When you evaluate lithium battery housing, ultrasonic welding offers superior sealability, high strength, and rapid production. This welding method ensures robust protection against dust and moisture. In the Ultrasonic Welding vs Threaded Fastening of Battery Housing debate, welding delivers reliability and efficiency, making it the preferred solution for most advanced battery applications.

Key Takeaways

Ultrasonic welding creates strong, permanent, and fast seals ideal for high-volume battery production, offering excellent protection against dust and water.

Threaded fastening allows easy disassembly and maintenance, making it suitable for low-volume or custom battery packs that need frequent repairs or upgrades.

Choosing the right joining method depends on your production scale, sealing needs, and serviceability requirements to balance strength, cost, and flexibility.

Part 1: Ultrasonic Welding vs Threaded Fastening of Battery Housing

1.1 Key Differences

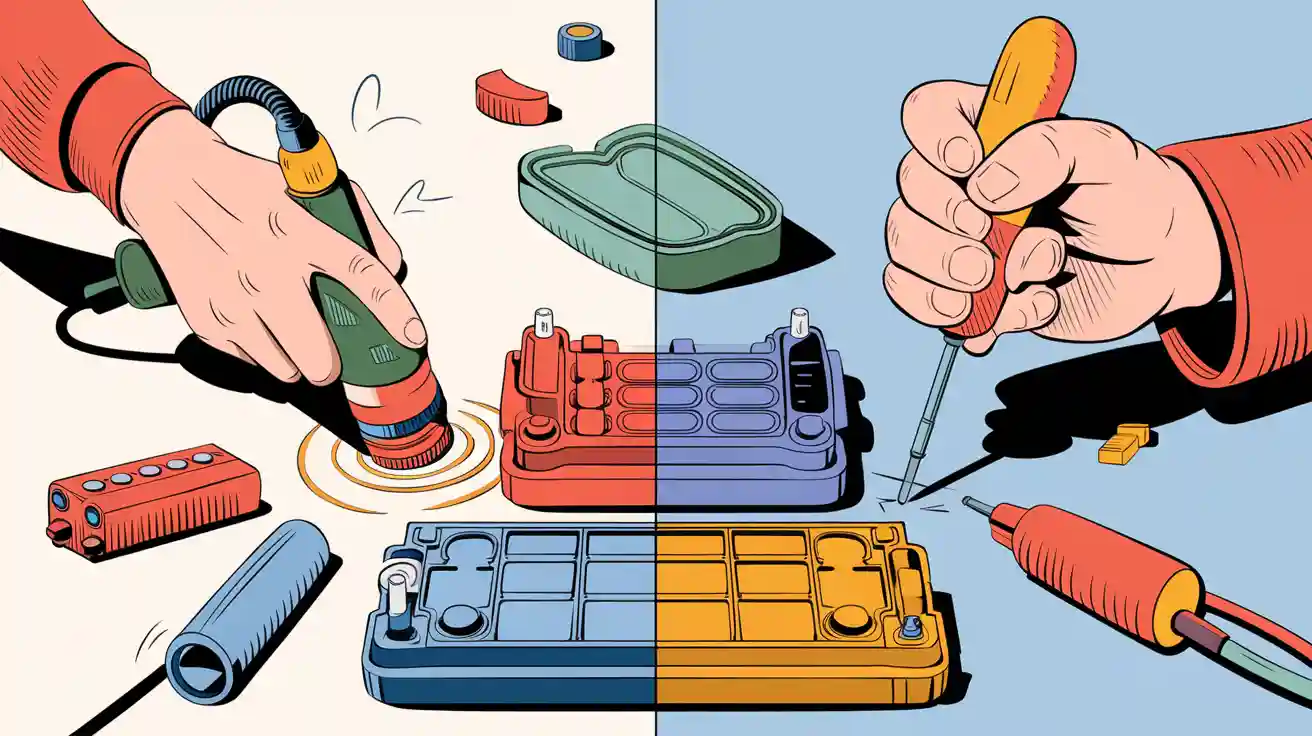

When you compare ultrasonic welding vs threaded fastening of battery housing, you see two fundamentally different approaches to joining. Ultrasonic welding uses high-frequency vibrations to fuse thermoplastic parts or thin metal foils. This welding process creates a permanent, robust bond in seconds. Threaded fastening, on the other hand, relies on screws or bolts to mechanically join components. You can disassemble and reassemble these joints as needed.

