The evolution of nickel and NMC battery technology has revolutionized energy storage. You now rely on these batteries for EV applications and renewable energy systems. High-nickel chemistries have emerged as a game-changer, offering superior energy efficiency while reducing cobalt usage. This shift also addresses the growing battery nickel demand, ensuring sustainable and scalable solutions.

Key Takeaways

NMC 811 batteries have lots of energy, great for electric cars.

Using less cobalt in batteries helps the planet and saves money.

Recycling can get back 97% of battery materials, helping the Earth.

Part 1: Evolution of Nickel and NMC Battery Technology

1.1 Early developments in NMC batteries

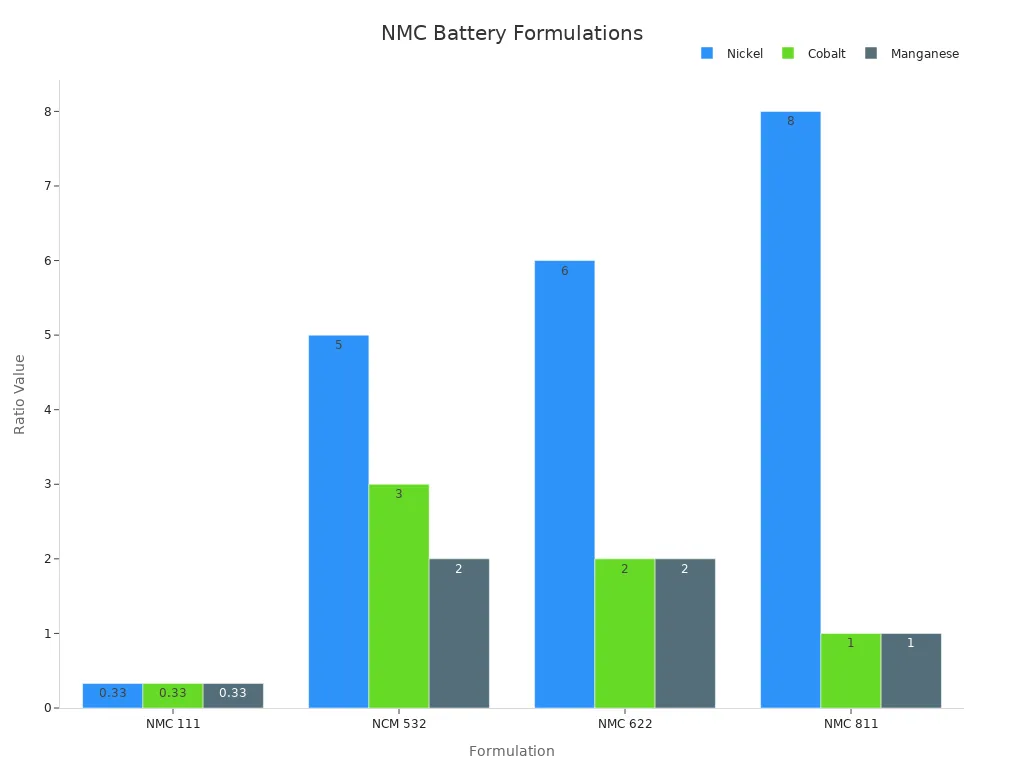

The journey of NMC batteries began with the introduction of balanced formulations like NMC 111. This early design combined nickel, cobalt, and manganese in equal proportions, offering a harmonious blend of energy density, stability, and cost-effectiveness. As the demand for better performance grew, researchers explored new formulations, leading to advancements such as NMC 532 and NMC 622. These iterations reduced cobalt content while enhancing energy density, making them more suitable for modern applications like EVs.

NMC Formulation | Nickel | Cobalt | Manganese | Characteristics |

|---|---|---|---|---|

NMC 111 | 1/3 | 1/3 | 1/3 | Balanced performance |

NMC 532 | 5 | 3 | 2 | Reduced cobalt content |

NMC 622 | 6 | 2 | 2 | High energy density |

NMC 811 | 8 | 1 | 1 | Very high energy density |

These developments laid the foundation for the high-nickel chemistries that dominate today’s battery technology.

1.2 Transition to high-nickel chemistries

The transition to high-nickel chemistries marked a pivotal moment in battery innovation. By increasing the nickel content, manufacturers achieved higher energy densities, which are critical for EV applications. Research, such as the study published on OSTI.GOV, highlights how the crystal structures of nickel-rich materials like LiNiO2 contribute to their superior performance. However, this shift also introduced challenges, including stability and safety concerns, which researchers continue to address.

