Choosing the right lipo battery connector, such as when considering XT90 vs EC5 connectors for battery applications, impacts your device’s performance and efficiency. For high-current industrial setups, connectors like XT90 excel due to their robust build and low resistance. Compact lithium battery systems often benefit from EC5’s lightweight design and compatibility with smaller devices. Reduced voltage sag and extended battery life highlight the importance of selecting connectors tailored to your application.

Key Takeaways

Pick XT90 connectors for strong power needs. They work with 90 amps and last in rough conditions.

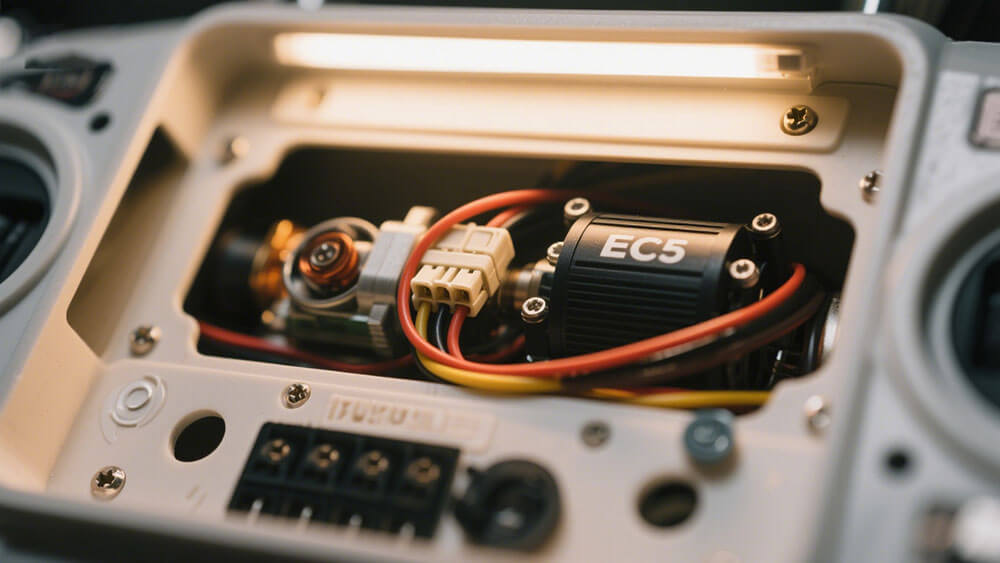

Use EC5 connectors for small gadgets. Their light design works great in drones and RC cars.

Always check your battery’s current and voltage before choosing connectors. This keeps things safe and working well.

Part 1: Detailed Analysis of XT90 Connectors

1.1 Overview of XT90 Features

XT90 connectors are widely recognized for their robust design and high current-handling capabilities. These connectors can support demanding applications, making them ideal for industrial setups and high-performance lithium battery packs. Their durability ensures reliable operation in environments with heavy vibrations or rough terrain, such as robotics or transportation infrastructure.

Key features of XT90 connectors include:

High current capacity, suitable for applications requiring up to 90 amps.

Durable construction, minimizing wear and tear in challenging conditions.

Larger size, which may limit compatibility with compact devices.

The XT90 connector’s design prioritizes safety and efficiency. Its low resistance reduces heat generation, ensuring optimal performance for lithium-ion batteries. However, its size may pose challenges for smaller configurations, such as consumer electronics.

Tip: When selecting a lipo battery connector, consider the physical dimensions and current requirements of your battery setup to ensure compatibility.

1.2 Best Use Cases for XT90 in Lithium Battery Packs

XT90 connectors excel in scenarios requiring high power output and reliability. Below is a table showcasing a real-world example of XT90 connectors in lithium battery packs:

Specification | Value |

|---|---|

Battery Type | 52v 25amp 10Ah |

Cell Type | Samsung 21700 50S |

Continuous Power Output | 50 amps |

Total Power Capacity | Over 2500 watts |

Connector Type | XT90 |

Applications include industrial machinery, robotics, and transportation systems. These connectors are also favored in drones and e-bikes, where consistent power delivery is critical.

1.3 Pros and Cons of XT90

Pros:

High current capacity supports demanding applications.

