You need to know how to measure the remaining useful life of a battery to optimize your lithium battery packs for business. The remaining useful life gives you insight into when battery capacity drops below operational needs. By tracking remaining cycles and remaining energy, you can plan maintenance and avoid unexpected downtime.

Key Takeaways

Track battery capacity and cycle count regularly to estimate remaining useful life and plan timely maintenance before capacity drops below 80%.

Use State of Health (SOH) as a key metric to monitor battery condition and predict when replacement or service is needed to avoid unexpected failures.

Leverage advanced analytics and battery management systems to improve accuracy in predicting battery life, enabling smarter maintenance and cost savings.

Part 1: How to Measure the Remaining Useful Life of a Battery

1.1 Capacity and Cycle Count

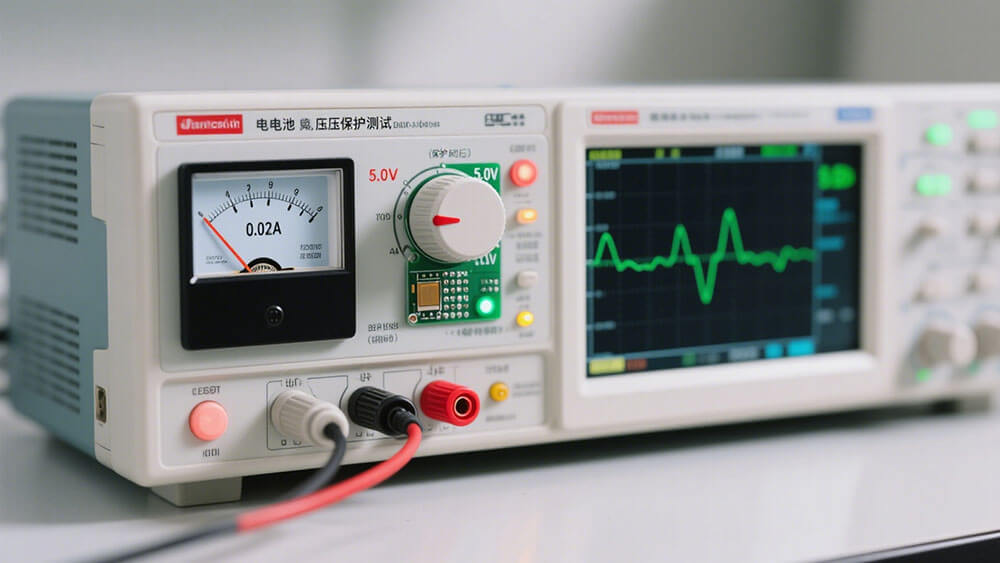

You need to start with battery testing focused on capacity and cycle count. Battery capacity measures the total charge a battery can deliver compared to its original specification. As batteries age, capacity decreases. You can track this decline through regular battery testing, which involves charging and discharging cycles under controlled conditions. In business applications, especially with lithium battery packs, you should record the number of cycles completed and monitor how much capacity remains after each cycle.

Tip: Industry standards define end-of-life (EOL) for lithium battery packs as the point when battery capacity drops to 80% of its original value. This threshold helps you decide when to schedule maintenance or replacement.

The formula for remaining useful life (RUL) is straightforward:

RUL = n − t

Where n is the total expected cycle life, and t is the number of cycles already completed. For example, if a battery is rated for 2,000 cycles and has completed 1,200, the remaining useful life is 800 cycles.