1.3 Milestones in NMC 811 batteries

NMC 811 batteries represent a significant milestone in nickel and NMC battery evolution. With a composition of 80% nickel, 10% cobalt, and 10% manganese, these batteries deliver exceptional energy density and reduced reliance on cobalt. Their adoption in EVs and renewable energy systems underscores their importance in modern energy storage solutions. As you look to the future, NMC 811 batteries promise to play a central role in advancing sustainable battery technology.

Part 2: Advancements in High-Nickel NMC Batteries

2.1 Energy density improvements

High-nickel NMC batteries have redefined energy storage by significantly enhancing energy density. By increasing the nickel content in NMC 811 batteries to 80%, you achieve a remarkable improvement in energy density compared to earlier formulations like NMC 111. This advancement allows batteries to store more energy in a smaller volume, making them ideal for applications requiring compact and lightweight designs, such as robotics and consumer electronics.

These enhancements are particularly beneficial for electric vehicles (EVs), where higher energy density translates to extended driving ranges and improved performance. Additionally, industries like medical and infrastructure benefit from these advancements, as they demand reliable and efficient energy storage solutions.

2.2 Cobalt reduction and sustainability

The shift towards high-nickel chemistries also addresses the critical issue of cobalt dependency. Cobalt, often sourced from conflict regions, poses ethical and environmental challenges. By reducing cobalt content to just 10% in NMC 811 batteries, you contribute to a more sustainable and ethical supply chain. This reduction not only minimizes reliance on conflict minerals but also lowers production costs, making these batteries more economically viable.

Recent technological breakthroughs have further enhanced sustainability. For instance, the use of optimized andalusite-mullite crucibles in battery production has increased efficiency by 25% and reduced defect rates by 20%. These innovations ensure that high-nickel NMC batteries meet the growing demand for sustainable energy solutions without compromising performance.

2.3 Recycling innovations

Recycling plays a pivotal role in the lifecycle of high-nickel NMC batteries. Advanced recycling technologies not only recover valuable materials but also reduce environmental impact. Companies like Altilium have pioneered processes like EcoCathode, achieving over 97% lithium recovery from lithium-ion batteries. This process has also enabled the production of advanced NMC 622 chemistry from mixed lithium scrap, which is currently undergoing testing at Imperial College London. These innovations reduce carbon emissions by 60% and production costs by 20%, setting new benchmarks for sustainability in the battery industry.

Recycling innovations ensure that high-nickel NMC batteries remain a cornerstone of sustainable energy storage. By recovering materials like nickel, cobalt, and lithium, you can extend the lifespan of these resources and reduce the environmental footprint of battery production. This approach aligns with global efforts to create a circular economy in the energy sector.

Part 3: Challenges in High-Nickel NMC Batteries

3.1 Resource and sustainability concerns

High-nickel NMC batteries face significant challenges related to resource availability and sustainability. The materials required for these batteries, such as nickel, cobalt, and lithium, are finite and subject to supply chain risks. You may already know that the supply risk for lithium in China increased from medium-high to high between 2006 and 2022. Similarly, nickel and cobalt remain in the high-risk range, with predictions indicating continued risks over the next three years. These constraints stem from factors like environmental safety, low resource recovery rates, and high external dependencies.

Factor | Description |

|---|---|

Supply Risk Evolution | The supply risk of lithium resources in China evolved from medium-high to high from 2006 to 2022. |

High-Risk Range | Risks for manganese, nickel, and cobalt resources remain within the high-risk range. |

Future Predictions | Predictions indicate that lithium, manganese, nickel, and cobalt will continue to be in the high-risk range over the next three years. |

Significant Factors | Environmental safety, resource recovery rates, substitution rates, external dependencies, and production concentration are significant constraints on supply risks. |

Scholarly research highlights the impact of supply chain disruptions on critical metals like nickel and cobalt. For example, Zeng and Li (2015) found that such disruptions significantly affect pricing and availability. Recycling from end-of-life products, as noted by Fu et al. (2019), is essential for mitigating these risks. However, the dominance of a few countries in the supply chain, as Shi et al. (2022) observed, poses additional challenges. Ignoring potential disruptions in these regions could hinder effective risk management.