The following table summarizes the main differences between ultrasonic welding and threaded fastening for lithium battery housing:

Aspect | Ultrasonic Welding | Threaded Fastening |

|---|---|---|

Detachability | Non-detachable; permanent joint, cannot be disassembled repeatedly | Detachable; allows repeated disassembly and reassembly |

Speed and Efficiency | High welding speed; most welds completed in seconds | Generally slower due to manual or semi-automated screwing |

Strength | High strength; can reach over 80% of plastic part strength, comparable to injection molding | Depends on screw design and material; generally reliable but may loosen over time |

Process Cleanliness | Clean process; no adhesives or additional materials needed | May require lubricants or thread locking compounds |

Material Compatibility | Best suited for thermoplastics; limited or no use with thermosetting plastics or elastomers | Compatible with a wide range of materials including metals and plastics |

Size and Shape Limitations | Suitable for medium and small parts (usually <250mm); complex shapes and large sizes are challenging | No significant size or shape limitations |

Impact on Components | Vibration during welding may cause cracking or affect internal electronic components | Minimal vibration; safer for sensitive electronics |

Initial Equipment Cost | High initial cost for ultrasonic welding machines and custom tooling | Lower initial equipment cost; standard tools suffice |

Design Considerations | Simplifies design by eliminating screws and related structures, saving space and improving appearance | Requires design for screw bosses, threads, and clearance |

Quality and Automation | Stable quality with low failure rate; suitable for mass production and automation | Quality depends on assembly process; automation possible but may be complex |

Tightness and Sealing | Can achieve water-tight or air-tight joints with proper design | Depends on gasket and screw torque; may require additional sealing methods |

You notice that the welding process offers significant advantages in speed, strength, and sealing. You also see some disadvantages, such as higher initial equipment costs and limited detachability. Threaded fastening provides flexibility and ease of maintenance, but may require extra steps for sealing and can slow down production.

1.2 Application Scenarios

You encounter ultrasonic welding vs threaded fastening of battery housing in many industries. Each method fits specific applications based on your product requirements.

Ultrasonic welding dominates in high-volume production of lithium battery packs, especially where you need strong, sealed joints. You find this welding process widely used in the automotive sector for electric vehicle battery modules, in the medical device industry, and in consumer electronics such as smartphones and tablets. The process excels when you assemble prismatic, pouch, and lithium-ion battery types. You benefit from rapid, repeatable, and clean joints, which are critical for safety and performance. In robotics, robotics battery packs often use ultrasonic welding for compact, lightweight, and reliable assembly. The process also supports industrial and security system batteries, where environmental sealing and vibration resistance matter.

Threaded fastening suits scenarios where you require frequent maintenance, prototyping, or mixed-material assemblies. You often see this method in infrastructure projects, infrastructure backup systems, and industrial equipment. Threaded joints allow you to open the housing for inspection, repair, or upgrades. This flexibility is valuable in custom or low-volume battery pack production, where design changes and serviceability are priorities.

Tip: If you need a custom battery housing solution tailored to your application, you can consult with our engineering team for expert guidance.

Part 2: Strength and Durability

2.1 Structural Integrity

When you select a joining method for lithium battery housings, you must consider structural integrity. Ultrasonic welding creates a continuous bond across the joint, fusing thermoplastic materials at the molecular level. This process delivers high strength and a seamless connection, which is essential for battery packs in demanding environments like robotics, medical devices, and industrial systems. Threaded fastening relies on mechanical pressure from screws, which can concentrate stress at specific points. Over time, this may reduce the overall strength of the housing, especially if you use lightweight or foam materials.

