Sector |

Battery Chemistry |

Application |

Key Benefit |

|---|---|---|---|

|

Medical |

LiFePO4 |

Surgical robots |

Predictive maintenance |

|

Medical |

NMC |

Portable monitors |

Reliable emergency response |

|

Robotics |

LCO |

Surgical tools |

Reduced failure risk |

|

Infrastructure |

LTO |

Backup systems |

Extended cycle life |

Note: Digital twins also support sustainability by optimizing battery usage and reducing waste. For more on sustainability, visit Sustainability in Battery Supply Chains.

5.2 Implementation Tips

Healthcare organizations face challenges when adopting digital twin batteries. Data integration, cybersecurity, and regulatory compliance require careful planning. Teams should start with a pilot project using a single device type, such as infusion pumps with LCO batteries. They should collect sensor data on temperature, voltage, and state-of-charge.

Best practices include:

-

Collaborate with battery and software experts.

-

Use standardized battery chemistries and data formats.

-

Integrate real-time monitoring with existing IoT platforms.

-

Train staff on digital twin analytics and maintenance procedures.

-

Review regulatory guidelines for medical device batteries.

Tip: Partnering with established technology providers can speed up deployment and ensure compliance. For further guidance, see FDA Medical Device Cybersecurity.

Healthcare providers who follow these steps can improve device reliability, reduce costs, and enhance patient safety. Digital twin batteries offer a scalable solution for smarter, safer medical devices across the industry.

Digital twin batteries drive safer and smarter medical devices by enabling real-time monitoring and predictive maintenance. Manufacturers and healthcare providers benefit from improved reliability, faster development, and better patient outcomes.

-

Digital twins replicate real-world conditions using real-time data, enhancing treatment simulations and disease predictions.

-

In cardiovascular surgeries, digital twins have reduced postoperative complications by 15%. Continuous monitoring of chronic diseases improves glycemic control and reduces hospitalizations.

|

Consideration |

Description |

|---|---|

|

Real-time data |

Enables continuous monitoring and analysis of product performance throughout its lifecycle. |

|

AI integration |

Enhances decision-making and predictive capabilities in product development. |

|

Risk management |

Allows for early identification of potential issues, reducing costly mistakes. |

|

Regulatory compliance |

Ensures products meet industry standards before market release. |

B2B stakeholders should evaluate digital twin technology to future-proof lithium battery packs in medical devices. Organizations can start with pilot projects, integrate real-time data, and prioritize regulatory compliance for successful adoption.

FAQ

What is a digital twin battery in medical devices?

A digital twin battery is a virtual model that mirrors a physical lithium battery pack. It tracks real-time data, predicts performance, and supports safety in medical devices using chemistries like LiFePO4, NMC, and LCO.

How does digital twin technology improve battery safety?

Digital twin technology enables real-time monitoring and predictive analytics. It detects risks such as thermal runaway, leaks, and degradation in lithium battery packs, helping manufacturers prevent failures in medical and industrial applications.

Which battery chemistries benefit most from digital twins?

LiFePO4, NMC, LCO, LTO, solid-state, and lithium metal chemistries gain significant advantages. Digital twins optimize platform voltage, energy density, and cycle life for each chemistry in medical, robotics, and infrastructure sectors.

Can digital twins reduce device downtime?

Digital twins predict maintenance needs and identify faults early. Hospitals and manufacturers schedule repairs before failures occur, minimizing downtime for devices powered by lithium battery packs.

What challenges exist when implementing digital twin batteries?

Organizations face data integration, cybersecurity, and regulatory compliance issues. Teams must standardize battery chemistries, train staff, and collaborate with experts to ensure successful deployment in medical and industrial environments.