Imagine your electric vehicle fleet halting during peak hours because outdated battery testing missed a critical fault. Today, advancements in battery testing transform how you manage batteries, especially for lithium battery technology and energy storage. Automated diagnostics and predictive analytics now empower you to detect issues early, optimize battery performance, and boost safety. In 2025, global demand for advanced battery technology in electric vehicle and industrial applications drives the market to over USD 7.5 billion, ensuring your batteries deliver reliability and longevity.

Key Takeaways

Advanced AI and machine learning tools help detect battery issues early, improving reliability and reducing costly downtime in electric vehicles and industrial systems.

Electrochemical Impedance Spectroscopy (EIS) offers fast, accurate, and non-destructive battery health assessments, supporting better quality control and longer battery life.

Real-time monitoring, predictive analytics, and eco-friendly testing practices enable safer, more efficient battery management while meeting evolving regulatory and sustainability standards.

Part 1: Advancements in Battery Testing

1.1 AI Diagnostics

You now have access to advanced AI diagnostics that transform how you manage batteries in electric vehicle fleets, energy storage systems, and industrial applications. Artificial intelligence and machine learning models, such as neural networks, fuzzy logic, and Gaussian Process Regression (GPR), deliver rapid and highly accurate assessments of battery health. These models analyze complex data from batteries, including voltage, current, and impedance, to predict failures before they disrupt your operations.

AI-driven diagnostics have already shown measurable benefits in the automotive sector. For example, General Motors uses predictive analytics to detect defects in Chevy Bolt EV batteries, leading to early recalls and lower warranty costs. Ford Motor Company’s AI-powered maintenance systems forecast battery failures with 22% accuracy up to 10 days in advance, reducing false positives to just 2.5%. These systems have prevented over 122,000 hours of vehicle downtime and saved $7 million through proactive maintenance. Over three years, Ford avoided $100 million in module replacement costs by using remote reprogramming, which also accelerated issue resolution and reduced field service expenses.

Neural networks and GPR models achieve up to 90% accuracy in predicting the state of health for lead acid batteries, with similar promise for lithium-ion batteries. Fuzzy logic, while common in EIS analysis, provides valuable insights, especially when combined with other AI methods. These advancements in battery testing enable you to identify weak batteries early, optimize replacement schedules, and reduce costly downtime.

Method | Accuracy | Battery Type | Notes |

|---|---|---|---|

Neural Network | ~90% | Lead acid batteries | Among best performers in predicting battery health on a pool of 800 batteries |

Gaussian Process Regression | ~90% | Lead acid batteries | Comparable to Neural Network, promising results |

Fuzzy Logic | N/A | Lead acid batteries | Common in EIS analysis, but lower accuracy on poor batteries |

You benefit from rapid diagnostics, with average trial errors for state of health (SoH), state of power (SoP), and state of charge (SoC) all below 0.01. Diagnostic times are under three minutes, and neural networks reconstruct incremental capacity extrema from pulse harmonics with less than 1% error. These results support the use of AI diagnostics for better and cheaper EV batteries, especially as you scale up your operations.

1.2 EIS Technology

Electrochemical Impedance Spectroscopy (EIS) stands at the forefront of advancements in battery testing. EIS technology provides you with a non-destructive, rapid, and highly accurate method to assess the state of health for lithium-ion, lead acid, and solid-state batteries. By applying sinusoidal signals across a range of frequencies, EIS captures the internal resistance and electrochemical dynamics of batteries, generating detailed Nyquist plots for analysis.

Recent studies show that EIS, combined with statistical learning models like support vector regression (SVR), can evaluate battery state of health in less than 10 seconds. This approach balances speed and accuracy, making it ideal for high-throughput environments such as electric vehicle manufacturing and large-scale energy storage deployments. EIS also isolates key impedance features—Ohmic, charge transfer, and SEI resistances—using distribution of relaxation time (DRT) analysis. This method maps state of health directly to electrochemical impedance, minimizing the impact of confounding factors like state of charge and temperature.

Experimental validation confirms that EIS-based models achieve a goodness-of-fit of 0.99 when predicting battery health across different temperatures and charge levels. This high level of precision allows you to monitor batteries throughout their lifecycle, from new EV batteries to end-of-life recycling. EIS technology supports the development of better and cheaper EV batteries by reducing testing time, improving reliability, and enabling robust quality control for solid-state and lithium-ion battery packs.

1.3 Predictive Analytics

Predictive analytics now play a critical role in optimizing battery performance and diagnostics. By integrating multi-model EIS data, Nyquist plotting, and advanced machine learning algorithms, you gain actionable insights into battery degradation, failure modes, and maintenance needs. These tools help you extend battery life, reduce warranty claims, and ensure the safety of electric car batteries and other high-value assets.