Feature | Ultrasonic Welding | Threaded Fastening |

|---|---|---|

Joint Type | Continuous, fused | Point-based, mechanical |

Strength Distribution | Even across the weld | Localized at fasteners |

Maintenance Needs | Minimal | May require retorquing |

Suitability for Plastics | Excellent | Good, but risk of damage |

You gain a more reliable and robust structure with welding, especially for battery packs that require long-term durability.

2.2 Vibration and Impact Resistance

Vibration and impact resistance play a critical role in battery housing performance. Ultrasonic welding eliminates the risk of fastener loosening, which often occurs with threaded connections under vibration. You avoid issues like hole elongation and local crushing, common with screws in foam or composite housings. Welded joints maintain their strength and remain reliable even after repeated shocks or vibrations. In contrast, threaded fasteners may require regular maintenance and can compromise impact resistance if the material deforms.

Note: For battery packs used in transportation, robotics, or industrial applications, welding offers superior vibration durability and impact protection. You ensure a reliable seal and mechanical strength, reducing the risk of failure in harsh conditions.

If you want to optimize your battery housing for strength and reliability, consider consulting our engineering team for a custom solution: Battery Customization.

Part 3: Sealability and Safety

3.1 Dust and Water Protection

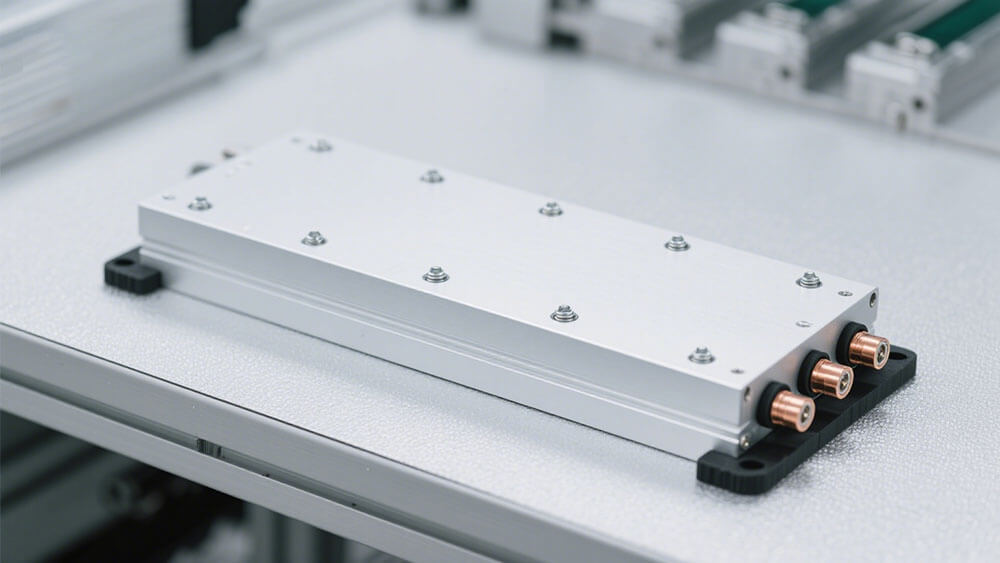

When you design lithium battery housings, sealability stands as a top priority. You want to keep dust and water out to protect sensitive cells and electronics. Ultrasonic welding creates a continuous, hermetic joint that delivers exceptional protection. This method often achieves IP68 ratings, which means your battery pack can withstand immersion in water for extended periods and block fine dust particles. You gain a robust, permanent seal that does not depend on gaskets or manual assembly.

