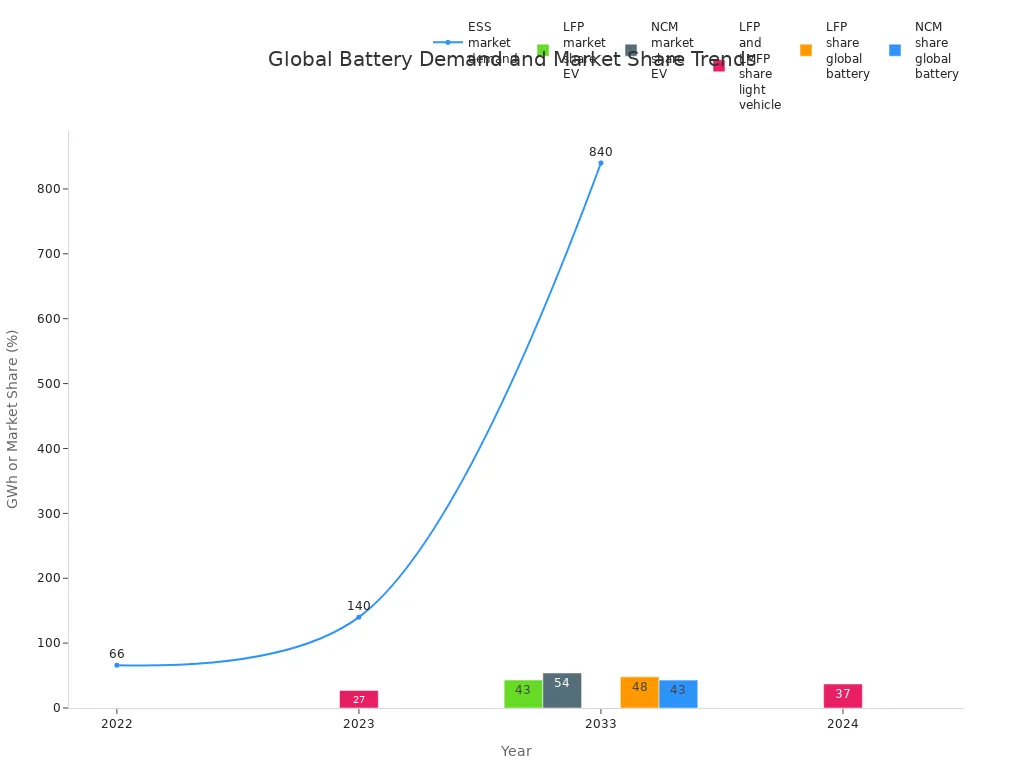

You need clear, reliable data to manage battery performance as electrification accelerates. Battery manufacturers now face soaring demand for transparent power metrics, especially with LiFePO4 and NMC lithium battery packs dominating the market.

Metric | Statistic | Year |

|---|---|---|

ESS market demand | 140 GWh | 2023 |

ESS market demand forecast | 840 GWh | 2033 |

LFP market share in global EV market | 43% | 2033 forecast |

Global initiatives like the Battery Passport now push for full lifecycle transparency, so battery manufacturers must adopt advanced power diagnostics and reporting. In Search for Performance Transparency with Batteries, you see industry standards require more than basic power data—they demand full performance visibility from every battery.

Key Takeaways

Monitor key battery metrics like capacity, state of health, internal resistance, and cycle life to ensure reliable power and safety throughout the battery’s lifespan.

Use advanced diagnostic tools such as Electrochemical Impedance Spectroscopy (EIS) and Battery Management Systems (BMS) for real-time data, early fault detection, and accurate performance tracking.

Follow industry standards and demand full transparency in battery sourcing, testing, and reporting to meet safety, compliance, and sustainability goals.

Part 1: Key Metrics

1.1 Capacity and State of Health

You need to monitor capacity and state of health (SOH) to ensure your lithium-ion batteries deliver consistent power and reliability. Battery manufacturers rely on these metrics to track degradation and predict end-of-life for each battery pack. SOH represents the ratio of current capacity to the initial capacity, or the ratio of current internal resistance to that of a new battery. As batteries age, available capacity drops, which limits power output and reduces the range or uptime of your equipment.

SOH typically triggers battery retirement when it falls to 70-80% of the original value.

Accurate SOH estimation is essential for battery management systems to maintain safety and reliability.

Cell-to-cell variation in large battery packs can cause uneven degradation, making SOH tracking more complex.

