Choosing the right lithium battery terminal is essential for maintaining performance and ensuring safety. You face challenges when trying to identify lithium battery terminals that match your system’s charging needs. Using proper battery terminals prevents issues like overheating or poor connections. Matching lithium battery connectors with your application guarantees reliability. Always follow safety precautions and best practices for installation to optimize functionality.

Key Takeaways

Picking the right lithium battery terminal is important for safety. Make sure it matches your battery type and voltage to avoid problems.

Terminals like bolt-on and quick-connect are made for certain uses. Choose one based on how much power you need and how easy it is to use.

Check your battery terminals often for rust or damage. Doing this helps them last longer and work better.

Part 1: Understanding Lithium Battery Terminals

1.1 What Are Lithium Battery Terminals?

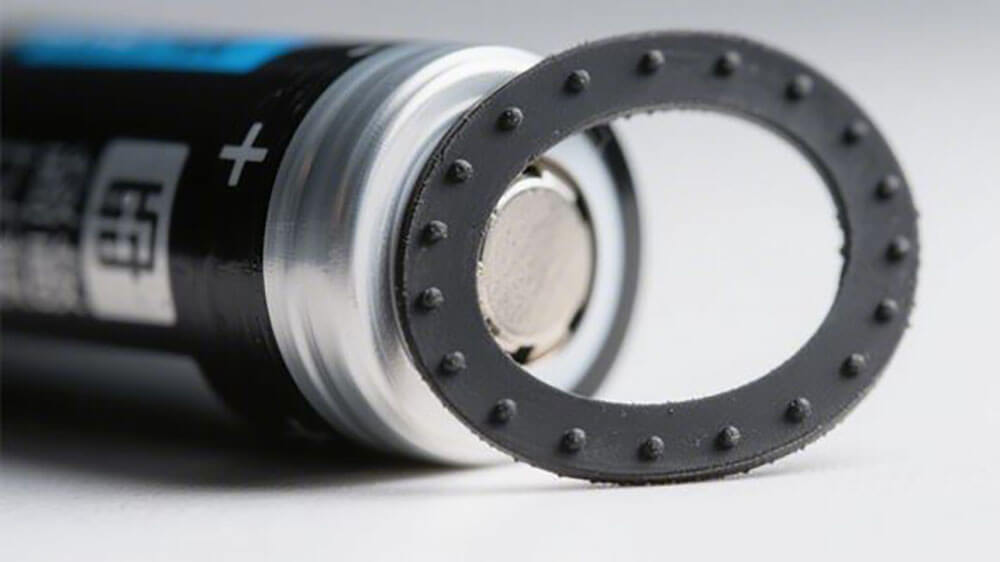

Lithium battery terminals are the critical connection points that allow electrical current to flow into and out of the battery. These terminals consist of a positive terminal and a negative terminal, each serving distinct roles in the charging and discharging process. The positive terminal connects to the device or system requiring power, while the negative terminal completes the circuit, enabling efficient energy transfer.

Tip: Always ensure proper alignment of connectors and cables with the positive and negative terminals to avoid short circuits or performance issues.

Different types of lithium battery terminals exist to suit various applications. Common examples include stud terminals, blade terminals, post terminals, and ring terminals. Each type offers unique features, such as secure connections for high-current applications or easy connectivity for smaller devices. Selecting the right terminal type ensures compatibility with your lithium-ion battery and its intended use.

1.2 Key Functions of Battery Terminals in Lithium Battery Packs

Battery terminals play a vital role in maintaining the performance and safety of lithium-ion batteries. Their primary function is to facilitate the flow of electrical current between the battery and the connected device. Properly designed terminals ensure minimal resistance, reducing energy loss during charging and discharging cycles.

The terminals also contribute to the longevity of lithium battery packs. Secure connections prevent overheating and inefficiencies, which can degrade the battery over time. Additionally, well-maintained connectors and cables protect against corrosion, ensuring reliable operation in various environments.

