The vibration test of lithium batteries evaluates their ability to withstand mechanical vibrations during transportation or operation. It ensures safety by identifying vulnerabilities like internal short circuits or casing failures. Compliance with standards such as UN 38.3 T3 demonstrates reliability and guarantees performance under real-world conditions, making this test essential for industrial and consumer applications.

Key Takeaways

Vibration testing checks if lithium batteries handle shakes and bumps. This helps make them safer and more reliable.

Proper tools, like a vibration test bench and charge tester, are needed. These tools give correct results and meet industry rules.

Following rules like UN 38.3 keeps you legal. It also shows the batteries are strong and safe.

Part 1: Preparation for the Vibration Test of Lithium Batteries

1.1 Equipment and Tools for Testing

To conduct a reliable vibration test of lithium batteries, you need specialized equipment designed to simulate real-world mechanical stresses.

Key Considerations for Equipment:

Accurate Signal Transmission: Ensure the vibration signal reaches the battery sample without distortion or deformation.

Multi-Directional Testing: Conduct tests in three mutually perpendicular directions to account for irregular battery shapes.

Post-Test Procedures: Perform a discharge-charging cycle after vibration testing to evaluate battery performance.

Testing Workflow:

Simulate transportation vibrations using a sine sweep from 7Hz to 200Hz over 15 minutes.

Execute 12 sweeps over 3 hours in three mutually perpendicular axes.

Monitor battery parameters such as voltage, temperature, and internal resistance during testing.

1.2 Compliance Standards and Their Relevance

Compliance with international standards ensures the safety and reliability of lithium batteries during transportation and operation. These standards define the parameters for vibration testing, including frequency ranges, amplitudes, and test durations.

Common Standards:

UN 38.3: Focuses on transportation safety. Requires testing across 7Hz–200Hz frequency range with specific amplitude and acceleration values.

IEC 62660-2: Targets automotive applications. Includes high-frequency testing up to 2000Hz with acceleration up to 30g.

UL 1642: Ensures consumer electronics safety. Specifies vibration testing at 10Hz–55Hz with a displacement amplitude of 0.8mm.

Tip: Adhering to these standards not only ensures regulatory compliance but also enhances customer trust in your product’s durability and safety.

1.3 Test Setup and Preconditioning

Proper test setup and preconditioning are critical for obtaining accurate results during vibration analysis. Follow these steps to prepare:

Test Setup:

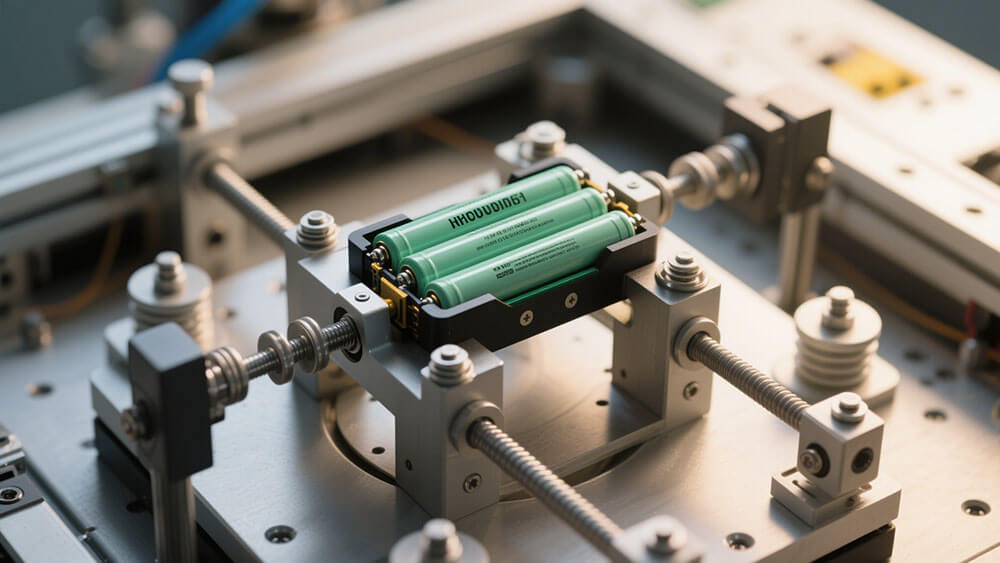

Secure the battery on the vibration test bench using a rigid fixture to prevent movement during testing.

Configure the vibration parameters (frequency, amplitude, and sweep rate) based on the chosen standard.

Ensure the testing environment matches real-world conditions, including temperature and humidity.

Preconditioning:

Stabilize the battery at room temperature for at least 24 hours before testing.

