When you select a battery pack for your next-gen stapler, you need to find the perfect balance of power and size. Industry standards show that a 3S1P configuration offers higher voltage in a compact form, while a 2S2P solution provides longer runtime with increased amp load capacity. You should evaluate operational priorities such as amp load, runtime, and device size. Matching the battery chemistry—like LiFePO4 or NMC—to your stapler’s use case ensures optimal performance. Consider both technical specifications and ergonomic factors to make the right choice.

Key Takeaways

Choose a 3S1P configuration for higher voltage and portability. This option is ideal for lightweight, ergonomic staplers used in mobile applications.

Opt for a 2S2P configuration if you need longer runtime and higher amp load capacity. This choice suits heavy-duty staplers in industrial settings.

Always match the battery chemistry to your stapler’s requirements. Selecting the right chemistry, like LiFePO4 or NMC, ensures optimal performance and longevity.

Consider the physical size and weight of the battery pack. A lighter pack enhances user comfort, while a larger pack supports demanding tasks.

Ask key questions about your stapler’s use case, runtime needs, and voltage requirements. This helps you make an informed decision that aligns with your operational goals.

Part1: Comparison Overview

1.1 Key Specs: 3S1P vs. 2S2P

You need to compare the technical specifications of 3S1P and 2S2P lithium battery packs before choosing the right solution for your next-gen stapler. The table below summarizes the main differences, focusing on standardized lithium chemistries and strict data for platform voltage, energy density, and cycle life.

Configuration | Cell Count | Series/Parallel | Typical Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Amp Load Capacity | Pack Size | Weight | Typical Applications |

|---|---|---|---|---|---|---|---|---|---|---|

3S1P | 3 | 3 in series, 1 in parallel | LiFePO4, NMC, LCO, LMO | 9.6-11.1 (LiFePO4: 9.6, NMC/LCO/LMO: 11.1) | 120-250 | 2000+ (LiFePO4), 800-1500 (NMC/LCO/LMO) | Moderate | Compact | Light | Portable, lightweight staplers |

2S2P | 4 | 2 in series, 2 in parallel | LiFePO4, NMC, LCO, LMO | 6.4-7.4 (LiFePO4: 6.4, NMC/LCO/LMO: 7.4) | 120-250 | 2000+ (LiFePO4), 800-1500 (NMC/LCO/LMO) | High | Larger | Heavier | Heavy-duty, long runtime staplers |

Tip: Always verify the chemistry and platform voltage to ensure compatibility with your stapler’s motor and control electronics.

1.2 Power, Size, Weight

You must consider how each configuration affects power delivery, physical size, and overall weight. The 3S1P pack delivers higher voltage, which supports faster stapling and more efficient motor operation. You get a compact and lightweight solution, ideal for portable devices. The 2S2P pack provides increased amp load capacity and longer runtime. You sacrifice some compactness and add weight, but you gain endurance for heavy-duty stapling tasks.

3S1P Advantages:

Higher voltage output (9.6-11.1V)

Smaller footprint

Lower weight

Suitable for portable and ergonomic designs

2S2P Advantages:

Greater amp load capacity

Extended runtime

Better for high-volume stapling

Supports larger motors and longer duty cycles

Note: You should match the battery pack size and weight to the stapler’s intended use. A lightweight pack improves user comfort, while a larger pack supports demanding applications.

1.3 Use Cases

You need to align your battery choice with the operational requirements of your stapler. The following examples illustrate typical scenarios for each configuration:

3S1P Use Cases:

Portable office staplers

Field service tools

Lightweight, ergonomic models

Applications where the perfect balance of power and size is critical

2S2P Use Cases:

Industrial staplers for packaging

High-capacity office staplers

Devices requiring long runtime between charges

Heavy-duty stapling in manufacturing environments

When you select a battery configuration, always consider the stapler’s duty cycle, expected amp load, and the need for portability versus runtime. This approach helps you achieve the perfect balance of power for your next-gen stapler.

Part2: Power & Performance

2.1 Voltage & Current Output

You must understand how battery configuration impacts voltage and current output. The 3S1P pack uses three cells in series, delivering a platform voltage of 9.6V for LiFePO4 or 11.1V for NMC, LCO, and LMO chemistries. The 2S2P pack uses two cells in series and two in parallel, providing 6.4V (LiFePO4) or 7.4V (NMC/LCO/LMO). Higher voltage supports faster motor operation and more efficient stapling. Parallel cells in the 2S2P configuration increase amp load capacity, which allows your stapler to handle higher current demands during heavy-duty tasks.

Note: You should always verify the platform voltage and amp load requirements for your stapler to ensure compatibility and safety.

