Internal short circuits in lithium batteries can arise from various factors, including material impurities, manufacturing inconsistencies, and environmental stressors. These issues disrupt the battery’s internal structure, leading to safety risks and reduced efficiency. For applications in sectors like medical devices, robotics, and consumer electronics, understanding the root causes of an internal short circuit about lithium battery systems is essential to ensure optimal performance and reliability.

Key Takeaways

Tiny impurities in battery parts can cause short circuits. Pick batteries from trusted suppliers with good quality checks to avoid this.

Lithium spikes may grow during charging and harm separators, leading to short circuits. Use batteries with better separator materials for more safety.

Things like very hot or cold temperatures and moisture can make batteries unsafe. Choose batteries built to last and sealed well to stop these problems.

Part 1: Material Impurities and Their Role in Internal Short Circuits

1.1 Contaminants in Battery Electrodes

Material impurities in battery electrodes often act as a catalyst for internal short circuits. When you examine lithium-ion batteries, contaminants such as metal particles or dust can infiltrate the electrode layers during manufacturing. These foreign particles disrupt the uniform flow of ions, creating localized hotspots that may lead to thermal runaway. For example, in medical devices, where precision and reliability are paramount, even minor contamination can compromise battery safety and performance.

To mitigate this risk, manufacturers employ advanced filtration systems and cleanroom environments during electrode production. However, challenges persist, especially in high-volume production settings. You should prioritize sourcing batteries from suppliers with stringent quality control measures to ensure minimal contamination.

1.2 Impurities in Electrolyte Solutions

Electrolyte solutions play a critical role in lithium battery functionality, acting as the medium for ion transport between electrodes. Impurities such as water molecules or unwanted chemical residues can alter the electrolyte’s conductivity. This alteration increases the likelihood of an internal short circuit about lithium battery systems, particularly in applications like robotics, where consistent energy delivery is essential.

You can address this issue by selecting batteries with high-purity electrolytes. Manufacturers often use advanced purification techniques, such as vacuum distillation, to remove impurities. Additionally, regular testing of electrolyte composition ensures compliance with industry standards, reducing the risk of performance degradation.

1.3 Lithium Dendrite Formation and Separator Damage

Lithium dendrites are needle-like structures that form on the battery’s anode during repeated charging cycles. These dendrites can pierce the separator, a thin membrane designed to prevent direct contact between the anode and cathode. Once the separator is compromised, an internal short circuit occurs, posing significant safety risks. This phenomenon is particularly concerning in consumer electronics, where compact designs often exacerbate dendrite formation.

To combat dendrite formation, you should consider batteries with advanced separator materials, such as ceramic-coated membranes. These separators offer enhanced durability and resistance to punctures. Additionally, adopting charging protocols that limit high current rates can reduce dendrite growth, extending battery lifespan and safety.

Part 2: Manufacturing Defects Leading to Internal Short Circuits

2.1 Defects in Separator Materials

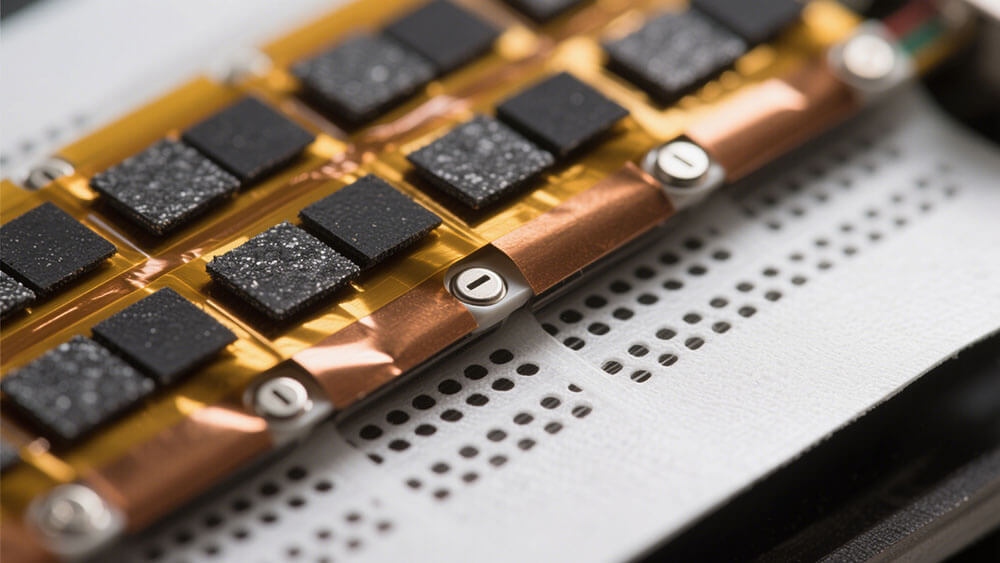

Separator materials play a crucial role in preventing direct contact between the anode and cathode in lithium-ion batteries. However, defects in these materials can compromise their integrity, leading to internal short circuits. Common issues include uneven thickness, pinholes, or weak spots in the separator. These flaws allow lithium dendrites to penetrate the separator, creating a direct pathway for electrical contact.

In high-demand applications like robotics, where batteries endure frequent charge-discharge cycles, such defects can result in catastrophic failures. Manufacturers often employ advanced coating technologies, such as ceramic layers, to enhance separator durability. Despite these measures, defects remain a challenge due to the complexity of large-scale production.