1.3 Common Materials for Lithium Battery Connectors

The materials used for lithium battery connectors significantly impact their performance and durability. Copper and aluminum are the most common choices due to their excellent conductivity and lightweight properties. Copper offers superior electrical performance, making it ideal for high-drain applications, while aluminum provides a cost-effective alternative for less demanding uses.

Material | Properties | Ideal Applications |

|---|---|---|

Copper | High conductivity, durable | High-drain devices, EV batteries |

Aluminum | Lightweight, cost-effective | Low-drain devices, portable gadgets |

Research continues to explore advanced materials and coatings to enhance the efficiency and lifespan of lithium battery terminals. Innovations in ultrasonic welding and connector designs aim to reduce resistance and improve mechanical stability, ensuring optimal performance across diverse applications.

Part 2: Types of Lithium Battery Terminals

2.1 Bolt-On Terminals: Features and Applications

Bolt-on terminals are among the most commonly used lithium battery terminals due to their secure and reliable connections. These terminals feature a bolt mechanism that fastens the connector to the battery, ensuring a tight and stable fit. This design minimizes the risk of loose connections, which can lead to overheating or inefficient energy transfer.

You will often find bolt-on terminals in applications requiring high current flow, such as electric vehicles (EVs) and industrial machinery. Their robust construction makes them suitable for environments where vibration and mechanical stress are common. Additionally, bolt-on terminals are compatible with various connector types, including ring and spade connectors, offering flexibility for different setups.

Tip: Always ensure the bolt is tightened to the manufacturer’s specifications to avoid damaging the terminal or the battery.

Terminal Type | Conductivity | Corrosion Resistance | Mechanical Strength | Heat Resistance |

|---|---|---|---|---|

Brass | High | Moderate | Moderate | Moderate |

Nickel | High | High | High | High |

Copper | High | High | Moderate | High |

2.2 Stud Terminals: Features and Applications

Stud terminals are another popular choice for lithium-ion batteries, particularly in applications requiring quick and easy installation. These terminals consist of a threaded stud that allows you to attach connectors and cables using nuts or washers. The simplicity of this design makes it ideal for systems that require frequent maintenance or component replacement.

Stud terminals are commonly used in energy storage systems and backup power supplies. Their ability to handle moderate to high currents makes them versatile for various applications. However, they may not provide the same level of mechanical stability as bolt-on terminals, especially in high-vibration environments.

Terminal Type | Specifications | Seismic Resistance | Electrical Conductivity | Recommendations |

|---|---|---|---|---|

Welding studs (A type) | M6*10mm | Average | Average | Suitable for small current energy storage use |

Welding aluminum blocks (B type) | M6*11mm | Great | Great | Suitable for projects requiring high current and good seismic resistance |

2.3 Quick-Connect Terminals: Features and Applications

Quick-connect terminals are designed for convenience and speed. These terminals allow you to connect and disconnect the battery without the need for tools, making them ideal for portable devices and applications where mobility is essential. Quick-connect terminals often use a clip or slide mechanism to secure the connector, ensuring a firm connection while allowing for easy removal.

You will find quick-connect terminals in consumer electronics, medical devices, and other low-current applications. While they offer unmatched ease of use, they may not be suitable for high-current or high-vibration environments due to their less robust design.

Note: Regularly inspect quick-connect terminals for wear and tear, as their frequent use can lead to mechanical degradation over time.

2.4 Specialty Terminals for Custom Battery Packs

Specialty terminals are tailored for unique applications that standard terminals cannot accommodate. These terminals are often used in custom lithium-ion battery packs designed for specific industries, such as aerospace, defense, or advanced research. Specialty terminals may include features like enhanced corrosion resistance, high-temperature tolerance, or compatibility with emerging battery technologies like solid-state or lithium-sulfur batteries.

The growing demand for high-performance battery terminal connectors in industrial applications has driven innovation in this area. For example, the electric vehicle market’s expansion has increased the need for terminals that can handle high power levels while maintaining reliability. Similarly, the push for sustainability has led to the development of environmentally friendly terminal materials and designs.

Callout: When selecting specialty terminals, consult with Large Power to ensure compatibility with your battery type and application requirements.

