You depend on batteries to keep your devices running. When a battery drops below AA battery voltage thresholds, your devices risk unexpected shutdowns. Alkaline batteries often fail first, but rechargeable batteries also degrade. Accurate battery checks protect devices and reduce downtime. Recent advances in batteries, especially lithium battery packs, improve reliability.

Key Takeaways

Check AA battery voltage regularly using a voltmeter to avoid device failures and replace batteries below 1.2 volts for disposable types or when rechargeable batteries drop below 80% capacity.

Choose lithium AA batteries for cold environments and high reliability, as they keep voltage stable and resist leakage better than alkaline batteries.

Use rechargeable AA batteries with battery management systems to extend battery life, reduce waste, and maintain safe, efficient device operation.

Part 1: AA Battery Voltage Thresholds

Minimum Voltage for an AA Battery

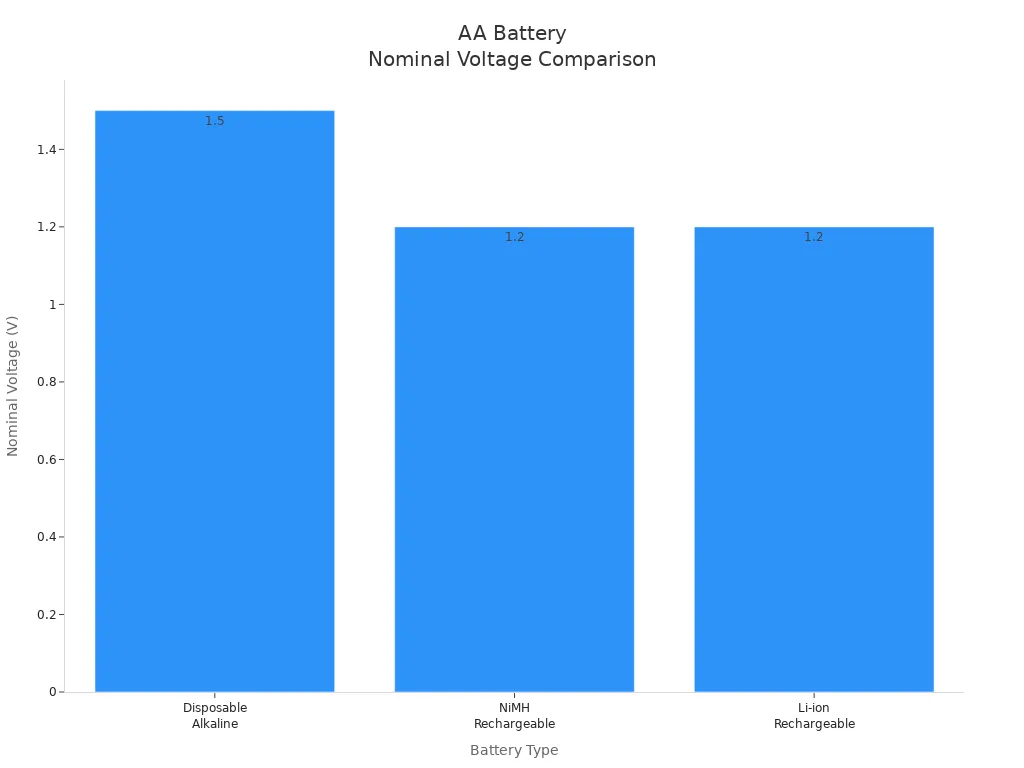

Understanding aa battery voltage thresholds is essential for maintaining reliable device operation. Disposable AA batteries, such as alkaline batteries and lithium types, have a nominal voltage of 1.5 volts. The minimum voltage for an aa battery in these types is typically 1.2 volts. When the voltage drops below this threshold, the battery is considered depleted and cannot power most devices efficiently. Fresh batteries can reach up to 1.65 volts, but once the voltage falls below 1.2 volts, you should replace the battery to avoid device downtime. Lithium AA batteries offer similar voltage stability and minimum voltage thresholds, making them suitable for critical applications.

