You need robust battery communication protocols to monitor battery status, including voltage, current, temperature, SOC, and SoH. In BMS, protocols like CANbus, RS-485, UART, i2c, SMBus, Modbus, SPI, and i2c enable accurate status tracking. BMS communication ensures real-time data, while i2c supports protocol functionality and integration. i2c enhances battery management system performance. With i2c, you monitor battery status, maintain safety, and optimize BMS. i2c remains essential for BMS communication and battery management systems, supporting status updates and advanced analytics.

Key Takeaways

Battery communication protocols like CAN Bus, RS485, UART, and i2c enable real-time monitoring and control of battery health, ensuring safety and efficiency.

Choosing the right protocol depends on factors like data speed, communication distance, fault detection, and system compatibility to match your battery management needs.

Protocols such as i2c and SMBus offer simple wiring and low power use for internal battery systems, while CAN Bus and RS485 provide robust, high-speed communication for demanding industrial and automotive applications.

Part 1: Battery Communication Protocols

1.1 CAN Bus

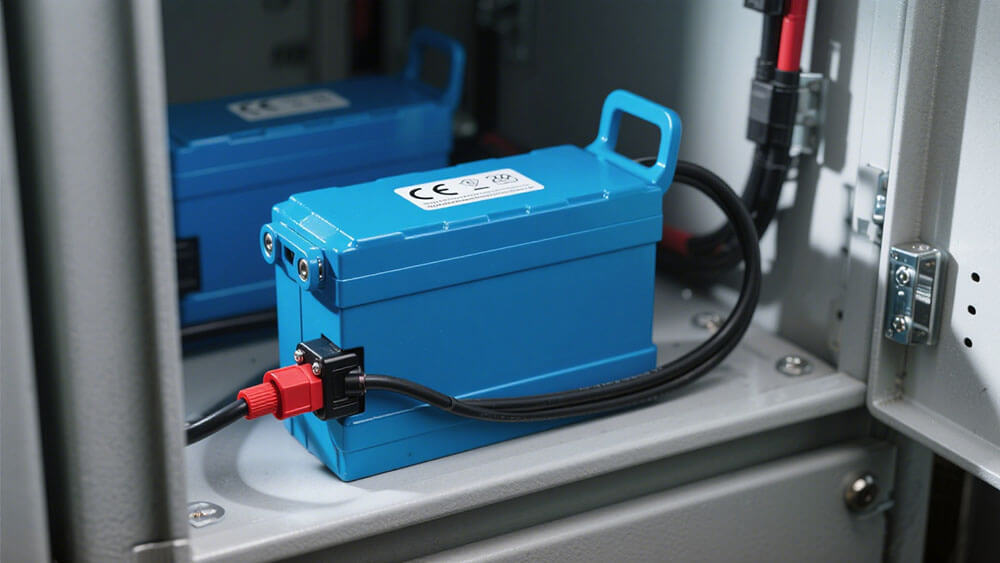

You encounter CAN Bus as one of the most robust battery communication protocols in lithium battery packs and BMS communication. CAN Bus enables high-speed, fault-tolerant data transfer between your battery, BMS, and external devices such as chargers, vehicle control units, and industrial automation systems.

CAN Bus supports real-time monitoring and control of voltage, current, temperature, SOC, and SOH.

Sensors in your BMS continuously acquire cell voltage, current, and temperature. CAN Bus transmits this data, allowing the BMS to estimate battery status and optimize charge/discharge strategies.

The protocol’s galvanic isolation and message-based architecture allow you to add or remove nodes easily, supporting hot-plugging and flexible system expansion.

CAN Bus is widely used in automotive battery management systems, electric vehicles, and industrial battery setups.