Durable design ensures longevity in harsh environments.

Low resistance reduces voltage sag and heat buildup.

Cons:

Larger size may limit compatibility with compact devices.

Higher cost compared to smaller connectors like EC5.

XT90 connectors are ideal for applications requiring reliability and high power output. However, their size and cost may make them less suitable for smaller or budget-sensitive setups.

Note: For custom battery solutions tailored to your specific needs, visit Large Power.

Part 2: Detailed Analysis of EC5 Connectors

2.1 Overview of EC5 Features

EC5 connectors are designed for applications requiring compactness and moderate current handling. Their smaller size makes them ideal for setups where space is limited, such as consumer electronics or portable lithium-polymer (LiPo) battery packs. These connectors can handle up to 120 amps of current, offering reliable performance for medium-power applications.

Key features of EC5 connectors include:

Compact design, ensuring compatibility with smaller devices.

High current capacity, suitable for moderate power demands.

Easy installation due to their straightforward plug-and-play design.

The EC5 connector’s lightweight construction enhances portability, making it a preferred choice for drones, RC vehicles, and other compact systems. Its gold-plated contacts reduce resistance, ensuring efficient power transfer and minimizing heat buildup.

Tip: If your battery setup prioritizes portability and space-saving, EC5 connectors provide an excellent solution.

2.2 Best Use Cases for EC5 in Lithium Battery Packs

EC5 connectors excel in applications requiring compactness and moderate power output. Below is a table illustrating their use in lithium battery packs:

Specification | Value |

|---|---|

Battery Type | 36v 15amp 5Ah |

Cell Type | LiPo 18650 |

Continuous Power Output | 30 amps |

Total Power Capacity | 540 watts |

Connector Type | EC5 |

These connectors are commonly used in RC vehicles, drones, and portable medical devices. Their compact design ensures compatibility with smaller battery setups, while their current-handling capacity supports reliable operation.

Note: For custom battery solutions tailored to your specific needs, visit Large Power.

2.3 Pros and Cons of EC5

Pros:

Compact design fits smaller devices and tight spaces.

Lightweight construction enhances portability.

Gold-plated contacts ensure efficient power transfer.

Cons:

Lower current capacity compared to XT90 connectors.

Less durable in high-vibration environments.

EC5 connectors are ideal for applications prioritizing portability and space-saving. However, their lower current capacity and durability may limit their use in industrial or high-power setups.

Callout: For applications requiring higher durability or current capacity, consider XT90 connectors as an alternative.

Part 3: Feature Comparison of XT90 vs EC5 Connectors for Battery

3.1 Dimensions and Size

When selecting the right lipo battery connector, dimensions play a crucial role in ensuring compatibility with your battery setup. XT90 connectors are larger, making them suitable for industrial applications where space constraints are less critical. On the other hand, EC5 connectors feature a compact design, ideal for consumer electronics or portable devices.

Here’s a detailed comparison of dimensions:

Feature | XT90 Connector Details | EC5 Connector Details |

|---|---|---|

Input Connector | 4.0mm banana male | 5.0mm banana male |

Output Connector | XT90 Male | EC5 Male |

Wire Gauge | 12 AWG silicone wire | 10 AWG silicone wire |

Wire Length | Approx. 25 cm / 9.8 inches |

The larger size of XT90 connectors provides better durability and current handling, while EC5 connectors excel in compact setups. You should evaluate your battery performance requirements and available space before making a choice.

Tip: For compact lithium-polymer battery packs, EC5 connectors offer a space-saving solution.

3.2 Materials and Build Quality

Material quality directly impacts the durability and reliability of connectors. XT90 connectors use high-temperature-resistant plastic and gold-plated contacts, ensuring longevity in industrial environments. EC5 connectors, while also featuring gold-plated contacts, are designed to withstand mechanical stress, making them suitable for portable applications.

