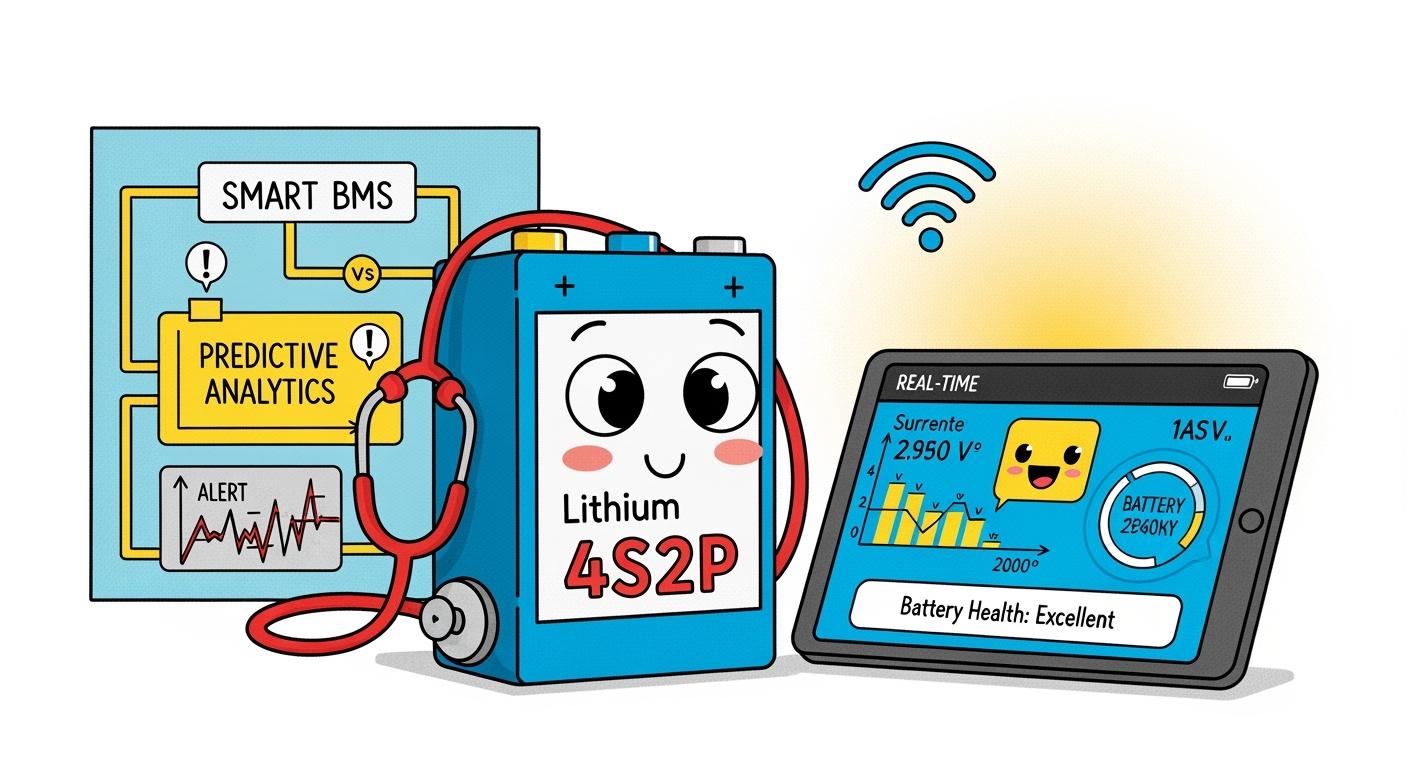

You can transform device performance by integrating smart bms into 4S2P Medical Lithium Battery Packs. Smart battery technology, paired with a battery management system, delivers real-time data for predictive maintenance. This approach increases operational safety, enhances reliability, and improves efficiency in critical healthcare environments.

Key Takeaways

Integrating smart BMS into 4S2P medical lithium battery packs enhances device performance and safety. This technology provides real-time data for predictive maintenance, reducing unexpected failures.

Remote monitoring capabilities allow for continuous tracking of battery health, ensuring optimal performance and compliance with safety standards. This proactive approach minimizes downtime and extends battery lifespan.

Adopting predictive maintenance strategies can lead to significant cost savings and improved operational efficiency. By addressing issues before they escalate, healthcare facilities can ensure uninterrupted service and better patient care.

Part1: Medical Lithium Battery Packs and Smart BMS

1.1 4S2P Battery Pack Structure

You often see 4S2P configurations in medical lithium battery packs because they deliver the right balance of voltage, capacity, and reliability for healthcare equipment. In a 4S2P pack, four cell groups connect in series, and each group contains two cells in parallel. This setup gives you a nominal voltage of 14.8V and doubles the capacity, which increases energy density and supports longer device operation. The structure maintains voltage stability and enhances discharge capabilities, both critical for medical environments.