Health feature extraction uses parameters such as voltage, current, temperature, internal resistance, and impedance.

Tip: You should implement advanced diagnostic tools, such as electrochemical impedance spectroscopy (EIS), to extract health indicators and improve SOH accuracy. This approach helps you avoid unexpected failures and optimize power consumption in demanding B2B applications.

For industrial lithium-ion batteries, SOH directly impacts operational reliability. When SOH drops below the threshold, the battery can no longer meet the energy and power requirements for safe operation. You must monitor SOH to prevent failures and ensure your systems deliver uninterrupted power.

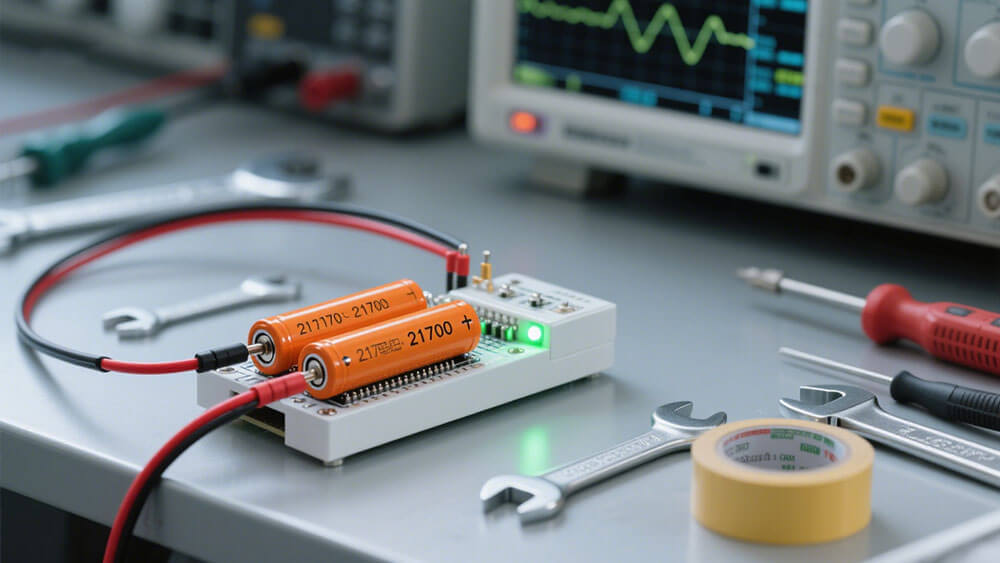

1.2 Impedance and Internal Resistance

Impedance and internal resistance are critical for evaluating how efficiently your battery delivers power under different current drain scenarios. Battery manufacturers use several methods to measure these metrics, each offering unique insights:

Method | Description | Measurement Focus | Advantages / Notes |

|---|---|---|---|

Step Methods | Apply current pulses and measure voltage drop immediately after pulse start | Large signal internal resistance | Predicts power loss and ability; requires precise timing |

Energy Loss Methods | Measure difference between charge and discharge energy or heat dissipation | Internal resistance via energy dissipation | Provides reliable ohmic resistance values; symmetrical current profiles improve accuracy |

AC Resistance at Fixed Frequency | Measure impedance at a single frequency (e.g., 1 kHz) | Small signal resistance | Fast results; ideal for quality screening of similar cell types |

Electrochemical Impedance Spectroscopy (EIS) | Apply small AC signal over a frequency range; analyze complex impedance spectrum | Small signal resistance and detailed electrochemical parameters | Offers detailed info on charge transfer, capacitance, and aging; requires expert analysis |

Internal resistance affects power capability, energy efficiency, and heat generation. High resistance leads to greater power loss, increased heat, and reduced efficiency, especially under high current drain. You must measure and manage these parameters to optimize battery application, cooling, and safety in industrial environments.

Note: Battery management systems (BMS) use real-time impedance and resistance data to adjust charging, balance cells, and prevent overheating.

1.3 Cycle Life and Safety

Cycle life defines how many full charge and discharge cycles your battery can complete before its capacity drops below a usable threshold. Battery manufacturers test cycle life under standard conditions to ensure your lithium-ion batteries meet the demands of industrial and commercial use.