Threaded fastening, in contrast, relies on compression seals like O-rings or gaskets. With careful engineering, you can reach IP67, which protects against dust and temporary water immersion. However, the seal’s effectiveness depends on consistent torque and assembly precision. Over time, repeated opening and closing may compromise the seal, reducing long-term protection.

Feature | Ultrasonic Welding | Threaded Fastening |

|---|---|---|

Typical IP Rating | Up to IP68 | Up to IP67 |

Seal Longevity | Permanent | May degrade |

Assembly Complexity | Low | Higher |

Maintenance Required | Minimal | Possible retightening |

For applications in medical, robotics, or security systems, you need a reliable, high-quality seal. Ultrasonic welding offers clear advantages for these demanding environments.

3.2 Electrical Safety

You must also consider electrical safety when selecting a joining method. Ultrasonic welding uses high-frequency vibration to join materials without melting, which generates minimal heat. This process preserves electrical insulation and reduces the risk of damaging battery cells. You avoid metallurgical defects and maintain low electrical resistance, which is critical for the quality and safety of lithium battery packs.

Welding ensures a solid-state bond, minimizing heat and protecting sensitive components.

You achieve reliable insulation, even with thin or highly conductive materials.

Quality control remains straightforward, supporting consistent results in mass production.

Threaded fastening does not introduce heat, but it may require metal inserts or conductive paths that could affect insulation if not designed properly. You must monitor assembly closely to maintain safety standards.

Tip: For high-quality, reliable battery housing solutions, consider consulting our engineering team for custom welding options.

Part 4: Production Efficiency

4.1 Assembly Speed

When you manage high-volume lithium battery production, assembly speed directly impacts your output and cost efficiency. Ultrasonic welding stands out for its rapid cycle times. Each weld typically completes in less than one second, making it ideal for mass production environments. In contrast, threaded fastening often requires more time per unit, especially when manual or semi-automated processes are involved. This difference becomes significant as your production volume increases.

Assembly Method | Average Assembly Time per Unit | Suitability for Production Volume |

|---|---|---|

Ultrasonic Welding | Less than 1 second per weld | Highly suitable for high-volume production |

Threaded Fastening | Not explicitly specified | Generally used in low-volume applications, implied longer times |

You gain a clear advantage with ultrasonic welding when you need to scale up lithium battery pack assembly. Fast welding cycles reduce labor costs and help you meet tight delivery schedules.

4.2 Automation Potential

You benefit from advanced automation when you choose ultrasonic welding for battery housing. Modern assembly lines use robotic loading, precise positioning, and integrated inspection systems. These lines connect with Manufacturing Execution Systems (MES) for real-time monitoring and quality control. The entire welding process, from cell loading to final inspection, operates with minimal human intervention. This level of automation ensures consistent weld quality and reduces operational risks.

Threaded fastening can use smart electric tools and digital torque monitoring. However, you often need more manual steps or semi-automated stations. While these tools improve quality, they do not match the full automation and modular design of ultrasonic welding lines. For large-scale lithium battery production, welding gives you the highest efficiency and process reliability.

Tip: If you want to optimize your battery assembly line for speed and automation, consider a custom battery solution from our engineering team.

Part 5: Cost and Materials

5.1 Equipment and Setup Costs

When you plan lithium battery pack production, you must evaluate the total cost of joining methods. Ultrasonic welding requires a higher initial investment in specialized equipment and tooling. You need to budget for ultrasonic generators, welding horns, and custom fixtures. However, the per-unit cost drops significantly as your production volume increases. This makes welding a cost-effective solution for large-scale manufacturing.

Threaded fastening uses standard tools and hardware, so your upfront cost stays low. You only need basic assembly stations and screwdrivers. For small batches or prototypes, this method seems cost-effective. As your production grows, labor and assembly time increase your total cost per unit.

