You see digital twin batteries, especially advanced lithium-ion types like LiFePO4 and NMC, driving the Future of Robotics in inspection and patrol robots. These systems use simulation, real-time information, and predictive maintenance to deliver better uptime and lower costs.

IoT sensors gather data to detect potential failures before they happen.

Predictive maintenance boosts uptime by up to 20% and cuts costs by 10%.

AI and VR help you visualize battery health, making your robots more reliable and efficient.

Key Takeaways

Choose advanced lithium-ion battery chemistries like LiFePO4 and NMC to enhance robot reliability and reduce downtime.

Implement real-time monitoring systems to track battery health and prevent overheating, ensuring safe robot operations.

Utilize predictive maintenance strategies to increase robot uptime by up to 20% and lower maintenance costs by 10%.

Leverage digital twin technology for real-time insights into battery performance, optimizing maintenance schedules and extending battery life.

Integrate IoT connectivity to automate monitoring and improve the efficiency of robot operations across various environments.

Part1: Impact on Robot Performance

1.1 Reliability

You rely on inspection and patrol robots to deliver consistent results in demanding environments. The reliability of these robots depends on the performance of their lithium-ion battery packs. When you choose advanced chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, or lithium metal, you gain advantages in platform voltage, energy density, and cycle life. These factors directly affect how long your robot can operate and how often you need to replace battery packs.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-500 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

You see robots using ROS for navigation and mapping in factories, warehouses, and outdoor sites. These robots depend on reliable battery packs to power lidar, sensor arrays, and onboard computing. When you deploy robots with robust lithium-ion batteries, you reduce downtime and improve operational efficiency. You also minimize the risk of unexpected failures during critical patrol or inspection missions.

Tip: Choose battery chemistries with higher cycle life for robots that require frequent charging and discharging. This strategy helps you extend the lifespan of your fleet and lower maintenance costs.

1.2 Real-Time Monitoring

You monitor your robot fleets in real time using advanced sensor networks and ROS-based platforms. Real-time monitoring lets you track key battery parameters such as State of Charge (SOC) and temperature. You prevent overheating and overcharging by continuously analyzing sensor data. This approach keeps your robots safe during charging and discharging cycles.

You use lidar and sensor fusion to enhance robot navigation and mapping accuracy.

You process sensor data to optimize battery performance and extend robot uptime.