Aspect | Details |

|---|---|

Typical cycle life range | 300 to 500 full charge-discharge cycles under standard conditions |

Capacity retention after cycles | Above 80% capacity after about 500 cycles |

National standard test | Charge/discharge at 1C, capacity > 60% after ≥300 cycles |

Cycle life definition | One full charge cycle = full discharge + full recharge |

Usage implication | Charging once per day yields about 2 years of battery life |

Effect of charge depth | Deep or shallow charging affects total charge throughput (300Q-500Q) rather than cycle count |

You must also prioritize safety indicators to protect your assets and personnel. Key safety metrics include:

Cell voltage and total battery voltage

Cell temperature and heat sink temperature

Battery current and current drain

Pressure (early warning for off-gassing or short circuits)

Water intrusion detection

Continuous monitoring of these parameters helps you prevent fire, explosion, and toxic exposure. Advanced BMS solutions provide visual and audio alarms, automatic shutdown, and integration with ventilation systems for hazardous gas removal. Monitoring state of charge and SOH is essential for battery longevity and safety.

For sustainable battery solutions and responsible sourcing, explore our sustainability approach and conflict minerals statement.

If you operate in industrial sectors, you must demand transparent reporting from battery manufacturers. This ensures your lithium-ion batteries deliver the power, safety, and reliability your business requires. For custom solutions tailored to your unique needs, contact our team.

Part 2: Diagnostic Methods

2.1 EIS and Advanced Testing

You need advanced diagnostic tools to ensure true transparency in battery performance. Electrochemical Impedance Spectroscopy (EIS) stands out as a leading method for battery manufacturers who demand accuracy, speed, and non-destructive testing. EIS, especially when integrated into solutions like Cadex Spectro™, provides a comprehensive view of your battery’s internal processes and health.

Key advantages of EIS for battery diagnostics:

EIS enables real-time monitoring of battery state during charging and discharging, capturing transient electrochemical processes.

You can detect early faults by observing abnormal impedance changes, even without long rest periods.

EIS analyzes non-linear and non-steady-state behaviors, which are common in real-world battery use.

The large datasets generated by EIS improve battery modeling, state-of-health (SOH) estimation, and lifetime prediction.

EIS is fast and non-invasive, allowing you to diagnose batteries without causing damage.

You gain rich electrochemical information, such as charge transfer resistance, internal resistance, and diffusion characteristics.

EIS results can be visualized and modeled to track SOH over time, supporting predictive maintenance.

Compared to traditional testing methods, EIS offers faster, more comprehensive analysis. You avoid the lengthy cycling tests and preserve battery integrity. EIS also enables early detection of degradation, allowing you to schedule maintenance before failures occur. This method adapts to various battery chemistries, including LiFePO4, NMC, and LCO, making it versatile for different industrial applications.

Diagnostic Method | Speed | Invasiveness | Data Depth | Predictive Capability | Suitability for B2B |

|---|---|---|---|---|---|

EIS | Fast | Non-invasive | High (multi-param) | Strong | Excellent |

Traditional Cycling Test | Slow | Invasive | Moderate | Limited | Moderate |

Load Test | Moderate | Invasive | Low | Weak | Limited |

Tip: For large-scale battery emulation and automated battery profiling, EIS-based systems provide the rigorous testing procedures needed for industrial reliability.

