You see lightweight design trends changing how you use inspection devices in industrial settings. Energy density, cell design, and portability now shape how you select and use equipment. Manufacturers push for higher battery energy storage while reducing size and weight. This shift creates new challenges for balancing lightweight needs, energy output, and safety. Modern battery cells require strict quality checks because you work with compact, powerful solutions. The demand for portable platforms grows rapidly, showing how new materials, battery formats, and smart cell integration drive these trends.

Key Takeaways

Lightweight design improves the portability and efficiency of inspection devices, reducing fatigue and increasing productivity during long shifts.

Advanced materials like aluminum alloys and carbon fiber can reduce device weight by up to 75%, leading to lower transportation costs and improved handling.

Selecting the right battery chemistry is crucial; lithium-ion batteries offer high energy density and long cycle life, making them ideal for portable inspection devices.

Solid-state batteries provide higher energy density and safety, while lithium polymer batteries offer design flexibility; consider both when choosing a battery.

Stay informed about emerging battery technologies and sustainability practices to ensure your inspection devices remain competitive and environmentally friendly.

Part1: Lightweight Design Trends in Inspection Devices

1.1 Benefits of Lightweight Construction

You see lightweight design trends changing how you approach inspection devices. When you use lighter equipment, you can carry it longer and move it more easily in tight spaces. Lightweight design helps you reduce fatigue and increase productivity during long shifts. Many industries, such as robotics, security systems, and infrastructure inspection, now demand portable devices that do not sacrifice performance. These trends also help you lower transportation costs and improve device handling. As you adopt lightweight design, you notice that your devices become more efficient and easier to deploy in the field.

1.2 Material Innovations

You benefit from new materials that make inspection devices lighter without losing strength. Manufacturers now use advanced materials to achieve the right balance between weight and durability. The table below shows some of the most common materials and their properties:

Material Type | Properties | Use Cases |

|---|---|---|

Aluminum Alloys | Lighter weight, good strength, corrosion resistance | Common in various designs |

Carbon Fiber | High strength-to-weight ratio, expensive | Popular in advanced applications |

Fiber-Reinforced Polymer | Lightweight, good performance, higher cost | Structural components |

Magnesium Alloys | Excellent lightweight properties | Aerospace applications |

Plastics | Affordable, versatile, easy to manufacture | Insulation, packaging, structural |

You see that using these materials can reduce the weight of your devices by up to 75%. Research shows that a 10% reduction in mass can lower fuel consumption by 5-7%. Lightweight materials also help you cut greenhouse gas emissions and replace heavier metals like steel.