Here’s a comparison of build quality:

Connector | Continuous Current | Burst Current | Connection Type | Insulation Options | Durability Features |

|---|---|---|---|---|---|

XT90 | 120-130 Amps | Tight fit | Plastic cap option | High temperature resistance | |

EC5 | 120 Amps | 150 Amps | Larger surface area | No heat shrink needed | Designed for mechanical stress |

XT90 connectors excel in high-temperature environments, such as robotics or transportation infrastructure. EC5 connectors, with their larger surface area, provide reliable connections for portable devices.

Callout: For industrial applications requiring high durability, XT90 connectors are a better choice.

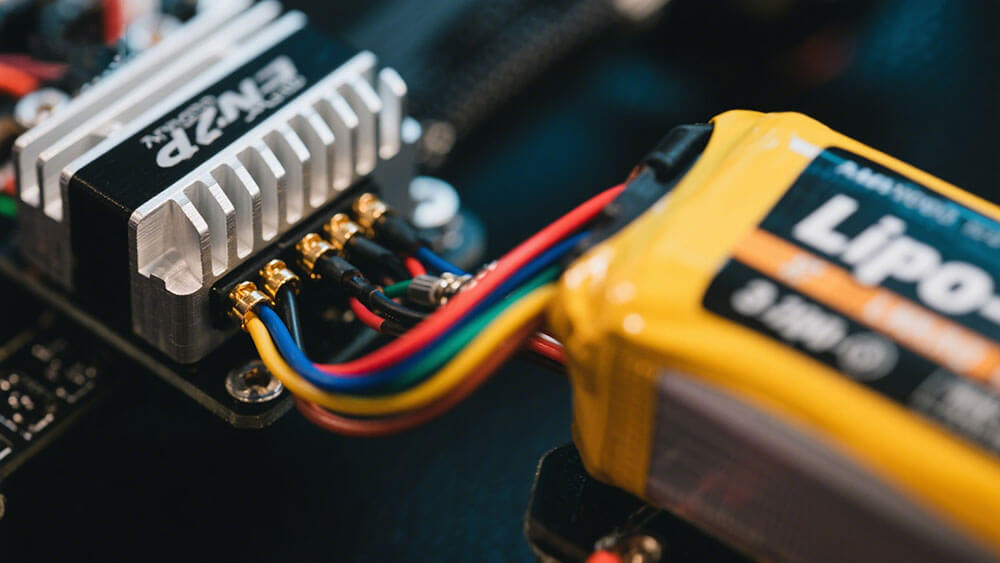

3.3 Current Capacity and Voltage Ratings

Current capacity determines how well a connector can handle power demands. XT90 connectors are designed for high-current applications, supporting up to 90 amps continuously. EC5 connectors, however, can handle currents up to 120 amps, making them suitable for medium to high-power setups.

Key performance details:

XT90: Handles currents exceeding 90 amps, ideal for larger RC models, electric boats, and high-performance aircraft.

EC5: Supports power demands ranging from 80 to 120 amps, commonly used in electric cars, boats, and larger aircraft.

Both connectors deliver reliable performance, but XT90 connectors are better suited for applications requiring consistent high-current delivery.

Note: For lithium-ion battery packs used in high-performance drones or e-bikes, XT90 connectors ensure optimal power transfer.

3.4 Price and Cost-Effectiveness

Cost-effectiveness depends on your application and budget. XT90 connectors are generally more expensive due to their robust design and higher current capacity. EC5 connectors, with their compact design, offer a more affordable solution for smaller setups.

When comparing costs, consider the long-term benefits of durability and performance. XT90 connectors may have a higher upfront cost, but their reliability in industrial applications can save you money in the long run. EC5 connectors, while cheaper, may require replacement sooner in high-stress environments.

Tip: Select the right lipo battery connector based on your budget and the expected lifespan of your battery setup.

Part 4: Choosing the Right Lipo Battery Connector

4.1 Factors to Match Connector to Battery Setup

Selecting the right lipo battery connector requires careful consideration of several factors to ensure optimal battery performance and compatibility. Each factor plays a critical role in determining how well the connector integrates with your battery setup.

Cable Gauge: The thickness of the cable impacts power transmission efficiency. Thicker cables (lower gauge numbers) are better for high-current applications, as they reduce voltage drop and heat generation.

Cable Length: Longer cables introduce resistance, which can lead to power loss. For extended distances, thicker cables are essential to maintain efficiency.

