You need custom battery packaging to ensure safety and performance in medical devices, diagnostic equipment, and lithium batteries for medical use. Failure to meet standards can cause serious risks. See the table below for common safety hazards:

Risk Type | Description |

|---|---|

Thermal Runaway | Excessive heat generation leading to ignition due to uncontrollable heat and pressure. |

Leakage | Release of corrosive and toxic chemicals causing severe health issues. |

Fumes | Off-gassing of combustible and toxic hydrocarbons posing evacuation risks. |

Explosions | Result from thermal runaway, causing severe damage and risks for implantable devices. |

Custom battery packaging supports battery pack quality, quality assurance for battery packs, end customer quality assurance measures, safety functions, and safety in custom battery packs. Custom battery pack manufacturing aligns with certification standards and safety for international markets.

Key Takeaways

Custom battery packaging is essential for ensuring safety and performance in medical devices and diagnostic equipment.

Meeting international certification standards like UN38.3 and ISO 13485 is crucial for regulatory compliance and product reliability.

Rigorous testing and quality assurance processes help validate battery performance and enhance patient safety in critical applications.

Part1: Certification Standards for Custom Battery Packaging

1.1 UN38.3 and UL Requirements

You must meet strict regulatory standards when designing custom lithium battery solutions for inspection and medical devices. Learn more about medical devices and lithium-ion batteries. UN38.3 and UL standards set the foundation for global compliance. These standards ensure safe shipping, storage, and use of lithium battery packs. You need to understand the classification and testing requirements:

Classification | Description |

|---|---|

UN 3090 / UN 3480 | Applies to cells and batteries shipped alone. |

UN 3091 / UN 3481 | Applies to devices with batteries installed or packed together. |

Test | Purpose |

|---|---|

T1 | Altitude Simulation |

T2 | Thermal Test |

T3 | Vibration |

T4 | Shock |

T5 | Short Circuit |

T6 | Impact |

T7 | Overcharge |

T8 | Forced Discharge |

You must ensure your custom battery design passes each test to achieve regulatory readiness and avoid shipment delays.

1.2 ISO 13485 and Medical Devices

ISO 13485 certification is essential for custom lithium battery solutions in medical devices. This standard focuses on safety, reliability, and regulatory compliance. You must address several criteria:

Safety of battery packs protects human health.

Reliability and uniformity in performance support diagnostics.

Timely delivery of components ensures device availability.

Traceability of components supports regulatory audits.

Accurate labeling prevents errors in device usage.

Commitment to quality assurance leads to safe products.

ISO 13485 creates a quality management framework. You benefit from robust documentation and stringent controls. This approach improves product consistency and patient outcomes.

1.3 Compliance Challenges in Hazardous Environments

You face unique compliance challenges when deploying custom lithium battery solutions in hazardous environments. Common causes of certification failure include:

Manufacturing defects

Physical damage or punctures

Overcharging or short-circuiting

Exposure to high heat

Improper packaging during shipping

You must prioritize regulatory readiness and reliability in your custom battery design. Addressing these risks ensures consistent performance and regulatory compliance for medical devices and diagnostics in demanding conditions.

