The wearable technology market is set to grow to over $190 billion by 2032, a testament to the relentless innovation in sensors, processors, and connectivity. Yet, for all this advancement, the single greatest bottleneck holding back the next generation of smart rings, medical patches, and AR glasses is the battery. Off-the-shelf power solutions are a dead end, forcing designers into compromises that sacrifice ergonomics, performance, and user trust.

A truly innovative wearable demands a custom-engineered power source. This isn’t just about fitting a battery into a small space; it’s a complex, multi-disciplinary engineering challenge that balances chemistry, mechanics, and firmware. This guide provides a deep dive into the five critical challenges of designing custom battery packs for wearable technology and outlines the engineering-led solutions required to overcome them.

1. The Tyranny of Space: Mastering Miniaturization and Complex Form Factors

In wearable design, every cubic millimeter is precious. The challenge goes beyond simple miniaturization; it requires creating power sources that conform to the non-rectangular, ergonomic shapes of devices that live on the human body.

The Engineering Solution: Application-Specific Cell Technology

Standard cylindrical or prismatic cells are non-starters. The solution lies in advanced Lithium Polymer (LiPo) technology, which allows for radical customization of shape and size.

- Shaped Pouch Cells:For devices like smart rings or hearables, where the internal cavity is curved or irregular, custom-shaped LiPo pouch cells are essential. These can be manufactured in curved, D-shaped, C-shaped, or even polygonal forms, allowing designers to maximize every bit of available space. This is how a feature-rich smart ring can fit all its electronics, including a curved LiPo battery, inside a band just a few millimeters thick.

- Ultra-Thin and Narrow Batteries:For medical patches or smart clothing, thickness is the enemy. Custom ultra-thin LiPo batteries can be manufactured to be as slim as 0.5mm, and ultra-narrow cells can be as slender as 4.1mm wide. This allows the power source to be integrated seamlessly without creating uncomfortable bulk.

- Advanced Materials for Higher Density:To extract maximum runtime from these tiny cells, energy density is critical. Innovations like using silicon-carbon anodes in place of traditional graphite can increase a battery’s energy capacity by up to 30% without changing its physical dimensions—a game-changer for extending the life of a smart ring from 4 days to over a week.

2. The Energy Trilemma: Balancing Density, Power Delivery, and Cycle Life

A wearable user expects multi-day battery life, but the device’s high-performance sensors and processors demand high peak currents that can cripple a battery’s long-term health. A spec sheet claiming “500 cycles” is often meaningless, as this is typically measured under ideal, low-stress conditions that don’t reflect real-world use.

The Engineering Solution: A Systems Approach to Power Management

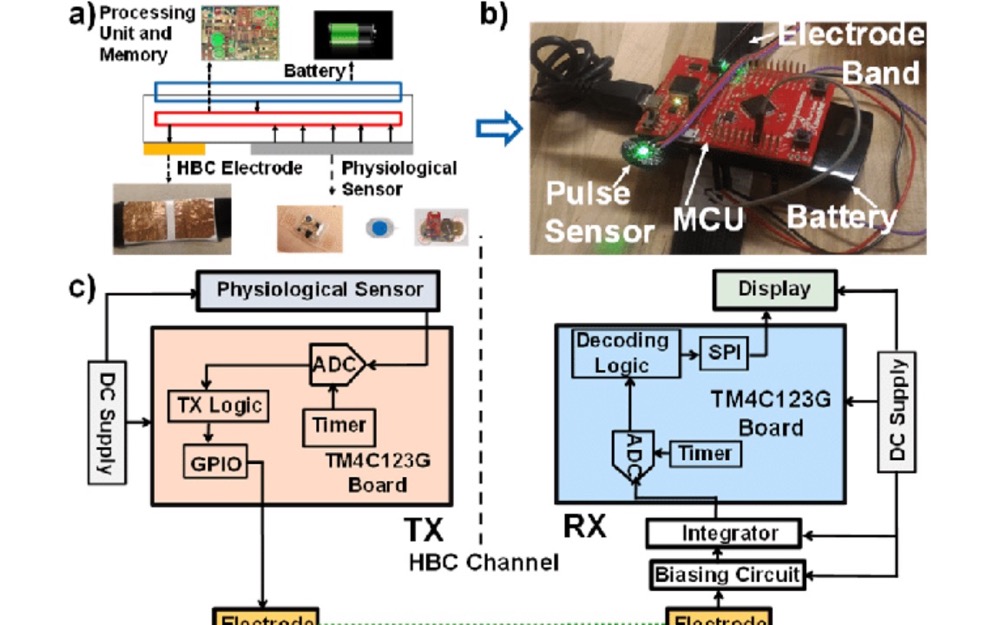

Solving this trilemma requires looking beyond the cell itself and engineering the entire power delivery system, as demonstrated by Texas Instruments’ comprehensive AR glasses power solutions.