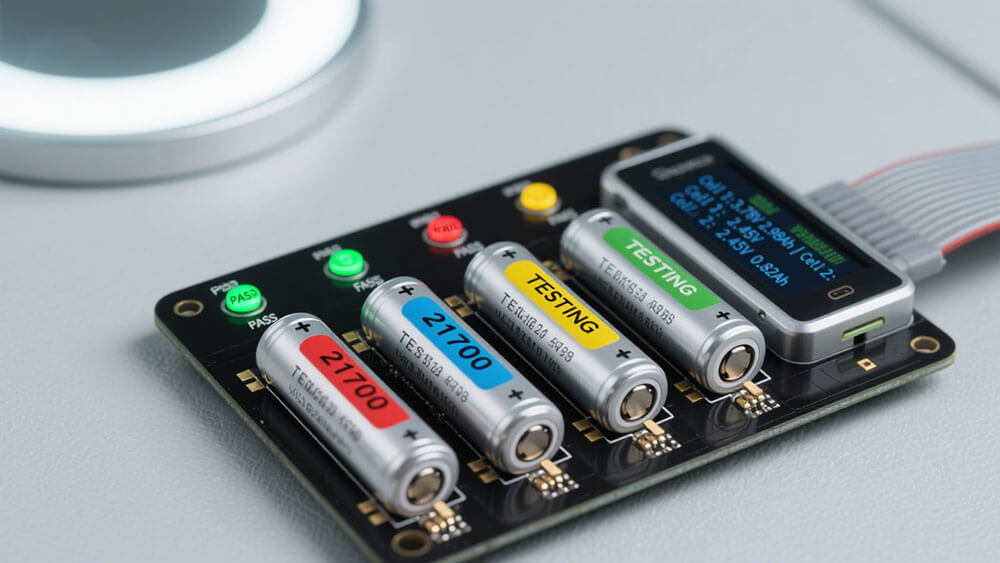

2.2 Calibration and Profiling

Accurate calibration and battery profiling are essential for transparent performance data. You must calibrate voltage and current sensors precisely to ensure reliable state-of-charge (SoC) and SOH readings. Begin by fully discharging the battery until the device shuts down. This resets the management system’s discharged flag, which is critical for accurate SoC estimation.

You should not rely solely on software-based low battery warnings. Instead, combine Coulomb counting with model-based approaches that use voltage, current, and temperature data. This method improves SoC convergence and accuracy. Advanced fuel gauge ICs further enhance reliability and reduce the computational load on your main controller.

Best practices for calibration and profiling:

Calibrate voltage and current sensors for precise SoC estimation.

Configure cell balancing parameters to maintain safe and efficient operation.

Conduct thorough testing and validation of the Battery Management Unit (BMU) under various conditions.

Avoid insufficient testing and inadequate calibration, which can lead to unreliable data.

Battery profiling systems embedded in industrial and automotive applications provide real-time data on usage, thermal profiles, and degradation events. This transparency supports predictive maintenance, warranty management, and regulatory compliance. Automated battery profiling, combined with AI and IoT, enables you to monitor battery health and lifecycle status with clarity.

For more on sustainable battery practices and lifecycle transparency, see our approach to sustainability.

2.3 BMS and Data Logging

A robust Battery Management System (BMS) forms the backbone of real-time data logging and transparency. You need a BMS that constantly monitors key parameters such as voltage, current, temperature, and SoC. This continuous monitoring enables early detection of abnormalities and supports predictive maintenance.

Common data points collected by BMS for performance monitoring:

Current monitoring: Tracks charging and discharging currents to enforce limits and detect faults.

Temperature monitoring: Measures pack or module temperatures for safe operation and longevity.

Voltage monitoring: Measures individual cell voltages for accurate state estimation.

SoC estimation: Calculates remaining battery capacity.

SOH assessment: Evaluates battery degradation over time.

Fault detection: Identifies abnormal conditions such as shorts or loose connections.

Battery balancing: Ensures uniform SoC across cells to maximize usable capacity and lifespan.

Electrical protection: Monitors voltage and current limits to prevent damage.

Thermal management: Controls heating and cooling elements for optimal temperature.

Capacity management: Manages cell SoC to avoid premature aging.

Your BMS should log this data over time, enabling you to analyze trends and optimize battery emulation strategies. Advanced BMS solutions use communication protocols to share telemetry data via apps, displays, or cloud services, increasing transparency for operators and end users.

Note: In sectors like industrial, medical, robotics, security, infrastructure, and consumer electronics, BMS-driven transparency is vital for safety, compliance, and operational efficiency.

2.4 Machine Learning and Cloud Analytics

Machine learning and cloud analytics have transformed battery emulation and performance transparency. You can now leverage historical and real-time data to predict key metrics such as SoC, SOH, and Remaining Useful Life (RUL). Machine learning models, including random forest classifiers and hybrid neural networks, deliver high-precision predictions and fault detection.

How machine learning and cloud analytics benefit battery manufacturers:

Predict key performance metrics using historical and real-time data.

Improve battery design, safety, and lifetime predictions by integrating data-driven and physics-based models.

Detect internal faults with high accuracy, supporting proactive maintenance.

Accelerate battery development and optimization for industrial applications.

Cloud analytics platforms enable you to monitor battery health parameters continuously. You can track charge-discharge cycles, temperature, voltage, and internal resistance. These platforms use anomaly detection and predictive modeling to forecast future performance and optimize maintenance schedules. Remote monitoring via IoT and cloud services allows centralized, real-time data analysis, minimizing downtime and reducing costs.

