You rely on the fundamentals in battery testing to ensure lithium battery packs deliver consistent performance and meet strict safety demands. Reliable testing methods, such as vibration and shock tests, achieve over 95% reliability, as shown below. These fundamentals in battery testing directly impact battery durability and operational trustworthiness.

Test Type | Reliability (%) | Z-score |

|---|---|---|

Vibration | > 95 | 0.84 |

Shock | > 95 | 0.75 |

Key Takeaways

Perform regular capacity and internal resistance tests to track battery health and predict failures before they happen.

Always follow safety standards and use certified equipment to protect people and ensure reliable, consistent battery performance.

Choose precise, automated testing tools with temperature control and maintain them well to get accurate results and extend equipment life.

Part 1: Fundamentals in Battery Testing

1.1 Key Principles

You need to understand the fundamentals in battery testing to ensure reliable performance and safety in lithium battery packs. Capacity stands as the leading health indicator. When you perform basic battery tests, you measure how much charge the battery can hold and deliver. If capacity drops below 80%, the battery is considered to have failed. Internal resistance also plays a crucial role. As resistance increases, the battery loses efficiency and may fail even before capacity falls below the threshold.

Tip: Combine multiple health metrics—such as charge curves, open circuit voltage, and internal resistance—to get a complete picture of battery health.

You should use basic battery tests like open circuit voltage checks, load testing, and cycling to track aging features. These include constant current charging time, constant voltage charging time, and peak incremental capacity. Modern battery testers help you analyze these features and spot early signs of degradation. By following these principles, you improve the accuracy and consistency of battery testing and extend the service life of your lithium battery packs.

1.2 Safety and Standards

You must prioritize safety and compliance when conducting battery testing. Lithium battery incidents often result from electrical, thermal, or mechanical abuse. Adhering to industry safety standards and protocols reduces these risks. Basic battery tests should always follow established guidelines to prevent accidents.

Use certified battery testers and follow risk assessment procedures.

Implement unified emergency response strategies and regulatory frameworks.

Regularly review and update your testing protocols to align with the latest standards.

By maintaining strict compliance, you protect your operations and reputation. Consistent application of safety standards in battery testing leads to fewer incidents and greater trust in your products. For custom solutions or further guidance, consider consulting with our experts.

Part 2: Basic Battery Testing Contents

When you test lithium battery packs, you must use a range of standardized methods to ensure safety, performance, and compliance. Each method provides unique insights into battery health and reliability. The following sections break down the core procedures and considerations for each essential test.

2.1 Open Circuit Voltage (OCV)

Open Circuit Voltage (OCV) testing gives you a quick, non-invasive way to estimate the state of charge (SOC) and detect early signs of degradation in lithium battery packs. You measure OCV by allowing the battery to rest—typically for at least 2 hours—so that surface charge dissipates and the voltage stabilizes. After this rest period, you record the voltage across the terminals without any load applied.

OCV reflects the difference between the cathode and anode half-cell potentials as a function of charged capacity.

Advanced models let you analyze OCV curves in real time, helping you diagnose degradation mechanisms such as loss of active mass or lithium.

For blended cathode chemistries, OCV curves can reveal the health of individual components.

Note: OCV testing alone cannot provide a complete picture of battery health. You should combine it with other tests for a comprehensive assessment.

2.2 Load Testing

Load testing evaluates how your lithium battery pack performs under real-world operating conditions. You apply a controlled load and monitor voltage drop, current, and temperature response. This method helps you identify weak cells, mechanical defects, and safety risks.

You can use protocols such as compression, indentation, bending, nail penetration, and drop tests to simulate abuse scenarios.

Load testing reveals differences in deformation, stiffness, and failure modes based on impact velocity, geometry, and SOC.

Higher SOC improves corrosion resistance, but also increases the risk of severe internal short circuits during abuse.

Tip: Always use certified battery testers and follow safety protocols to prevent hazards during load testing.

2.3 Capacity Testing

Capacity testing stands as the most critical indicator of lithium battery health. You fully charge the battery, then discharge it at a controlled rate (often 0.5C or 1C) until it reaches the cut-off voltage. The total ampere-hours (Ah) delivered during discharge defines the usable capacity.

Statistical Method / Feature | Description | Outcome / Result |

|---|---|---|

Incremental Capacity (IC) Curves | Extracts health indicators (peak amplitude, area, shifts) | Strong correlation with capacity and SOH |

Gaussian Process Regression | Estimates capacity using dimension-reduced health indicators | Average error of 2.3% (high reliability) |

Linear Regression on Peak Height | Relates SOH to IC curve peak height ratio | Demonstrates linear relationship |

Feature Extraction from IC/DV Curves | Identifies feature points for capacity estimation | Effective for BMS implementation |

You should repeat capacity testing periodically to track aging and predict remaining useful life. Modern battery management systems (BMS) use advanced algorithms, such as Bi-LSTM-AM, to predict state of health (SOH) with less than 1.5% error.