Tip: The 4S2P design fits well in space-constrained devices and holds a charge for months, making it ideal for emergency medical equipment.

Here are some common medical devices that use 4S2P medical lithium battery packs:

Medical Device Type |

|---|

Hospital-grade breast pumps |

Portable patient monitors and infusion pumps |

Handheld diagnostic instruments |

The technical advantages of this configuration include:

Advantage | Description |

|---|---|

Consistent Power | Maintains voltage within ±0.1V under load, crucial for accurate readings. |

Long Shelf Life | Holds charge for months without degradation, ideal for emergency reserves. |

Compact Design | Enables integration into space-constrained medical devices. |

1.2 Smart Battery BMS Features

Smart BMS (Battery Management System) technology brings advanced monitoring and protection to medical lithium battery packs. You benefit from real-time tracking of state of charge (SOC) and state of health (SOH), which helps you plan maintenance and avoid unexpected failures. The BMS uses adaptive algorithms like Coulomb counting and Kalman filters to estimate battery status and predict performance.

Key features of smart BMS in medical lithium battery packs include:

Feature | Description |

|---|---|

Monitoring and Balancing | Ensures individual cells are charged and discharged evenly, preventing degradation and failures. |

Safety Mechanisms | Includes temperature monitoring and fault protection to prevent hazardous situations. |

Communication Capabilities | Allows real-time data transmission for tracking battery status and performance metrics. |

Advanced Algorithms | Optimizes performance and enhances safety measures in energy storage solutions. |

You also gain robust safety features such as overcharge, overdischarge, short circuit, and thermal protection. The BMS alerts you to issues like high temperature or cell imbalance and signals when the battery reaches end-of-life. These capabilities ensure that your medical lithium battery packs deliver reliable power and meet strict healthcare standards.

Part2: Monitoring and Predictive Maintenance

2.1 Remote Monitoring Technologies

You can achieve advanced remote monitoring for medical lithium battery packs by leveraging modern communication protocols and sensor technologies. These systems enable you to track critical parameters such as temperature, voltage, and current, ensuring optimal battery management and safety. The integration of real-time monitoring allows you to detect electrolyte leaks, water penetration, and gas emissions, which are essential for maintaining high safety standards in healthcare environments.

Protocol Type | Description |

|---|---|

Modbus RTU | A simple client/server architecture allowing multiple batteries to connect to a server. |

CAN bus | A message-based protocol derived from the automotive industry, utilizing a standard two-wire transmission. |

Ethernet | Offers optional connections running proprietary protocols, Modbus TCP, or SNMP. |

You benefit from these protocols by gaining seamless connectivity between your battery management system and your facility’s central monitoring infrastructure. This connectivity supports real-time data collection and remote diagnostics, which are vital for proactive management of medical devices.

Monitors temperature, voltage, and current levels.

Provides safety protection through electrolyte leak detection, water penetration, and gas detection.

Cloud connectivity further enhances your management capabilities. You can collect and analyze data in real time, enabling predictive actions before failures occur. The system automatically monitors operating data daily, helping you identify potential issues early and optimize battery sizing for specific applications. You receive alerts for low battery levels, which supports efficient power management and uninterrupted device operation.

Note: Reliable network availability is crucial for effective remote monitoring. You must ensure stable connectivity to avoid disruptions, especially during critical patient care periods.