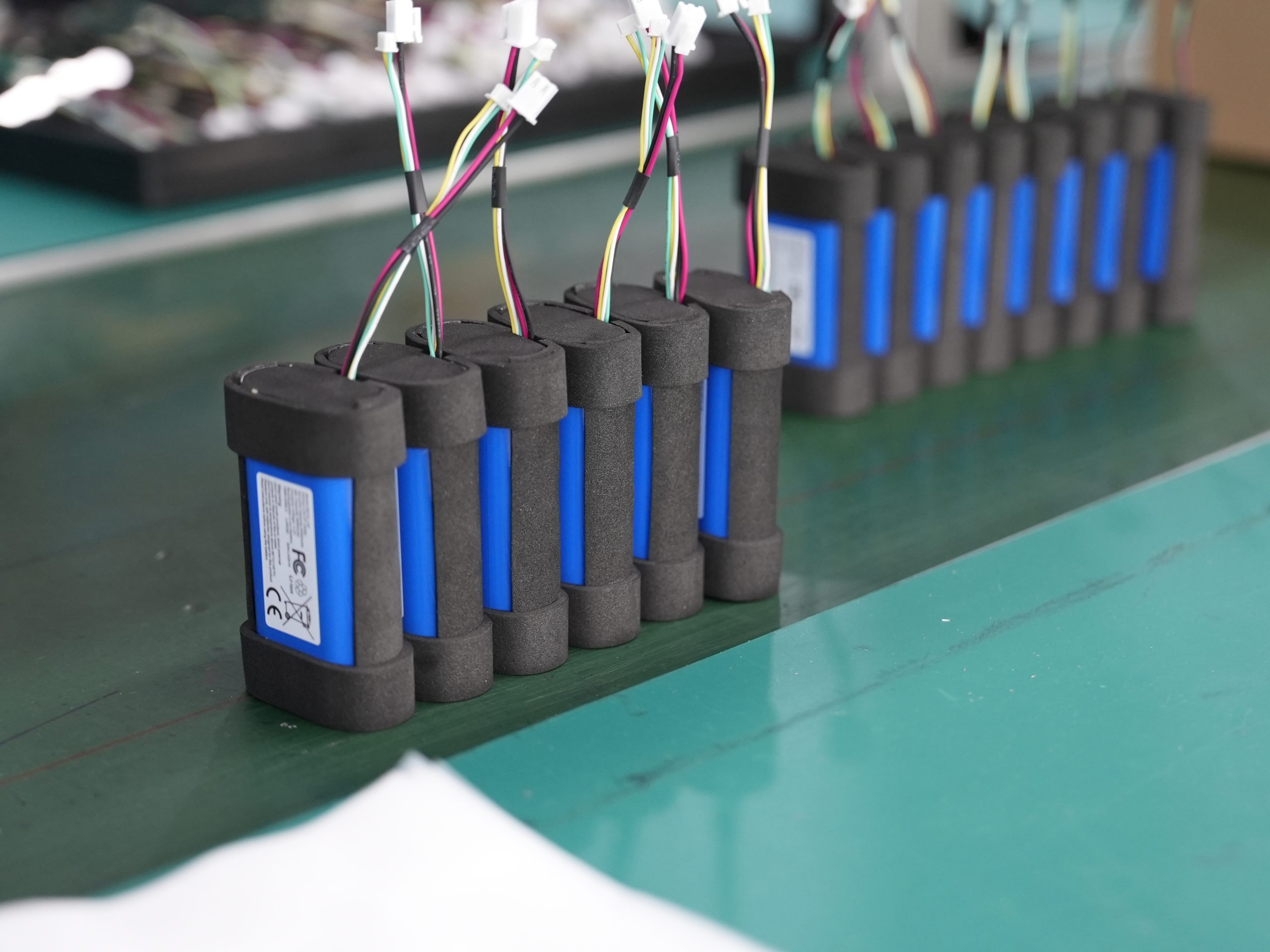

Part2: Testing and Quality Assurance in Custom Battery Packaging

2.1 Design for Safety and Quality

You must prioritize safety and quality when designing custom battery packaging for inspection and medical devices. The engineering process starts with a deep understanding of lithium battery chemistry and the unique risks it presents, such as thermal runaway, fire, or explosion. For lithium-ion battery packs, you need to integrate advanced safety features that address these hazards.

Key safety features include:

Integration of a battery management system (BMS) for temperature monitoring, current and voltage regulation, and thermal management. Explore battery management systems (BMS).

Use of robust enclosures, such as metal casings, shrink-wrap, or vacuum-formed plastic, to protect against environmental hazards and ensure user safety.

Implementation of temperature sensors and thermal management systems to monitor and dissipate heat.