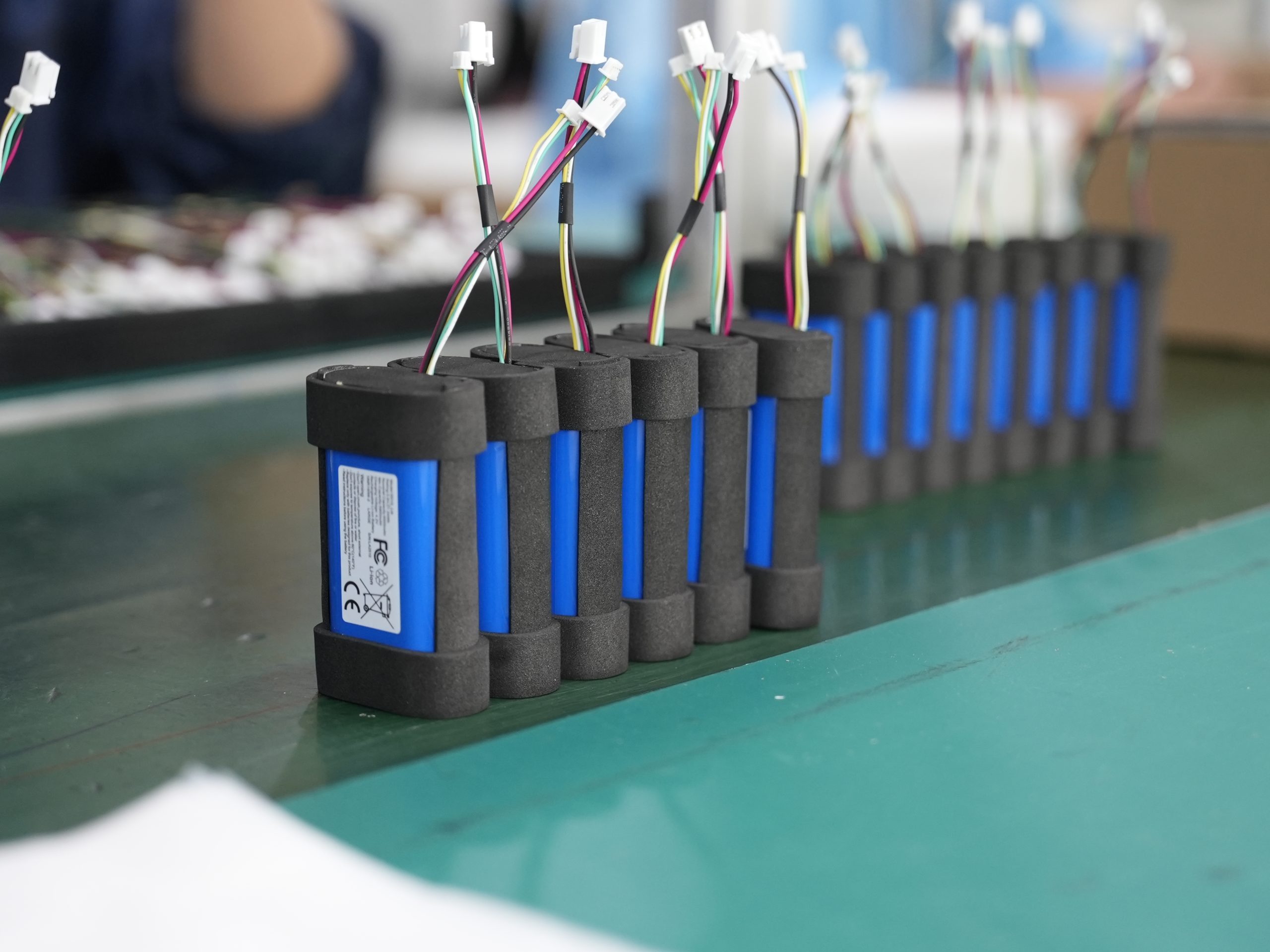

1.3 Battery Pack Integration

You rely on smart battery pack integration to keep your inspection devices light and powerful. Modern assembly uses machine vision systems to guide robots, ensuring each cell is placed correctly. Technologies like X-ray and CT scans let you inspect battery packs without taking them apart. These methods help you spot defects early and keep the packs safe. Structured light imaging and diffuse lighting improve how you see cell positions, making assembly more accurate. When you use advanced integration strategies, you reduce the overall weight of your battery packs. Companies now work together to design lighter packs, which makes your devices easier to carry and use in the field.

Part2: Energy Density and Battery Technology Advances

2.1 Gravimetric Energy Density in Device Design

You rely on energy density to determine how long your inspection device can operate before you need to recharge or replace the battery. Energy density measures how much energy a cell stores for its weight. This metric is critical for portable inspection devices in medical, robotics, security systems, infrastructure, and industrial sectors. You see trends in battery chemistry driving improvements in energy density, which directly impacts device design and performance.

