You face rising demands for compact, reliable power in healthcare. High-energy-density battery solutions like 21700 cells in 3S/4S packs deliver the high energy density and long runtime your medical devices require. Healthcare trends show explosive growth in wearables and smart batteries, fueling innovation in medical technology and improving patient outcomes.

Key Takeaways

21700 cells provide higher capacity and energy density than traditional batteries, supporting longer runtimes for medical devices.

Choosing the right 3S or 4S pack configuration maximizes battery efficiency and ensures stable energy delivery for healthcare applications.

High-energy-density batteries enhance the portability and usability of medical devices, improving patient comfort and device performance.

Part1: 21700 Battery Pack Basics

1.1 21700 Cell Features

You benefit from the advanced design of 21700 cylindrical cells, which deliver higher capacity and improved energy density compared to traditional 18650 cells. These lithium-ion batteries offer up to 5000mAh per cell, supporting longer runtimes for portable medical devices and implantable medical devices. The larger format enables better thermal management and consistent performance, which is essential for healthcare monitoring devices and medical equipment. You see these cells adopted in leading-edge applications, including Tesla’s electric vehicles, which demonstrates their reliability and scalability for demanding environments.

1.2 3S/4S Series Configurations

You select 3S or 4S series pack configurations to match the voltage and power requirements of your medical devices. A 3S pack delivers a nominal voltage of 11.1V, while a 4S pack provides 14.8V, both ideal for portable and implantable medical equipment. These configurations ensure stable energy delivery and support advancements in battery technology, allowing you to meet the strict safety and reliability standards in healthcare. Custom pack designs enable you to optimize form factor and integration for specialized equipment.

Tip: Choosing the right series configuration helps you maximize battery efficiency and device performance.

1.3 High Energy Density in Medical Devices

You rely on high energy density to power advanced medical equipment and healthcare monitoring devices. 21700 lithium-ion batteries provide superior energy storage, supporting longer operation times and reducing the frequency of maintenance. This advantage is critical for portable and implantable devices, where space and weight constraints demand efficient solutions. You drive advancements in battery technology by adopting these cells, ensuring your equipment meets the highest standards for safety and reliability in healthcare.

Cell Type | Typical Capacity (mAh) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

18650 | 2600–3500 | 200–250 | 500–1000 |

21700 | 4000–5000 | 250–300 | 1000–2000 |

Part2: Advantages of High-Energy-Density Battery Solutions

2.1 Longer Runtime and Reliability

You demand high-energy-density battery solutions that deliver extended runtime and consistent reliability for medical equipment. When you deploy 21700 cells in 3S/4S packs, you achieve longer operational periods for portable and implantable medical devices. These battery packs support healthcare monitoring devices and critical medical equipment, reducing downtime and minimizing the need for frequent recharging. You benefit from stable voltage output and robust cycle life, which ensures your devices operate efficiently in demanding healthcare environments. The advanced design of these battery solutions also enhances reliability, supporting continuous monitoring and emergency medical interventions.

Note: Reliable battery performance is essential for life-supporting medical equipment and monitoring systems in healthcare settings.

