You see fewer service calls when you use Battery Data Analytics for patient monitors. Proactive maintenance extends battery life and lowers operational expenses. The shift to lithium-ion batteries and real-time data minimize downtime. Remote monitoring and predictive insights help you manage healthcare technology more efficiently.

Key Takeaways

Battery Data Analytics helps reduce after-sales costs by predicting battery failures before they disrupt operations.

Switching to lithium-ion batteries lowers service calls and extends battery life, improving overall efficiency.

Implementing predictive maintenance strategies allows for timely interventions, minimizing downtime and optimizing resource allocation.

Part 1: Battery Performance and Cost Drivers

1.1 Battery Issues in Patient Monitors

You face significant after-sales costs when battery failures occur in patient monitors. Premature battery failure creates operational inefficiencies, costing organizations over $75 million each year. These costs include direct battery replacements and indirect expenses, such as lost productivity and labor for troubleshooting.

Neglecting battery health can lead to unexpected monitor shutdowns. This causes unplanned downtime and increases maintenance costs. Equipment failure delays admissions and results in lost revenue. Preventive maintenance helps you address minor issues before they become expensive repairs.

You see three main cost drivers:

Unplanned downtime from battery failures leads to immediate replacement costs.

Indirect costs arise from lost productivity and troubleshooting labor.

Overall maintenance expenses rise when you neglect battery health.

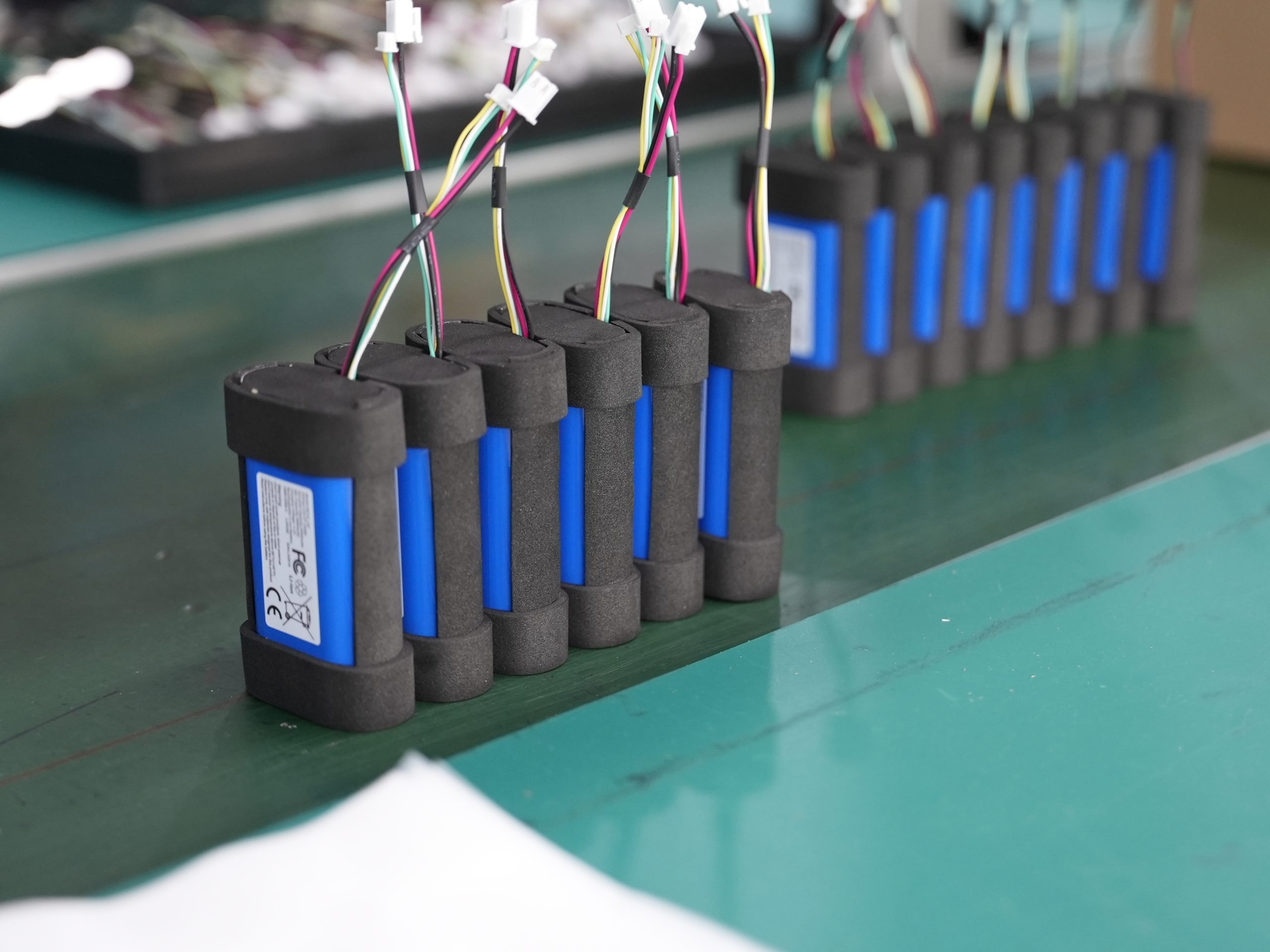

1.2 Lithium-Ion Transition and Service Call Reduction

The transition from lead-acid and nickel-metal hydride batteries to lithium-ion batteries has changed the landscape for patient monitor maintenance. Lithium-ion batteries offer longer lifespans and more charge cycles, which reduces the frequency of service calls.

