Battery systems drive the performance of Infrared Thermometers in demanding environments. You rely on robust lithium-ion and rechargeable options for consistent uptime. Features such as low battery indicators, alternate power solutions, and enhancements like LED flashlights or backlit displays improve usability and operational reliability in industrial applications.

Key Takeaways

Choose lithium batteries like NMC for higher energy density and longer shelf life. This choice reduces downtime and maintenance costs in industrial settings.

Regularly recharge built-in lithium batteries every three months. This practice prevents deep discharge damage and extends battery lifespan.

Look for infrared thermometers with usability features like low battery indicators and backlit displays. These enhancements improve operational efficiency in challenging environments.

Part1: Infrared Thermometers Battery Types and Features

1.1 Alkaline vs. Lithium Batteries

When you select Infrared Thermometers for industrial or commercial use, the choice of battery type directly impacts device performance and reliability. Alkaline and lithium batteries remain the most common options. Each offers distinct advantages and limitations in terms of energy density, shelf life, and operational suitability.

Feature | Lithium Batteries | Alkaline Batteries |

|---|---|---|

Energy Density | Higher energy density, stores more energy in the same volume or weight | Lower energy density, stores less energy in the same volume or weight |

Shelf Life | Longer shelf life, remains charged longer when not in use | Shorter shelf life, discharges more quickly, especially at high temps |