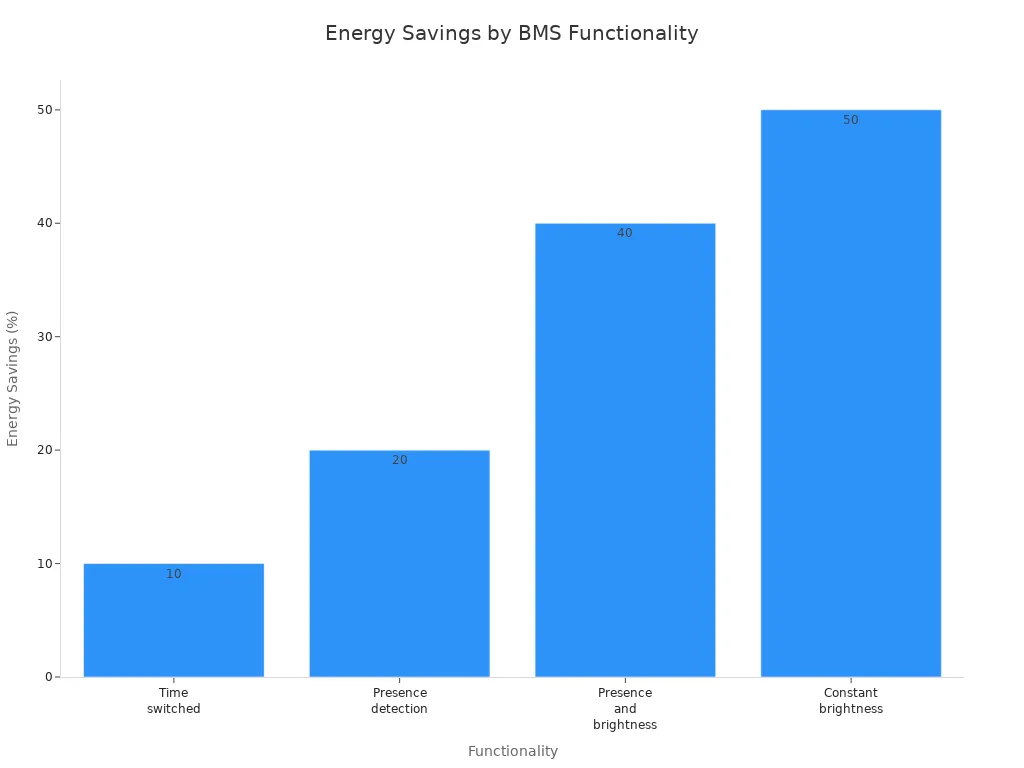

2.2 Predictive Maintenance with BMS

Predictive maintenance, powered by smart BMS, transforms how you manage medical lithium battery packs. The BMS uses advanced monitoring tools, including IoT sensors and AI-driven battery management algorithms, to continuously assess battery condition. By analyzing real-time data, the system identifies anomalies in performance and degradation patterns, allowing you to address issues before they escalate.

Smart BMS employs predictive analytics methods such as data-driven, model-based, and hybrid approaches. These methods focus on forecasting the remaining useful life and state of health of lithium batteries. Machine learning models, like Long Short-Term Memory (LSTM), enhance the accuracy of predictions by continuously monitoring battery degradation and performance. This predictive approach ensures you can plan maintenance activities efficiently, reducing the risk of unexpected device failures during critical treatments.

Predictive maintenance enables timely alerts to your maintenance team, allowing proactive intervention.

You minimize unplanned downtime and extend the lifespan of your medical devices.

Predictive analysis supports cost-effective management by preventing complete battery failure and eliminating inefficient manual monitoring.

Predictive Maintenance System | Downtime Reduction | Cost Savings |

|---|---|---|

Hitachi’s Sentinel Analytics | 16.3% | Significant |

GE Healthcare’s OnWatch Predict | Up to 40% | Substantial |

A medium-sized healthcare facility may spend around $5 million annually on equipment maintenance. By adopting predictive maintenance, you can achieve substantial cost savings and improve operational efficiency across your organization.

2.3 Benefits for Medical Devices

Integrating smart BMS and predictive management into your medical lithium battery packs delivers measurable benefits for device reliability, safety, and compliance. You gain continuous monitoring of battery health, which supports optimal performance and extends the lifespan of your equipment. The system ensures that you maintain high energy density and long cycle life, both essential for medical applications.

Battery Health Range | Actions Taken | Operational Impact |

|---|---|---|

Optimal Range (90-100%) | Standard operations continue, routine monitoring in place | Full performance and reliability expected |

Watch Range (80-90%) | Increased monitoring frequency, replacement queue initiated | Device reassignment considerations begin |

Action Range (Below 80%) | Immediate reassignment evaluation, replacement plans active | Critical operations prioritized for newer batteries |

You also address key compliance requirements by integrating smart BMS. Your battery management system helps you meet FDA regulations, UL and IEC safety standards, and ISO biocompatibility guidelines. This compliance ensures your devices remain safe and legal for use in healthcare settings.

Advanced battery management enhances safety by continuously regulating battery performance.

You reduce the risk of hazardous situations through real-time monitoring and predictive analysis.

The system supports adherence to regulatory frameworks, including FDA, UL, IEC, and ISO standards.

Tip: Regular calibration and verification of your monitoring systems ensure data accuracy and support effective diagnosis and maintenance planning.

By adopting predictive management and smart BMS, you improve efficiency, reduce degradation, and ensure uninterrupted healthcare services. This approach positions your organization at the forefront of medical device innovation and operational excellence.

You transform medical device management by adopting smart BMS and remote monitoring in 4S2P lithium battery packs. You achieve improved battery performance, enhanced battery thermal management, and longer battery lifespan.

You experience significant reduction in downtime and extended battery lifespan.

You optimize battery performance and battery thermal management for reliable service.

You meet strict safety standards and improve operational efficiency.

You position your organization for future-ready medical devices with advanced battery thermal management and predictive maintenance.

FAQ

What advantages does a smart BMS system offer for medical lithium battery packs?

You gain precise control over energy flow, enhanced safety, and real-time diagnostics. The system uses ai algorithms to optimize energy distribution and predict maintenance needs.

How does ai-driven predictive maintenance improve operational efficiency in healthcare facilities?

Ai analyzes system data to forecast battery health and energy consumption. You reduce downtime, extend device lifespan, and ensure uninterrupted energy supply for critical medical equipment.

Can Large Power customize lithium battery packs for unique industrial energy requirements?

Large Power designs system solutions tailored to your energy needs. Ai-powered monitoring maximizes energy efficiency.