Connector Type: Compatibility between the connector, battery, and device is crucial. Ensure the connector type matches the specific requirements of your lithium battery connectors and devices.

Insulation Material: Environmental conditions, such as exposure to moisture or heat, demand high-quality insulation to protect the connector and battery.

Flexibility and Durability: Flexible connectors are easier to route through tight spaces, while durable materials withstand frequent use and harsh conditions.

Environmental Considerations: Flame resistance, UV resistance, and chemical protection are vital for applications in challenging environments.

Tip: Evaluate your battery’s current and voltage requirements alongside the physical constraints of your setup. This ensures you select the right lipo battery connector for both performance and longevity.

4.2 Recommendations for Specific Applications

Different applications demand specific connector types to meet their unique requirements. Below are recommendations based on common use cases:

High-Power Industrial Applications:

For industrial setups requiring high current and durability, XT90 connectors are ideal. Their robust design and high-temperature resistance make them suitable for robotics, transportation infrastructure, and heavy machinery.Compact Consumer Electronics:

EC5 connectors are perfect for consumer electronics where space is limited. Their compact size and lightweight design ensure compatibility with smaller devices like drones, RC vehicles, and portable medical equipment.Portable Lithium-Polymer Battery Packs:

EC5 connectors excel in portable setups due to their ease of installation and reliable performance. They are commonly used in lithium-polymer battery packs for applications requiring moderate power output.High-Performance Lithium-Ion Battery Systems:

XT90 connectors provide superior performance for lithium-ion battery systems in e-bikes, drones, and electric boats. Their low resistance and high current capacity ensure consistent power delivery.

Callout: For custom battery solutions tailored to your specific application, consult Large Power.

4.3 Common Mistakes to Avoid

When selecting a lipo battery connector, avoiding common mistakes can save you time, money, and potential performance issues. Here are some pitfalls to watch out for:

Ignoring Current and Voltage Ratings: Using a connector with insufficient current or voltage capacity can lead to overheating, voltage sag, or even damage to your battery. Always verify the ratings before making a choice.

Overlooking Compatibility: Mismatched connectors can result in poor connections or the need for adapters, which may compromise efficiency. Ensure the connector type aligns with your battery and device specifications.

Choosing Based on Price Alone: While cost is a factor, prioritizing cheaper connectors may lead to frequent replacements or performance issues. Invest in high-quality connectors for long-term reliability.

Neglecting Environmental Factors: Failing to consider insulation and durability in harsh conditions can shorten the lifespan of your connectors. Choose materials that withstand moisture, heat, and mechanical stress.

Using Incorrect Cable Gauge: Thin cables in high-current setups can cause excessive heat and power loss. Match the cable gauge to your application’s current requirements.

Note: Proper planning and attention to detail ensure your battery setup operates efficiently and safely. For expert guidance, explore Large Power’s custom solutions.

Choosing between XT90 and EC5 connectors depends on your battery setup and application needs. XT90 connectors excel in industrial environments and high-power lithium-ion battery systems due to their durability and cost-effectiveness. EC5 connectors, with their compact design, are better suited for consumer electronics and portable devices.

Features | EC5 | XT90 |

|---|---|---|

Dimensions | 9.5×19.6×33.4 mm | 1x1x1 inches |

Material | Brass and fireproof plastic insulation | Gold plated and Nylon insulation |

Capable Continuous Amps | 120A | 90A+ |

Compatibility | Yes | Yes |

Price range | Moderately priced | Cheaper comparatively |

Aligning your connector choice with technical requirements ensures optimal battery performance and extended battery life. For custom solutions tailored to your specific needs, consult Large Power.

FAQ

1. How do I know if XT90 or EC5 is compatible with my battery?

Check your battery’s current and voltage requirements. Match these with the connector’s specifications to ensure proper compatibility and performance.

2. Can I use adapters to switch between XT90 and EC5 connectors?

Yes, adapters are available. However, they may introduce resistance and reduce efficiency. Use them only when necessary for temporary setups.

3. Which connector is better for high-vibration environments?

XT90 connectors perform better in high-vibration conditions due to their robust build and secure connection design.