You can learn how to repair a lithium battery pack by following practical troubleshooting steps. Scientific studies show that performance degradation, functional failure, and safety events often affect these systems. By understanding how to repair a lithium battery pack with the right approach, you can protect safety features and extend the lifespan of your lithium-ion battery.

Key Takeaways

Regularly inspect lithium battery packs for signs like swelling, low voltage, or overheating to catch problems early and keep them safe.

Use simple tests such as visual checks, connection inspections, and voltage measurements to troubleshoot battery issues before they worsen.

Replace faulty cells carefully and seek professional help for serious problems like swelling, BMS failures, or short circuits to ensure safe and effective repairs.

Part 1: Common Lithium Battery Issues

Lithium battery packs face several common failures that can disrupt operations and pose safety risks. You need to recognize these problems early to prevent battery pack failure and ensure reliable performance.

1.1 Inability to Charge

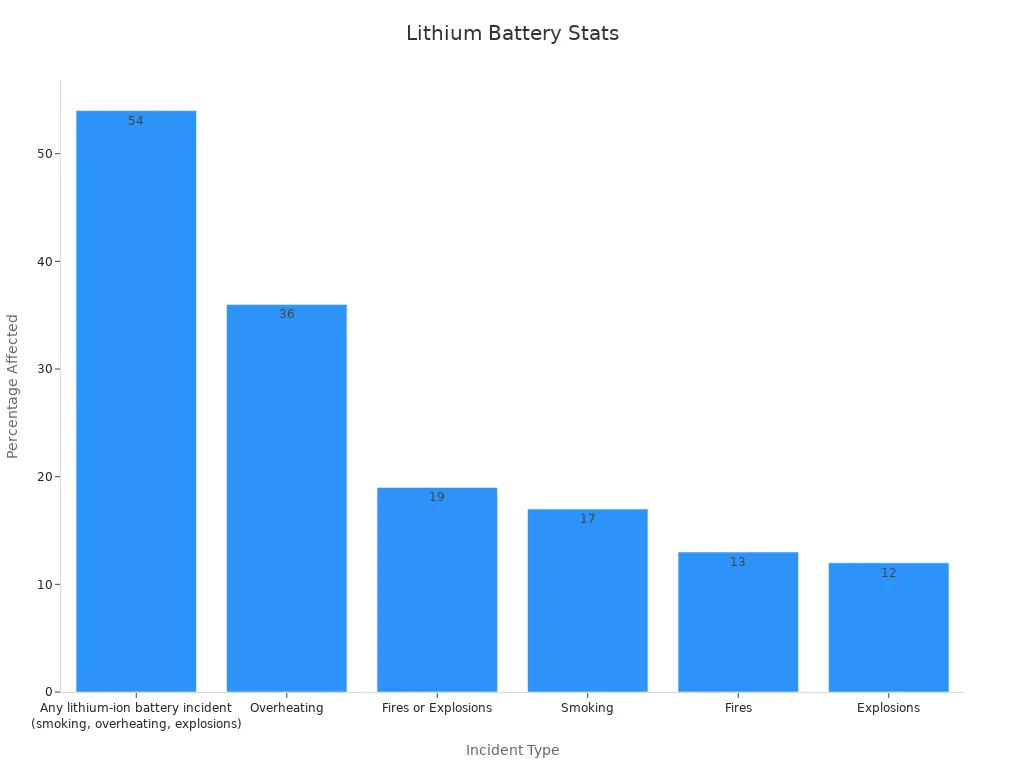

You may notice your battery pack not charging or charging issues such as slow or incomplete charging. This problem often results from faulty connections, damaged chargers, or internal cell imbalances. In business environments, over half of companies have reported lithium-ion battery incidents, with 54% experiencing at least one event related to charging or discharging.