Temperature also affects the minimum voltage and performance of batteries. Lithium AA batteries maintain voltage and capacity even at temperatures as low as -40°C, while alkaline batteries lose up to 60% of their capacity at freezing temperatures. This makes lithium types the preferred choice for environments with extreme cold, as they ensure stable energy delivery and reduce the risk of leakage or device failure.

Feature | Lithium AA Batteries | Alkaline AA Batteries |

|---|---|---|

Nominal Voltage | 1.5 V | 1.5 V |

Minimum Voltage | 1.2 V | 1.2 V |

Low Temp Performance | Effective to -40°C | Poor below 0°C |

Voltage Stability | High | Drops quickly in cold |

Leakage Risk | Low | Higher, especially when depleted |

End-of-Life Indicators

You can identify end-of-life in batteries by monitoring voltage and other performance metrics. For disposable alkaline batteries, a rapid voltage drop signals that the battery is nearing depletion. When the voltage of aa batteries falls to about 1.2 volts, half of the battery’s energy has already been used. As the battery ages, internal resistance increases, causing further voltage drops under load. This makes voltage decline a reliable indicator of end-of-life and potential leakage risk.

For rechargeable aa batteries, capacity loss is the most reliable end-of-life indicator. In industrial applications, you should consider a battery at end-of-life when its capacity drops to 80% of its original value. Other important signs include increased internal resistance, electrical anomalies, and the presence of shorts or dendrite formation. Battery management systems (BMS) track these parameters, combining historic data and real-time measurements to predict remaining useful life. Cloud analytics and diagnostic tools further improve accuracy, helping you avoid unexpected device failures and energy loss.

Tip: Establish a minimum viable performance threshold for your application, often set at 80% capacity for rechargeable types. This helps you replace batteries before they impact device performance or cause leakage.

Measuring Voltage with a Voltmeter

Accurate measurement of aa battery voltage thresholds ensures you only replace batteries when necessary, optimizing operational efficiency and reducing waste. Follow these steps to measure the voltage of aa batteries with a voltmeter:

Disconnect the battery from any circuit to prevent interference.

Set your voltmeter or multimeter to a DC voltage range higher than 1.5V (choose 2V or 20V).

Connect the red probe to the positive terminal (+) and the black probe to the negative terminal (-).

Read the voltage displayed on the meter.

Compare the reading to the table below to determine the battery’s condition.

