Ensuring the safety and performance of lithium batteries requires efficient testing methods. Rapid-test about lithium battery health can help you detect potential issues early, preventing costly failures. Knowing how to test lithium-ion battery capacity provides valuable insights into its reliability, making it a critical step in industrial applications.

Key Takeaways

-

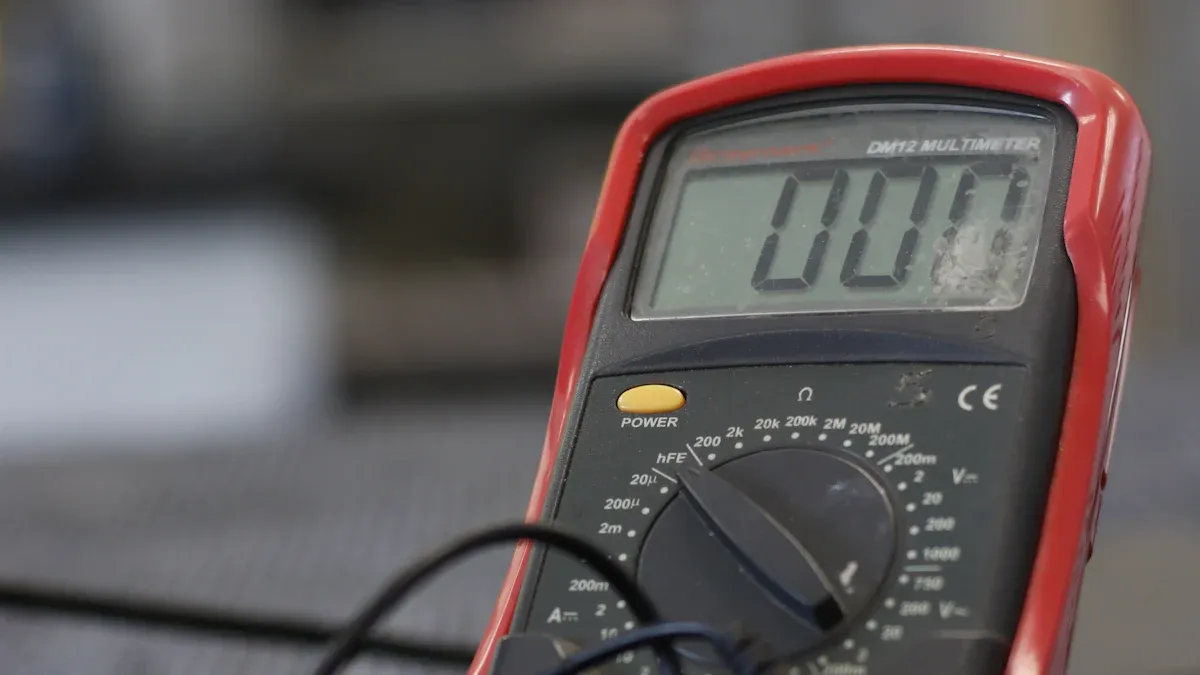

Pick the correct tools to test lithium batteries. Use a multimeter, load tester, and capacity checker for good results.

-

Stay safe while testing. Fully drain batteries, use covers, and wear safety gear to avoid harm.

-

Check battery health often with voltage checks and discharge tests. This finds problems early and keeps them working well.

Part 1: Preparation and Safety Measures for Rapid-Test About Lithium Battery

1.1 Essential Tools and Equipment for Testing Lithium-Ion Battery

To perform accurate rapid tests on lithium batteries, you need the right tools. A basic multimeter with a voltage range of 0-20V and ±0.5% accuracy is suitable for simple voltage checks. For more advanced testing, a professional multimeter with data logging and temperature probes is ideal. Load testers with adjustable loads and cooling fans are essential for conducting load tests, while capacity analyzers with programming capabilities and data export functions help you test lithium battery capacity effectively. Impedance testers with frequency sweep features are also valuable for assessing internal resistance.

Investing in high-quality equipment ensures reliable results and minimizes errors during testing lithium-ion battery capacity.

1.2 Setting Up a Safe Workspace for Testing Lithium Battery Capacity

A safe workspace is critical when testing lithium batteries. Choose a well-ventilated area free from flammable materials. Use non-conductive surfaces to prevent accidental short circuits. Ensure proper lighting to identify potential hazards. Keep fire extinguishers rated for electrical fires nearby. Organize tools and equipment to avoid clutter, reducing the risk of accidents.