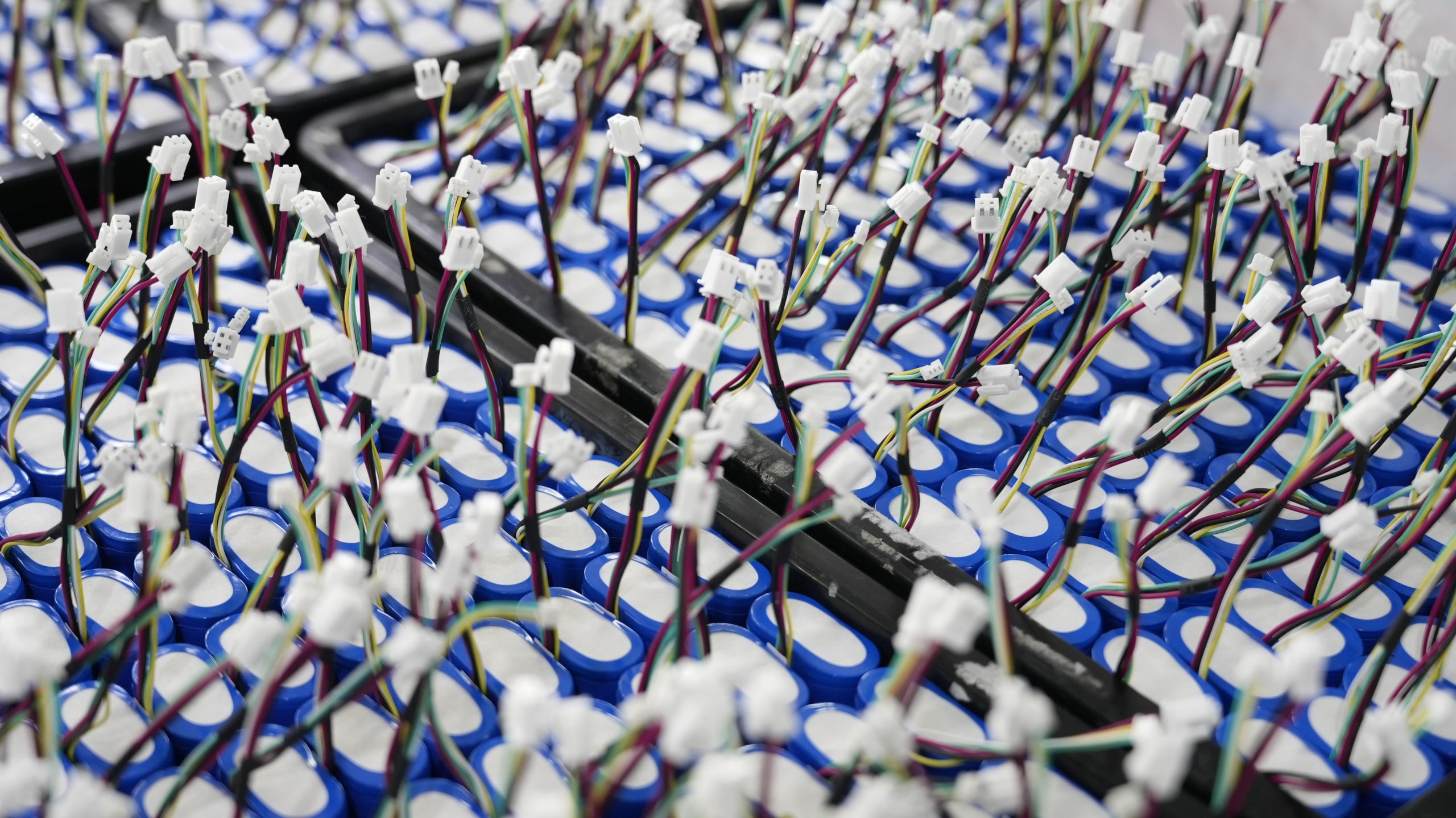

Lithium batteries, including lithium-ion, LiFePO4, and lithium-polymer (LiPo), deliver higher energy density and longer shelf life than alkaline batteries. This means you can expect longer operational periods and less frequent battery changes, which is critical in industrial settings where downtime can disrupt workflows.

Alkaline batteries, while widely available and cost-effective, tend to discharge faster and require more frequent replacement. This can increase maintenance demands and operational costs over time.

Tip: For applications in medical, robotics, security cameras, infrastructure, consumer electronics, and industrial sectors, lithium battery packs such as LiFePO4, NMC, LCO and LMO offer platform voltages from 3.2V to 3.7V, energy densities up to 260 Wh/kg, and cycle lives exceeding 2,000 cycles. These characteristics make them ideal for high-demand environments.

1.2 Rechargeable Systems and Alternate Power

Rechargeable battery systems have become the standard in modern Infrared Thermometers, especially for B2B users who prioritize sustainability and operational efficiency. The most common rechargeable chemistries include lithium-ion, lithium-polymer (LiPo), and, in some compact models, button cell batteries. Each type supports different device sizes and usage patterns.

Battery Type | Advantages |

|---|---|

AAA Batteries | Widely available and easy to replace |

AA Batteries | Used in larger thermometers requiring extended power capacity |

Button Cell Batteries | Compact and lightweight, ideal for smaller thermometers |

Lithium-ion (Li-ion) | Rechargeable, long-lasting, high energy density, stable voltage output, low self-discharge |

Lithium Polymer (LiPo) | Lightweight and flexible, suitable for compact devices like forehead thermometers |

Lithium-ion and LiFePO4 batteries stand out for their rechargeability, long cycle life, and stable voltage output. These features reduce the frequency of battery replacements and lower the total cost of ownership. Rechargeable systems also support environmental goals by minimizing battery waste, as lithium batteries can be recharged and reused many times. In contrast, single-use alkaline batteries contribute more to electronic waste and are less recyclable.

Infrared Thermometers often include usability enhancements that further improve operational efficiency:

Feature | Description |

|---|---|

Backlit Display | Enables easy reading of temperature measurements in dark environments |

LED Flashlight | Illuminates the work area, facilitating targeted measurements in low-light conditions |

Low-Battery Indicator | Alerts users when it’s time to replace or recharge the battery, preventing unexpected downtime |

Instant Readings | Displays temperature readings on a backlit LCD, making it easy to read in low light |

Built-in LED Flashlight | Enhances visibility in dark environments, aiding in accurate measurements |

These features allow you to operate Infrared Thermometers efficiently in challenging industrial environments, such as poorly lit factories or outdoor sites at night. The non-contact measurement capability ensures safety and speed, especially when checking temperatures of hard-to-reach or hazardous objects.

Note: If your operations require custom battery solutions or integration with existing power systems, consult with a lithium battery pack specialist to ensure compatibility and maximize device uptime.

Infrared Thermometers with advanced battery systems and usability features help you maintain productivity, reduce maintenance, and support sustainability initiatives across your organization.

Part2: Performance and Maintenance

2.1 Battery Life and Reliability

Battery systems play a critical role in the uptime and reliability of Infrared Thermometers in industrial environments. You depend on consistent power delivery to maintain measurement accuracy and avoid costly interruptions. Lithium battery packs, such as LiFePO4, NMC, LCO and LMO offer platform voltages from 3.2V to 3.7V, energy densities up to 260 Wh/kg, and cycle lives exceeding 2,000 cycles. These specifications ensure that your devices operate efficiently during extended shifts and demanding applications.