Aspect | Advantages | Disadvantages | Common Implementations |

|---|---|---|---|

Speed | Up to 1 Mbps for real-time data transfer | Limited cable length (~500m) | Automotive, industrial BMS |

Fault Tolerance | High error detection, robust in noise | Higher cost and complexity | EVs, automation setups |

Robustness | Operates in harsh environments | Some transceivers may not survive all faults | Electric vehicles, industrial BMS |

Flexibility | Easy node addition/removal | Requires separate power sources | Automotive, industrial |

Cost | Reduces wiring complexity | Higher initial implementation cost | Automotive, industrial |

CAN Bus offers high reliability and scalability for bms communication protocols. You benefit from reduced wiring complexity and robust error handling, making it ideal for demanding environments. However, you must consider the higher cost and complexity compared to simpler protocols.

Tip: For electric vehicles and industrial battery management systems, CAN Bus remains the preferred choice for real-time data exchange and system reliability.

1.2 RS485

RS485 stands out as a cost-effective and reliable protocol for bms communication in lithium battery packs. You use RS485 for long-distance data transfer, supporting up to 32 nodes on a single bus line in half-duplex mode.

RS485’s differential signaling provides strong noise immunity, making it suitable for industrial and renewable energy storage systems.

The protocol supports multi-point communication, allowing you to connect multiple devices and simplify wiring.

You must manage timing and addressing externally, as RS485 lacks built-in arbitration and error correction.

Feature/Aspect | Description |

|---|---|

Communication Type | Differential signaling, multi-point (up to 32 nodes) |

Wiring | 2-wire half-duplex; 4-wire full duplex possible |

Data Rate and Distance | Up to 10 Mbps at 12m; 1 Mbps at 122m; 100 kbps at 1219m |

Topology | Linear bus (daisy chain) |

Error Handling | No built-in arbitration or fault tolerance; external management needed |

Application Suitability | Simple, cost-effective for fewer devices; less suitable for high-reliability needs |

You find RS485 widely used in electric vehicles, renewable energy storage, UPS, microgrid systems, and remote monitoring of lithium battery health.

Benefits include robust communication, long-distance capability, multi-device support, and low power consumption.

Limitations involve lower speed, configuration complexity, and lack of built-in redundancy.

RS485 remains relevant for bms communication protocols where budget and infrastructure compatibility matter.

Note: RS485 is ideal for medium-sized lithium battery systems and industrial automation, but you should avoid it for very large or highly reliable systems.

1.3 UART

UART provides a simple and versatile solution for bms communication in lithium battery packs. You use UART for asynchronous data transfer, relying on start and stop bits to frame each byte.

UART operates with two lines (Tx and Rx), supporting point-to-point or multi-point configurations.

You benefit from low protocol overhead and easy implementation, making UART suitable for basic battery monitoring and control.

UART’s daisy-chain architecture offers cost-effectiveness and robustness, especially in noisy environments.

Feature | UART | Other Protocols (CAN Bus, SPI, I2C, Ethernet) |

|---|---|---|

Communication Type | Asynchronous (no shared clock) | Synchronous or packet-based |

Data Framing | Start/stop bits | Clock signals or packet structures |

Data Lines | 2 (Tx and Rx) | Varies |

Error Detection | Limited (optional parity bit) | Advanced error detection (CAN Bus) |

Topology | Point-to-point or multi-point | Multi-master or point-to-point |

Overhead | Low | Higher |

You commonly use UART in automotive electric vehicles, hybrid vehicles, 48V systems, electric bikes, battery-powered tools, and backup systems.

Advantages include simplicity, flexibility, and reliability.

Drawbacks involve lower speed and risk of communication disruption in daisy-chain wiring breaks.

UART suits applications prioritizing simplicity, low cost, and moderate data transfer.

Tip: For basic bms communication and battery monitoring, UART remains a practical choice.

