ISO 13485 and lithium battery certification serves as the global benchmark for quality management systems in medical devices. For lithium battery manufacturers, this ISO 13485 certification ensures compliance with rigorous safety and quality standards. Medical devices like pacemakers and insulin pumps depend on reliable lithium batteries. Adhering to ISO 13485 guarantees consistent performance, reducing risks and enhancing patient safety.

Key Takeaways

ISO 13485 certification makes sure lithium battery makers follow safety and quality rules. This helps keep medical devices safe for patients.

Using a Quality Management System (QMS) with ISO 13485 makes production smoother, lowers risks, and makes products more dependable.

Getting ISO 13485 certification helps companies compete better. Certified products are more trusted by healthcare workers and get approvals faster.

Part 1: Understanding ISO 13485 and Lithium Battery Manufacturing

1.1 What is ISO 13485 Certification?

ISO 13485 certification is a globally recognized standard for quality management systems (QMS) in the medical device industry. It provides a framework for organizations to design, develop, and manufacture products that meet stringent regulatory requirements. This certification emphasizes risk management, process control, and continuous improvement, ensuring that medical devices, including their components, are safe and reliable.

The ISO 13485 standard has evolved over time to address the growing complexity of medical technologies. Key updates in the 2016 version introduced a stronger focus on risk management, usability, and post-market surveillance. These changes align with the increasing demand for high-quality medical devices and components, such as lithium batteries, which play a critical role in life-saving equipment.

Did you know? ISO 13485 certification not only ensures compliance with regulatory guidelines but also enhances market access by meeting international standards.

1.2 Key Features of ISO 13485 for Medical Device Components

The ISO 13485 standard outlines specific requirements that directly impact the quality and safety of medical device components. For lithium battery manufacturers, adhering to these features ensures that their products meet the rigorous demands of the healthcare industry. Below is a summary of the key features:

Key Feature | Description |

|---|---|

General Requirements | Establishes expectations for implementing a QMS, including documentation and risk management. |

Documentation Requirements | Requires creation of a quality manual and specific records to ensure compliance and transparency. |

Management Responsibility | Emphasizes the role of top management in setting quality objectives and ensuring resource availability. |

Measurement, Analysis, Improvement | Focuses on continuous improvement through regular assessments and corrective actions to enhance quality. |

These features ensure that every stage of the manufacturing process, from design to delivery, adheres to strict quality standards. For example, the emphasis on documentation and traceability helps manufacturers track components, ensuring consistency and reliability in production.

1.3 Why ISO 13485 is Essential for Lithium Battery Manufacturers

Lithium batteries are integral to the functionality of many medical devices, such as pacemakers, defibrillators, and insulin pumps. The reliability and safety of these batteries directly impact patient outcomes. ISO 13485 certification is essential for battery manufacturers because it ensures compliance with regulatory guidelines and promotes high-quality production standards.

The benefits of ISO 13485 for lithium battery manufacturers include:

Enhanced Safety: The certification ensures that batteries meet stringent safety requirements, reducing the risk of device failure.

Improved Reliability: Consistent performance under various conditions is guaranteed, which is critical for medical applications.

Streamlined Processes: Adopting a QMS under ISO 13485 helps manufacturers optimize their design and production workflows.

Market Competitiveness: Certified products are more likely to gain regulatory approvals and access global markets.

However, achieving ISO 13485 certification comes with challenges. Compliance with the standard and FDA approvals can extend production cycles by 12–18 months. Additionally, manufacturers may need to allocate 8–15% of their R&D budgets toward meeting these requirements. Despite these hurdles, the long-term benefits of certification, such as improved product quality and marketability, outweigh the initial costs.

Tip: Investing in ISO 13485 certification not only enhances product quality but also builds trust with healthcare providers and patients.

