Reverse polarity in batteries occurs when you connect the battery terminals incorrectly, causing current to flow in the wrong direction. This can create serious safety risks, including overheating and fire, especially in lithium battery packs. You must recognize the importance of reverse polarity protection to maintain user safety.

Large lithium battery packs often use fuses and protection circuits to isolate faulty cells and prevent high current flow, reducing hazards from reverse polarity.

You should always understand polarity basics and handle every battery with care in professional environments.

Key Takeaways

Always check battery terminals carefully before connecting to avoid reverse polarity, which can cause overheating, damage, or fire.

Use battery packs and chargers with built-in protection features like fuses, MOSFETs, and keyed connectors to prevent incorrect connections.

Follow safety steps such as wearing protective gear, connecting chargers correctly, and performing regular maintenance to ensure battery and user safety.

Part 1: Reverse Polarity in Batteries

1.1 Polarity Basics

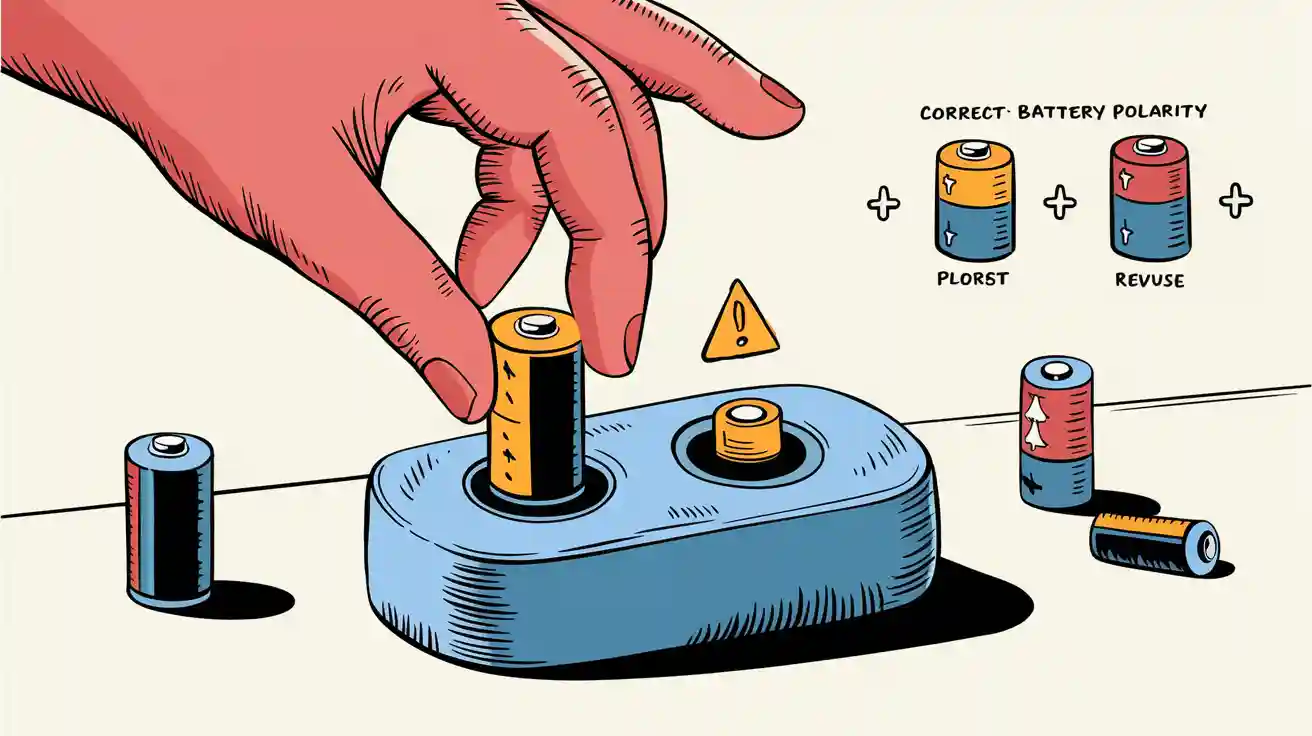

You must understand battery polarity to ensure safe and reliable operation in any application. Battery polarity refers to the orientation of the positive (+) and negative (–) terminals. In a typical battery, electrons flow from the negative terminal (anode) to the positive terminal (cathode) through the external circuit. This flow enables devices to function as intended.

Reverse polarity in batteries, as defined by electrical engineering standards, occurs when you connect the terminals incorrectly. This causes current to flow in the opposite direction, disrupting normal operation and creating significant safety risks.

The table below highlights the differences between correct and reverse polarity in battery systems:

Aspect | Correct Polarity (Normal) | Reverse Polarity (Incorrect) |

|---|---|---|

Electron Flow Direction | Electrons flow from negative terminal (anode) to positive terminal (cathode) through external circuit. | Electrons are dragged from the battery’s negative terminal and pushed to the positive terminal, opposite to normal flow. |

Chemical Reaction | Reversible chemical reactions occur during charging and discharging, maintaining battery function. | Chemical processes are disrupted, causing gradual discharge and potential damage to battery components. |

Effects on Battery | Battery discharges normally supplying power to load; charging reverses current flow safely. | Battery may discharge unintentionally, overheat, produce hydrogen gas, and risk explosion or acid leakage. |

Effects on Connected Devices | Loads operate correctly with proper polarity; devices like diodes and ECUs function as intended. | Loads may malfunction or be damaged; sensitive electronics like ECUs and alternators can be harmed. |

Safety Concerns | Normal operation with standard precautions. | Risk of overheating, sparks, explosion, and damage to equipment and users due to incorrect current flow. |

You should always verify battery polarity before installation or maintenance, especially in high-stakes environments such as medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors. Lithium battery packs, such as Lithium Iron Phosphate (LiFePO4) and Lithium Nickel Manganese Cobalt Oxide (NMC), require even greater attention due to their higher energy density and stricter safety requirements.