1.3 Key Safety Precautions When Testing Lithium-Ion Battery

Safety should always be your top priority. Fully discharge batteries before testing to minimize overheating risks. Protect battery terminals with insulating covers to prevent short circuits. Use sturdy packaging with adequate cushioning to avoid physical damage. Clearly mark packages with required labels, such as “Class 9” or “Cargo Aircraft Only,” to indicate the presence of lithium batteries.

Wear personal protective equipment (PPE), including safety goggles and insulated gloves, to protect yourself from potential hazards. Regularly inspect tools and equipment for damage or wear. Avoid using damaged batteries, as they can pose significant risks during testing.

By following these precautions, you can safely perform capacity testing and monitor battery health without compromising safety.

Part 2: Step-by-Step Methods for Testing Lithium Battery Capacity

2.1 Voltage Measurement for Rapid-Test About Lithium Battery

Voltage measurement is a fundamental step in assessing the health and capacity of lithium-ion batteries. It provides a quick snapshot of the battery’s state of charge (SOC) and helps identify potential issues such as overcharging or deep discharging. To perform this test, you can use a multimeter or a professional battery tester. Follow these steps:

-

Prepare the Equipment: Ensure the multimeter is set to the appropriate voltage range (e.g., 0-20V for most lithium-ion batteries). If you’re using a professional battery tester, refer to the manufacturer’s guidelines.

-

Connect the Probes: Attach the positive (red) probe to the battery’s positive terminal and the negative (black) probe to the negative terminal.

-

Record the Voltage: Observe and note the voltage reading. A fully charged lithium-ion battery typically measures around 4.2V, while a discharged one may drop to 3.0V or lower.

Voltage measurement is not only quick but also effective for evaluating the state of health (SOH) of lithium batteries. By incorporating voltage measurement into your testing routine, you can monitor battery health effectively and identify early signs of degradation.

2.2 Testing Lithium Battery Capacity Using Discharge Methods

Discharge testing is a reliable way to measure battery capacity and evaluate its performance under load. This method involves discharging the battery at a controlled rate and recording the energy output until it reaches its cutoff voltage. Here’s how to test lithium battery capacity using discharge methods:

-

Set Up the Equipment: Use a battery capacity tester or a programmable load tester. Configure the device to match the battery’s specifications, including its nominal voltage and discharge rate.

-

Initiate the Discharge: Begin discharging the battery at a constant current. For example, a 1C discharge rate means the battery will be fully discharged in one hour.

-

Monitor the Process: Record the voltage and current throughout the discharge cycle. Ensure the battery does not overheat or drop below its cutoff voltage.

-

Calculate the Capacity: Multiply the discharge current by the time taken to reach the cutoff voltage. The result, measured in ampere-hours (Ah), represents the battery’s capacity.

Discharge methods reveal valuable insights into the battery’s internal resistance and thermal behavior. The testing not only helps measure battery capacity but also provides insights into its longevity and thermal stability.

2.3 Load Testing to Evaluate Lithium-Ion Battery Performance

Load testing is an essential method for assessing the performance of lithium-ion batteries under real-world conditions. This test involves applying a specific load to the battery and observing its behavior, including voltage drop and recovery. To conduct a load test:

-

Select the Load: Use a programmable load tester or a resistor bank. Set the load to match the battery’s intended application, such as powering an electric vehicle or a portable device.

-

Apply the Load: Connect the load to the battery and initiate the test. Monitor the voltage, current, and temperature throughout the process.

-

Analyze the Results: Evaluate the battery’s ability to maintain a stable voltage under load. A significant voltage drop may indicate high internal resistance or capacity loss.

Load testing provides a realistic assessment of the battery’s performance and helps identify potential issues such as overheating or voltage sag. By incorporating this method into your testing routine, you can ensure the battery meets its performance requirements and remains safe for use.

Part 3: Interpreting Results and Troubleshooting During Testing Lithium-Ion Battery

3.1 How to Assess Battery Health and Performance

Interpreting the results of lithium-ion battery tests is crucial for evaluating their health and performance. You can use several key performance indicators (KPIs) to assess the overall condition of the battery. These metrics provide insights into its capacity, efficiency, and reliability.

|

KPI Metric |

Description |

|---|---|

|

Battery Capacity Utilization |

Measures how effectively the battery’s capacity is being used. |

|

Impedance |

Indicates internal resistance, which affects energy efficiency and lifespan. |

|

Swell Rate |

Evaluates the expansion of anode material during charging cycles. |

|

Defect Rate |

Identifies the percentage of batteries that fail to meet quality standards. |

For a more advanced analysis, consider using the QuickSort™ method. This technique measures the electrochemical dynamic response of the battery and compares it against predefined parameters. QuickSort™ achieves a prediction accuracy of 9 out of 10 for most lithium-ion battery packs. Additionally, frequency domain analysis can help you differentiate between healthy and degraded batteries. Impedance readings between 1Hz and 10Hz often show significant variations, making it easier to identify issues.