Callout: If capacity drops below 80% of the rated value, you should consider the battery pack as failed for most professional applications.

2.4 Internal Resistance

Internal resistance testing measures how much the battery resists current flow, which directly impacts power delivery and efficiency. You can use either AC (typically 1,000Hz) or DC pulse methods, depending on your application.

For example, a standard 18650 cell shows about 36 milliohms with AC and 110 milliohms with DC.

Lower internal resistance means better performance, especially in high-drain applications like electric vehicles or industrial robots.

As batteries age, internal resistance increases due to electrode degradation and electrolyte depletion.

Temperature and SOC affect resistance: higher temperatures and full charge reduce resistance, while cold or depleted batteries show higher values.

Internal resistance testing helps you identify failing cells, prevent unbalanced loads, and avoid thermal hotspots that could lead to thermal runaway.

Tip: Use Electrochemical Impedance Spectroscopy (EIS) for detailed analysis, but remember it requires specialized equipment and expertise.

2.5 Battery Cycling

Battery cycling tests the long-term durability and reliability of lithium battery packs. You repeatedly charge and discharge the battery under controlled conditions, recording capacity, voltage, and temperature over hundreds or thousands of cycles.

Parameter / Condition | Observed Effect / Result |

|---|---|

Depth of Discharge (DoD) | Lower DoD extends cycle life and slows capacity fade |

Temperature | High temperature (45°C) increases degradation rate by up to 8.4% in 300 cycles |

Discharge Rate | Higher rates (0.8C) reduce cycle life by up to 53% |

Cycle Life Range (LFP cells) | 1800–2500 cycles at 80% DoD under recommended conditions |

Failure Rate / Hazard Rate | Hazard rate rises by 70% at 0.5C and 30% at 0.8C with temperature increase |

Median Time to Failure | Decreases by 41% at 0.5C and 23% at 0.8C with temperature increase |

You should use dynamic cycling protocols that mimic real-world usage, such as those found in electric vehicles or industrial applications. These protocols provide more accurate lifetime predictions than constant current cycling, which can underestimate battery life by up to 38%.

Note: Periodic capacity checks during cycling help you monitor degradation trends and optimize maintenance schedules.

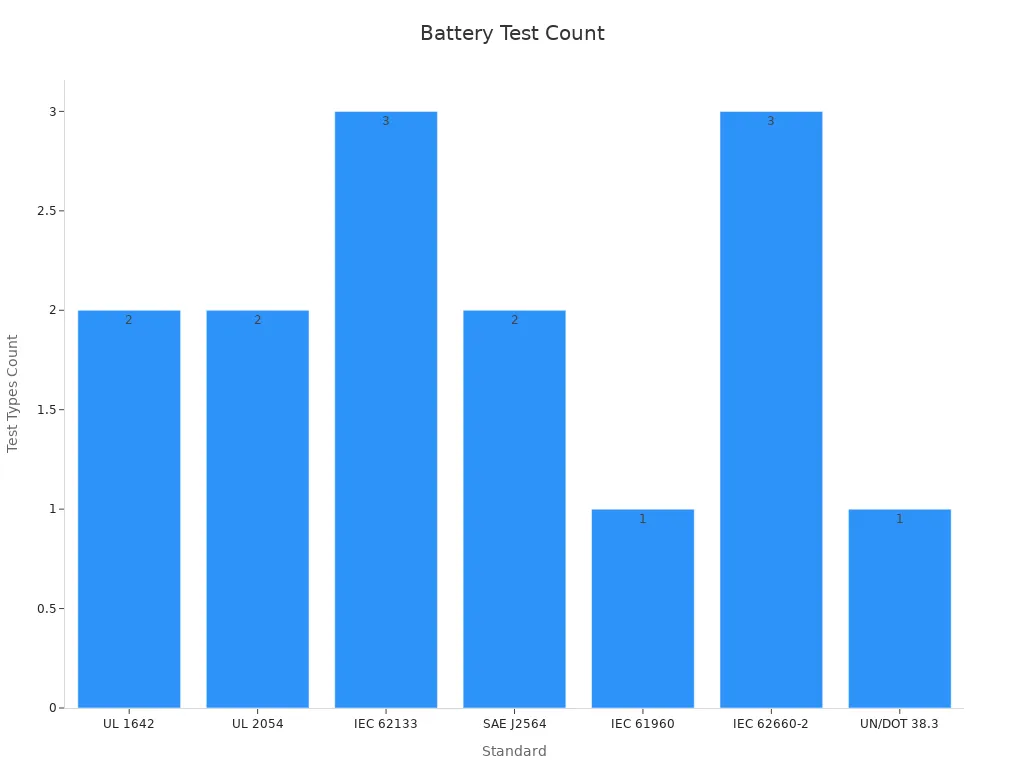

Technical Standards and Equipment Overview

You must follow international standards to ensure your battery testing meets regulatory and safety requirements. The table below summarizes key standards and their focus areas:

Standard | Test Types Included | Purpose and Key Details |

|---|---|---|

UL 1642 | Short circuit, temperature cycling | Assesses battery response to internal short circuits and lifecycle under extreme temperature cycles. |

UL 2054 | Mold stress relief, temperature cycling | Examines battery design and construction for household/commercial use; ensures no mechanical damage. |

IEC 62133 | Short circuit, mold stress relief, thermal abuse | Confirms internal safety mechanisms under thermal abuse and temperature cycling for portable devices. |

SAE J2564 | Thermal stability, thermal shock | Simulates electric/hybrid vehicle conditions; monitors thermal response and safety under rapid changes. |

IEC 61960 | Discharge performance | Measures battery power delivery and capacity at various temperatures for portable applications. |

IEC 62660-2 | Thermal test, temperature cycling, capacity discharge | Focuses on electric vehicle batteries; tests reliability, abuse tolerance, and discharge capacity. |

UN/DOT 38.3 | Temperature cycling | Ensures safety for transportation by exposing batteries to wide temperature ranges and monitoring safety. |

You need environmental chambers, industrial ovens, analyzers, and impact testers to simulate real-world and extreme conditions. These tools help you monitor voltage, current, deformation, and thermal response, ensuring your lithium battery packs meet the highest standards for safety and performance.

For custom battery testing solutions or expert consultation, contact our team.

Part 3: Equipment and Best Practices

3.1 Testing Instruments

You need reliable battery test equipment to ensure accurate results in lithium battery testing. Modern battery testers use advanced thermodynamic frameworks and electrochemical impedance spectroscopy (EIS) to deliver precise measurements. EIS, combined with machine learning, captures complex battery states and reduces prediction errors, even under uneven usage or temperature changes. You benefit from high-dimensional data, which provides a robust assessment of battery health. Technical reports, such as those from Gamry, detail setups using Kelvin sensing and specialized holders, ensuring precise voltage and current monitoring. You can measure capacity, voltage limits, and long-term behavior with these instruments, making them essential for professional battery applications.

3.2 Tool Selection

Selecting the right battery test equipment requires careful evaluation. You should prioritize accuracy and precision for reliable data. Look for battery testers with comprehensive data acquisition, real-time monitoring, and customizable protocols. Automation features, such as automated cycle testing, reduce human error and support long-duration tests. Integrated temperature control is critical, as lithium batteries are sensitive to temperature changes. Safety features, including explosion-proof enclosures and emergency shut-offs, protect your team during high-stress tests. Scalability and modular design allow you to test various battery sizes, from single cells to large packs. Different battery tester models suit different needs—R&D labs need precision, while manufacturing benefits from automation and energy feedback technology.

Criteria | Importance for Battery Test Equipment |

|---|---|

Accuracy & Precision | Ensures reliable, reproducible results |

Automation | Reduces error, supports long-term testing |

Temperature Control | Maintains analysis accuracy |

Safety Features | Protects operators and equipment |

Scalability | Supports different battery formats |

3.3 Calibration and Maintenance

You must maintain your battery test equipment to guarantee consistent performance. Use a Battery Management System (BMS) for real-time monitoring and automated alerts. Schedule regular inspections, including cleaning terminals and air filters, to prevent overheating. Smart technology, such as remote monitoring and predictive analytics, helps you identify inefficiencies early. During summer, use temperature-compensated charging and store batteries in shaded areas to reduce heat-related wear. If you notice persistent overheating or rapid capacity loss, schedule professional maintenance to prevent serious damage. These practices help you avoid downtime and extend the life of your battery testers.