You can expect the following battery life performance under continuous use:

The Klein Tools IR5 model delivers up to 10 hours of continuous operation with both the laser and backlight activated.

Typical lithium batteries (300mAh–500mAh) last 2–4 weeks with regular use in commercial settings.

Features such as Bluetooth connectivity or frequent backlight usage may reduce battery life.

Tip: To maximize device uptime, select models with low battery indicators and advanced battery management systems (BMS). These features alert you before performance drops and help you plan maintenance proactively. For more information, refer to our [Battery Management Systems (BMS) guide].

Industrial users often report battery-related issues that impact reliability. The table below summarizes common faults and solutions:

Fault Type | Description | Solution |

|---|---|---|

Low battery level | Device fails to operate or displays low battery warning | Replace battery or recharge promptly |

Slow startup | Device takes longer to power on | Check battery health and replace if necessary |

Dim screen | Display brightness decreases unexpectedly | Recharge or replace battery |

Delayed readings | Measurement response slows down | Ensure battery is fully charged |

Frequent shutdowns | Device powers off unexpectedly | Inspect battery and consider replacement |

You should prioritize lithium battery packs with robust cycle life and stable voltage output to minimize downtime and maintain measurement accuracy. For sustainability and compliance, review your supplier’s [conflict minerals statement] and [sustainability practices] before procurement.

2.2 Maintenance and Replacement Tips

Proper battery maintenance extends the lifespan of your Infrared Thermometers and ensures reliable performance. You can follow these best practices to optimize battery health:

Recharge built-in lithium batteries every three months to prevent deep discharge damage.

Remove disposable batteries and store them in sealed containers to avoid leakage.

Monitor device indicators for signs of battery replacement, such as slow startup, dim screens, delayed measurements, or frequent shutdowns.

Note: Regular maintenance reduces the risk of unexpected downtime and supports your organization’s sustainability goals. For guidance on battery recycling and disposal, consult your local regulations and our [sustainability resource center].

When selecting Infrared Thermometers for your business, consider the following factors:

Battery Type and Chemistry

Choose lithium battery packs (LiFePO4, NMC, LCO, LMO, LTO) for high energy density, long cycle life, and stable voltage output.Operational Environment

Assess temperature extremes, vibration, and humidity in your facility. Select batteries rated for industrial conditions.Regulatory Compliance

Ensure batteries meet environmental and safety standards. Review documentation for conflict minerals and hazardous substances.Usability Features

Look for devices with low battery indicators, backlit displays, and integrated BMS for enhanced reliability.Custom Solutions

If your application requires unique power configurations, consult with our lithium battery pack specialists for tailored recommendations.

⚡ Alert: Battery performance directly affects device uptime and measurement accuracy. Invest in regular maintenance and select advanced lithium battery systems to support your operational efficiency.

By following these guidelines, you maintain reliable temperature measurement, reduce maintenance costs, and support sustainability initiatives across your organization. For more details on application scenarios and battery types, visit our [application scenarios page] and [battery types overview].

You improve operational reliability when you choose lithium battery packs like LiFePO4, NMC, LCO and LMO.

Evaluate platform voltage (3.2V–3.7V), energy density (up to 260 Wh/kg), and cycle life (over 2,000 cycles).

Maintain batteries regularly.

Upgrade to rechargeable systems for cost savings and sustainability.

Consult with battery specialists for custom solutions.

FAQ

What lithium battery types does Large Power recommend for infrared thermometers?

You should choose LiFePO4, NMC, LCO, LMO, or LTO packs. These offer platform voltages from 3.2V to 3.7V, energy densities up to 260 Wh/kg, and cycle lives over 2,000 cycles.

How do I extend battery life in industrial infrared thermometers?

Recharge lithium batteries regularly. Monitor low battery indicators. Store devices in moderate temperatures. Replace batteries when cycle life drops. Consult Large Power for custom battery solutions.

Tip: For tailored battery packs, visit Large Power’s custom battery solution page.

Why should my business consider custom lithium battery solutions?

Custom lithium battery packs optimize device uptime, match your operational needs, and support sustainability. Large Power provides expert consultation for B2B clients seeking reliable, long-lasting battery systems.