Fully charge or discharge the battery to its nominal state to simulate operational conditions.

Inspect the battery for any pre-existing damage or defects.

Note: Preconditioning helps eliminate variables that could skew test results, ensuring the vibration test accurately reflects the battery’s mechanical stability.

Part 2: Conducting the Vibration Test of Lithium Batteries

2.1 Sinusoidal and Random Vibration Testing

When performing the vibration test of lithium batteries, you must choose between sinusoidal and random vibration testing methods. Each method serves distinct purposes and provides unique insights into battery performance.

Vibration Type | Characteristics | Applications | Implications for Battery Performance Evaluation |

|---|---|---|---|

Sine Vibration | Periodic, can be fixed or sweep frequency, simulates fixed-speed machinery. | Testing resistance to resonance frequency and predetermined frequency. | Can identify structural weaknesses at specific frequencies. |

Random Vibration | Irregular waveform, reflects real-world conditions, statistically expressed. | Better simulates transportation and operational vibrations. | More accurately assesses overall vibration resistance and durability. |

Sinusoidal vibration testing is ideal for identifying resonance frequencies and evaluating structural integrity at specific points. For example, it helps detect weak spots that may fail under repetitive stress. On the other hand, random vibration testing better replicates real-world conditions, such as those encountered during transportation or industrial operations. This method provides a comprehensive assessment of the battery’s durability and overall vibration resistance.

Tip: Use random vibration testing for applications like transportation or robotics, where batteries face unpredictable mechanical stresses. For fixed-speed machinery, sinusoidal testing may suffice.

2.2 Frequency Ranges and Axial Testing

Frequency ranges and axial testing play a critical role in vibration analysis. Numerical analyses reveal that resonance frequencies and structural responses vary significantly under different loading conditions. For instance, the UN 38.3 T3 standard mandates that lithium batteries withstand sinusoidal vibration tests from 7 Hz to 200 Hz without failure. This range effectively simulates the mechanical stresses experienced during transportation.

Numerical analyses help identify resonance frequencies and assess structural responses under specific loading conditions.

The UN 38.3 T3 standard requires battery modules to withstand sinusoidal vibration tests from 7 Hz to 200 Hz without failure.

SimScale allows for virtual testing, enabling designers to analyze potential resonant behavior and structural responses before physical testing.

Axial testing ensures that the battery’s performance is evaluated across all three mutually perpendicular axes (X, Y, and Z). This approach accounts for the irregular shapes and mounting orientations of lithium batteries in real-world applications. Each axis undergoes testing for a specified duration, typically three hours, to ensure comprehensive evaluation.

Note: Always configure the vibration test parameters according to the relevant vibration test standards. This ensures compliance and provides reliable data for performance evaluation.

2.3 Environmental Conditions and Test Duration

The environmental conditions for vibration testing must be tailored to specific standards and application scenarios, primarily involving two parameters: temperature and humidity. For temperature conditions, ambient testing is typically conducted at room temperature (20°C–25°C) as a default across most standards. However, high/low-temperature testing may be required under specialized standards or scenarios: high-temperature environments (e.g., 40°C to simulate extreme heat in tropical regions or high-load operation of equipment), low-temperature environments (e.g., -20°C to replicate cold climates or low-temperature storage), and temperature cycling (where vibration is combined with temperature variations, such as in automotive battery testing).

Regarding humidity, most standards do not mandate strict humidity control but emphasize maintaining a condensation-free environment to prevent moisture-induced performance degradation. Exceptions exist for specialized applications, such as outdoor energy storage systems, which may require testing under high-humidity conditions (85% RH) to validate reliability in damp or coastal environments. These parameters ensure that vibration tests accurately reflect real-world operational stresses while safeguarding battery integrity and safety.