Incident Type | Percentage of Businesses Affected |

|---|---|

Any lithium-ion battery incident (smoking, overheating, explosions) | 54% |

Overheating | 36% |

Fires or Explosions | 19% |

Smoking | 17% |

Fires | 13% |

Explosions | 12% |

1.2 Swelling

Swelling is one of the most visible common lithium battery issues. You might see the battery pack swelling or feel it bulging. Swelling often signals internal gas buildup from overcharging, over-discharge, or electrolyte leakage. Battery pack swelling can lead to puncture and leakage, increasing the risk of thermal runaway. If you detect swelling, stop using the battery immediately to avoid further leakage or runaway.

⚠️ Tip: Swelling and electrolyte leakage are warning signs of imminent battery pack failure. Always handle swollen packs with care.

1.3 Low Voltage

Low voltage problems often occur after repeated over-discharge or due to cell degradation. You may observe the battery not charging fully or shutting down quickly. Research shows that low-frequency AC exposure accelerates voltage polarization and capacity loss, leading to more frequent low voltage issues in lithium battery packs. Voltage drops can also signal early-stage thermal runaway or electrolyte leakage.

1.4 Capacity Loss

Capacity loss is a gradual reduction in the battery’s ability to store energy. You will notice shorter runtimes and more frequent charging cycles. Studies confirm that capacity loss rates peak in the first 200 cycles and again when capacity drops below 70-85% of nominal value. Fast charging at low temperatures and overcharging accelerate this process. Capacity loss is one of the most common failures in lithium battery packs.

Cold temperatures and fast charging can drop capacity below 65% after only 132 cycles.

Overcharging and over-discharge both contribute to rapid degradation.

1.5 Overheating

Overheating is a critical safety concern. You may feel the battery becoming hot during charging or discharging. Overheating often results from internal short circuits, overcharging, or runaway reactions. More than 25,000 fire or overheating incidents have been reported in the last five years, with thermal runaway being a leading cause. In utility-scale systems, overheating accounts for a 1-2% failure rate globally.

Note: Overheating, swelling, and leakage are interconnected problems that can trigger thermal runaway and catastrophic battery pack failure.

Part 2: Troubleshooting

2.1 Visual Inspection

Start your troubleshooting process with a thorough visual inspection. Look for signs of rust, dents, deformation, leaking, or damage to protective components. Swelling is a critical warning sign. If you see any of these issues, do not use the battery pack. Visual inspection helps you identify physical damage that could compromise safety or performance. This step is essential for all lithium battery packs, including those used in medical, robotics, and industrial applications.

🔍 Tip: Always inspect new battery packs upon delivery and before installation.

2.2 Connection Check

Loose or corroded connections often cause charging and discharging failures. Regular connection checks help you prevent accelerated battery degradation and safety hazards. Experimental studies confirm that diagnosing connection faults early can stop uneven current distribution and thermal runaway. Use a troubleshooting checklist to examine all terminals, connectors, and cables for tightness and corrosion.

2.3 Voltage and Current Test

Testing voltage and current is a core troubleshooting method. Use a voltmeter and ammeter to measure open circuit voltage and current flow. Compare your readings to the battery’s rated values. The table below shows how voltage readings relate to battery health:

Voltage Range | Battery Health Status | Interpretation |

|---|---|---|

Above Rated Voltage | Healthy | Fully charged, excellent condition |

At Rated Voltage | Healthy | Normal operation |

Slightly Below Rated Voltage | Weak | Needs recharge or replacement soon |

20-30% Below Rated Voltage | Weak | Reduced capacity and efficiency |

More than 30% Below Rated | Dead | Discharged or damaged; replace immediately |

High internal resistance also signals deterioration. Accurate voltage and current tests allow you to detect faults before they become severe.

2.4 BMS Reset or Replacement

The Battery Management System (BMS) protects your lithium battery pack from overcharge, over-discharge, and short circuits. If you suspect BMS failure, reset the system or replace it if necessary. For more details on BMS operation, see Battery Management System Operation & Components. Proper BMS troubleshooting ensures safe and reliable battery operation.

2.5 Cell Balancing

Cell balancing addresses voltage and capacity inconsistencies between cells. Technical studies show that active balancing methods improve efficiency, safety, and lifespan. Use a balancing charger or BMS with balancing features to equalize cell voltages. This step is vital for troubleshooting packs in demanding sectors like infrastructure and consumer electronics.