Part 2: Key Requirements of ISO 13485 Certification

2.1 Quality Management Systems (QMS) for Lithium Battery Production

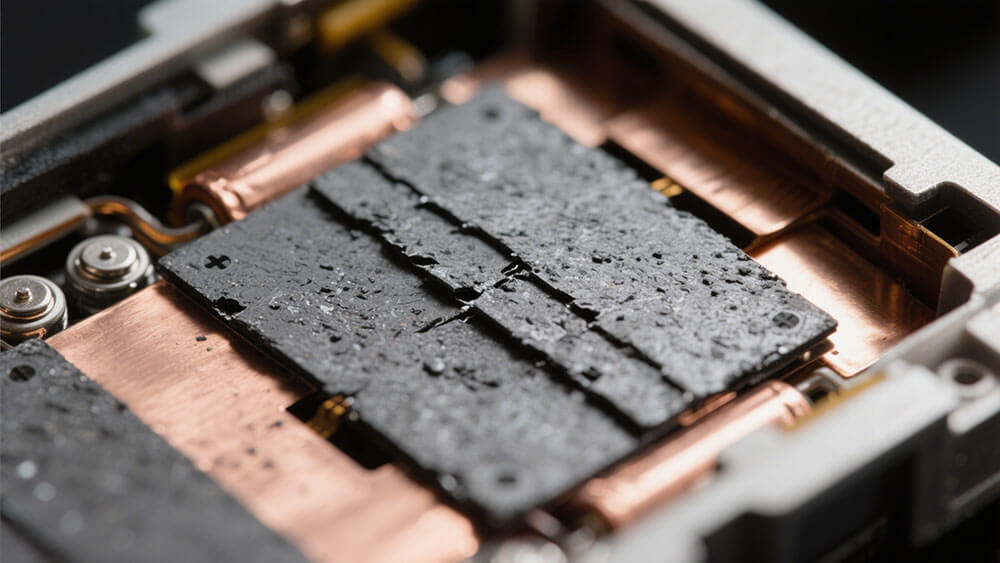

A robust quality management system is the backbone of ISO 13485 compliance. For lithium battery manufacturers, implementing a QMS ensures that every stage of production meets the stringent requirements of the ISO 13485 standard. This includes design, manufacturing, and post-production processes. The ISO 13485:2016 framework emphasizes risk management and process control, which are critical for producing safe and reliable batteries for medical devices.

A well-structured QMS offers several advantages:

It identifies potential risks early by evaluating design and process changes across the product lifecycle.

It ensures that batteries meet specifications through rigorous quality control measures, such as testing for voltage, charge cycles, and durability.

It enhances operational efficiency by streamlining workflows and reducing non-conformance issues.

By adhering to ISO 13485 requirements, you can produce high-quality batteries that comply with regulatory standards and deliver safe and reliable function in medical devices.

2.2 Regulatory Compliance in Medical Device Manufacturing

ISO 13485 serves as a global benchmark for regulatory compliance in the medical device industry. Lithium battery manufacturers must align their processes with this standard to meet the expectations of regulatory bodies like the FDA and EMA. The ISO 13485 certification promotes a culture of continuous improvement, requiring regular audits and corrective actions to enhance product quality and operational efficiency.

The standard also emphasizes rigorous risk management practices. Manufacturers must identify potential failures and implement preventive measures to ensure the reliability of their products. Additionally, the integration of digital tools, such as AI and digital quality management systems, has made it easier to meet ISO 13485 requirements. These advancements streamline compliance processes and improve overall product quality.

2.3 Safety and Risk Management in Lithium Battery Design

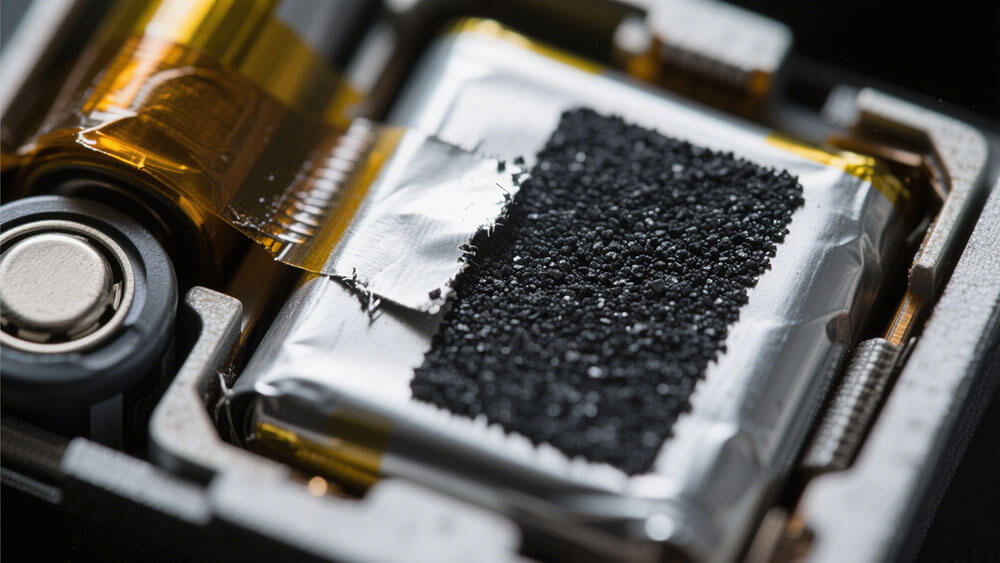

Safety and risk management are at the core of ISO 13485 compliance. Lithium battery manufacturers must prioritize these aspects during the design phase to ensure the safe and reliable function of their products. The ISO 13485 quality management system requires manufacturers to evaluate risks related to materials, contamination, and design changes. This proactive approach minimizes the likelihood of malfunctions or unsafe conditions.