1.4 I2C

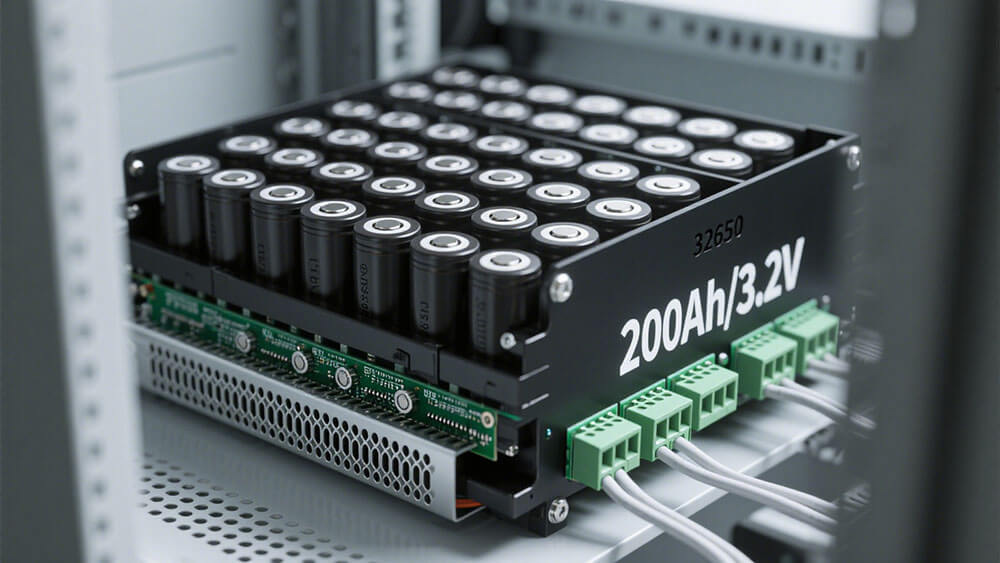

You rely on i2c as a foundational protocol for bms communication within lithium battery packs. The i2c communication protocol uses two bidirectional lines (SDA and SCL) for synchronous serial data transfer.

The master device controls the clock, enabling communication with multiple slave devices.

i2c supports standard (100 kbps), fast (400 kbps), high-speed (3.4 Mbps), and ultrafast (5 Mbps) modes.

You can connect up to 1008 nodes, though practical limits depend on bus capacitance and wiring length.

i2c serves as the basis for system management bus and power management bus protocols, which enhance battery monitoring and control.

Feature | Description |

|---|---|

Communication Type | Synchronous, serial bus (SDA and SCL) |

Wiring | 2 wires |

Clock Control | Master device |

Speed Modes | |

Addressing | Up to 1008 nodes |

Data Transfer | Frames with start, stop, acknowledge |

Electrical Characteristics | Open-drain outputs, pull-up resistors |

Bus Length | ~1 meter at 100 kbps |

You use i2c for internal bms communication, connecting controllers to low-speed peripherals like temperature sensors.

Strengths include simplicity, minimal wiring, multi-master/multi-slave support, and low power consumption.

Weaknesses involve lower speed and limited range compared to SPI and CAN Bus.

i2c is ideal for short-range, intra-board communication tasks in bms communication protocols.

Note: For internal battery management systems, i2c offers reliability and ease of wiring.

1.5 SMBus

You encounter system management bus (SMBus) as a specialized protocol built on i2c for bms communication in smart battery systems. SMBus shifts charge control from the charger to the battery, allowing universal chargers to service various chemistries with correct algorithms.

SMBus uses two lines (clock and data), supporting multiple devices and standardized communication.

Enhanced robustness comes from features like timeouts and packet error checking.

You find SMBus widely used in laptops, biomedical instruments, and survey equipment, where batteries provide detailed status data for precise monitoring.

Aspect | Details |

|---|---|

Advantages | Two lines, multiple devices, standardized, robust error checking |

Disadvantages | Slower data rate, limited frame size, more complex hardware |

Common Applications | Computer motherboards, embedded systems, smart battery systems (laptops, medical instruments) |

SMBus enables intelligent battery management, safety protections, and universal charging.

Tip: For smart battery systems in medical, robotics, and security applications, SMBus ensures accurate status reporting and safe operation.

1.6 Modbus

Modbus provides a simple and open protocol for bms communication in industrial and building automation. You use Modbus to organize data in memory maps, allowing efficient reading and writing of battery status and control parameters.

