Thermal-conducting interlayers about lithium battery safety and performance are crucial. They effectively manage heat, preventing catastrophic failures. For instance:

In impact tests, 17 out of 19 batteries with thermal-conducting interlayers about lithium battery remained intact, compared to only 7 in standard configurations.

Explosion rates dropped by 53%, showcasing the safety-enhancing capabilities of these interlayers.

The temperature in standard cells surged at 59.4 °C/s, while batteries equipped with thermal-conducting interlayers about lithium battery exhibited slower, controlled increases.

These innovations ensure safer, more reliable battery operations under demanding conditions.

Key Takeaways

Thermal-conducting layers help keep lithium batteries safe by controlling heat. They lower the chance of overheating or dangerous heat problems.

These layers also make batteries work better and last longer. This helps them perform well in things like medical tools and electric cars.

Picking the right material for these layers is very important. Talk to experts to find the best solution for your needs.

Part 1: Understanding Thermal-Conducting Interlayers About Lithium Battery

1.1 Definition and Key Features

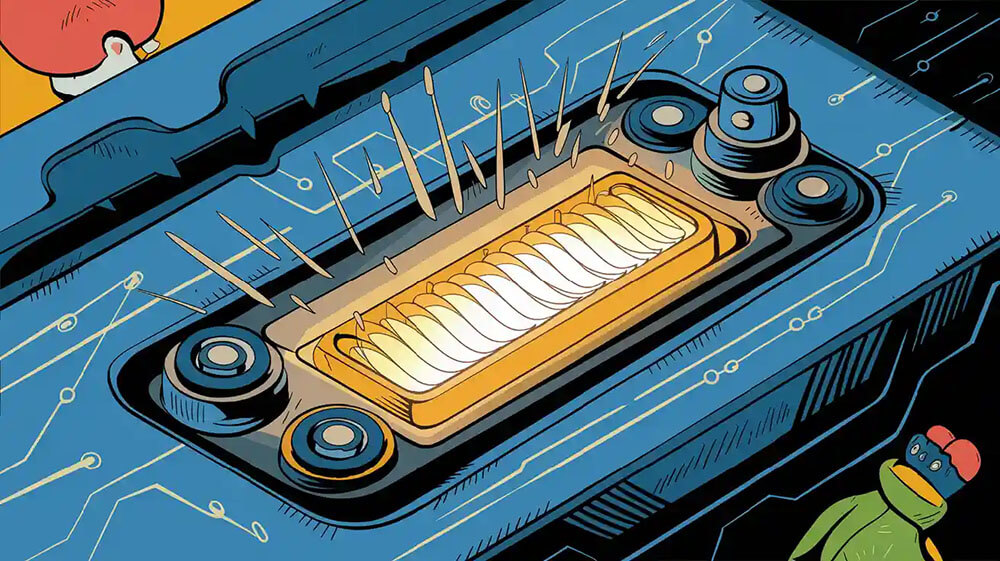

Thermal-conducting interlayers about lithium battery systems are specialized materials designed to manage heat effectively. These interlayers act as a bridge between battery components, facilitating efficient heat transfer. Their primary purpose is to enhance safety by preventing overheating and ensuring uniform temperature distribution. You will find these interlayers particularly valuable in high-performance applications like medical devices, robotics, and industrial systems.

Key features include high thermal conductivity, mechanical flexibility, and chemical stability. These properties allow the interlayers to withstand the demanding conditions of lithium battery operations. By integrating these materials, you can achieve improved thermal management and reduce the risk of thermal runaway.

1.2 Role in Battery Thermal Management

Thermal-conducting interlayers play a critical role in maintaining optimal battery performance. They dissipate heat generated during charging and discharging cycles, preventing localized hotspots. This function is essential for applications like consumer electronics and security systems, where consistent performance is crucial.

Efficient thermal management also extends the lifespan of lithium batteries. By maintaining a stable temperature, these interlayers reduce stress on battery cells, minimizing degradation over time. This makes them indispensable for infrastructure and transportation systems that demand long-lasting energy solutions.

1.3 Common Materials Used in Thermal-Conducting Interlayers

The materials used in thermal-conducting interlayers about lithium battery systems vary based on application requirements. Common options include graphite, aluminum, and ceramic-based composites. Graphite offers excellent thermal conductivity and flexibility, making it ideal for compact designs. Aluminum provides durability and high heat dissipation, while ceramics excel in extreme operating conditions.

For advanced applications like LiFePO4 Lithium batteries, these materials ensure reliable performance under high thermal loads. Selecting the right material depends on factors like operating temperature, mechanical stress, and safety requirements.

Tip: For custom battery solutions tailored to your specific needs, explore Large Power’s offerings.

Part 2: Safety Benefits and Thermal Runaway Prevention

2.1 Mitigating Overheating in Battery Modules

Overheating poses a significant risk to battery safety, especially in high-capacity lithium-ion batteries. Thermal-conducting interlayers act as a safety reinforced layer, effectively dissipating heat across the battery module. This prevents localized hotspots, which are a primary cause of thermal runaway. For example, in consumer electronics, overheating can lead to device malfunctions or even fires. By integrating interlayers, you can ensure consistent thermal protection, reducing the likelihood of such failures.

