When you want to learn how to measure capacity of lithium batteries accurately, constant current discharge testing is the industry standard. Research, including the CALCE dataset, demonstrates that this method provides reliable and repeatable results for lithium-ion battery packs. Obtaining precise data on lithium battery capacity is essential to meet strict industrial and professional standards, ensuring safe and efficient operations.

Key Takeaways

Use the constant current discharge method with proper tools and controlled conditions to measure lithium battery capacity accurately and reliably.

Prepare batteries carefully by fully charging, resting at room temperature, and ensuring balanced cells before testing to get consistent results.

Prioritize safety when testing large lithium battery packs by inspecting for damage, using protective equipment, and following strict protocols to prevent accidents.

Part 1: How to Measure Capacity of Lithium Batteries

1.1 Preparation Steps

Accurate lithium battery capacity measurement begins with careful preparation. You must fully charge the lithium ion battery using a charger that matches the manufacturer’s specifications. This ensures the battery starts at its maximum state of charge, which is critical for reliable results. Allow the battery to rest at room temperature (20°C to 25°C) to stabilize before testing. Use a multimeter to record the initial voltage as a baseline. For lithium battery packs, confirm that all cells are balanced and that the battery management system (BMS) is operational.

Tip: Always document the battery type, chemistry (such as NMC Lithium battery, LiFePO4 Lithium battery, or LCO Lithium battery), rated capacity in ampere-hours or milliamp-hours, and the cutoff voltage specified by the manufacturer.

A step-by-step process for testing lithium-ion battery capacity includes:

Gather all necessary tools and equipment.

Fully charge the battery and let it rest.

Record the initial voltage.

Set up the discharge test with a constant current load.

Monitor voltage and temperature during discharge.

Stop the test at the cutoff voltage.

Calculate the capacity using the discharge current and time.

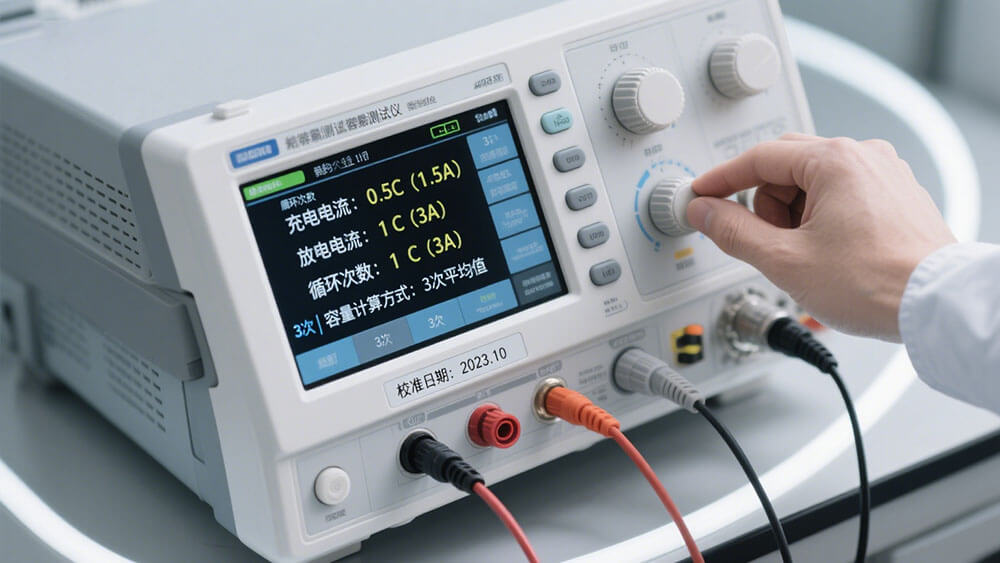

Industry best practices recommend controlling environmental conditions and using calibrated equipment. Periodic calibration and long-term trending of parameters like impedance and voltage help validate your measurement setup and ensure ongoing accuracy.

1.2 Tools and Equipment

You need specialized tools to measure battery capacity with precision. The essential equipment includes:

High-precision electronic load testers or battery analyzers for controlled discharge and data logging.

Multimeters for measuring voltage, current, and resistance.