Part 3: Choosing the Right Lithium Battery Terminal

3.1 Compatibility with Battery Type and Voltage

Selecting the right battery terminal begins with ensuring compatibility with your lithium-ion battery’s type and voltage. Different lithium batteries, such as Li-ion, LiPo, and LiFePO4, have unique voltage requirements that influence the choice of terminals. Matching the terminal to the battery’s voltage ensures safe and efficient charging while preventing potential damage to the battery or connected devices.

Charge Voltage:

Li-ion Batteries: 4.2 to 4.3 volts per cell.

LiPo Batteries: 4.2 to 4.3 volts per cell.

LiFePO4 Batteries: 3.6 to 3.8 volts per cell.

When choosing a terminal, ensure it supports the voltage range of your battery. For example, a terminal designed for LiFePO4 batteries may not perform optimally with Li-ion batteries due to differences in voltage thresholds. Always verify that the terminal’s specifications align with your battery’s requirements to maintain a secure connection and reliable power transfer.

Tip: Double-check the voltage compatibility of your battery terminal before installation to avoid operational issues.

3.2 Application-Specific Requirements for Battery Terminal Connectors

The application of your lithium-ion battery significantly impacts the choice of battery terminal connectors. Different industries and devices demand specific features to ensure optimal performance and durability. For instance, electric vehicles (EVs) require terminals that can handle high currents and withstand mechanical stress, while portable devices prioritize lightweight and compact designs.

Standard | Description |

|---|---|

UL 1977 | Performance and safety for electrical connectors. |

ISO 6469 | EV-specific electrical and mechanical safety requirements. |

SAE J1772 | Guidelines for EV charging interfaces. |

In addition to adhering to industry standards, consider the following factors:

Optimized Shapes and Sizes: Compact designs improve space efficiency in portable devices.

Hybrid Material Combinations: High-current paths benefit from materials like copper-nickel composites, which reduce thermal degradation by 25% compared to nickel-copper alternatives.

Callout: Applications with frequent maintenance needs, such as backup power systems, benefit from stud terminals due to their ease of installation and replacement.

3.3 Environmental Factors: Corrosion Resistance and Durability

Environmental conditions play a crucial role in determining the best battery terminal for your application. Exposure to moisture, temperature fluctuations, and corrosive elements can degrade connectors and cables, leading to poor performance or failure. Choosing terminals with high corrosion resistance and durability ensures long-term reliability.

Copper and nickel-plated connectors offer excellent resistance to corrosion, making them ideal for outdoor or marine applications. For high-temperature environments, terminals with heat-resistant coatings provide added protection. Additionally, proper installation techniques, such as tightening bolts to the manufacturer’s specifications, enhance the terminal’s lifespan by preventing loose connections.

Note: Regularly inspect your battery terminals for signs of wear or corrosion to maintain a secure connection and prevent power transfer issues.

Choosing the right lithium battery terminals is essential for optimizing performance and ensuring safety. Proper selection enhances energy efficiency, prevents operational issues, and extends battery life. You should evaluate compatibility, application needs, and environmental conditions when selecting battery terminal connectors.

By considering the factors about your battery pack with Large Power, you can ensure the reliability and longevity of your battery terminal connectors.

FAQ

1. What is the best way to prevent corrosion on battery terminals?

Apply a thin layer of dielectric grease or anti-corrosion spray to the terminals. This protects them from moisture and environmental damage, ensuring long-term reliability.

Tip: Regularly clean terminals with a baking soda solution to remove corrosion buildup.

2. Can I use any terminal type for my lithium battery?

No, you must select a terminal compatible with your battery type, voltage, and application. Using the wrong terminal can lead to poor performance or safety risks. For professional guidance on sterminal type for your lithium battery, visit Large Power.

3. How often should I inspect my battery terminals?

Inspect your battery terminals every 3-6 months. Look for signs of corrosion, loose connections, or wear to ensure optimal performance and prevent potential failures.

Note: Frequent inspections are crucial for batteries in harsh environments or high-vibration applications.