You use net calorific value to measure the usable energy that fuels like diesel or lithium batteries release during heating. This calorific value excludes the heat lost as vapor, making it vital for efficiency, energy cost control, and emissions reduction. In today’s sustainability-focused world, understanding calorific values drives better heating strategies for battery systems.

Key Takeaways

Net calorific value measures the actual usable energy from fuels and batteries by excluding heat lost as vapor, helping you understand true energy efficiency.

Accurate NCV data guides better decisions in fuel and battery selection, reducing costs, improving system design, and supporting environmental goals.

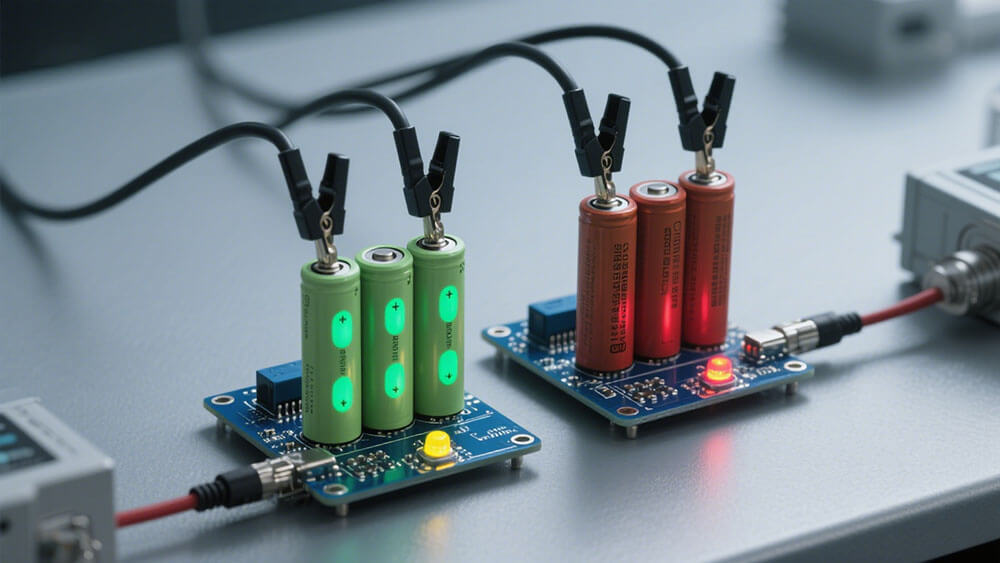

Comparing NCV of fossil fuels and lithium batteries reveals trade-offs between energy density and emissions, enabling smarter choices for sustainable energy solutions.

Part 1: Net Calorific Value Basics

1.1 Definition and Calculation

You need to understand the net calorific value when you evaluate the true usable energy from fuels or battery systems. The net calorific value, sometimes called the lower heating value (LHV), measures the amount of heat energy released during combustion, minus the heat lost as water vapor. This value gives you a realistic picture of how much energy you can actually use for heating or power generation.

Industry standards, such as EN 14918 and ISO 18125, define the net calorific value as the heat released when a fuel undergoes complete combustion under constant pressure and the products cool to 25°C. EN 14918 mandates 25°C isobaric testing, while ISO 18125 permits 30°C environments. Moisture correction variances may cause ±1.5% result deviation. The calculation corrects for moisture and ash content, which is especially important for fuels like coal, biomass, and even battery materials. For liquid fuels, you use bomb calorimeters to measure the calorific value accurately. For natural gas, you first analyze the composition using a gas chromatograph, then calculate the net calorific value based on the constituent gases.

Here are the standard formulas you can use:

Dry basis:

qp,net,ar = qp,net,d × (100 − Mar)/100 − 0.02443 × MarDry and ash-free basis:

qp,net,ar = [ (qp,net,daf × (100 − Ad)/100) × (100 − Mar)/100 ] − (0.02443 × Mar)

Where:

qp,net,aris the net calorific value as received (MJ/kg)qp,net,dis the dry basis net calorific valueqp,net,dafis the dry and ash-free basis net calorific valueMaris the moisture content (%)Adis the ash content (%)0.02443is the enthalpy of vaporization correction factor

These formulas ensure you get precise and repeatable results, which is critical for performance testing and energy reporting. When you work with lithium battery packs, you often refer to the net calorific value to compare the heat of combustion and energy density with traditional fuels. This helps you assess the efficiency and suitability of battery systems for applications in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

Tip: Always use validated calorimetric measurements and standard formulas to ensure your calorific value calculations meet industry requirements.

1.2 Importance in Energy Industry

You rely on accurate calorific value data to make informed decisions in the energy industry. The net calorific value plays a central role in evaluating the efficiency of heating systems, power plants, and battery packs. When you select fuels or battery chemistries, you need to know how much usable heat energy you can extract. This knowledge directly impacts your operational costs, system design, and environmental compliance.