Modbus operates on a client-server architecture, supporting serial (RS232, RS485) and TCP/IP communication.

The protocol’s message frame includes function codes, addresses, data fields, and error checking.

Modbus RTU and Modbus TCP variants offer flexibility for different integration needs.

Benefits include simplicity, reliability, and wide compatibility with industrial systems.

Limitations involve lack of built-in security, limited data types, and master-slave topology constraints.

You use Modbus for real-time status updates, predictive maintenance, and performance tracking in high-voltage lithium battery systems such as electric vehicles, UAVs, and marine systems.

Note: Modbus supports centralized and decentralized bms communication protocols, reducing wiring complexity and enabling remote monitoring.

1.7 SPI

SPI (Serial Peripheral Interface) offers high-speed, short-distance data transfer for bms communication within lithium battery packs. You use SPI for rapid and reliable communication between microcontrollers and peripherals such as sensors or memory chips.

SPI supports speeds up to 50 MHz, making it faster than i2c and ideal for embedded systems requiring fast data acquisition.

The protocol’s simple bus architecture allows daisy chaining, reducing the need for costly digital isolators.

You commonly use SPI for monitoring cell voltages and managing stacked lithium battery modules in electric and hybrid vehicles.

Communication Protocol | Operational Mechanism | Key Features for BMS Applications |

|---|---|---|

SPI | High-speed, short-distance | Fast data acquisition, ideal for embedded systems |

Advantages include simple communication, flexibility, and modularity.

Disadvantages involve high cost and complexity for isolation, risk of communication loss in daisy chain setups, and challenges with high voltages.

SPI suits scenarios requiring modularity and robust communication in high-voltage lithium battery packs.

Tip: For battery pack management in automotive and industrial applications, SPI delivers rapid data transfer and reliable performance.

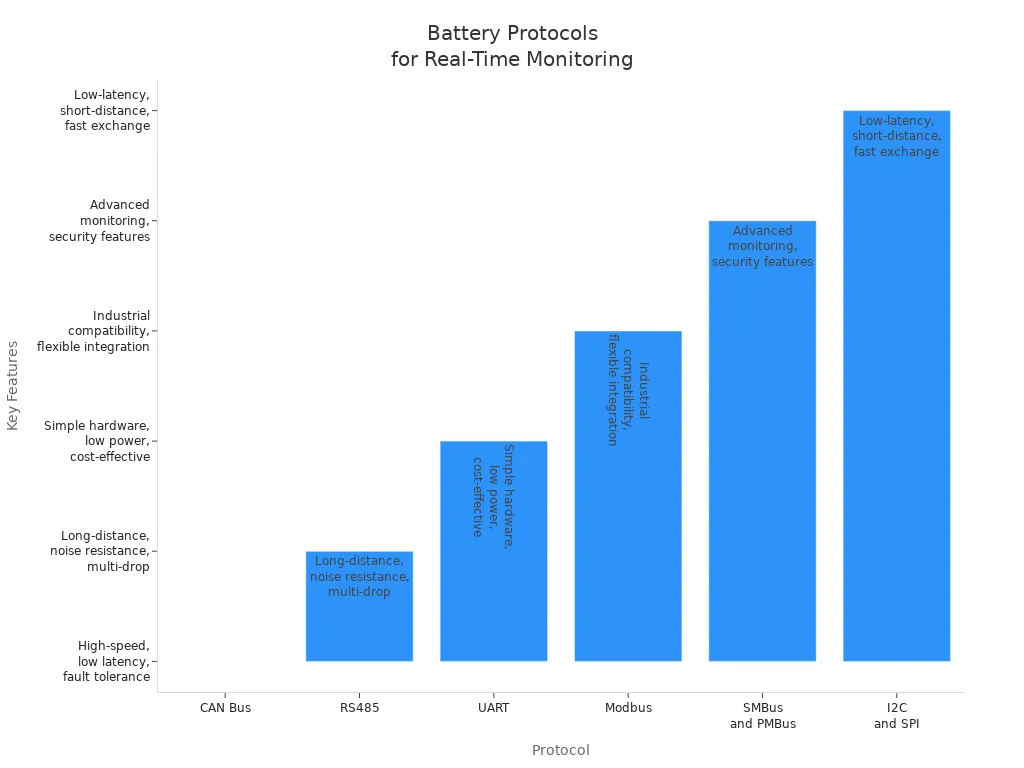

You rely on these battery communication protocols to enable real-time data exchange, precise monitoring, and control of battery parameters. CAN Bus, RS485, UART, i2c, system management bus, power management bus, Modbus, and SPI each offer unique strengths for bms communication protocols.