Approved lithium-ion battery chargers.

Thermal cameras to monitor temperature during testing.

Data loggers for recording performance metrics.

Tool/Equipment | Function | Key Specification |

|---|---|---|

Electronic Load Tester | Applies constant current load, logs data | High precision, safety features |

Battery Analyzer | Automated charge/discharge, diagnostics | Data logging, BMS compatibility |

Multimeter | Measures voltage, current, resistance | High resolution, accuracy |

Thermal Camera | Monitors temperature during testing | Real-time monitoring |

Data Logger | Records voltage, current, temperature | Trend analysis, reliability |

Modern battery testers and analyzers provide higher accuracy than manual tools. Automated systems execute tests consistently, measure multiple parameters, and use advanced algorithms for battery capacity calculation. These features reduce human error and improve the reliability of lithium battery capacity measurement.

1.3 Constant Current Discharge

The constant current discharge method is the gold standard for how to measure capacity of lithium batteries. You connect the lithium ion battery to an electronic load set to a fixed current. The battery discharges until it reaches the manufacturer’s cutoff voltage. You then calculate the capacity using the formula:

Capacity (Ah) = Current (A) × Time (h)

For example, if you discharge a 10Ah lithium battery at 2A and it takes 5 hours to reach the cutoff voltage, the measured capacity is 10Ah. This method provides repeatable and accurate results for lithium-ion battery capacity, especially in industrial and medical applications.

Parameter | Result (Mean ± Std Dev) |

|---|---|

84.6% ± 7% | |

Total charge capacity | 6.6 ± 0.5 kWh |

Useful discharge capacity | 5.5 ± 0.4 kWh |

Energy density (charge, Wh/kg) | 86 ± 6 |

Energy density (discharge, Wh/kg) | 73 ± 5 |

These results, obtained through constant current discharge cycling, confirm the method’s accuracy for testing lithium batteries. Advanced techniques, such as electrochemical dynamic response testing and frequency domain impedance spectroscopy, can further enhance reliability by analyzing internal resistance and ion mobility.

1.4 Shunt Resistor Method

The shunt resistor method allows you to measure current precisely during battery testing. You place a low-resistance, high-precision shunt resistor in series with the lithium ion battery. By measuring the voltage drop across the resistor, you calculate the current using Ohm’s law:

Current (A) = Voltage (V) / Resistance (Ω)

For example, a 0.01Ω resistor with a 100mV drop indicates a current of 10A. Select a resistor with a suitable power rating to avoid overheating. Use low-tolerance resistors and 4-wire Kelvin connections to maximize accuracy. This method is reliable and cost-effective for current measurement in lithium battery capacity tests, especially when integrated into battery management systems.

Note: The shunt resistor method is widely used in both laboratory and field settings for its precision and minimal impact on circuit performance.

1.5 Test Lithium Ion Battery with Multimeter

You can use a multimeter to test lithium-ion battery voltage, but this tool alone cannot measure battery capacity. A multimeter provides a snapshot of voltage, which helps identify fully charged or depleted cells. However, true lithium-ion battery capacity measurement requires you to measure voltage over time during a controlled discharge.

CR2032 coin cells, for example, show rated capacities over 200mAh at low currents, but real-world tests at higher currents reveal much lower capacities.

Temperature and load variations can cause up to a 30% reduction in capacity, which a multimeter cannot detect.

Alert: Relying solely on a multimeter for lithium battery capacity measurement can lead to inaccurate results. Always use a step-by-step process for testing lithium-ion battery capacity with proper load testing equipment.

For professional applications, battery testers and analyzers offer automated, repeatable, and highly accurate measurements. These devices use pre-programmed protocols, advanced diagnostics, and real-time data analysis to measure battery capacity, state of charge, and internal resistance. Automated systems reduce errors and provide comprehensive reports, making them essential for industrial, medical, and infrastructure battery packs.

If you want to explore custom solutions for your lithium battery capacity testing needs, consider our custom battery consulting services.