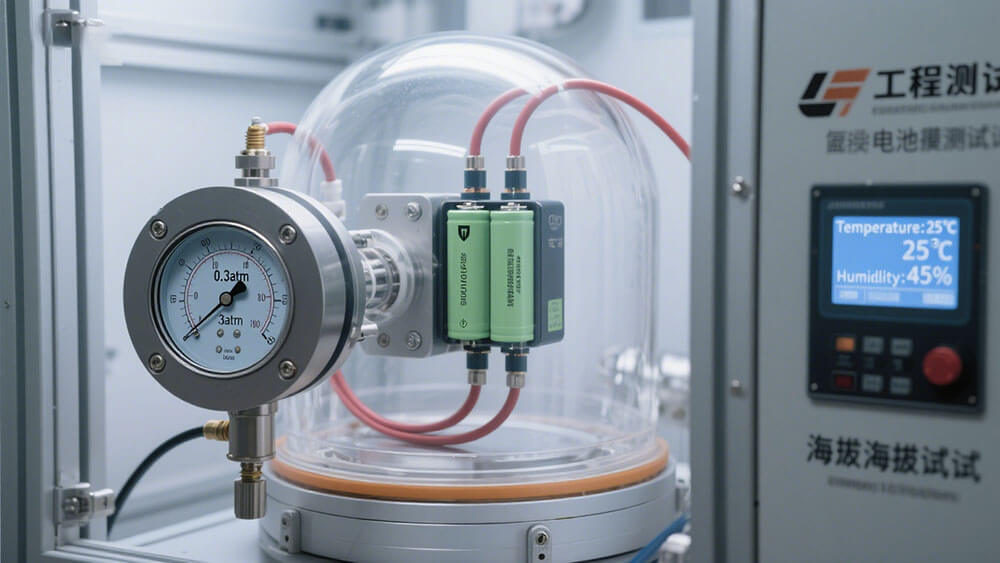

You ensure reliable lithium battery performance by following standardized testing protocols and best practices.

Always calibrate pressure and temperature for each battery test.

Use protective equipment and follow strict safety protocols.

Store each battery at low charge and −27 °C to minimize aging.

Adhere to global standards for every battery application.

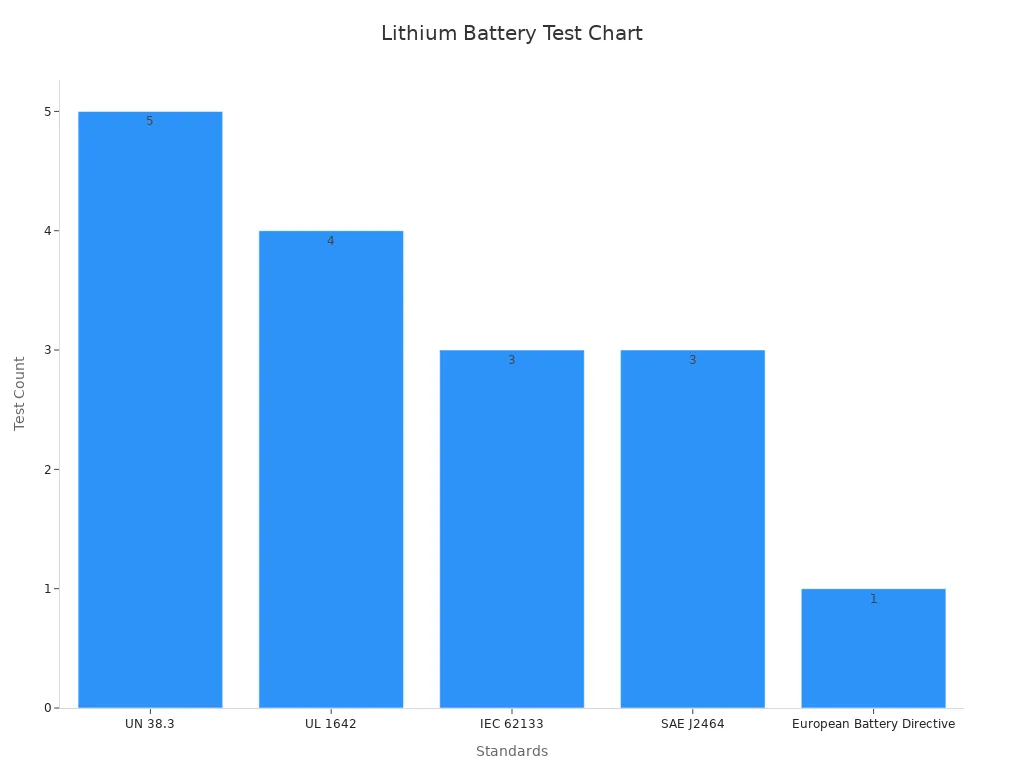

Standard | Key Tests Included |

|---|---|

UN 38.3 | Short circuit, vibration, shock |

UL 1642 | Overcharge, crushing |

IEC 62133 | Mechanical, thermal abuse |

FAQ

1. What is the most important test for lithium battery packs?

You should prioritize capacity testing. This test shows how much energy your battery can deliver. It helps you determine if your battery meets operational requirements.

2. How often should you calibrate your battery test equipment?

You need to calibrate your battery test equipment every six months. Regular calibration ensures your battery test results remain accurate and reliable for industrial and commercial use.

3. Where can you get custom battery solutions for your business?

You can contact Large Power for custom battery solutions. Their team provides expert consultation and advanced battery pack designs for your specific needs.