2.2 Stapler Efficiency

Battery chemistry and configuration directly affect stapler efficiency. A 3S1P pack provides higher voltage, which improves motor speed and reduces cycle time per staple. This configuration suits applications where speed and responsiveness matter. The 2S2P pack, with its increased amp load, supports longer duty cycles and sustained performance. You gain reliability for industrial staplers that operate continuously. Both configurations offer energy densities between 120-250 Wh/kg and cycle lives of 800-2000+ cycles, depending on chemistry. You can optimize efficiency by pairing the right battery management system (BMS).

2.3 Runtime Analysis

You need to analyze runtime to achieve the Perfect Balance of Power for your stapler. The 2S2P configuration, with double the parallel cells, extends runtime and supports longer periods between charges. This feature benefits high-volume stapling environments. The 3S1P pack, while more compact, offers shorter runtime but excels in portability and quick operation. You must weigh runtime against size and weight to select the best solution for your business needs.

Quick Reference Table: Runtime & Efficiency

Configuration | Voltage (V) | Amp Load Capacity | Energy Density (Wh/kg) | Cycle Life (cycles) | Runtime | Efficiency |

|---|---|---|---|---|---|---|

3S1P | 9.6-11.1 | Moderate | 120-250 | 800-2000+ | Short | High |

2S2P | 6.4-7.4 | High | 120-250 | 800-2000+ | Long | Reliable |

Tip: You should match runtime and efficiency to your operational priorities. Consider both technical specs and ergonomic factors to maximize productivity.