Study | Findings |

|---|---|

Zeng and Li (2015) | Disruptions in supply chains can significantly impact the availability and pricing of critical metals like nickel and cobalt. |

Fu et al. (2019); Rasmussen et al. (2019) | Recycling from end-of-life products is crucial for addressing supply chain risks. |

Shi et al. (2022) | A few countries dominate the supply chain, and ignoring potential disruptions in these countries can hinder effective risk management. |

Blengini et al. (2020) | The European Commission conducted a double-stage supply risk assessment to address these issues. |

To address these concerns, you can explore sustainable practices like improving recycling technologies and developing alternative materials. These efforts align with global sustainability goals and reduce dependency on high-risk resources.

3.2 Stability and safety issues

Stability and safety remain critical challenges in high-nickel NMC batteries. The high nickel content, while beneficial for energy density, introduces structural instability. This instability often leads to degradation mechanisms, such as the migration of transition metal ions caused by oxygen vacancies. These processes result in irreversible phase transitions, which degrade battery performance and compromise safety.

To enhance stability, researchers have developed strategies like bulk doping, surface coating, and gradient material preparation. Doping with high-valent cations, such as Ta5+ or W6+, refines the grain structure and reduces lattice strain. These methods improve structural integrity and mitigate side reactions, ensuring better performance over long cycles.

Degradation Mechanisms: Transition metal ion migration due to oxygen vacancies leads to irreversible phase transitions.

Stability Enhancement Strategies:

Bulk doping with high-valent cations like Ta5+ or W6+.

Surface coating to protect against side reactions.

Gradient material preparation to improve structural integrity.

Safety concerns also extend to thermal runaway, a phenomenon where excessive heat generation leads to uncontrollable reactions. This issue is particularly relevant in applications like EVs, where battery safety is paramount. Advanced thermal management systems and robust safety protocols are essential to mitigate these risks.

3.3 Economic and scalability challenges

The economic viability and scalability of high-nickel NMC batteries present additional hurdles. While these batteries offer superior energy density, their production costs remain high. Recycling costs, for instance, vary significantly across different NMC chemistries. NMC 111 batteries are the most costly to recycle but offer competitive profitability at $0.55 per feedstock. In contrast, NMC 532 batteries are the least costly to recycle, making them suitable for remanufacturing. NMC 811 batteries, while promising for environmental aspects, face challenges in achieving cost-effective scalability.

Market studies emphasize the need for alternative technologies to address these economic challenges. For example, Mancheri et al. (2018) noted that price hikes in critical metals influence material substitution decisions. Developing cost-effective recycling methods and exploring alternative materials can help you overcome these obstacles. Additionally, scaling up production requires significant investment in infrastructure and technology, which may deter smaller manufacturers.

Despite these challenges, high-nickel NMC batteries remain a cornerstone of modern energy storage. By addressing these economic and scalability issues, you can unlock their full potential for applications in EVs, consumer electronics, and industrial systems. Explore custom battery solutions here.

Part 4: Future Prospects for NMC 811 Batteries

4.1 Innovations in nickel-rich chemistries

Nickel-rich chemistries continue to drive advancements in lithium-ion battery technology. High-capacity nickel-based cathode materials, such as NMC 811, are pivotal for applications in electrified transportation and energy storage. Recent breakthroughs focus on improving the structural stability of nickel-rich layered oxides. Researchers have developed advanced doping techniques and surface modifications to mitigate issues like lithium impurities and oxygen vacancies, which degrade performance during cycling.

The demand for high-energy-density batteries is accelerating innovation. Novel nickel-rich cathodes are being adopted in automotive applications, offering extended range and improved efficiency. These advancements also address challenges like thermal stability, ensuring safer and more reliable batteries for critical industries such as robotics and medical devices. Explore robotics applications here.