Method / Model | Data Type / Feature | Key Results | Advantages |

|---|---|---|---|

WOA-BP Neural Network with static multi-frequency EIS feature points from Nyquist plots | Static multi-frequency feature points from Nyquist plots | RMSE: 0.23% to 0.43% (including untrained data) | High accuracy, reduced training time, robustness, practical applicability, reduced testing time compared to full EIS |

VGG16 Neural Network with Gramian angular field images of EIS data | 2D images converted from EIS data | RMSE < 2% | Effective SOH estimation with image-based features |

Multi-Layer Perceptron (MLP) on statistical EIS features under varying temperatures | Statistical features from EIS | MAPE: 0.97% | Best performance among six ML models tested, good generalization across temperature cycles |

Gaussian Process Regression (GPR) on full EIS data | Full EIS data | High accuracy, no feature engineering needed | Adaptable to different battery types, strong nonlinear fitting, suitable for small datasets |

Adaptive State Observer (ASO)-BP model with bidirectional broadband EIS | Broadband EIS data | SOC error: 2.57%, SOH error: 0.838% | Accuracy, efficiency, stability improvements |

Support Vector Regression (SVR) and BP Neural Network on impedance module values at various frequencies | Characteristic frequency impedance values | SOH evaluation and frequency test completed in <10 seconds | Fast, non-destructive, low-cost |

You can leverage these predictive models to monitor batteries in real time, forecast failures, and optimize maintenance schedules. For example, the WOA-BP neural network uses static multi-frequency EIS feature points from Nyquist plots to achieve root mean square errors (RMSE) as low as 0.23% on untrained data. VGG16 neural networks process EIS data as images, delivering state of health estimation errors below 2%. Multi-layer perceptrons and GPR models generalize well across temperature cycles and battery chemistries, including solid-state and lithium-ion batteries.

These advancements in battery testing empower you to make data-driven decisions, reduce operational risks, and support the deployment of better and cheaper EV batteries. As you integrate these technologies into your battery management systems, you ensure the reliability and safety of batteries across electric vehicle, energy storage, and industrial applications. For custom solutions tailored to your needs, explore our cusotm battery consulting services.

Part 2: Real-Time Monitoring

2.1 Sensor Integration

You rely on advanced sensor integration to monitor batteries in real time. High-resolution sensors measure voltage, temperature, state of charge (SoC), and state of health (SoH) for each battery cell. These sensors use MEMS technology, which improves precision and durability while reducing power consumption. You can access real-time battery health data through vehicle dashboards or cloud platforms, making it easy to track performance and safety. Wireless connectivity allows you to receive instant alerts and recommendations for maintenance or charging adjustments. With continuous monitoring, you can optimize depth of discharge and extend the lifespan of lithium battery packs.

High-precision sensors track voltage, current, and temperature.

Real-time data supports immediate adjustments to charging and discharging.

Wireless connectivity enables remote diagnostics and integration with control systems.

IoT and telematics platforms provide remote access to battery analytics.

2.2 Digital Twins

Digital twins give you a virtual replica of your battery systems. You can simulate real-world conditions and predict how batteries will perform under different scenarios. This technology helps you identify potential failures before they occur. By using digital twins, you can test new strategies for charging, discharging, and thermal management without risking actual batteries. You gain insights that improve reliability and reduce operational costs for electric vehicles, industrial equipment, and infrastructure projects.

Tip: Digital twins work best when paired with real-time sensor data, creating a feedback loop that enhances predictive maintenance and extends battery life.

2.3 Usage Pattern Analysis

Analyzing usage patterns helps you optimize maintenance and reduce downtime. By comparing predicted failures with actual outcomes, you validate the accuracy of your predictive models. You track false positives and negatives, document maintenance actions, and measure cost savings from proactive interventions. Regular review cycles and cross-functional collaboration ensure your strategies stay effective.

Industry | Impact of Usage Pattern Analysis on Predictive Maintenance |

|---|---|

Healthcare (MRI) | 16.3% less downtime by analyzing three years of sensor data |

Telecommunications | 52% of failures predicted before they happen |

Manufacturing | 25-30% lower maintenance costs; 70-75% fewer breakdowns |

Energy & Utilities | 38% fewer unplanned outages; 20% longer equipment lifespan |

Transportation & Aviation | 16% fewer maintenance delays; $7-9 million annual savings |

You can apply these insights to lithium battery packs in electric vehicles, robotics, and industrial systems.

