You depend on your deep cycle battery systems for critical operations. Traditional testing often fails to reveal hidden faults, especially in advanced lithium packs. Deep battery diagnostics now gives you actionable insights and predictive accuracy, transforming how you maintain and deploy batteries in demanding business environments.

Key Takeaways

Per IEC 61960-3, 34% of hidden faults in lithium batteries evade traditional tests. Deep diagnostics require multidimensional approaches. Traditional battery tests often miss hidden problems; deep battery diagnostics reveal internal faults and predict failures early.

Advanced tools like Electrochemical Impedance Spectroscopy (EIS) provide fast, detailed health checks that improve battery safety and lifespan.

Combining regular checks with modern diagnostics helps you save costs, avoid downtime, and make smarter decisions about battery maintenance.

Part 1: Deep Cycle Battery Issues

1.1 Common Problems

You rely on deep cycle battery systems for uninterrupted operations in sectors like industrial, infrastructure, and medical. However, you often face several recurring challenges:

Capacity Fade: Over time, your deep cycle battery loses its ability to hold charge, reducing operational hours and increasing downtime.

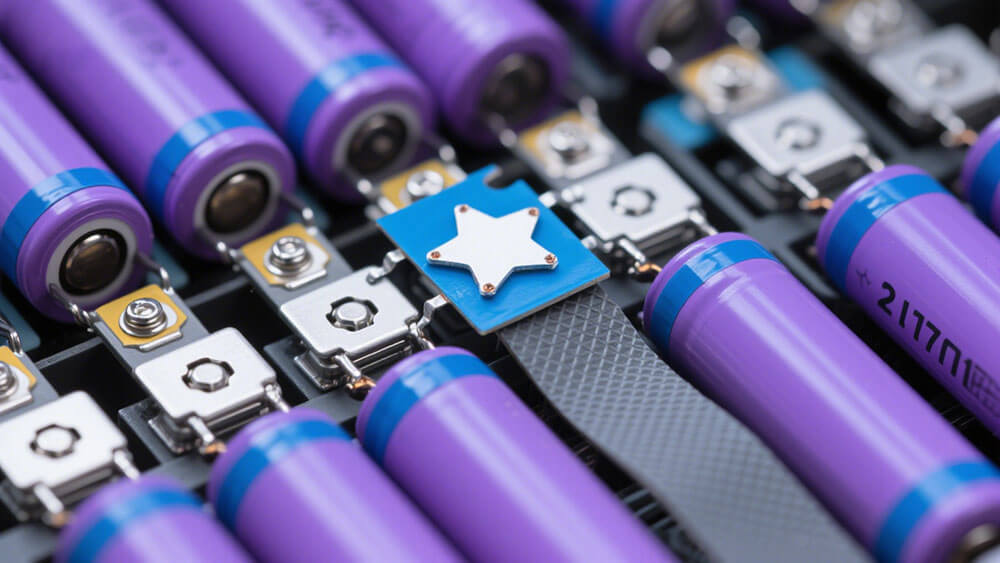

Inconsistent Performance: Variations in temperature, load, and charging cycles can cause unpredictable behavior in lithium-ion and LiFePO4 battery packs. Learn more about lithium-ion batteries.

Hidden Internal Faults: Micro-cracks, dendrite growth, or electrolyte degradation may not show up in basic voltage checks but can lead to sudden failures.

Battery Safety Risks: Without proper monitoring, thermal runaway or short circuits can threaten both equipment and personnel.

Premature Replacement: You might replace deep cycle battery packs too early, increasing costs and environmental impact.

Tip: Regularly review your battery management system (BMS) to catch early warning signs. Read more about BMS operation.

1.2 Need for Deep Battery Diagnostics

You need more than basic voltage or load tests to ensure reliable performance from your deep cycle battery fleet. Advanced diagnostics help you:

Diagnostic Method | What It Detects | Speed | Suitability for Lithium Packs |

|---|---|---|---|

Voltage/Visual Check | Surface faults, gross failures | Fast | Limited |

Load/Capacity Testing | Capacity loss, weak cells | Moderate | Moderate |

Deep Battery Diagnostics | Internal resistance, SoH, RUL | Rapid | Excellent |

Deep battery diagnostics uses tools like electrochemical impedance spectroscopy to give you a complete picture of your deep cycle battery’s health. This approach lets you predict failures, optimize replacement schedules, and improve battery safety across your operations. For custom solutions tailored to your business, contact our team for consultation.