Application-Specific Chemistry Selection: The choice of cathode and anode materials is a critical trade-off. A high-performance AR headset needs a high-discharge rate LiPo battery to handle power spikes from its processor and display. In contrast, a life-critical wearable medical sensor would benefit from a more stable Lithium Iron Phosphate (LiFePO4) battery, which offers superior thermal stability and a longer cycle life at the cost of slightly lower energy density.

Optimizing for Low Quiescent Current (Iq): Wearable devices spend most of their time in a low-power standby state. The power management integrated circuits (PMICs), particularly the DC/DC buck converters that power the main processor, must have an extremely low quiescent current (Iq). Modern components, such as Texas Instruments’ BQ25120A, feature an Iq as low as 700 nanoamps (nA), drastically extending the time between charges.

Realistic Cycle Life Validation: Instead of relying on a generic datasheet, a true engineering partner will test a battery using a simulated load profile that precisely mimics the device’s actual usage—from high-current sensor readings to low-power sleep modes. This is the only way to accurately predict real-world battery degradation and provide a reliable service life estimate to the end-user. Keysight’s usage-pattern based testing methodology and Emitech’s IEC-compliant cycling test procedures provide accurate real-world battery degradation predictions.

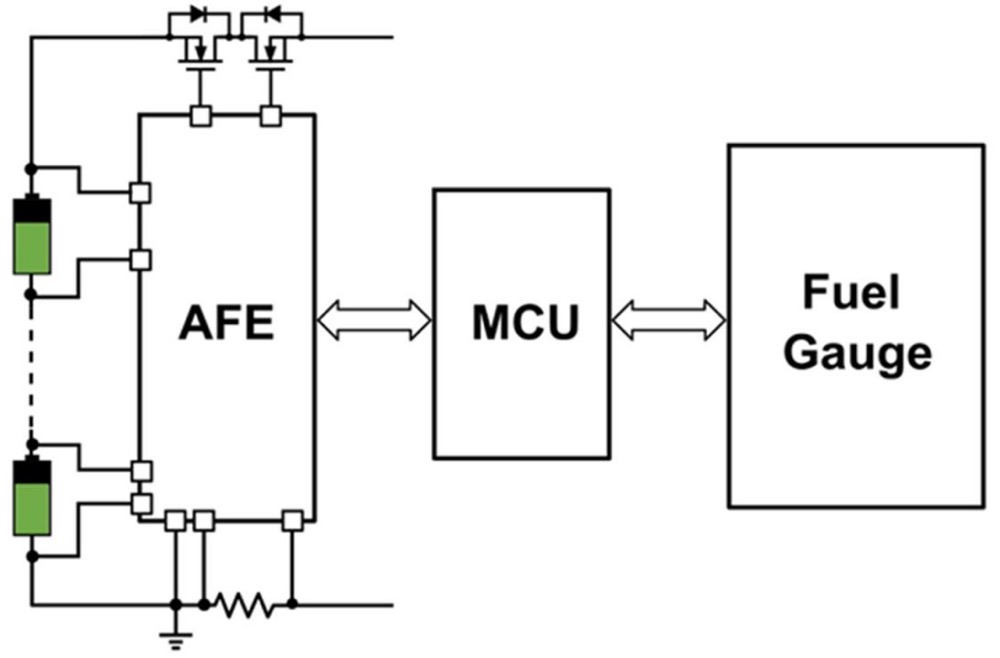

3. The Unseen Guardian: Designing an Intelligent BMS for Miniaturized Systems

A simple protection circuit module (PCM) is not enough for a modern wearable. Given the battery’s proximity to the user’s skin, an intelligent Battery Management System (BMS) is the non-negotiable brain of the pack, essential for safety, performance, and reliability.

The Engineering Solution: Custom-Tuned Firmware and Precision Monitoring

- Tailored Safety Parameters:A custom BMS allows firmware to be tuned to the device’s specific operational profile. Over-current, over-voltage, and temperature cutoffs are set with enough headroom for normal peak operations (like a processor waking up) without causing nuisance shutdowns, while still providing robust protection against genuine fault conditions.

- Accurate Fuel Gauging:For medical devices, “runtime anxiety” can be a serious issue. A sophisticated BMS with a dedicated fuel gauge IC (like the MAX17260) uses advanced algorithms like coulomb counting to provide an accurate State of Charge (SoC) and, just as importantly, State of Health (SoH). This tells the user not just how much charge is left, but also when the battery is nearing the end of its life and needs replacement.

- Integrated Thermal Monitoring:The BMS must actively monitor cell temperature via an NTC thermistor. This data is used to prevent charging or discharging in extreme temperatures (e.g., below 0°C or above 55°C for most lithium cells), which is a primary cause of permanent battery damage and a major safety risk.

4. The Real-World Gauntlet: Ensuring Durability, Safety, and Global Compliance

Wearable devices live a hard life. They are subjected to constant motion, accidental impacts, vibrations, and exposure to sweat and moisture. Ensuring safety and reliability in this environment is a complex mechanical and regulatory challenge.