Part 2: Capacity Testing for Lithium-Ion Battery Packs

2.1 Safety Checks

Before you perform capacity testing for lithium-ion battery packs, you must prioritize safety. Large lithium ion battery packs can pose serious hazards, including thermal runaway, fire, and toxic gas release. Documented incidents, such as the Arizona battery facility explosion, show that inadequate safety protocols can lead to severe injuries and property damage. Always inspect for swelling, heat, or deformation before you test lithium ion battery packs. Use explosion-proof chambers, gas detection systems, and proper ventilation. Equip your team with protective gear and establish emergency plans with local fire departments. Follow manufacturer procedures for handling, lifting, and charging. These steps help you prevent accidents and ensure a safe testing environment.

Key Safety Tests:

External Short Circuit Test

Forced Internal Short Circuit Test

Overcharge Test

Forced Discharge Test

Cycle Life Test

Crush Test

2.2 Recording and Calculating Results

To measure battery capacity accurately, you need to record discharge time and current throughout the test lithium ion battery process. Use calibrated instruments and data loggers to capture every detail. For constant current discharge, multiply the current by the discharge time to get capacity in ampere-hours (Ah). For more advanced analysis, integrate current over time using Q = ∫ I dt. You can also convert to watt-hours (Wh) by multiplying Ah by the average voltage. Lower current and stable temperature yield more reliable lithium-ion battery capacity results. Always document environmental conditions and equipment settings for traceability.

Computation / Formula | Description | Practical Considerations |

|---|---|---|

Q = ∫ I dt | Integrate current over time for total charge | Best for variable current |

Q = I × Δt | Multiply current by time for constant current | Most common in lab tests |

Peukert’s Law | Adjusts for current dependence | Useful for high-current loads |

2.3 Interpreting Lithium-Ion Battery Capacity Data

After you measure battery capacity, compare your results to the manufacturer’s specifications. New lithium ion battery packs should deliver close to 100% of rated capacity, but real-world values often fall short. For example, a battery rated at 2000mAh may only deliver 727mAh in actual tests. Aging, recent charge cycles, and environmental factors all impact lithium-ion battery capacity. If your measured capacity drops below 80% of the rated value, consider the battery for replacement. Use capacity as a key indicator of battery life and capacity health in your industrial, medical, or infrastructure applications.

Manufacturer specs reflect new battery performance.

Real-world capacity declines after production.

Measured capacity below 80% signals end-of-life.

2.4 Troubleshooting and Common Mistakes

You may encounter errors during lithium battery capacity testing. Common issues include not fully charging the battery, using the wrong cutoff voltage, or poor connections. Inconsistent readings often result from dirty terminals, loose cables, or environmental changes. Multimeter errors, such as incorrect settings or weak batteries, can also affect your results. Regularly calibrate your instruments and inspect all connections before you test lithium ion battery packs. Use a reliable battery management system (BMS) to improve accuracy and reduce random errors. Advanced analytics and AI tools can help you predict failures and optimize battery life and capacity.

Poor probe contact and corroded terminals cause inconsistent readings.

Incorrect cutoff voltage leads to inaccurate lithium-ion battery capacity results.

Regular calibration and maintenance prevent measurement errors.

For custom solutions and expert support on lithium battery capacity testing, explore our custom battery consulting services.

You achieve accurate capacity measurement for lithium battery packs by following strict protocols, using calibrated tools, and applying advanced methods like Electrochemical Impedance Spectroscopy. Reliable capacity data supports battery health management and safety. The table below shows how proper protocols improve capacity estimation and state-of-health accuracy.

Protocol | Improved Capacity Estimation | Enhanced SOH Prediction |

|---|---|---|

Standard | Yes | Yes |

Inconsistent | No | No |

FAQ

1. How often should you test the capacity of lithium battery packs in industrial applications?

You should test capacity every 6–12 months. Regular testing helps you track battery health and prevent unexpected failures in industrial systems.

2. What is the most reliable method for measuring lithium battery pack capacity?

Constant current discharge testing gives you the most accurate results. This method follows industry standards and works well for NMC, LiFePO4, and LCO lithium battery packs.

3. Can Large Power provide custom lithium battery capacity testing solutions?

Yes. Large Power offers tailored consulting and testing solutions for your specific lithium battery pack needs.