Part3: Size & Ergonomics

3.1 Physical Dimensions

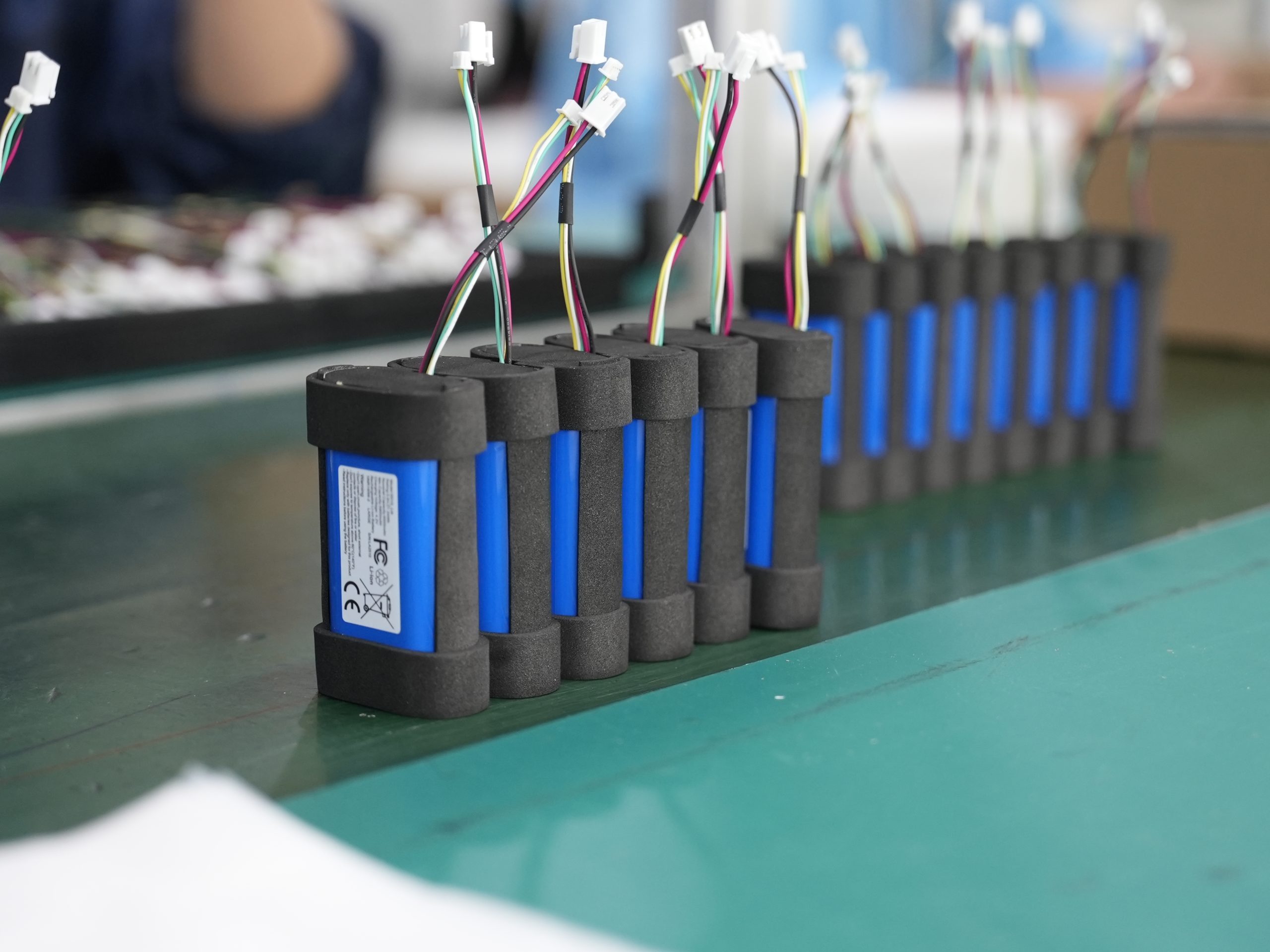

You must evaluate the physical dimensions of lithium battery packs when designing your next-gen stapler. The 3S1P pack uses three cells in series, which creates a compact and streamlined shape. You can fit this configuration into smaller housings, making it ideal for portable staplers. The 2S2P pack contains four cells—two in series and two in parallel. This arrangement increases the overall size and requires more space inside the device. You should measure the available compartment and compare it to the standardized dimensions of LiFePO4, NMC, LCO, or LMO cells. The table below summarizes the typical pack sizes:

Configuration | Cell Count | Typical Pack Size (mm) | Platform Voltage (V) |

|---|---|---|---|

3S1P | 3 | 65 x 45 x 20 | 9.6-11.1 |

2S2P | 4 | 80 x 50 x 30 | 6.4-7.4 |

Note: You should always confirm the pack size with your supplier to ensure compatibility with your stapler’s design.

3.2 Weight Impact

Weight plays a critical role in user comfort and device handling. The 3S1P lithium battery pack remains lighter due to fewer cells. You can expect a weight range of 120-180 grams, depending on the chemistry. The 2S2P pack, with an extra cell, increases the weight to 160-240 grams. You must consider the impact on the stapler’s balance and ease of use. Lighter packs improve portability and reduce fatigue during extended use. Heavier packs suit industrial staplers that require stability and longer runtime.

3S1P: Lightweight, enhances portability.

2S2P: Heavier, supports longer operation.

3.3 User Experience

You should prioritize user experience when selecting a battery configuration. A compact and lightweight stapler with a 3S1P pack offers better ergonomics for mobile workers and office staff. You can achieve the Perfect Balance of Power by matching the pack to the user’s workflow. The 2S2P pack, while heavier, provides longer runtime and supports high-volume stapling. You must weigh the trade-off between comfort and endurance. Consider grip design, trigger placement, and overall device balance. You can improve productivity and satisfaction by aligning battery choice with user needs.

Tip: You should conduct user testing with both configurations to identify the best fit for your team.

Part4: Application Scenarios

4.1 Heavy-Duty Use

You need a battery solution that supports demanding environments. Industrial staplers in packaging, infrastructure, and manufacturing often require extended runtime and high amp load. The 2S2P configuration, with its increased parallel cell count, delivers greater amp load capacity and longer runtime. You can rely on this setup for continuous operation in assembly lines or large-scale installations. In robotics and security systems, where reliability and endurance matter, the 2S2P pack ensures your stapler performs consistently. You should select LiFePO4 or NMC chemistry for cycle life above 2000 cycles and energy density between 120-250 Wh/kg.

For organizations focused on sustainability, review our approach to sustainability.

4.2 Portability Needs

You may prioritize portability and ergonomic design for field service, medical device assembly, or consumer electronics. The 3S1P configuration offers a compact and lightweight solution. You can easily integrate this pack into handheld staplers used by technicians or healthcare professionals. The higher platform voltage (9.6-11.1V) supports efficient motor operation, while the reduced weight improves user comfort. In mobile applications, such as infrastructure inspections or on-site repairs, the 3S1P pack provides the agility you need.

If your supply chain requires conflict-free minerals, see our conflict minerals statement.

4.3 Long Runtime vs. High Power

You must decide between long runtime and high power output. The 2S2P pack excels in scenarios where uninterrupted operation is critical, such as industrial stapling or security system installations. You gain extended runtime and support for higher amp loads. The 3S1P pack delivers the Perfect Balance of Power for portable staplers, offering high voltage in a smaller footprint. You should match the configuration to your operational priorities, whether you need endurance for industrial use or agility for field applications.