4.2 Role of nickel in sustainable energy

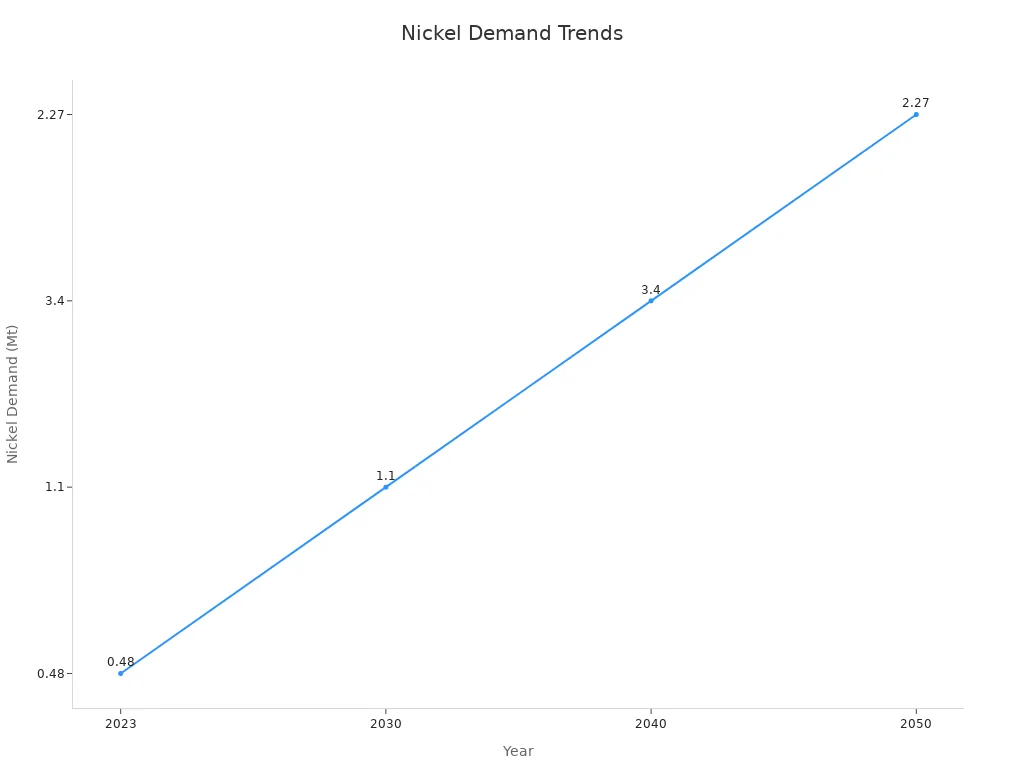

Nickel plays a significant role in advancing sustainable energy strategies. Its high energy density makes it a key driver for nickel demand in clean energy applications. Approximately 15% of global nickel production currently supports sustainable technologies, with projections indicating a surge to 2.27 million tons annually by 2050. This growth underscores nickel’s importance in meeting the rising demand for renewable energy storage and EV batteries.

To enhance sustainability, increasing end-of-life nickel recycling rates is essential. However, even with a 100% recycling rate, mining will remain necessary to meet future demand. These efforts align with global goals for sustainable battery manufacturing.

4.3 Market trends and projections

The market for nickel-rich NMC 811 batteries is poised for exponential growth. Projections estimate the Nickel Manganese Cobalt Battery Market will expand from USD 74.35 billion in 2023 to USD 594.9 billion by 2032, reflecting a compound annual growth rate (CAGR) of 26.0%. Key drivers include technological advancements and cost reductions.

By 2026, NMC 811 is expected to dominate the market due to its superior energy density and reduced cobalt dependency. These batteries will play a crucial role in industries like consumer electronics, infrastructure, and industrial systems. As the market evolves, manufacturers must focus on scalability and cost-effective production to meet growing demand.

Nickel-based NMC batteries have transformed energy storage with their high energy density and reduced cobalt dependency. Addressing challenges like stability and resource constraints will unlock their full potential. NMC 811 batteries, with their superior performance, will continue driving innovation in EV applications and sustainable energy solutions, shaping the future of clean technology.

FAQ

1. What makes NMC 811 batteries suitable for EV applications?

NMC 811 batteries offer high energy density and reduced cobalt content. These features improve driving range and sustainability, making them ideal for EVs and other energy-intensive applications.

2. How does cobalt reduction impact battery production?

Reducing cobalt lowers production costs and minimizes reliance on conflict minerals. This shift enhances sustainability while maintaining the performance of high-nickel batteries like NMC 811.

3. Can NMC 811 batteries be recycled effectively?

Yes, advanced recycling technologies recover over 97% of valuable materials like nickel and lithium. This process reduces environmental impact and supports a circular economy in battery production.

Tip: For professional guidance on recycled battery configurations, visit Large Power.