Overcharge and over-discharge protection to prevent unsafe voltage levels.

Short-circuit protection using fuses, circuit breakers, and current-limiting devices.

Fire suppression measures, including fire-resistant materials and extinguishing systems for critical applications.

You must select the enclosure design based on the device’s operating environment. For example, medical devices require packaging that resists punctures and contamination, while industrial robots need shock and vibration resistance. Each design decision supports compliance with international safety standards and enhances the overall quality of your battery solution.

You also need to consider regulatory requirements for transportation and handling. The table below summarizes key international standards that govern lithium battery packaging:

Regulatory Standard | Description |

|---|---|

IATA DGR | Governs the transport of lithium-ion batteries by air, ensuring compliance is mandatory for air carriers. |

IMDG Code | Regulates the sea transportation of hazardous materials, including lithium-ion batteries. |

DOT Regulations | Oversees transportation regulations in the U.S. through Hazardous Materials Regulations (HMR). |

UN Model Regulations | Provides a standardized framework for the global transport of dangerous goods, ensuring consistency across borders. |

By engineering your battery packaging for safety and quality, you reduce the risk of failure and support the long-term reliability of your devices.

2.2 Performance Testing and Device Load Profiles

You cannot achieve international certification without rigorous testing and quality assurance. Each custom battery pack must undergo a series of performance tests that simulate real-world conditions and device load profiles. This process ensures that your battery will deliver consistent power and reliability in critical applications, such as medical diagnostics, robotics, and security systems.

Standard performance tests for lithium battery packs include:

Performance Metric | Description |

|---|---|

Specific capacity (Ah) | Measures how much charge a battery can store. |

Energy (Wh) | Indicates the total energy output available for your application. |

Cycle life | Shows how many charge-discharge cycles the battery can complete before capacity drops. |

Voltage window | Defines the safe operating voltage range for the battery. |

Coulombic efficiency (CE) | Reflects the ratio of charge output to input, impacting long-term reliability. |

Thermal stability | Assesses how well the battery resists overheating during operation or environmental tests. |

Environmental conditions | Includes temperature, humidity, and vibration resistance, vital for transportation and industrial use. |

Capacity and energy tests | Verify that the battery delivers the expected charge and energy output. |

Cycle life tests | Assess how the battery performs over repeated charge-discharge cycles. |

Environmental tests | Simulate real-world conditions such as extreme temperatures, humidity, and vibration. |

Thermal stability and abuse tests | Evaluate the battery’s resistance to overheating, short-circuiting, and mechanical stress. |

Transportation safety tests | Confirm that the battery can withstand shocks, drops, and other hazards during shipping. |

You must test prototype units under actual device load currents and temperature conditions. This approach mimics the end-use profile, validating the battery’s life expectancy and performance. Cycle life testing helps you identify potential degradation issues before the product reaches the market. These quality assurance measures ensure patient safety, device reliability, and compliance with regulations from organizations such as the FDA, ISO, or IEC.

During the design phase, you should validate safety features through:

Battery cell testing for state of health (SoH), state of charge (SoC), and capacity.

Evaluation of production circuit boards to ensure connection quality and durability.

Validation of battery management system (BMS) functions for safe monitoring of critical parameters.

You must also evaluate tolerances, enclosure design, and assembly processes to confirm that all safety features are effectively integrated. Placement of environmental, caution, and safety labels is essential for compliance and user safety.

2.3 Documentation and Traceability for Certification

You need comprehensive documentation and traceability to achieve and maintain international certification for your custom battery packaging. Proper documentation demonstrates your commitment to quality and regulatory compliance. The following table outlines the key documents required:

Title | Description |

|---|---|

Declaration of Conformity | Indicates the manufacturer responsible for the product’s conformity. |

Technical Documentation | Contains information to assess the battery’s conformity with regulations. |

Digital Battery Passport | Provides consumers with online access to specific battery information. |

Documentation on recycled content | Accompanies certain batteries to indicate their recycled content share. |

Quality system documentation | Assessed for manufacturers applying quality assurance processes. |

Traceability plays a critical role in quality assurance. You must maintain a thorough paper trail for each battery pack, tracking components from sourcing through production and delivery. This process allows you to isolate and address issues with specific batches, reducing the risk of non-compliance and costly recalls. Traceability data also supports your marketing claims and enhances customer trust during certification audits.