From 2010 to 2021, you notice a steady increase in gravimetric energy density across lithium-ion batteries. Manufacturers focus on optimizing cell design to deliver more energy in smaller, lighter packages. The table below shows the gravimetric energy density values for common lithium-ion battery chemistries used in inspection devices:

Battery Chemistry | Platform Voltage (V) | Gravimetric Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

Lithium Cobalt Oxide (LiCoO2) | 3.7 | 150-200 | 500-1000 |

Lithium Iron Phosphate (LiFePO4) | 3.2 | 90-120 | 2000+ |

Lithium Nickel Manganese Cobalt (NMC) | 3.7 | 200-250 | 1000-2000 |

Lithium Polymer | 3.7 | 150-200 | 500-1000 |

You use lithium-ion batteries in medical imaging devices, robotic arms, and portable security scanners. These applications demand high energy density and long cycle life. You select the battery chemistry based on your device’s weight, runtime, and safety requirements. You see that lithium-ion battery packs offer the best balance for most inspection devices.

2.2 Higher Energy Density: Solid-State and Lithium Polymer

You look for higher energy density to extend device runtime and reduce weight. Solid-state batteries and lithium polymer batteries represent the latest advances in cell design. You see solid-state batteries reaching energy densities between 300 and 500 Wh/kg. These batteries use solid electrolytes, which improve safety by eliminating flammable liquids. You avoid risks of thermal runaway, making solid-state batteries suitable for critical inspection devices in medical and infrastructure sectors.

Lithium polymer batteries give you flexibility in design. You shape the battery pack to fit compact devices, such as handheld scanners and consumer electronics. You benefit from energy densities up to 250 Wh/kg. You find lithium polymer batteries cost-effective, but you must manage safety risks. These batteries can experience thermal runaway if damaged or improperly charged.

Tip: When you select a battery for your inspection device, consider both energy density and safety. Solid-state batteries offer higher energy density and improved safety, while lithium polymer batteries provide design flexibility and cost savings.

Advantages of Solid-State and Lithium Polymer Batteries:

Solid-state batteries deliver higher energy density and improved safety for inspection devices in medical, robotics, and infrastructure sectors.

Lithium polymer batteries offer flexible design and cost-effectiveness for portable devices in consumer electronics and security systems.

2.3 Lithium-Sulfur and Emerging Alternatives

You explore lithium-sulfur batteries for high-energy density applications. These batteries promise theoretical energy densities between 2500 and 2600 Wh/kg. You see potential for lightweight inspection devices in aerospace and advanced robotics. However, you face challenges with cycle life and rate capability. Lithium-sulfur batteries typically last only 100 to 200 cycles, and their performance drops at low temperatures.

Metric | Lithium-Sulfur Batteries | Lithium-Ion Batteries |

|---|---|---|

Theoretical Energy Density (Wh/kg) | 2500-2600 | 387 |

Capacity (mAh/g) | Up to 1675 | 150-200 |

Cycle Life | 100-200 cycles | 1000+ cycles |

Rate Capability | Poor | Superior |

Temperature Range | Poor low-temperature performance | -20°C to 60°C with reduced performance |

You use lithium-ion batteries for most inspection devices because they offer superior cycle life and rate capability. You see lithium-sulfur batteries as promising for future lightweight designs, but you must address their limitations before widespread adoption.

You also consider emerging alternatives for high energy density. Vanadium Redox Flow Batteries (VRFBs) provide non-flammable characteristics and thermal stability, which you value for safety in industrial inspection devices. Sodium-ion batteries offer a cost-effective and abundant solution, especially for large-scale infrastructure and automotive battery applications.

Vanadium Redox Flow Batteries give you thermal stability and safety for industrial inspection devices.

Sodium-ion batteries provide a cost-effective option for high energy density in automotive battery and infrastructure sectors.

You stay informed about trends in battery chemistry and cell design. You evaluate new technologies for your inspection devices, balancing energy density, safety, and cost. You see that lithium-ion batteries remain the standard for most applications, but you monitor advances in solid-state, lithium polymer, lithium-sulfur, and emerging alternatives to meet future demands.