Part 3: Interpreting Results and Ensuring Compliance

3.1 Evaluating Structural Integrity and Failures

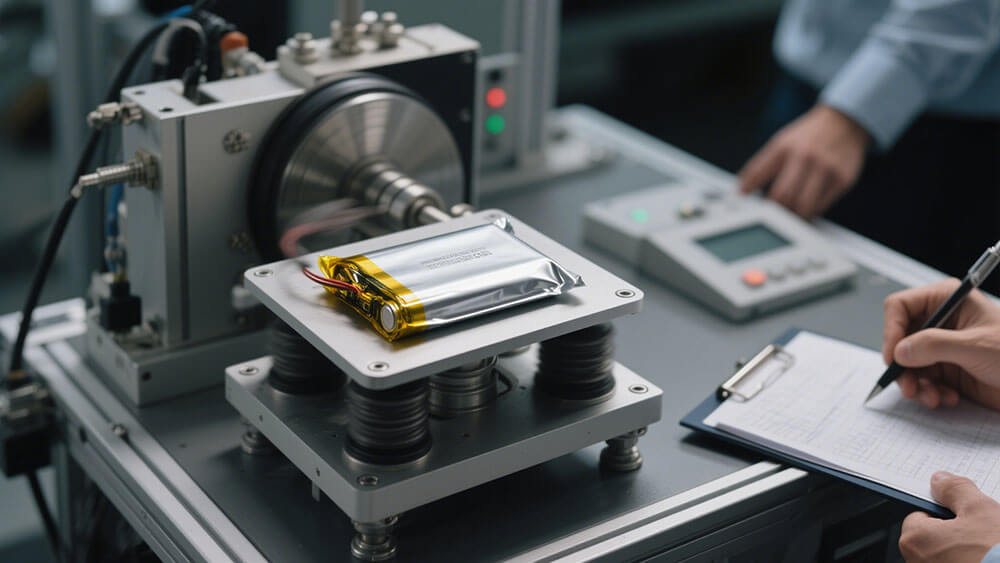

Interpreting the results of vibration testing begins with assessing the structural integrity of the lithium battery. You should carefully examine the battery for physical damage, such as cracks, leaks, or deformation, which could compromise its safety and performance. Mechanical testing, including drop tests, crush tests, and vibration tests, simulates real-world conditions to evaluate the battery’s durability. These procedures ensure the battery can withstand everyday handling, transportation, and operational stresses without failure.

Key aspects to monitor during evaluation include:

External Damage: Inspect for casing cracks, leaks, or visible deformation.

Internal Stability: Check for signs of internal short circuits or electrode misalignment.

Performance Metrics: Measure voltage, capacity retention, and internal resistance post-testing.

Tip: If you detect abnormalities, conduct a root cause analysis to identify potential design flaws or material weaknesses.

3.2 Verifying Compliance with Standards

Compliance verification ensures that your lithium batteries meet industry safety and performance standards. Testing protocols like those outlined in UN 38.3 and UL 1642 provide benchmarks for evaluating battery reliability under mechanical stress. These standards help you confirm that the battery can endure transportation and operational conditions without posing safety risks.

To verify compliance:

Compare test results with the parameters specified in the relevant standard.

Document findings, including any deviations or failures.

Implement corrective actions if the battery does not meet the required criteria.

Note: Adhering to these standards not only ensures regulatory approval but also enhances customer confidence in your product’s quality.

3.3 Common Vibration Test Standards for Lithium Batteries

Several standards govern the vibration testing of lithium batteries, each tailored to specific applications and industries. Below is a summary of the most widely recognized standards:

Standard | Application | Key Testing Parameters |

|---|---|---|

UN 38.3 | Transportation safety | Frequency: 7Hz–200Hz; Amplitude: 1.5mm; Acceleration: 15g; Duration: 3 hours per axis. |

IEC 62660-2 | Automotive applications | Frequency: 10Hz–2000Hz; Acceleration: 30g; Duration: 8 hours per axis. |

UL 1642 | Consumer electronics safety | Frequency: 10Hz–55Hz; Displacement: 0.8mm; Duration: 90 minutes per axis. |

These standards provide a framework for ensuring the safety and reliability of lithium batteries across diverse applications, from consumer electronics to industrial and automotive sectors.

Vibration testing ensures lithium batteries meet safety standards like UN 38.3, mitigating risks such as leakage or fire during transportation. Accurate testing identifies structural weaknesses, enhancing reliability. By simulating real-world conditions, this process guarantees durability across applications, from consumer electronics to industrial sectors. Explore custom battery solutions for tailored testing and compliance.

FAQ

1. What is the purpose of vibration testing for lithium batteries?

Vibration testing ensures lithium batteries can withstand mechanical stresses during transportation or operation. It identifies structural weaknesses, ensuring safety and reliability in real-world applications.

2. How does vibration testing differ for consumer electronics and industrial batteries?

Application | Frequency Range | Duration | Key Focus |

|---|---|---|---|

Consumer Electronics | 10Hz–55Hz | 90 minutes/axis | Durability under light stresses. |

Industrial | 5Hz–200Hz | 12 hours/axis | Resistance to heavy vibrations. |

Tip: Learn more about consumer electronics and industrial battery solutions.

3. Why choose Large Power for custom battery solutions?

Large Power offers tailored vibration testing and compliance services. Ensure your batteries meet industry standards. Explore our custom battery solutions today.