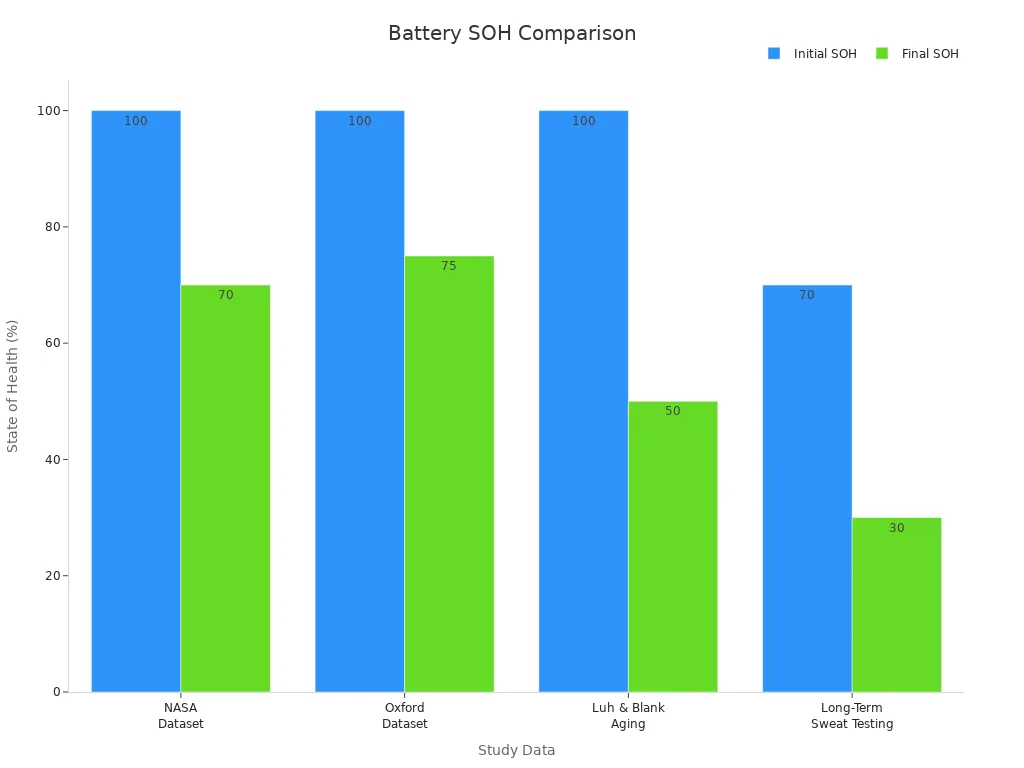

You can see how different research datasets approach capacity and cycle count tracking in the table below:

Dataset/Study | Test Conditions | Battery Cell Info | Capacity & SOH Range |

|---|---|---|---|

NASA Dataset | Charge/discharge cycling at varied temperatures; deep discharge to 2.7 V; EOL at 30% capacity fade | 34 cells; 2.0 Ah; LCO chemistry | SOH from 100% to 70% |

Oxford Dataset | 40°C thermal chamber; CC-CV charging; Urban Artemis drive cycle; Characterization every 100 cycles | 8 cells; 0.74 Ah; LCO chemistry | SOH from 100% to 75% |

Luh & Blank Comprehensive Aging | Standard CC-CV cycling with periodic impedance and capacity measurements | 228 cells; 1.5-2.0 Ah; NMC chemistry | SOH from 100% to 50% |

Long-Term Sweat Testing SLBs | Long-term cycling under 6 real-world energy storage scenarios | 6 modules (2S2P); 66 Ah; LMO chemistry | SOH from 70% to 30% |

These studies use high-resolution battery testing, sometimes recording data every few seconds, to track battery capacity and cycle count. This approach supports accurate rul estimation and helps you understand how your lithium battery packs degrade over time.

1.2 State of Health (SOH)

State of Health (SOH) is a key metric in battery diagnostics. SOH compares the current battery capacity to its rated capacity at the beginning of life. You can use SOH to assess how much useful life remains in your battery packs. SOH changes as the battery ages, influenced by cycle count, voltage fluctuations, and internal resistance. These condition indicators are essential for predicting remaining useful life.

Industry studies show that SOH is typically calculated as:

SOH = (Current Capacity / Rated Capacity) × 100%

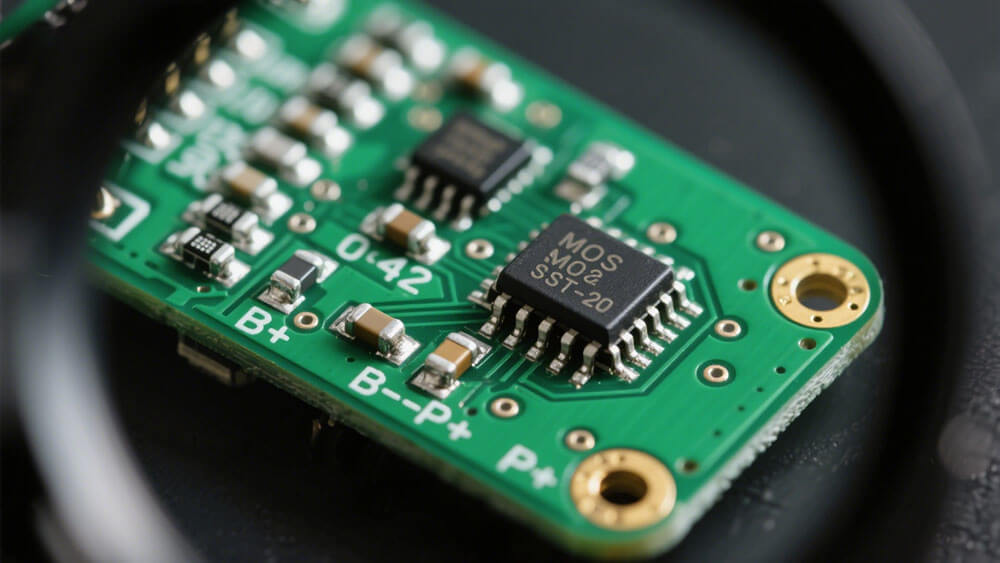

A battery with an SOH of 80% or less is usually considered at the end of its useful life. Accurate SOH estimation relies on regular battery testing, including capacity checks and resistance measurements. You can extract SOH data from your battery management system, which tracks cycle count, depth of discharge, and coulomb counting. This data-driven approach enables you to make informed decisions about predictive maintenance and replacement.