Part3: Cell Design and Custom Battery Packs

3.1 Self-Standing Electrodes and Cost Reduction

You see cell design innovations transforming how you approach lithium-ion batteries for inspection devices. Self-standing electrodes eliminate the need for metal current collectors, additives, and binders. This change helps you reduce manufacturing costs and increase energy density. You benefit from up to 40% higher energy density compared to conventional electrodes. The table below shows how self-standing electrodes impact battery cell design:

Feature | Description |

|---|---|

Energy Density Improvement | Up to 40% higher compared to conventional electrodes |

Components Eliminated | Metal current collectors, additives, and binders |

You use these advanced cell designs to boost the performance and capacity of lithium-ion batteries in medical imaging, robotics, and industrial inspection devices. Higher energy density means you can design lighter packs with longer runtime, which is critical for portable equipment.

3.2 Custom Battery Pack Trends

You notice custom battery pack designs evolving to meet the specific needs of inspection devices. Manufacturers now focus on improving energy density, reducing weight, and enhancing performance. Key trends include:

Silicon anodes boost lithium-ion performance and reduce weight. By replacing graphite with silicon, you achieve up to 40% higher energy density, which is valuable for electric vehicles and portable inspection devices.

Alternative chemistries such as sodium-ion, LiFePO4, and nickel-zinc batteries help you address supply chain challenges and rising costs.

Solid state batteries and composite enclosures shape next-generation packs. You gain higher safety, energy density, and reduced thermal risk, especially in demanding industrial and medical applications.

Hybrid battery packs combine different chemistries for dynamic power delivery. You benefit from both high-power and long-duration energy delivery, which is useful for microgrids and automotive battery systems.

New federal testing standards require you to stay updated on procedures for wireless chargers and maintenance mode power capture. Compliance ensures your lithium-ion battery packs meet regulatory requirements.

You select custom battery pack designs based on your device’s energy needs, weight limits, and application scenario. You see these trends driving innovation in lithium-ion batteries for security systems, infrastructure inspection, and consumer electronics.

3.3 System Integration for Weight Reduction

You integrate advanced systems to reduce the weight of inspection devices. Automatic visual inspection systems record the geometry of cast components, helping you ensure completeness and reduce vehicle weight in the automotive sector. In pharmaceutical manufacturing, you use visual inspection systems with trajectory algorithms and line scan cameras to improve inspection speed and product integrity. You also rely on Ensenso 3D cameras to inspect die cast parts made of aluminum and magnesium alloys, which supports lightweight design in automotive battery packs.

You combine these system integration strategies with optimized lithium-ion battery cell design to achieve higher energy density and better performance. You see that integrating advanced inspection technologies allows you to design lighter, more efficient devices for medical, robotics, and industrial sectors.

Part4: Practical Battery Selection Guide

4.1 Assessing Device Requirements

You start by evaluating the specific needs of your inspection device. You consider the size, weight, and energy requirements for your application. You look at how long your device must operate before recharging. You check the available space for the battery pack and the total weight your device can support. You also review the power demands during peak operation.

You use a step-by-step approach to select the right battery:

Define Application Scenario

You identify whether your device operates in medical, robotics, security systems, infrastructure, consumer electronics, or industrial sectors. Each scenario has unique energy and safety needs.Calculate Energy Needs

You estimate the total energy your device requires. You multiply the operating voltage by the current and runtime to get the required capacity in watt-hours.Match Chemistry to Requirements

You compare lithium-ion battery chemistries. You select LiFePO4 for stability and long cycle life, NMC for higher energy density and lighter weight, and LCO for compact designs. You use the table below to compare options:Chemistry Type

Platform Voltage (V)

Energy Density (Wh/kg)

Cycle Life (cycles)

Weight per kWh (kg)

Characteristics

LiFePO4

3.2

100–160

2000+

Higher

Stable, long-lasting but heavier and lower energy density.

NMC

3.7

Up to 265

1000–2000

Lower

Lighter, higher energy density, ideal for portable applications.

LCO

3.7

150–200

500–1000

Moderate

Compact, suitable for consumer electronics.