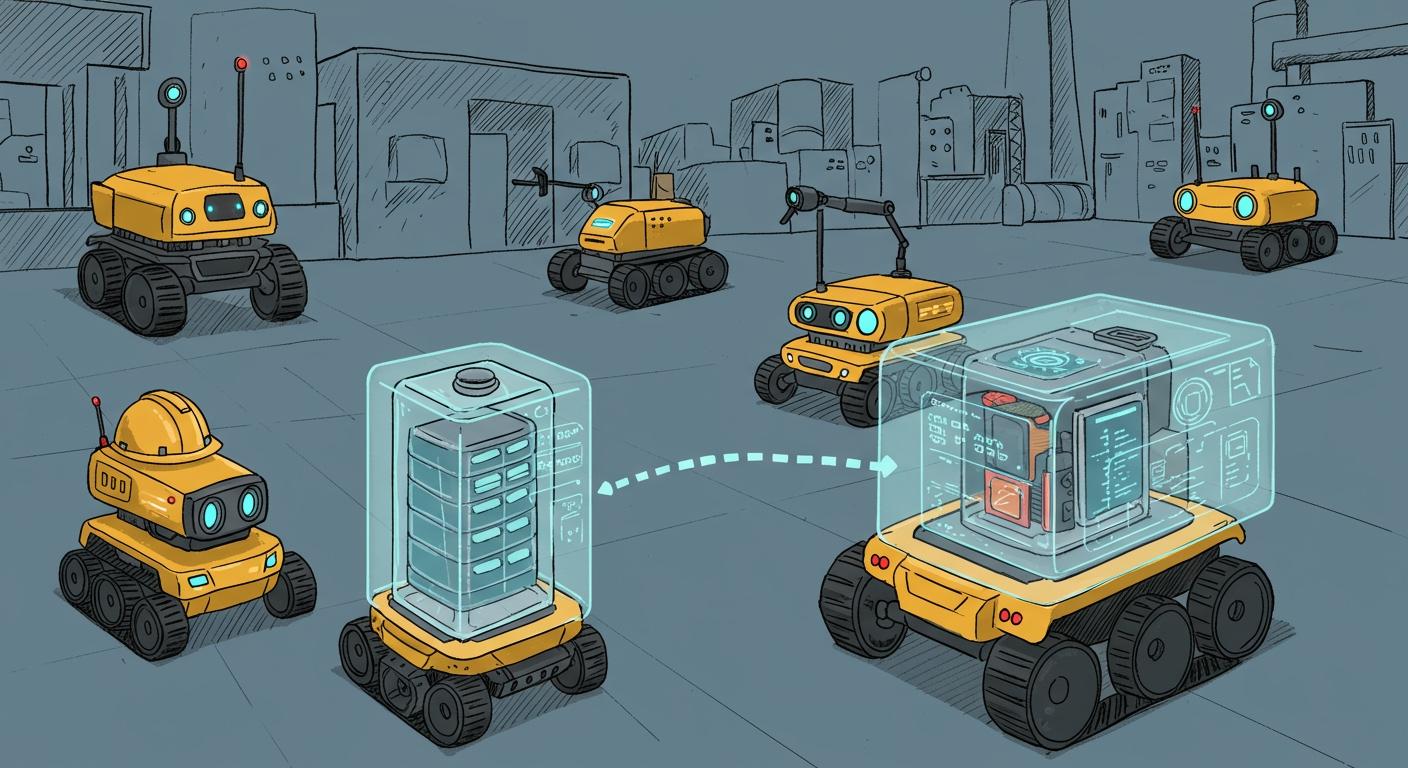

You rely on digital twinning of robots to visualize battery health and predict failures before they occur.

When you integrate real-time health monitoring systems, you ensure that your robots operate safely in harsh environments. You can quickly respond to abnormal temperature readings or voltage drops. This proactive approach protects your investment in lithium battery packs and keeps your robots running smoothly.

1.3 Predictive Maintenance

You use predictive maintenance to maximize the performance and lifespan of your robots. By analyzing data from ROS, lidar, and sensor arrays, you identify patterns that signal potential battery issues. You schedule maintenance before failures occur, reducing unplanned downtime and repair costs.

You leverage AI algorithms to forecast battery degradation and optimize replacement schedules.

You use mapping data to correlate battery health with robot navigation routes and operational stress.

You deploy robots with digital twin models to simulate battery aging and predict maintenance needs.

Predictive maintenance helps you maintain high reliability across your robot fleet. You avoid costly interruptions in inspection and patrol operations. You also improve safety by addressing battery risks before they impact robot performance.

Note: Predictive maintenance can increase robot uptime by up to 20% and reduce maintenance costs by 10%. You gain a competitive edge by keeping your robots available for critical tasks.

Part2: Digital Twin Technology Overview

2.1 Definition

You use digital twin technology to create a virtual copy of your robot and its lithium-ion battery system. This technology gives you a real-time, digital representation of your robot’s physical state. You combine AI, machine learning, and IoT to build these digital twins. With this approach, you can see how your robot, lidar, and sensor systems perform during inspection, patrol, and 3d mapping tasks. You rely on digital twins to monitor battery health, predict failures, and optimize robot performance. In battery management, you use advanced multi-layer models and AI to mirror the actual battery system. This method improves safety, performance, and cost-effectiveness for your robot fleet.

2.2 Lithium-Ion Battery Role

You model lithium-ion batteries in your digital twin platform using both physics-based and machine learning methods. This lets you track how your robot’s battery behaves during real-world operations. You simulate battery operation to help with material selection, cell sizing, and lifecycle management. You use AI algorithms to predict battery reliability and aging. Your digital twin combines data from lidar, sensor arrays, and ROS to give you a complete view of battery health. This approach supports smarter control strategies and reduces risks in robot design and deployment.

Aspect | Description |

|---|---|

Modeling Approach | Integration of physics-based models and machine learning algorithms for real-time monitoring and control. |

Benefits | Enables smarter controlling strategies, reduces risks and expenses in design and development. |

Challenges | High accuracy of physics-based models increases computational cost, limiting real-time application. |

Hybrid Models | Combining physics-based and machine learning models for improved accuracy and computational efficiency. |

Applications | Relevant for battery design, development, and real-time monitoring in robotics and electric vehicles. |

Tip: Use hybrid models to balance accuracy and speed when monitoring lithium-ion batteries in your robots.