CAN Bus and RS485 excel in automotive and industrial environments, providing robust, fault-tolerant communication.

UART and i2c deliver simplicity and flexibility for internal battery management systems.

SMBus and power management bus enhance diagnostics and safety in smart battery systems.

Modbus and SPI support integration with industrial automation and high-speed embedded applications.

You face interoperability challenges when integrating these protocols with energy management systems (EMS) and inverters. The lack of industry-wide standards can cause compatibility issues, requiring careful protocol selection and management.

You must coordinate bms communication with EMS and inverters to optimize battery life, grid stability, and safety.

Cybersecurity and protocol maturity are critical considerations for seamless integration.

Standards like IEEE 1547-2018 and IEEE 2030.5 support standardized communication for distributed energy resources.

Note: Selecting the right battery communication protocols for your lithium battery packs and bms communication ensures reliable status monitoring, efficient data transfer, and safe operation across diverse applications.

Part 2: BMS Communication Comparison

2.1 Protocol Features

When you evaluate bms communication options for lithium battery packs, you must compare each protocol’s features, advantages, and limitations. This helps you select the right communication protocol architecture for your application. The table below summarizes the most relevant protocols for bms, focusing on their suitability for lithium battery chemistries such as LiFePO4 and NMC.

Protocol | Key Features & Advantages | Limitations & Disadvantages | Typical Use Cases in BMS Applications |

|---|---|---|---|

CAN Bus | High reliability, multi-master, robust noise immunity, up to 1 Mbps, strong fault detection mechanisms | Requires terminators, limited network size (~30 nodes), setup complexity | Automotive, e-bike, industrial battery management systems, multi-node bms communication |

RS-485 | Long-distance (up to 1200 m), supports up to 32 devices, differential signaling, robust in noise | Requires careful cable handling, moderate data rate (up to 10 Mbps), external fault detection mechanisms | Industrial BMS, large battery packs, remote monitoring, scalable bms communication |

UART | Simple, asynchronous, low-cost, easy integration, point-to-point or daisy chain | Short range, low data rate, limited fault detection mechanisms | E-bike batteries, basic monitoring, internal bms communication |

I2C | Two-wire, low power, easy setup, supports up to 1008 nodes, ideal for intra-board comms | Sensitive to noise, limited range (~1 m), low to moderate data rate (100 kbps to 3.4 Mbps) | Internal bms communication, sensor integration, smart battery modules |

SMBus | Built on i2c, standardized, robust error checking, supports smart battery data exchange | Slower data rate, limited frame size, more complex hardware | Laptops, medical devices, robotics, smart battery management systems |

Open protocol, simple memory mapping, supports serial and TCP/IP, scalable | No built-in security, master-slave topology, limited data types | Industrial automation, high-voltage lithium battery systems, centralized bms communication | |

SPI | High-speed (up to 50 MHz), short-distance, fast data acquisition, modular | High cost for isolation, daisy chain risk, not ideal for high voltages | Embedded bms, cell voltage monitoring, automotive and industrial battery management systems |

RS-232 | Simple, point-to-point, easy to implement | Short distance (15 m), low data rate (20 kbps), susceptible to noise | |

Bluetooth/BLE | Wireless, energy efficient (BLE), easy integration, no wiring | Lower data rate and range, wireless security concerns | Remote monitoring, portable lithium battery packs, IoT-enabled bms communication |

Very high data speed (up to 10 Gbps), large network support | High cost, high power consumption, less suitable for low-power battery management systems | Large-scale industrial battery management, grid-connected lithium battery pack integration |

You should focus on protocols that match your bms communication needs, considering data rate requirements, network size, and environmental conditions. CAN Bus and RS-485 offer robust fault detection mechanisms and high data rates for demanding applications. I2C and SMBus provide simplicity and efficiency for internal bms communication, especially in smart battery modules.