Optimize Cell Design and Pack Configuration

You select the cell format and pack layout that best fits your device. You consider cylindrical, prismatic, or pouch cells. You use linear programming and energy storage system planning to optimize capacity and charging strategy.Method

Description

Linear Programming

Allocates resources to meet planning objectives and constraints, optimizing capacity and charging/discharging strategy to minimize costs or maximize performance.

Energy Storage System Planning

Involves selecting battery type, size, and configuration to meet power system needs and maximize reliability.

Review Weight and Portability

You ensure the battery pack does not exceed the device’s weight limit. You prioritize lightweight designs for handheld or mobile inspection devices.Validate Runtime and Performance

You test the battery pack to confirm it meets the expected runtime and energy output. You adjust cell design or pack configuration if needed.

Tip: You use battery management systems and test equipment to verify performance and safety before finalizing your selection.

4.2 Safety and Regulatory Factors

You prioritize safety and compliance when selecting batteries for inspection devices. You understand that battery failures can cause overheating or loss of critical functions, especially in medical and industrial applications. You follow strict regulatory standards to protect users and equipment.

You consider these safety and regulatory factors:

Patient safety is critical. Battery failures can lead to severe consequences such as loss of life support or overheating.

Compliance with regulatory bodies like the FDA, ISO, and IEC is essential for medical devices, including their battery systems.

Battery lifecycle, traceability, and maintenance are important as batteries degrade over time, affecting performance.

Interconnectivity and portability of battery packs can increase risks, especially when they power critical systems.

Adherence to standards such as FDA’s QSR, UL 2054, and IEC 60601 is necessary for ensuring safety and regulatory compliance.

Customized testing is necessary to ensure that batteries meet operational and safety requirements specific to medical devices.

Evaluating supplier reliability and quality control processes is vital to mitigate risks associated with battery failures.

Conducting charge/discharge studies helps validate battery performance and predict shelf life.

Assessing the supplier’s ability to deliver high-quality batteries consistently is crucial.

Auditing the supplier’s production facility can help ensure compliance with safety and quality standards.

Understanding the implications of manufacturing defects and environmental factors on battery performance is essential.

You use battery management systems to protect lithium-ion batteries from high temperatures, overcharging, and undercharging. You select enclosures such as shrink wrap or injection-molded plastic to protect the pack from physical damage and allow for heat dissipation. You rely on circuit protection devices like PPTC to safeguard circuits during transport.

4.3 Performance vs. Cost

You balance performance and cost when choosing batteries for inspection devices. You recognize that custom battery pack designs drive innovation but also increase costs. You see the projected growth of the custom battery pack market, which highlights economic trade-offs.

You consider these factors:

Industries like medical, aerospace, and military have stringent safety and performance requirements that can elevate costs.

Compliance with national or international standards can also influence the overall cost of battery packs.

Higher performance often requires the use of specialized components, which can lead to increased costs.

Conversely, opting for lower-grade components to reduce costs may negatively affect performance.

You select lithium-ion batteries for most inspection devices because they offer high energy density, long cycle life, and reliable performance. You use battery test equipment such as the DSF20 Charge-Discharge Tester to enhance testing accuracy and automation. You optimize cell design and pack configuration to achieve the best balance between energy output, weight, and cost.

Note: You always evaluate the total cost of ownership, including maintenance, replacement, and compliance costs, before finalizing your battery selection.

You follow trends in energy storage systems and cell design to stay competitive. You use advanced design tools and methods to optimize lithium-ion battery packs for your inspection devices in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors.

