When assessing the question, “Will LiFePO4 Replace NMC Batteries?” it’s essential to examine their distinct advantages and evolving market trends. LiFePO4 batteries have gained significant traction due to their cost-effectiveness and superior safety features. For instance:

LiFePO4 battery cells are approximately 30% cheaper than NMC batteries, which were priced at $95 per kWh in 2023.

The lithium iron phosphate market is forecasted to expand from $18.69 billion to $117.62 billion by 2037, showcasing a robust CAGR of over 15.2%.

However, NMC batteries continue to dominate high-performance applications, such as electric vehicles, where energy density remains a pivotal factor.

Learn more about LiFePO4 batteries here.

Key Takeaways

LiFePO4 batteries cost about 30% less than NMC batteries. This makes them a good choice for big projects.

LiFePO4 batteries are safer and less likely to overheat. This makes them great for electric cars and storing energy.

However, LiFePO4 batteries hold less energy than NMC batteries. This limits their use in fast and powerful electric cars.

Part 1: Advantages of LiFePO4 Over NMC

1.1 Safety and Thermal Stability

When it comes to safety, LiFePO4 batteries outperform NMC batteries due to their superior thermal stability and chemical composition. The inherent stability of LiFePO4 reduces the risk of thermal runaway, a critical safety concern in lithium-ion batteries. Laboratory tests confirm that LiFePO4 batteries exhibit significantly lower risks of combustion or explosion, even under extreme conditions.

Feature | LiFePO4 Batteries | NMC Batteries |

|---|---|---|

Chemical Stability | Stable chemistry reduces thermal runaway | Less stable, higher risk of thermal runaway |

Thermal Runaway Resistance | Significantly reduced risk | Higher risk of thermal runaway |

Lifespan | Longer lifespan confirmed by tests | Shorter lifespan |

Safety at High Temperatures | More stable at elevated temperatures | Less stable at elevated temperatures |

This makes LiFePO4 batteries ideal for applications requiring high safety standards, such as electric vehicles, solar energy storage, and medical devices.

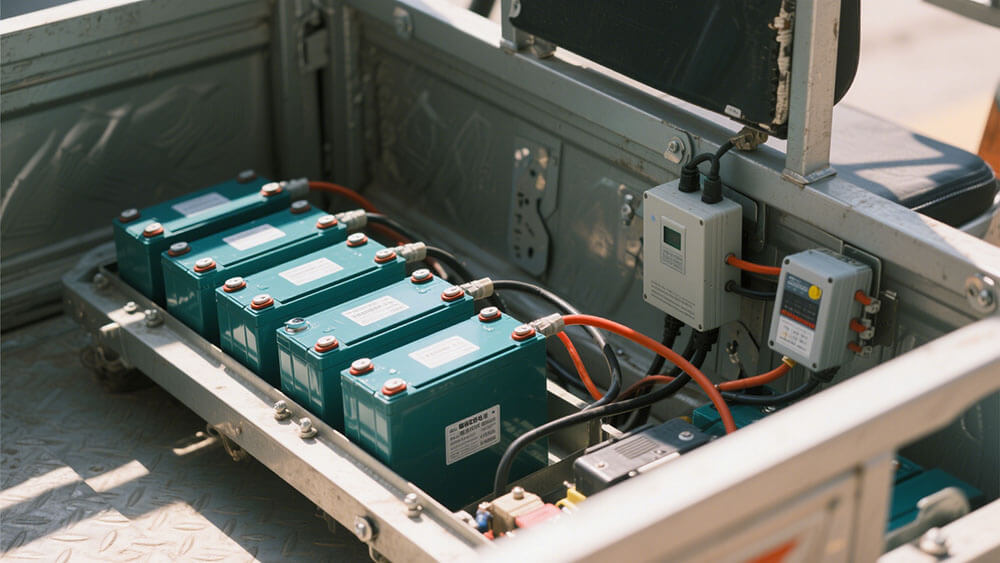

1.2 Cost-Effectiveness for Large-Scale Applications

LiFePO4 batteries offer a cost advantage over NMC batteries, particularly in large-scale applications. The use of abundant and less expensive materials like iron and phosphate significantly reduces production costs. This affordability makes LiFePO4 the preferred choice for energy storage systems, electric buses, and trucks.

Attribute | LFP Batteries | NMC Batteries |

|---|---|---|

Cycle Life | Longer cycle life, better for frequent charge/discharge | Shorter cycle life, needs more frequent replacement |

Cost | More affordable, less expensive materials | Generally more expensive due to cobalt content |

Application Suitability | Ideal for energy storage, electric buses/trucks | Better suited for applications needing high energy density and compact size |

The cost-effectiveness of LiFePO4 batteries ensures their dominance in markets where affordability and reliability are critical. For custom battery solutions tailored to your needs, visit Large Power.