Scenario | Recommended Pack | Chemistry Options | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|---|---|

Heavy-duty/Industrial | 2S2P | LiFePO4, NMC | 6.4-7.4 | 120-250 | 2000+ |

Portable/Field Service | 3S1P | LiFePO4, NMC, LCO, LMO | 9.6-11.1 | 120-250 | 800-2000+ |

Long Runtime | 2S2P | LiFePO4, NMC | 6.4-7.4 | 120-250 | 2000+ |

High Power/Agility | 3S1P | LiFePO4, NMC, LCO, LMO | 9.6-11.1 | 120-250 | 800-2000+ |

Tip: You should always align your battery selection with the specific requirements of your industry and application to maximize productivity and reliability.

Part5: Perfect Balance of Power Decision

5.1 Key Questions

You need to ask the right questions before you choose a battery configuration for your next-gen stapler. These questions help you align your decision with your operational goals and technical requirements.

What is the primary use case for your stapler? (e.g., heavy-duty industrial, portable field service, high-volume office)

How important is runtime versus device weight?

What is the required platform voltage for your stapler’s motor and electronics?

Does your application demand higher amp load capacity or maximum portability?

What are the size constraints within your stapler’s housing?

Which lithium chemistry best matches your cycle life and energy density needs? (LiFePO4, NMC, LCO, LMO)

How often will your team need to recharge the stapler during a typical workday?

What is the expected duty cycle and average daily usage?

Tip: You should involve both engineering and operations teams in this decision. Their input ensures you select a battery pack that meets both performance and ergonomic needs.

5.2 Selection Flowchart

You can use a simple flowchart to guide your battery selection process. This tool helps you visualize the decision path and quickly narrow down the best configuration for your stapler.

Choose 3S1P if you need high voltage, fast operation, and a compact design.

Choose 2S2P if you need long runtime, higher amp load, and can accommodate a larger pack.

Note: Always verify the platform voltage and chemistry compatibility with your stapler’s electronics before finalizing your choice.

5.3 Matching Packs to Needs

You must match the battery pack to your stapler’s specific requirements. Use the table below to align your operational priorities with the right configuration.

Operational Priority | Recommended Pack | Platform Voltage (V) | Chemistry Options | Key Benefit |

|---|---|---|---|---|

High Power & Speed | 3S1P | 9.6-11.1 | LiFePO4, NMC, LCO, LMO | Fast stapling, compact size |

Long Runtime | 2S2P | 6.4-7.4 | LiFePO4, NMC | Extended use, high amp load |

Lightweight & Portable | 3S1P | 9.6-11.1 | LiFePO4, NMC, LCO, LMO | Easy handling, ergonomic |

Heavy-Duty/Industrial | 2S2P | 6.4-7.4 | LiFePO4, NMC | Reliable, long duty cycles |

You should always balance power, runtime, and ergonomics. The Perfect Balance of Power comes from matching the battery pack to your stapler’s real-world demands. You can improve productivity, reduce downtime, and enhance user satisfaction by making an informed choice.

Callout: Consult with your battery supplier or engineering team if you have unique requirements. Custom solutions can help you achieve the best fit for your application.

You have seen how 3S1P and 2S2P lithium battery packs differ in voltage, amp load, size, and runtime. The 3S1P configuration gives you higher voltage and portability, while 2S2P offers longer runtime and greater amp load for heavy-duty use. To achieve the Perfect Balance of Power, you should match your battery choice to your stapler’s operational needs. Review the table below for expert recommendations on power source selection:

Power Source Type | Portability | Usage Implications |

|---|---|---|

Battery | High | Requires replacement, ideal for mobile use |

AC Power Adapter | Limited | Provides unlimited power, suitable for stationary use |

You should consult with battery experts to ensure your solution meets both performance and ergonomic requirements.

FAQ

What is the main difference between 3S1P and 2S2P battery packs?

You get higher platform voltage with 3S1P (9.6–11.1V) and longer runtime with 2S2P (6.4–7.4V). The 3S1P pack suits portable staplers. The 2S2P pack fits heavy-duty, high-volume applications.

Which lithium chemistry should you choose for industrial staplers?

You should select LiFePO4 or NMC for industrial staplers. These chemistries offer energy density between 120–250 Wh/kg and cycle life above 2000 cycles. They provide reliability and long-term performance in demanding environments.

How does battery pack size affect stapler design?

You must consider pack size when designing your stapler. A compact 3S1P pack enables ergonomic, lightweight devices. A larger 2S2P pack supports extended runtime but increases weight and space requirements.

Can you mix lithium chemistries in one battery pack?

You should never mix lithium chemistries in a single pack. Mixing LiFePO4, NMC, LCO, or LMO cells causes imbalance, reduces cycle life, and increases safety risks. Always use cells with identical chemistry and specifications.

What is the recommended cycle life for B2B stapler applications?

You should aim for a cycle life of at least 800 cycles for office staplers and 2000+ cycles for industrial models. LiFePO4 and NMC chemistries meet these standards and support reliable, long-term use.