Benefit of Cloud Analytics | Description |

|---|---|

Predictive Maintenance | |

Historical Data Analysis | Identifies long-term trends and potential problems |

Advanced Forecasting | Improves accuracy in predicting battery performance |

Scalable Data Processing | Handles large data volumes from extensive battery energy storage systems |

Enhanced Safety and Longevity | Complements BMS for better system reliability and lifespan |

Part 3: In Search for Performance Transparency with Batteries

3.1 Compliance and Standards

You operate in a market where in search for performance transparency with batteries drives every decision. Regulatory requirements now shape how you manage battery power, safety, and lifecycle. You must comply with evolving standards that demand digital tracking, carbon footprint reporting, and recycling targets. Here are key milestones you need to track:

February 2025: Third-party carbon footprint verification for each manufacturing batch.

December 2025: Minimum 65% recycling efficiency for lithium-based batteries.

December 2027: Critical mineral recovery targets—Lithium 50%, Cobalt 90%, Nickel 90%, Copper 90%.

February 2028: Lifecycle carbon footprint compliance.

2035+: Expansion to vehicle passports with full battery lifecycle data.

You must also align with the highest quality standards. The table below summarizes the most important regulations:

Category | Standard/Regulation | Description/Scope | Region |

|---|---|---|---|

Fire Safety & Installation | NFPA 855, NFPA 70 | Fire safety, installation, and operation of battery energy storage systems. | United States |

Safety Standards | UL 1973, UL 9540, UL 9540A | Stationary batteries, energy storage, and thermal runaway testing. | United States |

Industrial Battery Safety | IEC 62619 | Secondary lithium cells and batteries in industrial applications. | International |

Grid Integration | IEC 62933, IEC 62109, ISO 50001, IEEE 1547, UL 1741 | Grid performance, safety, and interconnection. | Global |

Transparency & Traceability | EU Battery Passport Regulation | Digital passports with identification, performance, carbon footprint, and supply chain data. | European Union |

Third-party testing ensures you meet these highest quality standards. Independent labs provide impartial validation of battery power, safety, and reliability. Certification builds trust and enables market access, especially as battery chemistries and applications diversify.

3.2 Supply Chain and Reporting

In search for performance transparency with batteries, you must demand full visibility from raw materials to end-of-life. Battery passports now digitally certify the origin and ethical sourcing of minerals. You benefit from third-party testing and independent audits, which verify responsible mining and processing. Robust due diligence and transparent reporting help you avoid unethical practices and support regulatory compliance.

Supply chain transparency also relies on standardized KPIs. You track on-time delivery, supplier quality, and responsiveness to identify bottlenecks and drive improvement. Real-time data collection and reporting create a transparent environment where all stakeholders understand battery performance and power delivery.

Ethical sourcing protects your brand and ensures responsible practices. You reduce risks like child labor and environmental harm, building trust with customers and regulators. Blockchain and digital platforms further enhance traceability and security across the battery supply chain.

For ongoing monitoring, you should use real-time systems to track voltage, current, and temperature. Regular calibration, software updates, and integration with predictive analytics extend battery life and improve operational efficiency. In search for performance transparency with batteries, these best practices ensure your power systems remain reliable and compliant.

For custom battery solutions that deliver transparency and reliability, consult our experts.

You drive battery performance transparency by using advanced diagnostics, regular calibration, and real-time data management. The table below highlights key KPIs for B2B battery power optimization. Adopting innovative tools and industry standards ensures your lithium battery systems deliver reliable power, maximize lifecycle value, and build trust across every industrial application.

KPI / Metric | Actionable Steps for Battery Power Transparency |

|---|---|

Customer Satisfaction Score | Collect feedback, monitor power delivery, update battery KPIs |

Cost Per Ton of Recycled Material | Benchmark costs, invest in battery recycling, optimize power use |

Material Recovery Rate | Use sensors, monitor battery processes, improve power efficiency |

Volume of Batteries Collected | Track battery collection, analyze power data, use cloud tools |

Partnerships and Collaborations | Measure impact, expand battery power networks, review results |

FAQ

1. How do you ensure battery performance transparency in large lithium battery packs?

You use advanced diagnostics like EIS, real-time BMS data logging, and cloud analytics. These tools provide accurate, transparent metrics for industrial and commercial applications.

2. What standards should you follow for lithium battery compliance?

You should follow IEC 62619, UL 1973, and EU Battery Passport regulations. These standards ensure safety, traceability, and lifecycle transparency for your lithium battery systems.

3. How can Large Power support your custom battery transparency needs?

Large Power offers tailored diagnostic solutions, compliance support, and transparent reporting. Request a custom consultation to optimize your lithium battery performance.