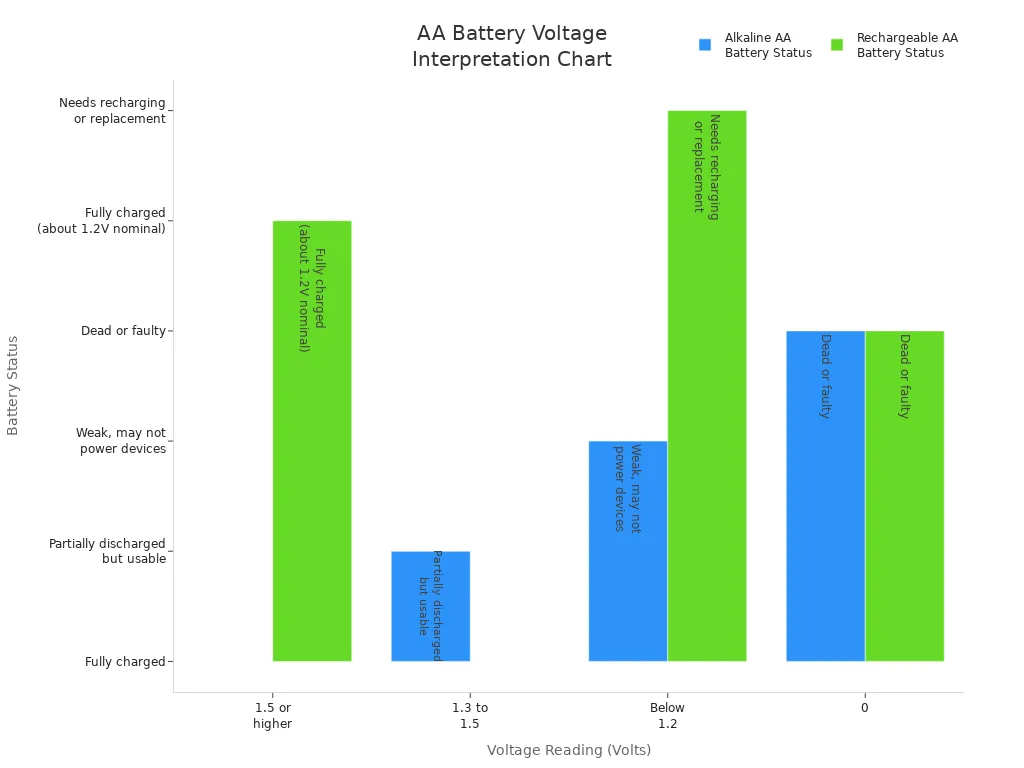

Voltage Reading (Volts) | Interpretation for Alkaline AA Battery | Interpretation for Rechargeable AA Battery (NiMH/NiCd) |

|---|---|---|

1.5 or higher | Fully charged | Fully charged (about 1.2V nominal) |

1.3 to 1.5 | Partially discharged but usable | N/A |

Below 1.2 | Weak, may not power devices effectively | Needs recharging or replacement (below 1.0V is critical) |

0 | Dead or faulty | Dead or faulty |

Note: Regularly calibrate your voltmeter to maintain accuracy. Inspect connection points for dirt or corrosion, and consider temperature effects on readings. Devices with thermal compensation help ensure reliable results, especially when testing batteries in cold environments.

By following these best practices, you can accurately assess the energy status of all types of AA batteries, minimize leakage risks, and maintain optimal device performance.

Part 2: Disposable vs. Rechargeable AA Batteries

Voltage and Chemistry Differences

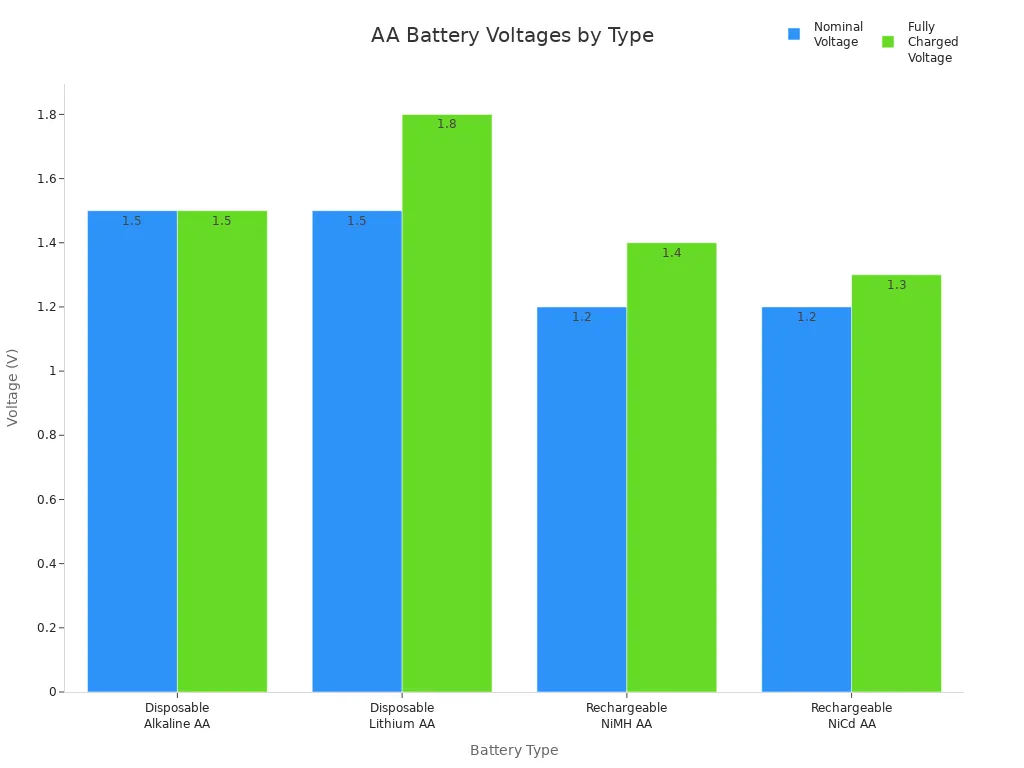

You encounter significant differences in voltage and chemistry between disposable and rechargeable AA batteries. Disposable alkaline batteries deliver a nominal voltage of 1.5V, while lithium types such as LiFePO4, NMC, LCO, LMO, and LTO reach up to 1.8V when fresh. Rechargeable batteries, including NiMH and NiCd, provide a lower nominal voltage of 1.2V, which can affect compatibility with high-drain equipment in medical, robotics, and security systems. Lithium rechargeable AA batteries use internal DC-DC converters to maintain a stable 1.5V output, supporting consistent performance in industrial and infrastructure applications.