2.2 Compact Size and Weight

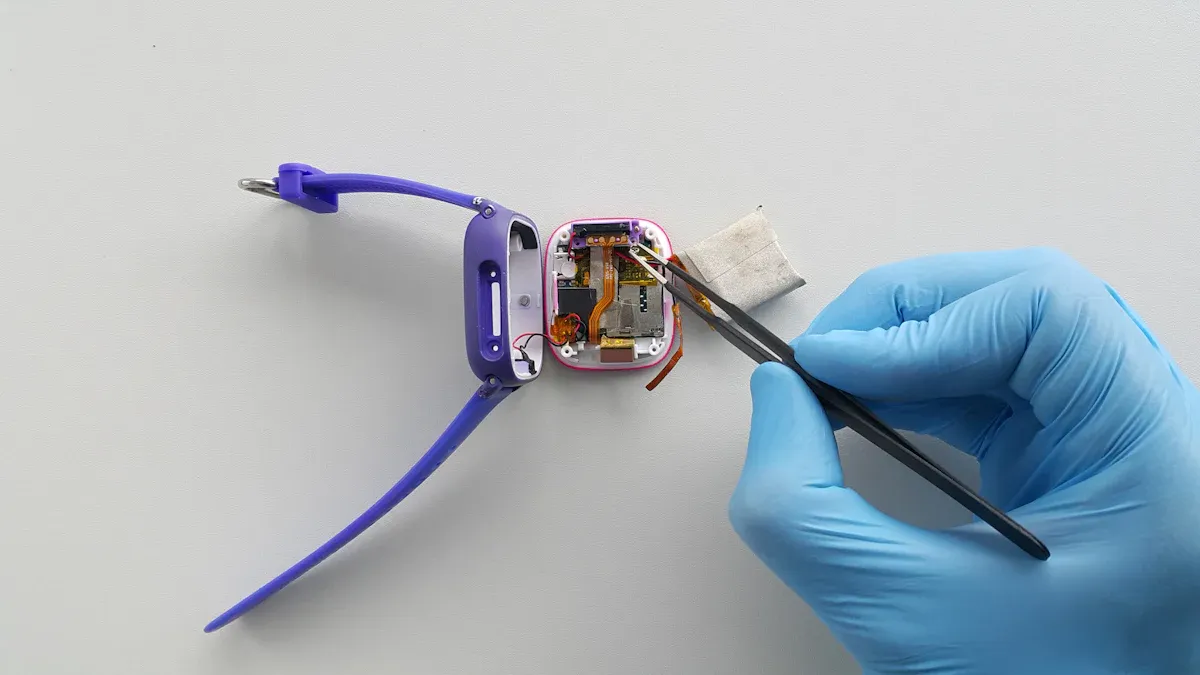

You prioritize light weight and compact size in your medical devices. High-energy-density battery solutions using 21700 cells allow you to reduce the overall footprint of your equipment. You achieve greater portability for both portable and implantable medical devices, which improves patient comfort and device usability. The compact design of these battery packs enables you to integrate advanced features into your medical equipment without sacrificing performance. You see significant advancements in battery technology that make it possible to deliver high energy in a small package, supporting the trend toward miniaturization in healthcare.

Benefits of compact battery packs:

Easier integration into portable medical devices

Enhanced mobility for healthcare professionals

Improved patient experience with implantable medical devices

2.3 Safety and Compliance

You must address safety concerns of lithium polymer battery and other chemistries when selecting battery solutions for medical equipment. High-energy-density battery solutions with 21700 3S/4S packs incorporate multiple safety features, including protection against thermal runaway and fire. You ensure compliance with international medical standards and regulations, which is critical for healthcare applications. These battery packs undergo rigorous testing to meet safety requirements for both portable and implantable medical devices. You mitigate risks by choosing battery designs that include advanced monitoring and management systems.

Tip: Always verify that your battery packs meet the latest medical safety standards and certifications before integration.

2.4 Comparison: Lithium Polymer Battery vs. Other Technologies

You evaluate different battery technologies to find the best fit for your medical equipment. Lithium polymer battery packs offer flexibility in shape and size, but you must consider safety concerns of lithium polymer battery, such as swelling and fire risk. You compare lithium polymer battery with other chemistries like 18650, NMC, LCO, LMO, LiFePO4, LTO, solid-state battery, and lithium metal. The following table summarizes key characteristics for medical device applications:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Concerns |

|---|---|---|---|---|

Lithium polymer battery (LiPo) | 3.7 | 180–220 | 300–800 | Swelling, fire |

18650 (Li-ion) | 3.6 | 200–250 | 500–1000 | Moderate |

21700 (Li-ion) | 3.6 | 250–300 | 1000–2000 | Moderate |

NMC | 3.7 | 220–260 | 1000–2000 | Moderate |

LCO | 3.7 | 150–200 | 500–1000 | Moderate |

LMO | 3.7 | 100–150 | 300–700 | Moderate |

LiFePO4 | 3.2 | 90–120 | 2000–5000 | Low |

LTO | 2.4 | 70–80 | 7000–10000 | Low |

Solid-state battery | 3.7 | 300–400 | 1000–2000 | Low |

Lithium metal | 3.7 | 400–500 | 500–1000 | High |

You notice that lithium polymer battery offers design flexibility but presents safety concerns of lithium polymer battery, especially in healthcare applications. 21700 cells provide higher energy density and longer cycle life, making them suitable for both portable and implantable medical devices. LiFePO4 and solid-state battery chemistries offer enhanced safety and longer lifespans, but may have lower energy density compared to 21700 lithium-ion solutions.

Callout: You should always balance energy density, safety, and cycle life when selecting battery technology for medical equipment.

You drive advancements in battery technology by choosing high-energy-density battery solutions that meet the strict requirements of healthcare. You ensure your medical devices deliver reliable performance, safety, and efficiency in every application.