2.3 Key Features

You gain several benefits when you use digital twin technology for battery management in robots. Real-time data integration gives you continuous updates on battery performance. Predictive maintenance helps you schedule service before failures occur, reducing downtime. You optimize battery performance based on current conditions, navigation routes, and mapping data. Enhanced safety features let you spot issues early, protecting your robot and its lithium battery pack. Adaptive temperature control keeps your battery at peak performance, even during demanding lidar and ROS operations. Accurate predictions of state of charge and health help you extend battery life and improve reliability.

Key Feature | Benefit |

|---|---|

Real-time data integration | Provides continuous performance data for better decision-making. |

Predictive maintenance | Enables forecasting of maintenance needs, reducing downtime and extending battery life. |

Improved performance optimization | Optimizes battery performance based on current conditions and usage patterns. |

Enhanced safety measures | Identifies potential issues, improving overall battery safety and reliability. |

Adaptive control of battery temperature | Maintains optimal performance and prevents overheating. |

Accurate prediction of state of charge/health | Critical for battery life and safety, enhancing overall management. |

Note: You can use digital twins to improve every aspect of your robot’s battery management, from lidar-based inspection to ROS-driven patrol and mapping.

Part3: Integration in Inspection and Patrol Robots

3.1 Software Systems

You use advanced software platforms to integrate digital twin batteries into your robot fleets. These platforms connect with ROS, lidar, and sensor arrays to deliver real-time monitoring and predictive maintenance. You rely on digital twin technology to create virtual models of your lithium battery packs. This approach helps you track State of Charge (SoC) and State of Health (SoH) for each robot. You optimize battery performance and extend cycle life by analyzing data from navigation, mapping, and surveillance missions.

You benefit from AI enhancements in software systems. AI algorithms process data from lidar and sensor networks to improve robot localization and object detection. You use these insights to refine path planning and mapping accuracy. VR tools let you visualize battery health and robot status in immersive environments. You see the impact of battery degradation on robot performance before failures occur.

You manage geofenced robots with software that supports remote monitoring and control. You set boundaries for patrol and inspection tasks. You monitor battery status and robot location in real time. You use software platforms to automate maintenance schedules and reduce downtime.

Aspect | Description |

|---|---|

Digital Twin Technology | Creates digital replicas of physical systems to enhance lifecycle management. |

Application in EVs | Improves design, construction, and operation of Electric Vehicles and robots. |

Importance of Data Analytics | Accelerates the adoption of Digital Twins for efficient system design and operation. |

Battery Management | Enables comprehensive digital lifecycle analysis for optimal SoC and SoH assessments. |

Tip: You can use software platforms to integrate AI and VR tools for advanced visualization and control of your robot fleets.

3.2 Hardware Aspects

You select hardware that supports digital twin integration for inspection and patrol robots. You choose lithium battery packs with chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. You match battery specifications to robot requirements for platform voltage, energy density, and cycle life. You install sensor arrays to collect data on battery temperature, voltage, and current. You connect these sensors to ROS-based controllers for real-time monitoring.

You equip robots with lidar systems to enhance navigation and mapping. You use hardware modules for path planning and robot localization. You deploy geofenced robots with hardware that supports surveillance and patrol in restricted areas. You integrate battery management systems (BMS) to protect lithium battery packs and optimize charging cycles.

You design hardware to support remote monitoring and predictive maintenance. You use modular battery packs for quick replacement during patrol and inspection missions. You select robust connectors and wiring to ensure reliable data transmission between sensors, lidar, and controllers.

Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-500 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

Note: You should match battery chemistry to robot mission profiles for optimal performance and reliability.

3.3 IoT Connectivity

You connect inspection and patrol robots to IoT networks for seamless data exchange. You use IoT sensors to monitor battery health, robot location, and environmental conditions. You transmit data from lidar, ROS, and sensor arrays to cloud platforms for analysis. You enable remote monitoring of geofenced robots during surveillance and patrol operations.

You use IoT connectivity to automate path planning and mapping updates. You receive alerts when battery levels drop or when maintenance is required. You track robot localization and object detection in real time. You integrate IoT modules with digital twin platforms to support predictive maintenance and reduce downtime.