Tip: When selecting batteries for critical applications, prioritize those with separators tested for high puncture resistance and thermal stability. This ensures better safety and performance under demanding conditions.

2.2 Contamination During Assembly

Contamination during the assembly process is another significant contributor to internal short circuits. Dust particles, metal shavings, or other foreign materials can become trapped within the battery cell. These contaminants disrupt the uniform flow of ions, leading to localized heating and potential short circuits.

The lithium-ion cell industry has made strides in minimizing contamination by adopting cleanroom environments and automated assembly lines. However, latent defects caused by microscopic contaminants still pose risks. For example, in medical devices, where battery reliability is non-negotiable, even minor contamination can jeopardize device functionality.

Key statistics highlight the impact of contamination:

Internal short circuits caused by assembly defects are rare but can lead to severe field failures.

The internal short circuit device (ISC-D) is widely used to simulate and study these failures, providing valuable insights for manufacturers.

To mitigate these risks, you should source batteries from manufacturers with stringent quality assurance protocols. Regular inspections and advanced imaging techniques, such as X-ray scanning, help detect and eliminate contaminants during production.

2.3 Challenges in Quality Control Processes

Ensuring consistent quality in lithium battery production is a complex task. Detecting latent defects, such as micro-cracks or uneven electrode coatings, requires sophisticated testing methods. Quality control processes often rely on metrics like impedance measurements, thermal imaging, and electrochemical analysis to identify potential issues.

Despite these efforts, challenges persist. For instance, high production volumes can strain quality control systems, increasing the likelihood of defective cells entering the market. In industrial applications, where batteries power critical infrastructure, such defects can lead to costly downtime or safety hazards.

Common quality assurance techniques include:

Visual inspections to identify surface defects.

Electrochemical testing to assess cell performance.

Thermal imaging to detect hotspots caused by internal short circuits.

Investing in advanced quality control technologies is essential for reducing defect rates. Manufacturers must also prioritize employee training to ensure adherence to best practices during production. By addressing these challenges, you can enhance the reliability and safety of lithium batteries across various applications.

Part 3: Environmental Factors Affecting Lithium Battery Safety

3.1 High and Low Temperature Exposure

Temperature extremes significantly impact lithium battery performance and safety. Cold temperatures reduce capacity and efficiency, while high temperatures enhance performance but increase the risk of damage and shorten lifespan. For instance, a battery operating at full capacity at 27°C (80°F) may deliver only 50% capacity at -18°C (0°F). At -20°C (-4°F), most batteries function at half their capacity. Effective thermal management is essential to maintain safety and performance.

A study highlights that lithium-ion batteries operating between 25°C and 55°C experience degradation, especially at higher temperatures. This degradation primarily affects the electrodes, with the LCO cathode deteriorating more than the graphite anode. You can mitigate these risks by using batteries with advanced thermal management systems, particularly in robotics applications where consistent energy delivery is critical.

3.2 Mechanical Stress and Vibration

Mechanical stress and vibration can compromise the structural integrity of lithium batteries. These factors often occur in industrial and transportation applications, where batteries endure constant movement and shocks. Over time, such stress can damage internal components, leading to an internal short circuit about lithium battery systems.

For example, mechanical shocks during waste processing, such as compaction or shredding, can initiate internal short circuits. Elevated temperatures from exothermic reactions further exacerbate these risks. To address this, you should select batteries designed for high durability, with reinforced casings and vibration-resistant materials. Regular inspections and proper mounting techniques also help minimize mechanical stress.

3.3 Moisture and Dust Ingress

Moisture and dust ingress pose significant threats to lithium battery safety. When moisture enters a battery, it reacts with the electrolyte, causing gas formation and pressure buildup. Dust particles, on the other hand, can create conductive pathways, increasing the likelihood of short circuits.

Environmental exposure during storage or operation often leads to these issues. For instance, batteries used in infrastructure projects may face harsh conditions, including high humidity and dust. To prevent ingress, you should use batteries with robust sealing and IP-rated enclosures. Additionally, storing batteries in controlled environments reduces exposure to harmful elements.

Internal short circuits in lithium-ion batteries stem from multiple factors, including material impurities, manufacturing defects, and environmental stressors. These issues can lead to severe safety risks, especially in critical applications like medical devices and robotics.

Preventing these risks requires strict quality control and proper handling. Industry reports recommend:

Conducting in-depth risk assessments to identify potential threats in manufacturing.

Maintaining high-quality standards across the battery supply chain.

Implementing rigorous inspections and compliance with safety regulations.

Manufacturers and users must collaborate to enhance battery safety and performance. For custom battery solutions tailored to your needs, visit Large Power.

FAQ

1. What are the most common signs of an internal short circuit in lithium batteries?

Rapid overheating

Sudden voltage drops

Swelling or deformation

Tip: If you notice these signs, stop using the battery immediately to prevent further damage or safety risks.

2. How can you prevent lithium dendrite formation in batteries?

Use batteries with ceramic-coated separators.

Avoid high charging currents.

Follow recommended charging protocols.

Note: Proper charging habits significantly reduce dendrite growth and extend battery life.

3. Are lithium batteries safe to use in extreme environments?

Yes, but only if designed for such conditions. Look for batteries with advanced thermal management systems and IP-rated enclosures to ensure safety in harsh environments.

Tip: For professional guidance on lithium batteries safe, visit Large Power.