Labeling is another essential aspect of compliance. Your battery packaging must include:

Labeling Requirement | Description |

|---|---|

HS and UN numbers | Must reference HS and UN numbers. Class 9 for lithium (UN3480/3481). |

Lithium battery mark | Include a phone number for emergencies. |

Cargo Aircraft Only | Label if necessary for air transport. |

State of charge | Must be less than 30% for air transport. |

This Way Up arrows | Indicate the correct orientation of the package. |

Clear labeling communicates hazards and handling procedures, minimizing the risk of fire, chemical leaks, or explosions. Proper documentation and labeling are vital quality assurance measures that support ongoing certification and safe operation of your devices.

Ongoing testing and quality assurance protocols, such as those required by ISO 13485, ensure that each batch of battery packs meets strict quality management requirements. You must keep detailed records of all quality assurance activities, including supply chain management and component traceability, to maintain certification and deliver reliable power solutions for inspection and medical devices.

Tip: Consistent quality assurance and traceability not only help you pass certification audits but also strengthen your reputation as a trusted supplier of lithium battery packs for critical applications.

You ensure inspection and medical devices meet international certification by integrating custom battery packaging into your process. Custom solutions address lithium battery pack safety, quality, and compliance. For medical applications, you must follow FDA, UL, and IEC standards. Medical device manufacturers should reference the table below for compliance steps:

Compliance Aspect | Description |

|---|---|

Application-Driven Standards | Different medical applications require specific standards, such as UL 2054 for battery safety. |

Functional Safety | Medical standards demand safety analysis and redundancy from the design phase. |

Regional/Market Standards | Medical devices must meet CE, FDA, or other market-specific certifications. |

Medical device manufacturers must plan for packaging and shipping compliance, especially for lithium-based packs. You align designs with target markets and certifications to avoid delays. Medical device reliability depends on rigorous testing and documentation. Medical device recalls often result from design oversights, especially in battery placement. Medical device failures can cause market delays and damage your brand. Medical device safety improves with robust traceability and labeling. Medical device packaging must include clear hazard communication. Medical device quality assurance requires ongoing testing and recordkeeping. Medical device manufacturers benefit from enhanced safety, regulatory compliance, and improved trust. Medical device packaging must adapt to evolving standards, such as IEC 62133 and UL 2054. Medical device manufacturers should monitor updates from IEC, ANSI, and IEEE. Medical device packaging must meet FDA and international requirements. Medical device manufacturers should review the latest changes in battery safety standards. Medical device teams must integrate compliance early in the design process. Medical device packaging must support safe transport and storage. Medical device manufacturers should consult experts for custom solutions. Medical device packaging must address functional safety and redundancy. Medical device manufacturers can request a custom solution consultation for guidance.

Stay informed on new medical device battery standards to maintain compliance and competitive advantage.

FAQ

What makes Large Power’s custom battery packaging ideal for medical and robotics applications?

You get packaging that meets strict medical and robotics standards. Large Power engineers solutions for lithium-ion battery packs with full compliance and traceability.

How does Large Power ensure lithium-ion battery pack safety and certification?

You benefit from advanced battery management systems (BMS), rigorous testing, and documentation. Large Power’s process supports international standards for lithium-ion battery packs.

Can Large Power provide custom battery solutions for security and industrial devices?

You receive tailored battery packs for security and industrial applications. Large Power addresses unique requirements for safety, durability, and certification. Request a custom battery solution.