Part 3: Testing Protocols

3.1 Fast-Charging Validation

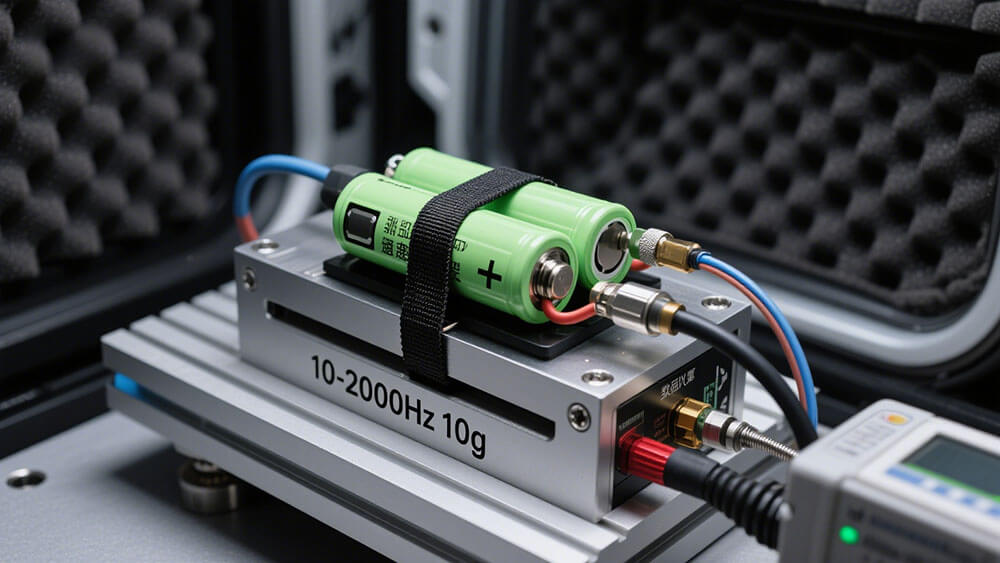

You face growing demand for fast-charging in electric vehicles, industrial equipment, and infrastructure projects. Validating fast-charging protocols ensures your batteries deliver both performance and longevity. Recent research highlights that DC fast charging, while convenient, can accelerate battery degradation. You must balance speed with battery health by using advanced control strategies and thermal management systems. Sensors monitor temperature and voltage in real time, helping you prevent overheating and lithium plating.

A Matlab/Simulink model evaluated battery lifetime under fast charging for NMC, LTO, and LiFePO4 Lithium battery chemistries across European city bus lines.

Sensitivity analyses identified charger power and battery capacity as critical factors for battery degradation.

Higher charger power increases degradation, while larger capacity reduces it by lowering C-rate and depth-of-discharge.

Fast charging effects vary by chemistry and operation, so protocols must reflect real-world driving and charging profiles.

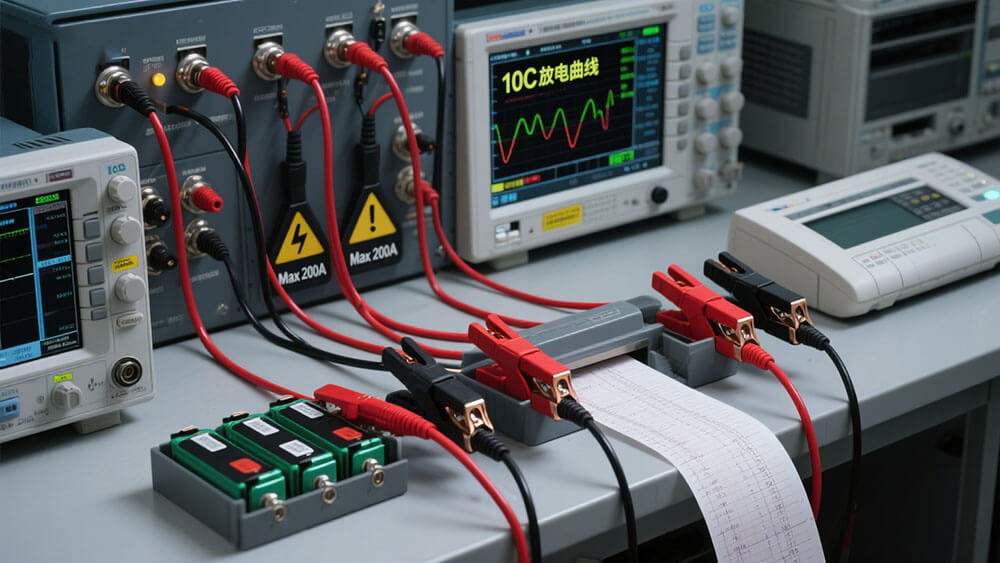

Experimental platforms tested charging and discharging on lithium-ion batteries of different shapes and chemistries, measuring open circuit voltage at various temperatures.

A review in Nature underscores the importance of AI-driven optimization and advanced sensors for thermal management. These tools help you validate fast-charging techniques and extend battery life, especially for solid-state and lithium-ion batteries. For more on lithium-ion technology, see here.