Note: SOH metrics directly inform rul estimation. As SOH declines, the remaining useful life shortens. Monitoring SOH helps you avoid unexpected failures and optimize battery performance.

1.3 Advanced Analytics

Advanced analytics have transformed how to measure the remaining useful life of a battery. You can now use artificial neural networks, machine learning, and cloud-based analytics to process large volumes of battery testing data. These tools analyze patterns in voltage, current, temperature, and internal resistance to predict remaining useful life with high accuracy.

Electrochemical Impedance Spectroscopy (EIS) is another powerful method. EIS, combined with AI, evaluates frequency scans and Nyquist plots to assess SOH and forecast battery degradation. Diagnostic chargers and cloud analytics further enhance battery diagnostics by integrating state of charge (SoC) measurements and coulomb counting with intelligent filtering algorithms.

Professional Insight: Leading business sectors such as healthcare, defense, and logistics use these advanced analytics for scheduled battery replacement and risk management. Predictive maintenance strategies rely on accurate rul estimation to reduce downtime and control costs.

Recent research highlights the effectiveness of these data-driven methods, but also notes challenges. Differences between laboratory and real-world conditions, lack of standardized datasets, and the need for detailed cell-level data can affect accuracy. Despite these hurdles, you can achieve 95-98% accuracy in capacity and resistance estimation by combining empirical, data-driven, and physics-based models.

To ensure precise measurement, you should use a battery management system equipped with integrated circuits for real-time monitoring. This system tracks voltage, capacity, and internal resistance, providing the foundation for reliable rul estimation and predictive maintenance.

If you want to optimize your lithium battery packs for sustainability, explore our approach to sustainability. For custom battery solutions tailored to your business, visit our OEM/ODM consultation page.

Part 2: Predictive Maintenance and Interpreting RUL

2.1 Key Indicators

You can use predictive maintenance to transform how you manage lithium battery packs. By leveraging remaining useful life data, you schedule interventions before failures occur. This approach relies on interpreting key condition indicators such as voltage, capacity, internal resistance, and cycle data. Regular battery testing provides these metrics, allowing you to spot early warning signs of battery performance decline. For example, a drop in voltage under load or a rise in internal resistance signals that the battery is nearing the end of its remaining cycles. Advanced battery diagnostics, including machine learning models, can achieve an average prediction error as low as 5.1% for RUL estimation. This precision enables you to minimize downtime and extend battery service life.

2.2 Degradation Factors

You need to understand the main factors that drive battery degradation to accurately estimate remaining useful life. Key contributors include temperature, depth of discharge, charge rate, and battery age. Real-world studies show that:

Lithium plating and dendrite formation accelerate capacity fade.

SEI formation and mechanical-chemical processes cause performance loss.

Operational factors like high charge rates and deep discharges shorten remaining cycles.

A table below summarizes how these factors impact battery life:

Degradation Factor | Impact on Battery Life | Quantitative Effect |

|---|---|---|

High Temperature | Increases chemical reaction rates | Reduces cycle life by up to 40% |

Deep Discharge | Accelerates capacity loss | Shortens remaining cycles by 20%+ |

Fast Charging | Promotes lithium plating | Increases internal resistance |

Battery Age | Natural capacity fade |

Real-time monitoring and battery management systems help you track these factors and adjust maintenance schedules accordingly.

2.3 Maintenance Decisions

You should base maintenance decisions on clear numerical criteria. Most industry guidelines define end-of-life for lithium-ion batteries as when capacity drops to 80% of the original value. Remaining useful life equals the number of cycles left before reaching this threshold. You can use both model-based and data-driven methods to predict RUL. Model-based approaches, such as mechanism and equivalent circuit models, offer high accuracy but require complex calculations. Data-driven methods, including machine learning, use operational data from battery testing to estimate RUL in real time.

Predictive maintenance strategies have proven benefits. In automotive and energy sectors, these strategies reduce unplanned downtime by up to 50% and cut maintenance costs by 10–40%. By acting on accurate RUL predictions, you improve reliability and safety while optimizing costs.

You can boost battery performance and cut costs by tracking RUL with advanced analytics and battery management systems. The table below shows how precise RUL models and active cell balancing deliver measurable benefits for lithium battery packs:

Method | Benefit | Impact on Cost & Performance |

|---|---|---|

ML RUL Prediction | Accurate maintenance planning | Fewer failures, lower lifecycle cost |

Active Cell Balancing | Improved battery health | Longer lifespan, better reliability |

Explore custom solutions with Large Power to maximize your battery investment.

FAQ

1. How often should you check the remaining useful life of lithium battery packs?

You should check RUL monthly using your battery management system. Regular monitoring helps you plan maintenance and avoid unexpected downtime in business-critical applications.

2. What factors most affect the RUL of lithium battery packs?

Temperature, charge rate, and depth of discharge impact RUL. You can optimize these factors to extend battery life in industrial, medical, and infrastructure projects.

3. How can Large Power help you optimize battery lifecycle management?

Large Power offers custom lithium battery solutions and advanced analytics. You can request a consultation here to maximize performance and reduce operational costs.