Part5: Sustainability and Compliance

5.1 Environmental Impact of Battery Choices

You make important decisions about sustainability when you select lithium battery packs for inspection devices. The materials in each cell affect the environment in different ways. You see that binders such as lithiated-nafion, PTFE, PVDF, PVP, PEO, and PE can increase environmental impact. Current collectors like carbon paper, nickel foam, aluminum, stainless steel, and copper also play a role. Electrolyte salts, including PVDF, LiTFSI, LiClO₄, LiPF₆, LiNO₃, Li, boric acid, TEOS, and PEO, contribute to the overall footprint. Solvents such as BMIM-C4mim, EMIM-BF4, TEGDME, DME, EC, PC, ACN, and DMSO add further complexity. Catalysts made from various metals often have high impacts in environmental categories.

Material Type | Environmental Impact Category |

|---|---|

Binders | lithiated-nafion, PTFE, PVDF, PVP, PEO, PE |

Current Collectors | carbon paper, nickel foam, aluminum, stainless steel, copper |

Electrolyte Salts | PVDF, LiTFSI, LiClO₄, LiPF₆, LiNO₃, Li, boric acid, TEOS, PEO |

Solvents | BMIM-C4mim, EMIM-BF4, TEGDME, DME, EC, PC, ACN, DMSO |

Catalysts | Various metals with high impacts |

You improve sustainability by choosing cell design strategies that reduce the use of high-impact materials. You also consider recycling and end-of-life management for each battery pack. When you select chemistries like LiFePO4, NMC, or LCO, you compare platform voltage, energy density, and cycle life to balance environmental impact with performance.

5.2 Safety Standards

You ensure safety by following strict standards when you design and select battery packs for inspection devices. You look for certifications that guarantee safe operation in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. UL certification means your battery has passed rigorous safety tests. CE marking shows compliance with European safety, health, and environmental protection requirements.

Certification | Description |

|---|---|

UL | Underwriters Laboratories, global safety certification for batteries and products |

CE | Conformité Européene, mandatory EU mark for safety, health, and environmental protection |

You use these certifications to confirm that your battery packs meet international safety standards. You protect users and equipment by choosing cells and chemistries that comply with these requirements.

Tip: Always verify that your battery packs carry UL and CE marks before deploying inspection devices in critical applications.

5.3 Regulatory Considerations

You address many regulatory requirements when you design battery systems for inspection devices. You follow standards for quality management, functional safety, electromagnetic compatibility, and cybersecurity. You see that IEC 60255 and IEC 61850 set requirements for measuring relays and communication networks. IEC 61000 ensures electromagnetic compatibility. ISO 9001 helps you maintain consistent quality. IEC 61508 provides guidelines for functional safety. IEEE C37 Series and ANSI/IEEE C37.90 cover power system protection and relay testing. ISO/IEC 27001 and IEC 62443 address information security and cybersecurity for industrial automation. NERC CIP Standards and UL 2900 Series focus on protecting critical cyber assets and evaluating cybersecurity. NIST Cybersecurity Framework, IEEE 1686, C2M2, and NIST SP 800-53 offer additional guidance for security and privacy controls.

Standard | Description |

|---|---|

IEC 60255 | Measuring relays and protection equipment requirements |

IEC 61850 | Communication networks for power utility automation |

IEC 61000 | Electromagnetic compatibility guidelines |

ISO 9001 | Quality management standard |

IEC 61508 | Functional safety guidelines |

IEEE C37 Series | Power system protection and relay testing |

ANSI/IEEE C37.90 | Relay system testing requirements |

ISO/IEC 27001 | Information security management system requirements |

IEC 62443 | Cybersecurity for industrial automation |

NERC CIP | Protection of critical cyber assets |

UL 2900 Series | Cybersecurity evaluation for network-connectable products |

NIST Framework | Cybersecurity risk management guidelines |

IEEE 1686 | Security for intelligent electronic devices |

C2M2 | Cybersecurity capability assessment model |

NIST SP 800-53 | Security and privacy controls for federal information systems |

You meet these standards to ensure your battery packs deliver reliable energy, high energy density, and safe cell design. You maintain compliance to protect your business and your customers.