Charging Level | Speed | Impact on Battery Health | Best Use Case |

|---|---|---|---|

Level 1 | Slow | Best for longevity | Overnight charging |

Level 2 | Moderate | Balanced | Daily operations |

DC Fast | Very fast | Accelerates degradation | Quick top-ups |

Note: Proper design of charging stations and battery sizing can reduce degradation and support longer battery life.

3.2 Lifecycle Testing

You need robust lifecycle testing to ensure your batteries meet safety and reliability standards. Lifecycle protocols simulate real-world usage, including dynamic loads, temperature changes, and fast-charging cycles. These tests help you predict battery lifespan and optimize maintenance schedules for industrial, infrastructure, and electric vehicle applications.

Experimental studies compare battery degradation under various charging protocols, temperatures, and dynamic loads.

Fast charging strategies analyzed across different state-of-charge intervals reveal temperature changes and thermal stress.

Open circuit voltage curves measured at different temperatures provide insights into battery behavior and help refine testing protocols.

A hybrid early life prediction model, validated on the MIT-Stanford dataset, uses early cycle data and domain knowledge features to predict battery life. The model achieved mean absolute percentage errors below 10%, showing strong performance across different fast-charging policies. This approach helps you identify degradation mechanisms like lithium plating and mechanical wear, especially in solid-state and lithium-ion batteries.

Part 4: Safety and Sustainability

4.1 Regulatory Trends

You face a rapidly evolving regulatory landscape for battery safety and sustainability in 2025. Global standards now demand rigorous testing and transparent compliance. The table below summarizes key standards shaping battery testing:

Regulatory Standard | Focus Area | Support for Battery Testing Trends |

|---|---|---|

IEC 62133 | Safety for portable sealed secondary cells | Addresses fire and explosion hazards, driving strict safety protocols |

UL 2054 | Reliability and performance evaluation | Supports environmental exposure and reliability, enhancing sustainability |

UN/DOT 38.3 | Transport safety for lithium cells | Ensures safe shipping, influencing transport testing |

ISO 12405 | Power source evaluation, cycle life | Maintains quality and lifecycle performance |

SAE J2464 | EV battery evaluation | Critical for electric vehicle market growth |

Recent updates, such as UL 9540A:2025, shift your focus from passing tests to designing for lifetime safety. You now see expanded applicability to more chemistries, improved flame spread criteria, and new requirements for thermal runaway prevention. The EU Batteries Regulation (EU) 2023/1543 enforces safety and sustainability across the battery lifecycle, including mandatory propagation testing and the Digital Battery Passport. These changes drive you to adopt advanced testing and documentation for all batteries, especially in renewable energy and infrastructure projects.

4.2 Eco-Friendly Testing

You can now implement eco-friendly testing practices that reduce environmental impact and support regulatory compliance. Sustainable testing methods optimize energy use, minimize resource consumption, and promote responsible sourcing. You achieve measurable reductions in energy consumption—up to 20%—by optimizing code and infrastructure. Real-time monitoring and containerization further minimize resource use. You set sustainability objectives and track progress with clear metrics.

Incorporate sustainability checks into compliance tests.

Use Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) for transparency.

Apply carbon footprinting to identify and reduce emissions.

Foster an energy-aware culture by rewarding sustainable development.

These practices support circular economy principles and help you meet both regulatory and market demands.

4.3 Recycling Protocols

You play a key role in advancing battery recycling protocols that lower environmental impact. Life-cycle assessments show that recycling retired batteries without second use reduces total carbon emissions by 0.8% to 3.4%. When you implement 100% second use, carbon emission reductions reach nearly 38%. Hydrometallurgical recycling techniques offer lower global warming potential and save up to 43% in cathode manufacturing costs compared to virgin materials. Optimizing reverse logistics and increasing collection rates further amplify these benefits.

Tip: Second-use strategies and advanced recycling methods help you achieve long-term sustainability goals and regulatory compliance.

You now see battery testing drive higher performance, safety, and reliability for lithium battery packs and emerging chemistries.

Automation, AI, and cloud analytics shape the future of battery diagnostics.

Regulatory standards and sustainability goals accelerate innovation.

Explore custom solutions to stay ahead in this evolving landscape. What will your next battery breakthrough be?

FAQ

1. What are the main benefits of advanced battery testing for lithium battery packs?

You gain higher accuracy, faster diagnostics, and predictive maintenance. These improvements reduce downtime and warranty claims for industrial, medical, and robotics applications.

2. How does Electrochemical Impedance Spectroscopy (EIS) improve battery health assessment?

EIS provides real-time, non-destructive analysis of internal resistance and electrochemical dynamics. You receive precise state-of-health data for lithium battery packs and other chemistries.

Method | Key Benefit | Application |

|---|---|---|

EIS | Accurate SoH | Lithium battery packs, industrial, infrastructure |

3. How can you customize battery testing solutions with Large Power?

You can request tailored consulting and custom battery services from Large Power to meet your unique requirements for lithium battery testing and management.