Part 2: Diagnostic Process

2.1 Tools and Preparation

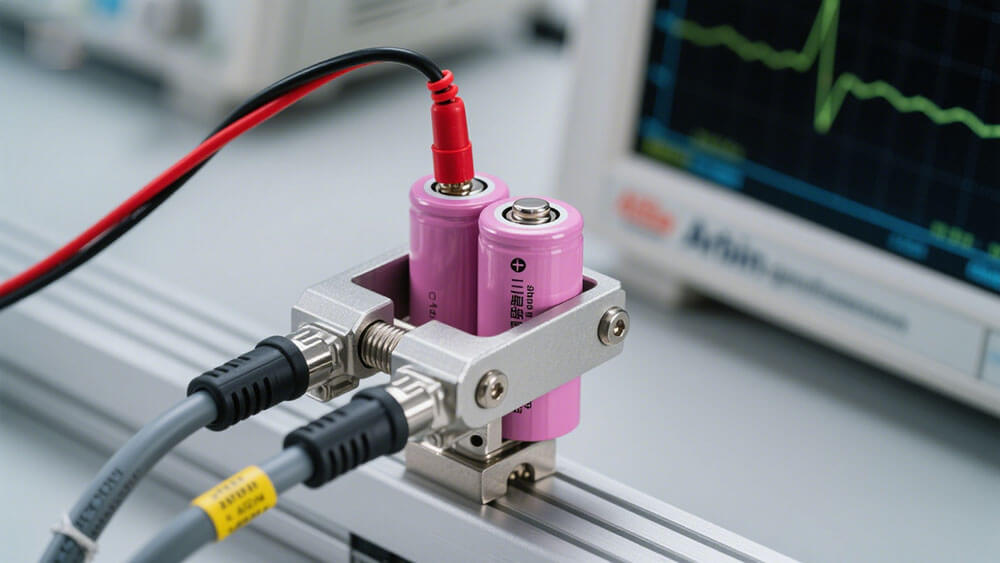

You need the right tools and preparation to ensure accurate results when diagnosing your deep cycle battery systems. Start by gathering essential equipment:

Multimeter: Measures voltage and basic electrical parameters.

Battery Analyzer: Provides more detailed information about battery health.

Load Tester: Assesses the battery’s ability to deliver current under load.

Electrochemical Impedance Spectroscopy (EIS) Device: Enables advanced diagnostics, such as those used in deep battery diagnostics.

Before testing, review your battery management system (BMS) settings. This step helps you identify any preset thresholds or alerts that could affect your results. For lithium-ion battery packs, always follow manufacturer safety guidelines and wear appropriate personal protective equipment.

Tip: For large fleets or critical infrastructure applications, schedule regular diagnostic sessions to prevent unexpected failures. Learn more about infrastructure battery solutions.

2.2 Visual and Voltage Checks

Begin your diagnostic process with a visual inspection. Look for signs of swelling, corrosion, or leakage on your deep cycle battery. These issues often indicate internal damage or safety risks.

Next, use a multimeter to check the open-circuit voltage. Compare your readings to the manufacturer’s specifications. For lithium-ion battery packs, a voltage outside the normal range may signal cell imbalance or deep discharge.

Check Type | What You Find | Action Needed |

|---|---|---|

Visual | Swelling, corrosion, leaks | Replace or service |

Voltage | Low/high readings | Investigate further |

Note: Visual and voltage checks offer a quick first look but may not reveal hidden faults inside your deep cycle battery.

2.3 Capacity and Load Testing

You can use capacity and load testing to measure how much energy your deep cycle battery can store and deliver. This step is crucial for applications in industrial, medical, and robotics sectors, where reliability is non-negotiable.

Capacity Testing:

Discharge the battery at a controlled rate and record the total ampere-hours delivered until it reaches the cutoff voltage. This test shows if your battery still meets operational requirements.