Part6: Recommendations and Future Outlook

6.1 Design Strategies for Next-Gen Devices

You see next-generation inspection devices using advanced design strategies to improve accuracy and efficiency. Manufacturers now use systems like the SQ7000™+ Multi-Function system, which supports AOI, SPI, and CMM applications. The MRS® sensor delivers high accuracy, speed, and resolution. You can review the table below to compare technology benefits:

Technology | Application | Benefits |

|---|---|---|

SQ7000™+ Multi-Function | AOI, SPI, CMM | High accuracy, speed, resolution (MRS®) |

You reduce human risk by using robotics for inspections. Visual and ultrasound technology lets you inspect hazardous areas remotely. Automated inspection processes use deep learning to identify objects and filter out background data. You improve inspection accuracy and reduce manual errors.

6.2 Battery Selection Best Practices

You select lithium-ion battery packs for inspection devices in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. You focus on platform voltage, energy density, and cycle life for each chemistry. You choose LiFePO4 for stability and long cycle life, NMC for high energy density and lighter weight, and LCO for compact designs. You match battery chemistry to your device’s energy needs and weight limits.

You follow these best practices:

Assess device requirements for size, weight, and energy.

Compare lithium-ion chemistries using platform voltage, energy density, and cycle life data.

Optimize cell design and pack configuration for maximum energy output and portability.

Validate battery performance with test equipment and battery management systems.

Ensure compliance with safety and regulatory standards.

Tip: You always confirm that your lithium-ion battery packs meet UL and CE certification before deployment.

6.3 Future Trends in Lightweight and Energy Dense Solutions

You see future inspection devices using lighter materials and higher energy density lithium-ion batteries. Manufacturers develop self-standing electrodes and silicon anodes to boost energy density and reduce weight. Solid-state batteries and lithium-sulfur batteries promise even greater energy storage, though you must address cycle life and safety challenges.

You expect more devices to use automated inspection systems and deep learning for improved accuracy. Robotics and remote sensing will reduce human risk in hazardous environments. You monitor advances in lithium-ion chemistry, such as NMC and LiFePO4, to balance energy density, cycle life, and safety.

You prepare for new regulations and sustainability requirements. You choose battery packs with lower environmental impact and plan for recycling and end-of-life management. You stay informed about trends in energy storage and cell design to keep your inspection devices competitive.

You see lightweight design and lithium-ion cell selection transforming inspection device performance in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. You improve runtime and portability by choosing lithium-ion packs with optimal platform voltage, energy density, and cycle life.

You evaluate lithium-ion chemistry for each application.

You integrate lithium-ion cells to reduce device weight.

You validate lithium-ion safety and compliance.

You drive innovation by adopting lithium-ion technology and monitoring future trends in energy density and lightweight design.

FAQ

What makes lithium-ion battery packs ideal for inspection devices?

You choose lithium-ion battery packs because they offer high energy density, long cycle life, and low weight. These packs support portable inspection devices in medical, robotics, security systems, infrastructure and industrial sectors.

How do you select the right lithium-ion chemistry for your application?

You compare LiFePO4, NMC, and LCO chemistries. LiFePO4 provides stability and long cycle life. NMC offers higher energy density and lighter weight. LCO suits compact designs. You match platform voltage, energy density, and cycle life to your device’s needs.

What safety standards apply to lithium-ion battery packs in industrial inspection?

You follow UL and CE certifications for lithium-ion battery packs. These standards ensure safe operation in medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. You also check IEC and ISO guidelines for compliance.

How does lithium-ion battery integration affect device weight and portability?

You integrate lithium-ion cells using advanced materials and smart pack designs. This reduces device weight and improves portability. You see benefits in medical imaging, robotic arms, and portable scanners where lightweight design is critical.

What are the main challenges with lithium-ion battery packs in inspection devices?

You face challenges with thermal management, regulatory compliance, and cycle life. You must balance energy density, safety, and cost. You use battery management systems and regular testing to maintain performance in medical, robotics, and industrial inspection devices.