You deploy robots in industrial environments with secure IoT connections. You protect data from unauthorized access and ensure reliable communication between robots and control centers. You use IoT networks to coordinate fleets of geofenced robots for large-scale surveillance and inspection tasks.

You monitor battery status and robot performance from any location.

You automate maintenance and optimize patrol routes using real-time data.

You improve safety and efficiency by integrating IoT with digital twin technology.

Tip: You can use IoT connectivity to scale your robot operations and enhance battery management across multiple sites.

Part4: Applications and Benefits

4.1 Industrial Inspection

You deploy robot fleets for industrial inspection in factories, power plants, and infrastructure sites. These robots use lithium battery packs such as LiFePO4, NMC, and LTO to support long missions. You rely on lidar and ros to guide each robot through complex environments. The sensor arrays on each robot collect data on equipment status and environmental conditions. You use digital twin technology to monitor battery health and schedule maintenance. This approach reduces downtime and improves safety for your operations.

4.2 Security Patrol

You use robot patrol units to secure warehouses, airports, and critical infrastructure. Each robot uses lidar and ros for navigation and mapping. The lithium battery packs, including solid-state and lithium metal chemistries, provide high energy density and long cycle life. You monitor each robot’s battery status in real time using sensor data. You can schedule patrols based on battery state of charge and health. This method ensures that your robot fleet remains active and reliable during security operations.

Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-500 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

Tip: Choose lithium battery chemistries with higher cycle life for robots that require frequent charging during continuous patrols.

4.3 Battery Management

You manage robot fleets using advanced battery management systems. You use ros and sensor data to track battery temperature, voltage, and current. Digital twin technology lets you predict battery aging and optimize replacement schedules. You can compare battery performance across different chemistries and select the best option for each robot mission. This process helps you reduce costs and extend the lifespan of your lithium battery packs.

4.4 Efficiency Gains

You achieve efficiency gains by integrating digital twin batteries with robot fleets. You use lidar and ros to optimize navigation and reduce energy consumption. Real-time sensor data helps you adjust robot routes and avoid unnecessary stops. You can automate maintenance and battery replacement, which increases uptime. You see these benefits in medical robots, security systems, industrial inspection, and infrastructure monitoring. Your organization gains a competitive edge by using advanced battery technology and digital twin solutions.

Note: Efficient battery management supports sustainability goals and reduces operational costs. Learn more about sustainability here.

Part5: Challenges

5.1 Data Security

You face new data security risks as you adopt digital twin batteries in your robot fleets. The future of robotics depends on secure data exchange between physical robots and their digital twins. You see more entry points for cyberattacks because robots constantly share information about lithium battery packs, lidar readings, and autonomous operations. Sensitive data, such as battery health and patrol routes, can attract identity theft or espionage. Third-party access to your digital twin platforms may allow unauthorized manipulation of battery data.

Increased entry points for cyberattacks due to constant data exchange between physical and digital twins

Exposure of sensitive data, making digital twins attractive targets for identity theft and espionage

Vulnerabilities related to third-party access, which can lead to unauthorized manipulation of data

You must protect your robot fleets with strong encryption and access controls. You should train your team to recognize threats and respond quickly. You improve the future of robotics by building secure systems for autonomous inspection and patrol.

5.2 Integration Complexity

You encounter integration challenges when you connect digital twin platforms to your robot hardware and software. Each robot uses different lithium battery chemistries, such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, or lithium metal. You must match battery specifications for platform voltage, energy density, and cycle life to each robot’s mission profile. You integrate lidar sensors, autonomous navigation modules, and automation software. You need to ensure that all systems communicate smoothly.

Tip: Use standardized protocols for battery management and lidar data to reduce integration errors.

You may need to customize automation workflows for each robot type. You should test all connections before deploying robots in industrial environments. You improve reliability and efficiency by solving integration complexity.

5.3 Scalability

You scale your robot fleets by using digital twin battery solutions. The future of robotics requires centralized management and automation for large numbers of autonomous robots. You monitor lithium battery packs, lidar sensors, and robot status from a single dashboard. You set up autonomous inspections and predictive maintenance programs. You create digital twins for facilities to improve operational efficiency.