Battery Type | Average Lifespan | Charge Cycles |

|---|---|---|

Lithium-ion (Li-ion) | 2–5 years | 300–2,000 |

Nickel-Metal Hydride | 1–3 years | 200–400 |

Lead-Acid | 3–5 years | N/A |

You benefit from fewer interruptions and lower replacement rates when you use lithium-ion batteries. Battery Data Analytics further supports this transition by helping you monitor battery health and predict failures before they disrupt operations.

Part 2: Battery Data Analytics for Cost Reduction

2.1 What Is Battery Data Analytics?

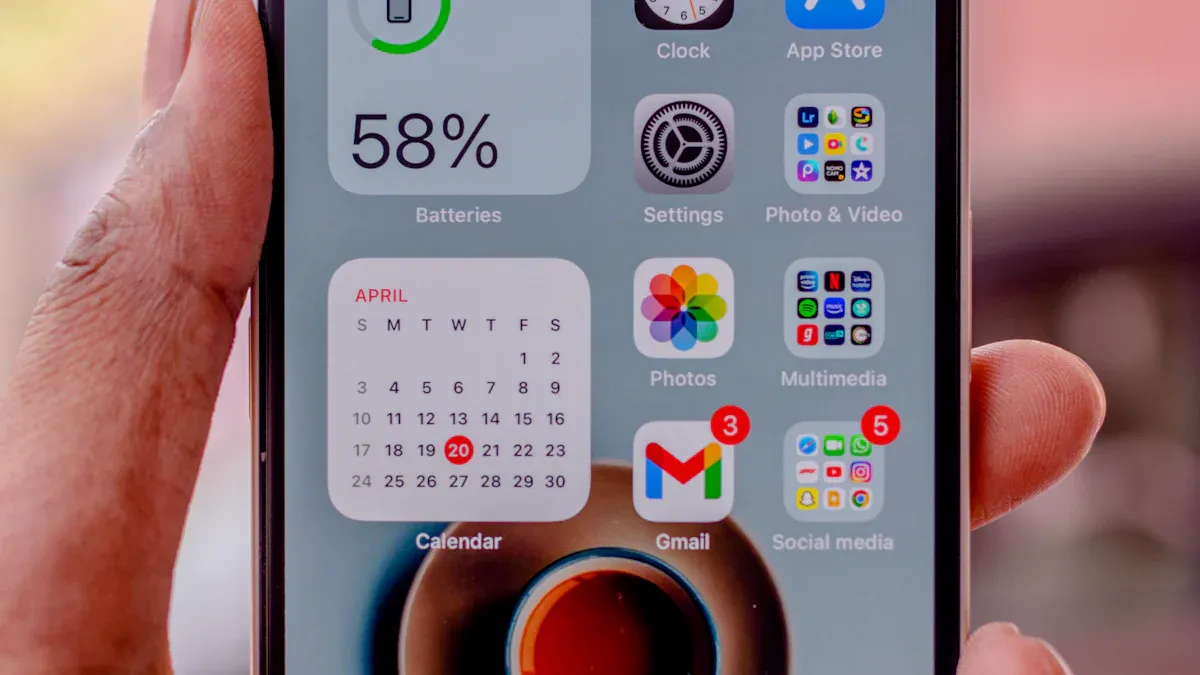

You use Battery Data Analytics to collect, process, and interpret battery health data from patient monitors. This approach leverages advanced sensors and software platforms to track battery performance in real time. You gain insights into state-of-charge, state-of-health, and usage patterns. These analytics help you make informed decisions about maintenance and replacement schedules.

Researchers from Palo Alto Research Center (PARC) and LG Chem Power have developed a method for real-time battery monitoring using embedded fiber-optic sensors. These sensors enhance state-of-charge and state-of-health estimations by directly monitoring internal battery conditions, such as strain and temperature, which allows for more accurate assessments and early failure detection. This technology addresses limitations of traditional battery management systems that rely on external measurements.

You can apply Battery Data Analytics to patient monitors powered by lithium-ion batteries. This technology supports your efforts to reduce downtime and extend battery life in medical environments.

2.2 Early Detection and Remote Monitoring

You rely on early detection to prevent unexpected battery failures. Battery Data Analytics platforms use remote monitoring to track battery status and alert you to potential issues. However, case studies show that remote monitoring alone may not always provide timely warnings. In some instances, patients with pacemakers experienced complete battery depletion without prior alerts, highlighting the need for more robust analytics and sensor integration.