Battery Type | Chemistry | Nominal Voltage | Fully Charged Voltage | Rechargeable | Typical Applications |

|---|---|---|---|---|---|

Alkaline AA | Alkaline | 1.5V | ~1.5V | No | Consumer electronics |

Lithium AA | LiFePO4/NMC | 1.5–1.8V | Up to 1.8V | No | Security, medical, robotics |

NiMH AA | NiMH | 1.2V | 1.3–1.4V | Yes | Industrial, infrastructure |

NiCd AA | NiCd | 1.2V | 1.3V | Yes | Legacy systems |

Lithium AA (Rechargeable) | LiFePO4/NMC | 1.5V (regulated) | 1.5V (regulated) | Yes | High-drain devices |

Rechargeability and End-of-Life

Rechargeable AA batteries offer clear advantages for sustainability and operational efficiency. You can recharge NiMH batteries up to 500 times, while NiCd types last for 1,000–2,000 cycles. These batteries reduce waste and lower energy costs in industrial and consumer electronics. End-of-life indicators include voltage drop, increased internal resistance, and capacity loss. Common failure modes involve weak cells, dendrite formation, and chemical degradation. Disposable batteries, such as alkaline batteries, show a gradual voltage decline and require frequent replacement, increasing environmental impact and safety concerns.

Tip: Use battery management systems (BMS) to monitor rechargeable alkaline batteries and optimize charge cycles, improving safety and device reliability. Learn more about BMS here.

Technological Advancements

Recent advancements in lithium battery packs have transformed battery performance and safety. Solid-state batteries and lithium iron phosphate (LiFePO4) chemistries deliver higher energy density, longer lifespan, and enhanced safety. AI-driven battery management systems extend battery life and predict failures, supporting critical infrastructure and medical devices. Smart chargers and voltage regulators prevent over-discharge and optimize charging, reducing downtime in robotics and security systems. These innovations address safety concerns and improve reliability for high-drain devices.

Note: Rechargeable alkaline batteries with advanced management systems minimize self-discharge and maintain voltage retention, supporting long-term energy efficiency and sustainability.

You monitor battery voltage thresholds to maintain device performance and safety. Use a multimeter for accurate battery checks. The table below compares batteries and their operational implications for B2B clients. Adopt smart charging, centralized hubs, and lithium battery packs to optimize battery use. Stay updated on battery advancements for improved safety and performance.

Battery Type | Nominal Voltage | Key Voltage Threshold | Notes |

|---|---|---|---|

Rechargeable NiMH | 1.2 V | ~1.1 V | Maintains voltage longer; monitor for device shutdown |

Disposable Alkaline | 1.5 V | N/A | Standard voltage; replace when performance drops |

Lithium-ion Rechargeable | ~1.2 V (varies) | N/A | Stable voltage; requires safety management |

FAQ

What is the best way to store AA batteries for industrial devices?

Store batteries in a cool, dry place. Avoid extreme temperatures. Use original packaging or battery cases. This prevents short circuits and extends battery life for your devices.

How do lithium battery packs compare to alkaline batteries in B2B applications?

Feature | Lithium Battery Packs | Alkaline Batteries |

|---|---|---|

Voltage Stability | Moderate | |

Cycle Life | Long | Single-use |

Advanced BMS | Basic |

Lithium battery packs offer higher voltage stability, longer cycle life, and advanced safety management for critical devices.

Can you mix different types of AA batteries in one device?

Never mix different batteries in one device. Mixing chemistries or brands causes uneven discharge, leakage, or device failure. Always use identical battery types for optimal device performance.