The Engineering Solution: A Multi-Layered Safety and Certification Strategy

- Robust Mechanical Design:The battery’s enclosure must be engineered to protect the delicate cells from punctures and shocks. Critically, the design must also account for the natural swelling of LiPo batteries as they age, leaving adequate room within the enclosure to prevent mechanical stress on the device’s other components. For devices exposed to moisture, waterproofing and corrosion-resistant contacts are essential.

- Navigating Global Certifications:This is where many product designs falter. A custom battery pack must be designed from the ground up to meet a complex web of safety and transportation standards. An experienced engineering partner manages this entire process, ensuring compliance with key standards like IEC 62133-2 (the core safety standard for portable lithium systems), UL 2054 (for household and commercial batteries), and the specific requirements for medical devices (IEC 60601-1).

| Global Certification Requirements

|

|

| UN 38.3

Transport safety tests including altitude simulation, thermal, vibration, shock, external short, impact/crush, overcharge, forced discharge

|

PHMSA Guidelines

|

| IEC 62133-2

Core electrical, mechanical, and abuse safety standard for portable lithium systems

|

Intertek Testing

|

| UL 2054

Household/commercial battery safety; FDA-recognized consensus standard for medical devices

|

UL FDA Recognition

|

| IEC 60601-1

Medical electrical equipment baseline safety; often paired with IEC 62133-2 for rechargeable packs

|

Medical Testing

|

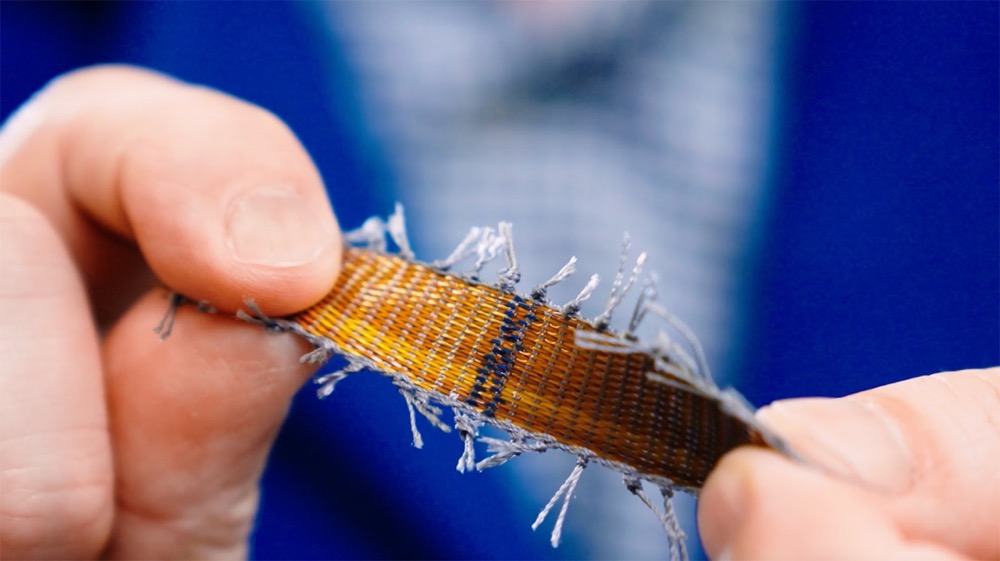

5. The Final Frontier: Weaving Power into Fabric

For the next generation of wearables, particularly smart clothing, the battery cannot be a discrete, rigid component. It must become an integral, flexible part of the textile itself.

The Engineering Solution: Advanced Flexible and Fiber-Based Batteries

- Flexible Solid-State Batteries:These emerging technologies replace the liquid electrolyte in a traditional Li-ion battery with a flexible, solid-state polymer. This not only allows the battery to bend and twist with the fabric but also enhances safety by removing flammable liquid electrolytes.

- Fiber Battery Technology:Pushing the boundaries further, researchers are now developing methods to create batteries in the form of thin fibers. This involves laminating the anode, cathode, and separator materials into a flat stack and then using precision laser cutting to create strands just 700 micrometers wide—about the width of five human hairs. These battery fibers can then be woven or knitted directly into a garment, creating a truly integrated power source.

- Energy Harvesting Textiles:Looking ahead, smart fabrics may not only store energy but also harvest it. Technologies like stretchable, sweat-activated yarn batteries are being developed that use electrolytes in the wearer’s sweat to generate power, offering a path toward self-powered smart clothing.

Conclusion: Your Wearable Demands an Engineering Partner, Not a Component Supplier

The unique challenges of powering wearable technology cannot be solved by simply selecting a battery from a catalog. It requires a holistic, engineering-led approach that integrates cell chemistry, mechanical design, firmware development, and regulatory expertise.

An off-the-shelf supplier sells a product. An engineering partner like Large Power delivers a fully integrated and de-risked power solution. We work as an extension of your team, collaborating on the design from day one, performing rigorous application-specific testing in our labs, and managing the entire certification and supply chain process.

Don’t let a battery compromise your design. Partner with Large Power’s engineering team to create a custom battery pack power solution that enables, rather than limits, your innovation.