⚡ Note: Proper cell balancing reduces the risk of overcharging or deep discharging individual cells, supporting long-term reliability.

Part 3: How to Repair a Lithium Battery Pack

Repairing a lithium battery pack requires a systematic approach. You need to identify the root cause of failure and apply targeted solutions. This section explains how to repair a lithium battery pack by addressing the most common issues: faulty cells, BMS errors, swelling, and short circuits. You will also learn when to attempt repairs yourself and when to consult a professional.

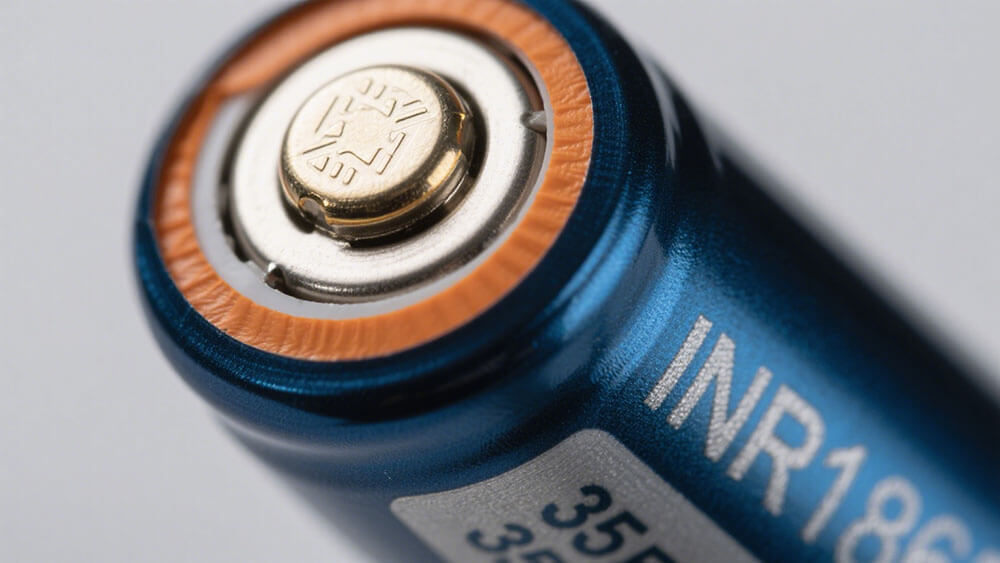

3.1 Replacing Faulty Cells

Faulty cells often cause low voltage, capacity loss, or complete pack failure. You can restore performance by replacing damaged cells. Start by isolating the battery pack and discharging it to a safe voltage. Use a voltmeter to identify cells with abnormal readings. Remove the faulty cell using insulated tools and proper safety gear. Install a new cell with matching chemistry and specifications. For example, if your pack uses NMC Lithium battery cells (platform voltage 3.6-3.7V, energy density 160-270Wh/Kg, cycle life 1000~2000 cycles), select a replacement with similar parameters.

Battery Chemistry | Platform Voltage | Energy Density (Wh/Kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.7V | 180~230 | 500~1000 |

NMC | 3.6~3.7V | 160~270 | 1000~2000 |

LiFePO4 | 3.2V | 100~180 | 2000~5000 |

LMO | 3.7V | 120~170 | 300~700 |

LTO | 2.4V | 60~90 | 10000~20000 |

After replacement, balance the cells using a balancing charger or BMS. This step prevents voltage drift and reduces the risk of thermal runaway. Always test the pack under load before returning it to service. If you manage battery packs in medical, robotics, or infrastructure applications, follow strict protocols to avoid permanent damage or safety incidents. For more on medical battery solutions, visit Medical Battery Solution. For robotics, see Robot Battery Solution.

⚠️ Tip: If you notice repeated cell failures or abnormal heating, consult a certified technician. Repeated issues may indicate deeper problems such as BMS malfunction or design flaws.