1.3 Environmental Benefits and Sustainability

LiFePO4 batteries contribute to greater sustainability compared to NMC batteries. Their longer lifespan reduces the frequency of replacements, minimizing resource consumption. Additionally, innovative recycling methods make LiFePO4 batteries less harmful to the environment.

LiFePO4 batteries result in lower carbon emissions, aiding global greenhouse gas reduction efforts.

The materials used, such as lithium, iron, and phosphate, are less toxic and more abundant, reducing ecological damage during mining and production.

These batteries are highly recyclable, promoting a circular economy and minimizing waste.

For more insights into sustainable battery solutions, explore sustainability at Large Power.

Part 2: Limitations of LiFePO4 Compared to NMC

2.1 Lower Energy Density and Weight Concerns

LiFePO4 batteries, while excelling in safety and longevity, face significant challenges in energy density. These batteries store less energy per unit volume or weight compared to NMC batteries, making them less suitable for applications requiring compact and lightweight designs. For instance, NMC batteries typically achieve energy densities between 160-270 Wh/kg, whereas LiFePO4 batteries range from 100-180 Wh/kg. This 30% lower energy density means that to achieve the same performance, LiFePO4-powered systems require additional battery packs, increasing overall weight.

LiFePO4 batteries have approximately 30% lower energy density than NMC batteries.

Additional LiFePO4 cells are needed to match the range of NMC-powered vehicles, leading to increased weight.

This limitation becomes particularly evident in high-performance automotive applications, where weight and space constraints are critical. While LiFePO4 batteries remain a reliable choice for stationary storage and cost-sensitive sectors, their lower energy density restricts their adoption in electromobility solutions like electric transport and aviation.

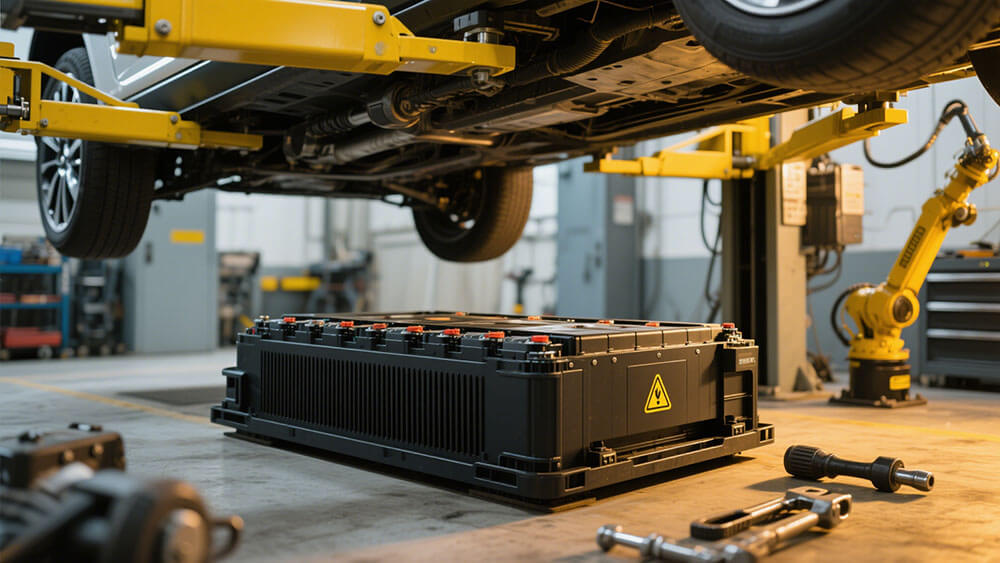

2.2 Limited Suitability for Next-Generation Batteries in EVs

The growing adoption of electric vehicles has intensified the demand for next-generation batteries that deliver higher energy density and longer driving ranges. NMC batteries, with their superior energy density and compact design, dominate this space. Engineering reports highlight that NMC batteries provide longer ranges for EVs, making them the preferred choice for manufacturers targeting high-performance automotive markets.

In contrast, LiFePO4 batteries hold a limited share in advanced EV designs. In Europe, for example, LiFePO4 batteries account for less than 2% of total battery capacity, reflecting minimal interest from OEMs. This trend underscores the challenges LiFePO4 faces in meeting the demands of next-generation EVs, where nickel manganese cobalt (NMC) chemistries offer a competitive edge.