Part3: Implementation in Medical Devices

3.1 Integration and Compatibility

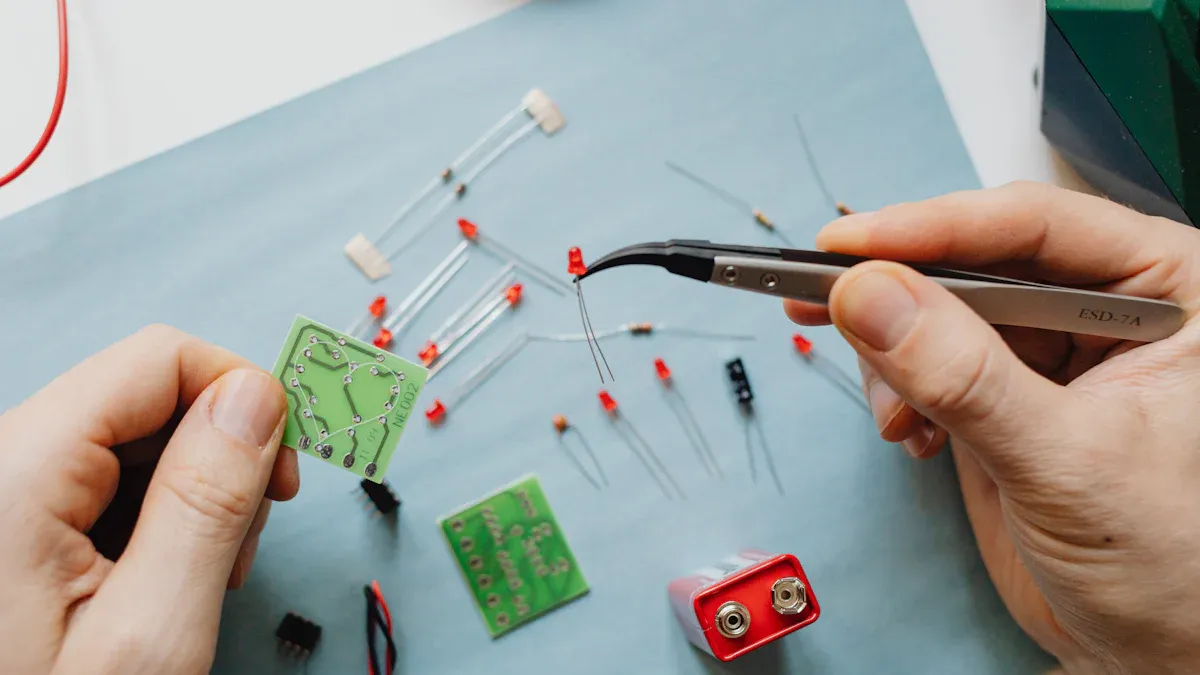

You face unique challenges when integrating 21700 battery packs into medical devices. You must ensure accurate positioning of cells for effective welding. Quick vision analysis helps you avoid production delays. High resolution is essential for maintaining tight tolerances during welding. Proper lighting provides clear visibility throughout the process. You focus on module integrity to prevent scrap production. Sensitive components require careful heat management during welding. Welds must meet specific strength and penetration requirements. You minimize electrical resistance for battery efficiency. Long-term performance validation of welds supports aging and reliability. These steps help you achieve compatibility with medical equipment and healthcare standards. You optimize form factor and ensure seamless integration with lithium polymer battery packs.

Integration challenges you may encounter:

X-Y-Z measurements for cell placement

Speed of vision analysis

High-resolution welding

Lighting for visibility

Module integrity

Heat management for sensitive components

Weld characteristics

Electrical resistance

Aging validation

3.2 Maintenance and Lifecycle

You prioritize maintenance and lifecycle management for medical equipment powered by lithium polymer battery packs. Routine inspections help you identify wear and aging in battery cells. You schedule replacements to maintain device reliability. Battery packs with longer cycle life reduce maintenance costs and downtime. You monitor battery health to ensure safety and performance in healthcare environments. Efficient lifecycle management supports cost-effective operation of medical devices and equipment.

3.3 Real-World Medical Device Applications

You see 21700 lithium polymer battery packs used in a variety of medical devices. Patient monitors, infusion pumps, and implantable medical equipment rely on these battery solutions for extended runtime and reliability. You also find applications in robotics, security, infrastructure, consumer electronics, and industrial sectors. These battery packs support advanced healthcare monitoring and critical medical equipment, helping you deliver safe and efficient solutions for patients and professionals.

Tip: You improve patient outcomes and device reliability by choosing high-energy-density lithium polymer battery packs for your medical equipment.

You recognize that 21700 3S/4S packs deliver unmatched energy density for medical devices. These solutions enhance reliability and safety in medical equipment. You improve device performance and reduce maintenance for medical equipment. You support advanced medical devices and critical equipment. You drive innovation in medical devices and equipment.

You should evaluate high-energy-density battery packs for future medical device development.

FAQ

What advantages do 21700 lithium battery packs offer for medical devices?

You gain higher energy density, longer cycle life, and improved reliability. These packs meet strict medical standards and support advanced healthcare equipment.

How does Large Power support custom lithium battery pack solutions?

You receive tailored battery designs for medical, industrial, and infrastructure applications. For custom battery consultation, contact Large Power.

What safety features should you expect in 3S/4S lithium battery packs?

You benefit from integrated protection circuits, thermal management, and compliance with international safety standards. These features ensure safe operation in critical medical environments.