Feature | Description |

|---|---|

Fleet Management | Software enables management of both single and multiple Spot robots from a distance. |

Data Accessibility | Centralized data access for monitoring and inspections of the fleet. |

Autonomous Inspections | Capability to set up robots for autonomous inspections, enhancing predictive maintenance programs. |

Digital Twin Integration | Supports the creation of digital twins for facilities, improving operational efficiency. |

You must plan for future growth as you add more robots and battery types. You should choose scalable software and hardware that support automation and autonomous patrol. You strengthen your business by preparing for the future of robotics.

Part6: Future of Robotics

6.1 AI Innovations

You see AI transforming how you manage robot fleets. AI-driven optimization lets you predict battery health and schedule maintenance before failures happen. You use machine learning to analyze data from lidar and robot operating system platforms. This helps you improve navigation and mapping accuracy. You visualize battery status with VR tools, making it easier to spot issues in real time. You collaborate with industry partners to develop smarter algorithms for lithium battery packs. These partnerships help you create robots that adapt to changing environments and mission profiles.

Program/Collaboration | Description |

|---|---|

IMEC-VUB-Brubotics | Develops intelligent solutions to monitor and predict robot battery behavior using digital twins. |

Dynamic Time Petri Net Study | Models structured disassembly procedures for EOL battery processes, addressing uncertainties and dynamics. |

Tip: You can use AI to optimize battery performance and extend the lifespan of your robot fleet.

6.2 Autonomous Robots

You deploy autonomous robots for inspection and patrol in complex environments. These robots use lidar and robot operating system software to navigate factories, warehouses, and outdoor sites. You rely on lithium battery packs with chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. You select batteries based on platform voltage, energy density, and cycle life to match each robot’s mission. You monitor battery health and robot location using real-time data from sensors and lidar. You automate patrol routes and inspection tasks, reducing manual intervention.

You use robots in logistics, including Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

You deploy robots in retail for delivery and inventory management.

You send robots outdoors for inspection of infrastructure and utilities.

Note: Autonomous robots improve safety and efficiency by reducing human exposure to hazardous environments.

6.3 Next-Gen Batteries

You invest in next-generation lithium-ion batteries to power your robot fleets. You choose chemistries that offer higher energy density and longer cycle life. You use solid-state and lithium metal batteries for advanced robots that need extended uptime. You track battery performance with digital twin models and robot operating system data. You compare battery options using standardized metrics:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-500 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

You see these batteries used in robots for logistics, retail, and outdoor inspection. You benefit from longer missions, reduced downtime, and lower maintenance costs. You prepare your organization for future growth by adopting advanced battery technologies and digital twin solutions.

Digital twin batteries are changing how you manage inspection and patrol robots. You gain real-time insights, predictive maintenance, and better safety. Many organizations use this technology to improve battery management across industries:

Application Area | Key Benefits |

|---|---|

Electric Vehicles (EVs) | Optimizes battery performance, extends lifespan, enhances safety, improves reliability |

Industrial Equipment | Improves efficiency and reliability of battery usage in industrial applications |

Energy Storage Systems | Manages large-scale installations, optimizes grid operations, predicts battery degradation |

Consumer Electronics | Enhances battery management for devices, ensuring longevity and performance |

You can lead your industry by adopting digital twin batteries and driving innovation in lithium battery management.

FAQ

What are the main benefits of digital twin batteries for inspection and patrol robots?

You gain real-time battery monitoring, predictive maintenance, and improved safety. Digital twins help you reduce downtime and extend the lifespan of lithium battery packs.

Tip: Use digital twins to optimize battery performance for every mission.

How do different lithium battery chemistries compare for robot fleets?

You can compare key chemistries using this table:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

3.2 | 90-160 | 2000-7000 | |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 250-500 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

How does predictive maintenance improve robot operations?

You use predictive maintenance to schedule service before failures occur. This approach increases uptime and lowers costs.

Predictive maintenance can boost robot availability by up to 20%.

What role does IoT play in digital twin battery management?

You use IoT sensors to collect and transmit battery data. This enables remote monitoring, automated alerts, and real-time updates for your robot fleet.

IoT helps you scale operations and improve battery safety.

How do you ensure data security for digital twin batteries?

You protect your data with strong encryption and strict access controls. You train your team to recognize threats and respond quickly.

Note: Secure data exchange is critical for safe and reliable robot operations.