Key safety measures include:

Implementing contamination prevention protocols during assembly.

Conducting thorough validation and verification processes to ensure batteries meet safety standards.

Establishing effective change control mechanisms to address risks associated with design modifications.

By following these practices, you can enhance the reliability of your batteries and build trust with healthcare providers and patients.

Part 3: Importance of ISO 13485 for Lithium Battery Manufacturers

3.1 Enhancing Safety and Reliability in Medical Devices

ISO 13485 plays a pivotal role in ensuring the safety and reliability of lithium batteries used in medical devices. You must prioritize risk management throughout the product lifecycle to meet the standard’s requirements. This approach helps identify and mitigate hazards, such as corrosion or bio-compatibility issues, that could compromise patient safety.

ISO 13485 mandates rigorous process validation, ensuring manufacturing processes consistently meet specifications.

Surface finishing processes are standardized and repeatable, reducing defects and enhancing product durability.

Validated processes minimize risks associated with design flaws, improving the reliability of medical devices.

By adhering to ISO 13485 compliance, you can produce batteries that perform consistently under various conditions. This reliability is critical for medical devices like pacemakers and insulin pumps, where even minor failures can have life-threatening consequences.

Note: Implementing ISO 13485 certification not only enhances medical product safety but also builds trust with healthcare providers and patients.

3.2 Streamlining Design and Manufacturing Processes

ISO 13485 fosters efficiency in design and manufacturing processes, enabling you to deliver high-quality lithium batteries for medical devices. The certification encourages a systematic review of each step in the production cycle, helping you identify and address shortcomings.

Improvement Type | Description |

|---|---|

Understanding Product Requirements | Better understanding and consistent fulfillment of product requirements. |

Process Performance | Achieving higher levels of process performance. |

Continuous Improvement Culture | Cultivating a mindset focused on continuous improvement. |

Cost Reduction | Reducing costs through improved quality and minimized waste. |

Customer Satisfaction | Enhancing customer satisfaction, leading to repeat business. |

Decision Making | Making data-driven decisions aligned with strategic goals. |

You can leverage these improvements to optimize workflows and reduce production costs. For example, ISO 13485 compliance ensures that design flaws are corrected early, enhancing device safety and market competitiveness. This proactive approach also fosters a culture of continuous improvement, driving innovation and operational excellence.

Tip: Regularly reviewing your design and manufacturing processes under ISO 13485 requirements can help you stay ahead in the competitive medical device industry.

3.3 Strengthening Supply Chain and Traceability

ISO 13485 certification enhances supply chain management and traceability, ensuring the seamless delivery of high-quality lithium batteries. The standard provides a unified framework for data sharing, improving product traceability and inventory control.

Benefit | Description |

|---|---|

Improved Efficiency | Streamlined processes enhance overall operational efficiency. |

Enhanced Traceability | Unified data-sharing frameworks improve product traceability. |

Optimized Inventory Management | Better inventory control reduces errors and waste. |

Streamlined Product Recalls | Effective recall management ensures patient safety. |

A diagnostic methodology developed for ISO 13485 implementation has shown significant improvements in quality management systems. Companies adopting this methodology achieved FDA approval, demonstrating enhanced operational compliance and effectiveness. You can use these insights to strengthen your supply chain, ensuring that every component meets stringent quality standards.

Callout: Strengthening traceability under ISO 13485 compliance not only improves operational efficiency but also simplifies product recalls, safeguarding patient health.

ISO 13485 certification is vital for lithium battery manufacturers in the medical device industry. It ensures your products meet stringent safety and reliability standards while complying with global regulations. This certification validates your quality management systems, aligning with FDA and EU requirements. Hospitals and procurement teams prioritize certified suppliers, enhancing your market competitiveness. By achieving ISO 13485 compliance, you reduce risks, improve product quality, and gain a significant edge in the medical device sector.

FAQ

1. What industries benefit most from ISO 13485 certification?

ISO 13485 certification primarily benefits the medical device industry. It ensures compliance with safety standards for components like lithium batteries, enhancing reliability and patient safety.

2. How does ISO 13485 improve lithium battery manufacturing?

ISO 13485 improves lithium battery manufacturing by enforcing strict quality management systems. It ensures consistent production, reduces risks, and enhances compliance with regulatory requirements.

3. Is ISO 13485 certification mandatory for lithium battery manufacturers?

ISO 13485 certification is not always mandatory. However, it is highly recommended for manufacturers like Large Power supplying batteries for medical devices to meet global regulatory standards and ensure product safety.