You can enhance early detection by combining remote monitoring with advanced analytics. This approach helps you identify battery degradation before it leads to emergency service calls. The following table summarizes how remote monitoring features can benefit your operations:

Feature | Benefit |

|---|---|

Wearable devices | Enhance battery efficiency |

Wireless charging | Prolongs battery life |

Wear detection mechanisms | Ensure continuous monitoring |

Early interventions | Reduce unnecessary hospital visits |

Alleviates ED pressures | Lighten healthcare professionals’ workloads |

You improve patient safety and reduce operational stress by adopting these remote monitoring strategies.

2.3 Predictive Maintenance Strategies

You implement predictive maintenance to address battery issues before they disrupt patient care. Battery Data Analytics uses algorithms to assess battery life, connectivity patterns, and sensor accuracy. This proactive approach allows you to detect potential failures in advance. You schedule maintenance based on actual battery conditions, not just time intervals.

Predictive maintenance ensures your patient monitors remain reliable. You avoid costly emergency repairs and minimize downtime. You also optimize resource allocation by focusing on devices that need attention, rather than servicing all units at once.

2.4 Optimized Battery Replacement

You use Battery Data Analytics to inform your battery replacement schedules. Analytics platforms provide insights into battery performance and consumption patterns. You identify inefficiencies in battery usage and make informed decisions about design optimizations. Power profiling tools help you visualize current consumption, allowing for targeted improvements that extend battery life.

Battery Data Analytics provides insights into battery performance and consumption patterns.

Engineers can identify inefficiencies in battery usage, leading to informed decisions on design optimizations.

Power profiling tools help visualize current consumption, allowing for targeted optimizations to extend battery life.

You reduce unnecessary replacements and lower after-sales costs by replacing batteries only when needed. This strategy supports sustainability and improves the overall efficiency of your patient monitor fleet.

Part 3: Implementing Analytics in Patient Monitor Fleets

3.1 Real-Time Data Collection Methods

You rely on IoT-enabled patient monitors to collect battery data continuously. These devices use sensors to convert physical battery conditions into digital data. Connectivity protocols such as Bluetooth Low Energy, Wi-Fi, and cellular networks support different monitoring needs. Edge computing processes data locally, which reduces bandwidth and enables instant responses. Cloud infrastructure stores large datasets securely, maintaining privacy and compliance.

Technology | Description |

|---|---|

Sensors | Convert physical conditions into digital data, ensuring accurate readings through calibration. |

Connectivity Protocols | Bluetooth Low Energy, Wi-Fi, Cellular networks, and RFID for different monitoring needs. |

Edge Computing | Processes data locally for instant responses to critical situations. |

Cloud Infrastructure | Stores large datasets securely while maintaining privacy and compliance. |

You benefit from continuous tracking, which allows early detection of battery health issues and supports precise analysis in critical medical scenarios.

3.2 Choosing Analytics Platforms

You select analytics platforms that integrate with your existing patient monitor fleet. Look for solutions that support real-time data visualization, predictive maintenance, and secure cloud storage. Training for your staff is essential. Staff must understand basic repair, battery management, software updates, and device operation. Preventive maintenance procedures and troubleshooting skills help your team maximize the value of analytics tools.

Tip: Choose platforms that offer intuitive dashboards and automated alerts. This reduces manual oversight and improves response times.

3.3 Integrating with Service Workflows

You integrate analytics into your service workflows by aligning data insights with maintenance schedules. Regular audits ensure compliance with healthcare regulations such as HIPAA. Data security remains a top priority due to frequent cyberattacks targeting patient records. You improve inventory management by tracking battery status and scheduling replacements only when necessary.

Compliance Aspect | Description |

|---|---|

HIPAA Compliance | Protects electronic Protected Health Information (e-PHI) and avoids fines. |

Data Security | Critical due to the risk of cyberattacks on patient records. |

Regular Audits | Ensure adherence to regulations and minimize mistakes. |

You streamline operations and reduce after-sales costs by leveraging analytics for proactive maintenance and regulatory compliance.

You can adopt battery data analytics by following these steps: collect real-time data, select robust analytics platforms, and integrate insights into maintenance workflows. The table below shows how analytics reduces service calls and optimizes maintenance:

Benefit | How It Works |

|---|---|

Fewer service calls | Identifies high-risk components and failure probabilities |

Optimized maintenance | Adapts strategies to component aging and failure modes |

Reliable battery performance ensures continuous power for patient monitors, which improves patient care and reduces operational costs. You gain better outcomes and lower expenses by leveraging analytics.

FAQ

How does Battery Data Analytics benefit your medical device operations?

You optimize maintenance schedules and reduce downtime. Analytics help you predict battery failures in patient monitors, improving reliability and lowering after-sales costs across healthcare facilities.

What makes lithium-ion battery packs preferable for patient monitors?

You gain longer lifespan and higher charge cycles. Lithium-ion battery packs outperform older chemistries in medical, robotics, and industrial applications. See custom battery solutions from Large Power for tailored options.

Can you integrate Battery Data Analytics with existing service workflows?

You can integrate analytics platforms with your current systems. Real-time data supports proactive maintenance in security, infrastructure, and consumer electronics sectors, streamlining operations and reducing manual oversight.