By monitoring these metrics, you can estimate battery life and ensure optimal performance. Regular assessments also help you detect early signs of degradation, allowing for timely interventions.

Tip: Use tools like impedance analyzers and capacity testers to gather accurate data. These devices simplify the process of evaluating battery health and performance. For professional guidance on assessing battery health and performance, visit Large Power.

3.2 Resolving Inaccurate Readings When Testing Lithium Ion Battery

Inaccurate readings during lithium-ion battery testing can lead to incorrect conclusions about battery health. To resolve these issues, you must first identify the root cause. Common factors include equipment calibration errors, environmental conditions, and operator mistakes.

Here are some steps to address inaccurate readings:

-

Calibrate Your Equipment: Ensure all testing devices, such as multimeters and load testers, are properly calibrated. Regular calibration minimizes errors and improves measurement accuracy.

-

Control Environmental Factors: Conduct tests in a controlled environment. Temperature fluctuations and humidity can affect the accuracy of your results.

-

Verify Connections: Check all connections between the battery and testing equipment. Loose or corroded terminals can lead to inconsistent readings.

-

Use Advanced Models: Consider using models like LP+FNN, which achieve a root mean square error (RMSE) as low as 0.39°C. These models provide more reliable data compared to traditional methods.

By implementing these measures, you can reduce the likelihood of errors and obtain more reliable data. Accurate readings are essential for making informed decisions about battery maintenance and replacement. For professional guidance on resolving inaccurate readings, visit Large Power.

3.3 Addressing Common Failures in Lithium Battery Packs

Lithium battery packs can experience various failures, ranging from capacity loss to thermal runaway. Understanding these failure modes is essential for effective troubleshooting and risk mitigation.

One common issue is gas venting during thermal runaway events. The volume of gas released depends on the battery’s state of charge (SOC). For example:

|

State of Charge |

Vented Gas Volume |

Volume per Wh |

|---|---|---|

|

50% |

0.8 L / 0.2 Gal |

0.10 L/Wh |

|

100% |

2.5 L / 0.7 Gal |

0.33 L/Wh |

|

150% |

6.0 L / 1.6 Gal |

0.78 L/Wh |

The composition of these gases also varies with SOC levels. High concentrations of carbon monoxide and hydrogen pose significant safety risks. Regular monitoring and adherence to safety precautions can help you mitigate these hazards.

Another frequent problem is capacity degradation due to high internal resistance. This issue often results from poor manufacturing practices or prolonged exposure to extreme temperatures. To address this, you should:

-

Replace damaged cells promptly to prevent further degradation.

-

Use batteries with robust chemistries like LiFePO4, which offer better thermal stability and longer cycle life. Learn more about LiFePO4 batteries here.

Finally, ensure compliance with industry standards such as UN/DOT 38.3 and IEC 62133. These benchmarks define acceptable performance ranges and include tests for altitude simulation, thermal stress, and overcharging. Adhering to these standards enhances safety and reliability.

Callout: For custom battery solutions tailored to your specific needs, visit Large Power’s Custom Battery Solutions.

By addressing these common failures, you can extend the lifespan of your lithium battery packs and maintain their performance.

Proper preparation and accurate testing ensure lithium battery packs perform safely and reliably. Rapid testing identifies issues early, preventing failures. Adhering to best practices minimizes risks and enhances reliability. Industry statistics emphasize this importance:

|

Aspect |

Details |

|---|---|

|

Battery Fires |

Non-compliant lithium-ion batteries cause rising incidents in e-bikes. |

|

Safety Testing |

Prevents thermal runaway through extensive abuse testing. |

|

Performance Testing |

Ensures batteries meet voltage, temperature, and current specifications. |

Tip: For tailored battery solutions, explore Large Power’s Custom Battery Solutions.

FAQ

1. What is the ideal temperature range for testing lithium batteries?

Testing lithium batteries works best between 20°C and 25°C. Extreme temperatures can distort results and damage the battery. Always maintain a controlled environment for accurate testing.

2. How can you prevent thermal runaway during testing?

Use batteries with stable chemistries like LiFePO4. Monitor temperature and voltage closely to avoid overheating or overcharging.

3. Why should you choose Large Power for custom battery solutions?

Large Power offers tailored solutions for industrial lithium battery needs. Their expertise ensures safety, reliability, and compliance.