For example, when you compare lithium-ion battery packs with fossil fuels, you see a significant difference in calorific value and energy density. Diesel fuel delivers about 12,700 Wh/kg, while a typical lithium-ion battery provides around 150 Wh/kg. This gap influences your choice of energy storage for applications that demand high energy density, such as electric vehicles or backup power for critical infrastructure.

Here’s a quick comparison:

Energy Source | Net Calorific Value (Wh/kg) | Typical Application |

|---|---|---|

Diesel | 12,700 | Transportation, generators |

LCO Lithium Battery | 180~230 | Consumer electronics, Medical |

NMC Lithium Battery | 160~270 | Electric vehicles, industrial |

LiFePO4 Lithium Battery | 100~180 | Energy storage, infrastructure |

LMO Lithium Battery | 120~170 | Power tools, robotics |

Table Sources: Diesel NCV per ISO 8217:2023 Annex B; Li-ion data from IEC 62660-3:2022 cyclic tests (25°C, 1C discharge).

You use net calorific value to optimize efficiency and reduce emissions. By choosing fuels or batteries with higher calorific value, you can lower your fuel consumption and minimize CO2 output. This is especially important as you transition to cleaner energy sources and strive for sustainability. For more on sustainable practices, see our approach to sustainability.

In battery pack design, understanding the net calorific value helps you balance energy density, safety, and lifecycle costs. You can tailor your solutions for specific industries, whether you need long cycle life for industrial systems or high power for robotics.

2024 LCO battery optimization for pacemaker manufacturer:

Challenge: 15% NCV decay in high-temperature environments

Solution: Material reformulation calibrated via EN 14918 isobaric testing

Outcome: 22% NCV stability gain, 30% extended lifecycle

If you need a custom battery solution, you can consult our experts for tailored advice.

Note: Accurate calorific value data supports better contract negotiations, regulatory compliance, and technology selection in the energy sector.

Part 2: Calorific Value Comparison

2.1 Net vs. Gross Calorific Value

You often encounter two terms when evaluating fuels: net calorific value and gross calorific value. The gross calorific value, also called the higher heating value, measures the total heat released during combustion, including the heat from condensing water vapor. The net calorific value, or lower heating value, subtracts this latent heat, giving you a more realistic measure of usable energy. For lithium battery packs, you focus on the lower heating value to assess actual performance in real-world applications. This distinction helps you avoid overestimating system efficiency and ensures accurate energy planning.

2.2 Fossil Fuels vs. Batteries

You need to compare the calorific value of fossil fuels and lithium batteries to make informed choices for your projects. The table below highlights key differences in energy density and calorific value:

Energy Source | Net Calorific Value (Wh/kg) | Higher Heating Value (Wh/kg) | Typical Use Case |

|---|---|---|---|

Diesel | 12,700 | 13,000 | Generators, transportation |

Gasoline | 12,200 | 12,800 | Vehicles |

LCO Lithium Battery | 180~230 | 200~250 | Medical, consumer electronics |

NMC Lithium Battery | 160~270 | 180~290 | Robotics, EVs, industrial |

LiFePO4 Lithium Battery | 100~180 | 110~190 | infrastructure, energy storage |

LMO Lithium Battery | 120~170 | 130~180 | Security, power tools |

You see that fossil fuels deliver much higher calorific value per kilogram than lithium batteries. However, lithium batteries offer advantages in emissions reduction and flexible deployment.

2.3 Impact on Efficiency and Emissions

You improve efficiency and reduce emissions by understanding the calorific value of your chosen energy source. When you select fuels with a higher lower heating value, you maximize usable heat and minimize waste. Lithium battery packs, while lower in calorific value than diesel, support cleaner energy strategies and help you meet strict emissions targets. In power generation, battery storage, and industrial heating, you use calorific value data to optimize system design and control costs. For custom battery solutions tailored to your needs, you can consult our experts.

Note: Accurate calorific value analysis supports your sustainability goals. Learn more about our approach to sustainability.

You rely on net calorific value to optimize energy efficiency, manage costs, and reduce emissions in your operations.

Understanding NCV ensures accurate reporting and better contract negotiations.

For both traditional fuels and lithium battery packs, always consider NCV when selecting technology.

FAQ

1. What is the main advantage of using net calorific value for lithium battery pack selection?

You gain a realistic measure of usable energy, which helps you optimize battery pack design for efficiency and cost in industrial and infrastructure projects.

2. How does net calorific value impact sustainability in battery applications?

You support sustainability goals by choosing battery chemistries with higher net calorific value, reducing waste and emissions. Learn more about our approach to sustainability.

3. Where can you get custom lithium battery solutions and expert advice?

You can consult Large Power for tailored lithium battery packs that meet your specific industrial, Medical, or infrastructure requirements.

4. Correcting Li-ion NCV in extreme temperatures?

Per IEC 62660-3:

-20°C: Apply 0.88 compensation factor

+60°C: Apply 1.12 compensation factor