Factor | Ultrasonic Welding | Threaded Fastening |

|---|---|---|

Initial Equipment Cost | High | Low |

Per-Unit Cost (High Volume) | Low | Higher |

Labor Requirement | Minimal | Higher |

Automation Potential | Excellent | Moderate |

Cost-Effective for | Mass Production | Small Batches |

Tip: For high-volume lithium battery production, you achieve the most cost-effective results with welding. If you want to optimize your cost structure, consider a custom battery solution from our engineering team.

5.2 Material Compatibility

You must match your joining method to the materials in your battery housing. Ultrasonic welding works best with thermoplastic polymers such as ABS, PC, and PP. This method gives you a strong, seamless joint without extra fasteners. If you use mixed materials or metals, welding may not be suitable.

Threaded fastening supports a wider range of materials. You can join plastics, metals, or composites with screws. This flexibility helps when you design battery housings for custom or hybrid applications. However, you may face disadvantages like thread wear in soft plastics.

Material Type | Ultrasonic Welding | Threaded Fastening |

|---|---|---|

Thermoplastics | Excellent | Good |

Metals | Limited | Excellent |

Composites | Limited | Good |

Mixed Materials | Not Recommended | Excellent |

You should always consider your material selection and production scale when choosing the most cost-effective joining method for lithium battery packs. For more on sustainable material choices, visit Our Approach to Sustainability.

Part 6: Serviceability and Design Flexibility

6.1 Maintenance and Repair

You must consider serviceability when selecting a joining method for lithium battery housings. Threaded fastening gives you the ability to open and reseal battery packs for inspection, repair, or upgrades. This feature is valuable in industrial, infrastructure, and security system applications, where regular maintenance extends product life and ensures compliance with safety standards. You can quickly replace damaged cells or update the battery management system (BMS) without damaging the enclosure.

Ultrasonic welding creates a permanent, tamper-resistant seal. You benefit from enhanced protection against dust and moisture, but you cannot reopen the housing without destroying the joint. This approach works best for applications where you do not expect frequent servicing, such as sealed medical devices or consumer electronics. For high-volume deployments, you reduce the risk of unauthorized access and improve overall reliability.

6.2 Design Adaptability

Ultrasonic welding offers unique advantages for design flexibility in lithium battery pack development. You can create lighter, more integrated housings by eliminating screws and adhesives. The process uses high-frequency vibration to join materials at precise locations, which preserves the softness and flexibility of thermoplastics. You can also integrate features like ventilation gaps or drainage channels to improve performance.

You reduce part complexity and weight by removing mechanical fasteners.

You support sustainability by lowering material consumption and improving recyclability.

You increase manufacturing efficiency by skipping adhesive curing steps.

Aspect | |

|---|---|

Joint Design | Requires precise geometry and alignment for quality welds |

Design Flexibility | Enables integration of ventilation and drainage features; supports compact, lightweight designs |

Material Impact | Localized heat preserves material properties; no adhesives needed |

Part Complexity | Eliminates screws, reducing weight and simplifying assembly |

You gain the ability to innovate with your battery housing designs, especially for advanced lithium battery packs in robotics, medical, and industrial sectors.

You gain the most value from ultrasonic welding for lithium battery housings when you prioritize strength, sealing, and production efficiency. Consider these factors:

High-volume production benefits from rapid, reliable welding.

Serviceability needs may favor threaded fastening for easier repair and recycling.

FAQ

1. What is the best joining method for high-volume lithium battery pack production?

You achieve the highest efficiency and sealing with ultrasonic welding. This method supports automation and delivers consistent quality for large-scale lithium battery manufacturing.

2. Can you repair or upgrade a welded lithium battery housing?

You cannot reopen ultrasonic welded housings without damaging the joint. For easy maintenance or upgrades, select threaded fastening for your lithium battery packs.

3. How do I choose the right joining method for my battery project?

Evaluate your production scale, serviceability needs, and sealing requirements. For expert guidance, consult Large Power for a custom lithium battery housing solution.