3.2 Fixing BMS Issues

The Battery Management System (BMS) protects against overcharge, over-discharge, and short circuits. If you suspect BMS failure, reset the system first. If the problem persists, inspect the BMS for visible damage or burnt components. You can replace the BMS or update its firmware if you have the technical expertise. In a recent case study, a regional fitness center chain restored over 30 lithium battery packs with BMS errors to full functionality within one week. The repair process included cell replacement, BMS firmware reprogramming, and rebalancing. Customers reported high satisfaction due to fast turnaround and clear communication.

Component-level repairs, such as BMS chip replacement and firmware updates, require certified technicians.

Strict protocols ensure high-performance restoration and minimize the risk of thermal runaway or leakage.

Professional repair services guarantee quality and successful restoration, even though explicit numerical success rates are not always published.

If you operate in industrial or consumer electronics sectors, a reliable BMS is critical for safety and uptime. For more on BMS operation, visit Battery Management System Operation & Components.

3.3 Addressing Swelling

Swelling is a serious warning sign. You may see the battery pack swelling or feel it bulging. Swelling often results from internal gas buildup due to overcharging, over-discharge, or electrolyte leakage. If you detect battery pack swelling, stop using the pack immediately. Isolate it in a fireproof container. Do not attempt to puncture or compress the pack, as this can cause puncture and leakage, leading to thermal runaway.

Remove the pack from service and store it in a well-ventilated area.

Contact a certified recycling or hazardous waste facility for safe disposal.

Never attempt to repair a swollen pack yourself. The risk of runaway and permanent damage is high.

🚨 Alert: Swelling and leakage are not repairable at the user level. Attempting to fix these issues can result in fire, explosion, or toxic exposure.

3.4 Handling Short Circuits

Short circuits can trigger immediate overheating, leakage, and thermal runaway. If you suspect a short circuit, disconnect the battery pack from all equipment. Inspect for melted wires, burnt connectors, or blackened areas. Use a multimeter to check for continuity between positive and negative terminals. If you confirm a short, do not attempt to recharge or reuse the pack.

Replace damaged wiring and connectors with high-quality, insulated components.

Inspect the BMS for damage, as short circuits often compromise its protective functions.

Test the pack thoroughly after repairs to ensure no residual faults remain.

If you manage large-scale battery systems in infrastructure or industrial settings, implement regular inspections and preventive maintenance. A survival analysis study on lithium battery failure in hospital infusion pumps found that replacing batteries every two years, rather than three, reduced unexpected failures from 28% to 7%. This proactive approach improves reliability and reduces risk, especially in critical applications.

💡 Note: If you encounter repeated short circuits or unexplained leakage, consult a professional. Persistent faults may indicate underlying design or manufacturing issues.

When to Attempt Repairs and When to Seek Professional Help

You can perform basic repairs such as cell replacement or connection checks if you have technical training and proper tools. For complex issues like BMS replacement, swelling, or repeated leakage, always seek professional assistance. Certified technicians follow strict safety protocols and use specialized equipment to prevent thermal runaway and permanent damage.

If you need customized solutions for your lithium battery pack, consider consulting with experts. Contact us for custom consultation to ensure safe, reliable, and sustainable battery management. For more on our approach to sustainability, visit Our Approach to Sustainability.

You can keep lithium battery packs reliable by following these steps:

Perform regular lithium battery maintenance and inspections.

Address issues early with proper lithium battery maintenance.

Monitor battery health and schedule lithium battery maintenance.

Replace faulty parts during lithium battery maintenance.

Prioritize lithium battery maintenance for safety.

A study found 37.5% of electric vehicle batteries maintained performance above 70% SOH with proper lithium battery maintenance, proving that consistent maintenance extends battery life.

FAQ

1. What safety precautions should you follow when repairing a lithium battery pack?

Always wear insulated gloves and safety goggles. Work in a well-ventilated area. Use only insulated tools. Never attempt repairs on a swollen or leaking pack.

2. How do you identify if a cell in your lithium battery pack needs replacement?

Check each cell’s voltage with a voltmeter. If a cell reads 20% lower than others or shows visible damage, you should replace it immediately.

3. Where can you get professional support for custom lithium battery pack solutions?

Contact Large Power for expert consultation and custom battery solutions tailored to your business needs.