Load Testing:

Apply a specific load and monitor voltage drop. A healthy deep cycle battery maintains voltage under load, while a weak battery drops quickly.

Test Type | What It Measures | Typical Use Case |

|---|---|---|

Capacity | Total energy stored | Fleet maintenance, backup |

Load | Performance under stress | Industrial, security |

Alert: Capacity and load tests take time and may not detect early-stage internal faults in lithium battery packs.

2.4 Advanced Methods: EIS and DBD

For a complete picture of your deep cycle battery’s health, advanced diagnostics are essential. Electrochemical Impedance Spectroscopy (EIS) stands out as a powerful tool. EIS, as used in deep battery diagnostics, sends a range of frequencies through the battery and measures its response. This process creates a unique electrochemical fingerprint.

Cadex Deep Battery Diagnostics (DBD) leverages EIS technology, known as Spectro™, to deliver rapid, non-invasive assessments. In less than a minute, you receive a detailed Nyquist plot that reveals internal resistance, capacity, and state-of-health. DBD compares your battery’s signature to a database of similar models, much like facial recognition, to determine remaining useful life and predict failures.

Diagnostic Method | Speed | Depth of Insight | Suitability for Lithium Packs |

|---|---|---|---|

Visual/Voltage Check | Seconds | Surface-level | Limited |

Capacity/Load Testing | Hours | Moderate | Moderate |

EIS (DBD) | <1 minute | Comprehensive | Excellent |

You can integrate DBD into chargers, analyzers, or cloud-based monitoring systems. This flexibility supports large-scale industrial and fleet operations, where downtime is costly. DBD also helps you set operational thresholds, ensuring your deep cycle battery always meets mission-critical needs.

Part 3: Interpreting Results

3.1 Data Analysis

You collect a wealth of data from advanced diagnostics on your deep cycle battery systems. To make sense of these results, focus on key indicators such as internal resistance, capacity retention, and state-of-health (SoH). For lithium battery packs, these metrics reveal how well your batteries perform under real-world conditions.

Parameter | What It Shows | Typical Range (Healthy) |

|---|---|---|

Internal Resistance | Cell aging, faults | Low and stable |

Capacity (%) | Usable energy left | 80–100% |

SoH (%) | Overall battery health | 85–100% |

Tip: Use trend analysis to spot early signs of degradation. Regularly compare new data with historical records for each deep cycle battery in your fleet.

You can also leverage cloud-based analytics platforms to visualize performance trends and predict failures. This approach supports proactive maintenance and reduces downtime in industrial and infrastructure applications.

3.2 Decision Making

You use diagnostic insights to guide your operational decisions. When a deep cycle battery shows declining capacity or rising internal resistance, you can plan for replacement before failure disrupts your workflow. Set clear thresholds based on your application’s criticality:

Critical Operations: Replace at 85–90% capacity.

Standard Operations: Replace at 70–80% capacity.

This strategy helps you balance reliability, cost, and environmental impact. For custom solutions or to optimize your lithium battery fleet, contact our team for consultation.

Note: Predictive diagnostics empower you to extend battery life and reduce unnecessary replacements, supporting both operational efficiency and sustainability.

You gain the most value by combining traditional checks with advanced diagnostics for lithium battery packs.

Predictive, data-driven battery maintenance improves reliability and reduces costs for your business.

Start using modern diagnostic tools today. Request a custom consultation to optimize your battery strategy.

FAQ

1. What makes deep battery diagnostics essential for lithium battery packs in industrial applications?

You gain precise insights into internal resistance, capacity, and state-of-health. This enables predictive maintenance and reduces costly downtime for your industrial lithium battery fleet.

2. How does EIS technology improve battery health assessment compared to traditional methods?

EIS technology provides a rapid, non-invasive scan. You receive a comprehensive electrochemical fingerprint, revealing hidden faults that standard voltage or load tests often miss.

3. Can Large Power customize diagnostic solutions for my lithium battery fleet?

Yes. Large Power offers tailored diagnostic and management solutions for your specific business needs. Request a custom consultation to optimize your battery operations.