Despite these limitations, the future outlook for LiFePO4 batteries remains promising in specific niches. Their safety, longevity, and cost-effectiveness make them ideal for applications like energy storage and industrial systems. However, for cutting-edge EV designs, NMC batteries continue to lead due to their ability to meet the rigorous demands of electromobility.

For tailored battery solutions that align with your specific needs, consult Large Power.

Part 3: Future Outlook for LiFePO4 Batteries

3.1 Advancements in LiFePO4 Technology

The future of LiFePO4 batteries looks promising, thanks to continuous advancements in materials and manufacturing processes. Researchers and manufacturers are focusing on improving energy density, safety, and cost-effectiveness to expand the applications of these batteries.

Aspect | Evidence |

|---|---|

Advanced Materials | Manufacturers are using advanced materials and new technologies to enhance performance and affordability. |

Environmental Safety | These batteries do not contain cobalt, reducing ethical and environmental concerns. |

Superior Safety | LiFePO4 batteries are more stable and less prone to overheating, reducing risks of thermal runaway. |

Cost-effectiveness | Their durability leads to financial viability over time, especially where replacements are costly. |

Improved Energy Density | Recent advancements have significantly improved the energy density of LiFePO4 batteries, making them more viable. |

Material Morphology | Companies are focusing on enhancing the core materials and adapting particle sizes of LiFePO4 batteries. |

These innovations make LiFePO4 batteries increasingly competitive in sectors like renewable energy storage and electric vehicles. For example, the integration of advanced material morphology has improved the energy density of LiFePO4 batteries, narrowing the gap with NMC batteries. This progress ensures that LiFePO4 remains a viable option for applications requiring safety and longevity.

3.2 Innovations in NMC Batteries for Safety and Cost

While LiFePO4 batteries are advancing, NMC batteries are also undergoing significant innovations to address safety concerns and reduce costs. Recent trends in battery technology highlight several key developments:

Battery pack designs are evolving to improve safety and lower costs.

The cell-to-pack approach reduces manufacturing costs and enhances efficiency.

Emerging chemistries like LMFP (lithium manganese iron phosphate) aim to bridge the gap between LiFePO4 and NMC in terms of performance and cost.

These innovations make NMC batteries more appealing for high-performance applications, such as electric vehicles and consumer electronics. By adopting safer designs and cost-effective chemistries, NMC batteries continue to maintain their relevance in the competitive lithium-ion battery market.

3.3 Market Dynamics and the Role of Next-Generation Batteries

The global battery market is undergoing rapid transformation, driven by advancements in lithium-ion technology and the emergence of next-generation batteries. According to market analysis, the demand for lithium-ion batteries is expected to exceed 2600 GWh by 2030, fueled by the electric vehicle sector.

Region | Key Insights |

|---|---|

Asia Pacific | Dominates global market share; significant adoption in automotive sector; driven by demand for electronics. |

North America | Notable market share; increasing sales of electric vehicles and energy storage devices. |

Europe | Growth supported by government focus on emissions; initiatives for innovative battery technology. |

Middle East & Africa | Anticipated growth due to construction activities requiring industrial tools powered by LFP batteries. |

The rise of solid-state batteries and other next-generation technologies will further shape the market. However, LiFePO4 and NMC batteries will continue to play a critical role in meeting the diverse needs of industries. While LiFePO4 dominates cost-sensitive and safety-focused applications, NMC remains the go-to choice for high-performance and compact designs.

For custom battery solutions tailored to your specific needs, consult Large Power.

LiFePO4 batteries and NMC batteries will coexist in the market due to their unique strengths. You will find LiFePO4 dominating energy storage systems and cost-sensitive applications, while NMC batteries excel in high-performance electric vehicles and compact designs. Advancements in both chemistries will shape the future of lithium-ion technology, meeting diverse industry needs. For tailored solutions, consult Large Power.

FAQ

1. What makes LiFePO4 batteries safer than NMC batteries?

LiFePO4 batteries have stable chemical properties and resist thermal runaway. This reduces the risk of overheating, combustion, or explosion, even under extreme conditions.

2. Are LiFePO4 batteries suitable for electric vehicles?

Yes, LiFePO4 batteries work well for affordable EVs. They offer safety, long lifespan, and cost-effectiveness but may not meet the energy density needs of high-performance EVs.

3. How do LiFePO4 batteries support sustainability?

LiFePO4 batteries use abundant, non-toxic materials like iron and phosphate. Their long lifespan and recyclability reduce waste and environmental impact, promoting a circular economy.