2.2 Selection Guide

Define Data Rate Requirements

Assess how much data your bms must transmit. High data rates are essential for real-time monitoring in automotive and industrial battery management systems. CAN Bus and SPI support high data rates, while i2c and UART suit lower data rate requirements.

Evaluate Communication Distance

For short-range, intra-board communication, i2c and SPI provide efficient solutions. For long-distance or multi-device networks, RS-485 and CAN Bus excel due to their robust communication protocol architecture and noise immunity.

Check Compatibility and Integration

Ensure your chosen protocol integrates seamlessly with your lithium battery chemistry (LiFePO4, NMC) and system voltage. Compatibility with external controllers and site systems is vital for B2B system requirements. CAN Bus and Modbus offer broad compatibility for industrial and automotive integration.

Prioritize Fault Detection Mechanisms

Select protocols with strong fault detection mechanisms to enhance safety and reliability. CAN Bus includes built-in error detection, while RS-485 and Modbus require external monitoring. I2c and UART offer basic error checking, suitable for less critical applications.

Consider Power Consumption and Complexity

For battery-powered systems, prioritize protocols with low power consumption like i2c and BLE. For complex, high-performance systems, accept higher power draw for advanced features and reliability.

Ensure Compliance and Support

Choose protocols that comply with industry standards (ISO 26262, UL 2580, IEC 62619, IEC 62133, UN 38.3). This guarantees safety, reliability, and legal conformity for your lithium battery pack integration.

Plan for Ongoing Maintenance

Implement ongoing monitoring and proactive maintenance using bms telemetry data. Ensure your protocol supports software updates and technical assistance for long-term performance.

Tip: For B2B lithium battery pack integration, insist on an integrated bms design. Verify compatibility and communication protocol architecture through supplier demonstrations and certifications. Prioritize safety, reliability, and seamless data exchange to meet your business needs.

Summary Checklist for Protocol Selection:

Match protocol to lithium battery chemistry and voltage.

Confirm data rate requirements and communication distance.

Verify compatibility with B2B system requirements.

Prioritize robust fault detection mechanisms.

Ensure compliance with industry standards.

Plan for ongoing support and maintenance.

By following these steps, you ensure your bms communication supports reliable, safe, and efficient operation of lithium battery packs in demanding B2B environments.

Selecting the right communication protocol, such as i2c, directly impacts lithium battery system performance, safety, and integration. You achieve stable voltage, extended cycle life, and seamless bms operation.

i2c, CAN, and RS485 in bms support remote diagnostics, firmware updates, and predictive analytics.

You must prioritize interoperability and future scalability by choosing protocols that enable modular upgrades and cloud integration.

Stay updated on evolving standards, including wireless i2c and AI-powered bms, to maintain reliability and compliance.

Tip: Regularly review protocol compatibility, maintain firmware, and monitor bms health to ensure long-term system stability.

FAQ

1. What makes i2c a preferred protocol for internal BMS communication in lithium battery packs?

You choose i2c for internal BMS communication because it offers simple wiring, low power use, and reliable data transfer. i2c supports multiple devices, making it ideal for lithium battery pack integration.

2. How does i2c improve interoperability between BMS and external monitoring systems?

You use i2c to connect BMS modules with sensors and controllers. i2c enables seamless data sharing, which helps you integrate lithium battery packs with industrial monitoring and automation platforms.

3. Can Large Power customize BMS solutions with i2c for different lithium battery chemistries?

You can request custom BMS solutions from Large Power. Their engineering team designs i2c-based BMS for LiFePO4, NMC, and other chemistries. Consult Large Power’s experts for custom battery solutions.