In high-energy-density battery modules, overheating can compromise both safety and performance. Thermal conductivity plays a crucial role in maintaining optimal operating temperatures. This is particularly important in applications like robotics, where precise and reliable energy delivery is critical. By managing heat effectively, interlayers enhance battery safety and extend the lifespan of the system.

Tip: To explore custom solutions for your specific battery needs, visit Large Power’s custom battery solutions.

2.2 Preventing Thermal Runaway in High-Density Applications

Thermal runaway prevention is a cornerstone of effective thermal safety management. In high-capacity lithium-ion batteries, a single cell failure can trigger a chain reaction, leading to catastrophic outcomes. Thermal-conducting interlayers serve as a safety reinforced layer, isolating heat and preventing it from spreading to adjacent cells. This containment strategy is vital in high-density applications like medical devices, where uninterrupted operation is non-negotiable.

The role of interlayers in thermal runaway prevention extends to industrial and infrastructure systems. These sectors demand high-performance energy solutions capable of withstanding extreme conditions. By incorporating interlayers, you can achieve effective thermal safety management, ensuring both reliability and safety in critical operations.

2.3 Enhancing Safety in Extreme Operating Conditions

Extreme operating conditions, such as high temperatures or rapid charge-discharge cycles, test the limits of battery safety. Thermal-conducting interlayers provide an additional layer of thermal protection, safeguarding the battery against these challenges. For instance, in security systems, where continuous operation is essential, interlayers help maintain thermal stability.

In transportation infrastructure, where high-energy-density battery modules power electric vehicles, thermal safety management becomes even more critical. Interlayers ensure uniform heat distribution, preventing thermal runaway and enhancing overall battery performance. This not only improves safety but also contributes to the sustainability of energy solutions. Learn more about sustainability at Large Power.

Note: Selecting the right interlayer material is crucial for achieving optimal thermal conductivity and safety. Consult with experts to tailor solutions to your specific requirements.

Part 3: Performance Enhancements in Lithium Battery Systems

3.1 Improving Energy Efficiency and Heat Distribution

Thermal-conducting interlayers significantly improve the energy efficiency of lithium-ion batteries by optimizing heat distribution. When batteries operate, they generate heat due to electrochemical reactions. Uneven heat distribution can lead to localized hotspots, reducing the electrochemical performance of the battery. By integrating thermal-conducting interlayers, you can ensure uniform heat dissipation across the battery module. This uniformity enhances the overall performance and reliability of the system.

In applications like robotics, where precise energy delivery is critical, maintaining consistent temperature levels is essential. Thermal interlayers help stabilize the temperature, ensuring the safe cycling of batteries even under high loads. For example, in industrial environments, where lithium-ion batteries power heavy machinery, efficient heat management prevents overheating and ensures uninterrupted operations.

Thermal interlayers also contribute to energy efficiency by reducing energy losses caused by excessive heat. In consumer electronics, where compact designs demand high energy density, these interlayers play a vital role in maintaining optimal electrochemical performance. By minimizing thermal resistance, they allow batteries to operate at peak efficiency, extending their usability in devices like smartphones and laptops.

Tip: For custom battery solutions tailored to your specific application, consult with experts at Large Power.

3.2 Extending Battery Lifespan Through Temperature Control

Temperature control is a critical factor in extending the lifespan of lithium-ion batteries. Excessive heat accelerates the degradation of battery cells, reducing their capacity and overall lifespan. Thermal-conducting interlayers mitigate this issue by maintaining a stable temperature within the battery module. This stability minimizes stress on the electrochemical components, ensuring long-term reliability.

In medical devices, where uninterrupted operation is crucial, thermal interlayers enhance the safe cycling of batteries by preventing overheating. For instance, in portable medical equipment, consistent temperature control ensures reliable performance, safeguarding patient safety.

Infrastructure systems, such as transportation networks powered by lithium-ion batteries, also benefit from extended battery lifespans. Electric vehicles, for example, require batteries that can endure thousands of charge-discharge cycles without significant capacity loss. Thermal interlayers help achieve this by reducing thermal stress, enabling batteries to maintain their electrochemical performance over time.

Moreover, thermal interlayers support sustainability by reducing the frequency of battery replacements. This not only lowers operational costs but also minimizes environmental impact. To learn more about sustainable energy solutions, visit Large Power’s sustainability page.

Note: Selecting the appropriate thermal-conducting interlayer material is essential for achieving optimal temperature control and extending battery lifespan. Consult with experts to determine the best solution for your specific needs.

Thermal-conducting interlayers represent a vital advancement in lithium battery technology. They enhance safety by addressing challenges like overheating and thermal runaway. These interlayers also improve energy efficiency and reliability, ensuring long-term performance. As you explore future energy solutions, integrating these innovations will help you achieve safer and more efficient battery systems.

FAQ

1. What are thermal-conducting interlayers, and why are they important for lithium-ion batteries?

Thermal-conducting interlayers manage heat effectively, preventing overheating and thermal runaway. They enhance safety, reliability, and lifespan in lithium-ion battery systems.

2. How do thermal-conducting interlayers improve battery performance in industrial applications?

They ensure uniform heat distribution, reducing thermal stress and enhancing energy efficiency. This improves reliability in industrial systems like heavy machinery.

3. Can thermal-conducting interlayers support sustainability in battery systems?

Yes, they extend battery lifespan, reducing replacements and environmental impact. Large Power offers sustainable solutions tailored to your needs.

Tip: For custom battery solutions, consult with experts at Large Power.