1.2 Causes of Reverse Polarity

Reverse polarity in batteries often results from simple mistakes or design flaws. In commercial and industrial settings, you may encounter several common causes:

Cause | Explanation |

|---|---|

Incorrect Battery Connection | Connecting the battery in the wrong orientation can cause reverse polarity and damage devices. |

Incompatible Power Adapters | Using power adapters with incorrect polarity connectors may lead to reverse polarity issues. |

Wiring Errors During Assembly | Mistakes in wiring or PCB assembly can result in reverse polarity, especially in power lines. |

Component Misplacement | Incorrect placement or orientation of components on a PCB can cause reverse polarity. |

User Errors | Improper handling or connection by users can lead to reverse polarity problems. |

You can reduce the risk of reverse polarity by implementing robust design features. Modern battery packs often include fuses, contactors, and Battery Management Systems (BMS) to monitor and protect against incorrect connections. Mechanical safeguards, such as keyed connectors and unique terminal shapes, physically prevent incorrect insertion. Electronic safeguards, including diodes and MOSFETs, block reverse current flow and protect sensitive components.

Tip: Always use battery packs with built-in protection against reverse polarity, especially in critical applications. This ensures both equipment and user safety.

1.3 Incorrectly Connecting a Battery Charger

Incorrectly connecting a battery charger poses severe risks, particularly for lithium battery packs. If you use an incompatible charger or connect the terminals in reverse, you may trigger overcharging, overheating, swelling, or even battery cell rupture. These failures can lead to power loss, reduced lifespan, and, in extreme cases, fire or explosion. Such incidents not only endanger users but also threaten valuable equipment and infrastructure.

To prevent these hazards, you should follow these steps when connecting a battery charger:

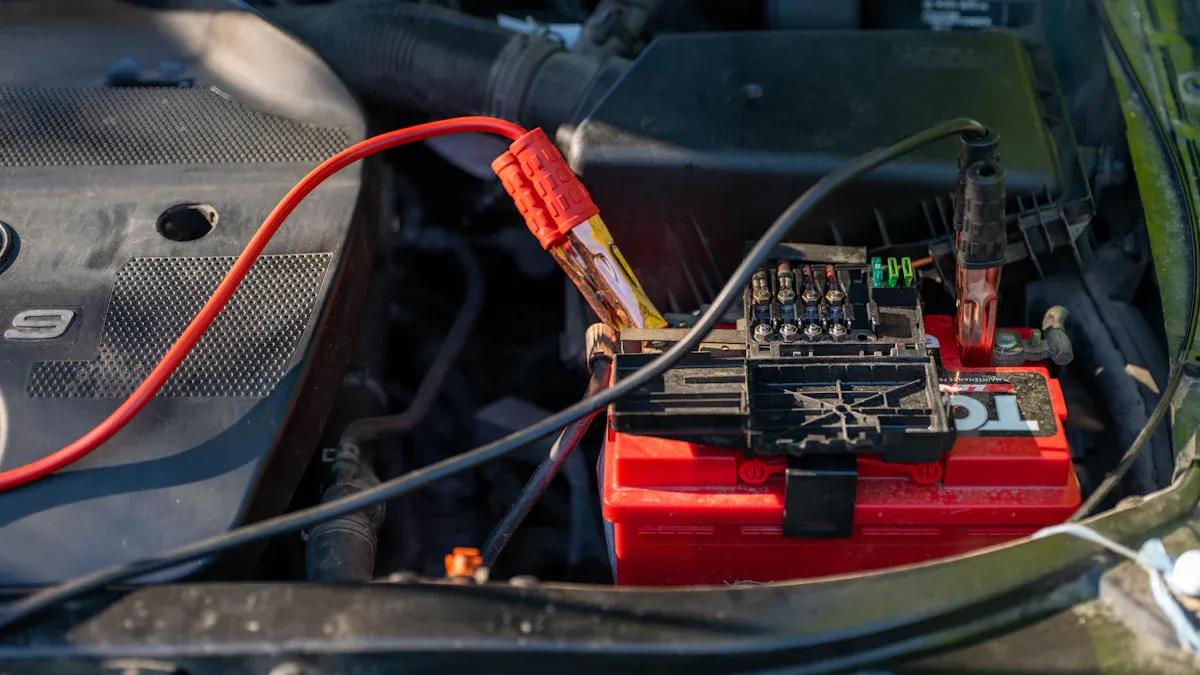

Turn off the charger before making any connections.

Identify the positive (+) and negative (–) terminals on both the battery and charger.

Attach the red clamp (positive) to the battery’s positive terminal.

Attach the black clamp (negative) to the battery’s negative terminal.

For vehicle batteries, connect the negative clamp to a chassis ground to protect sensitive electronics.

Note: Always wear insulated gloves and safety goggles. Charge batteries in well-ventilated areas and inspect for damage before starting.

Battery chargers designed for lithium battery packs often include advanced protection against reverse polarity. These systems use diodes, MOSFETs, and smart controllers to detect incorrect connections and disable current flow, preventing damage. Some chargers feature asymmetrical connectors or polarity detection circuits that prevent the charger from powering on if you connect the battery incorrectly.

You should select chargers that meet industry safety expectations and include robust reverse polarity protection. This approach minimizes the risk of electrical faults and ensures compliance with best practices in battery management.

Part 2: Dangers, Damages, and Safety Solutions

2.1 Dangers of Reverse Polarity

Reverse polarity in battery systems creates immediate risks for user safety and equipment reliability. You may encounter serious consequences such as electrical shorts, overheating, and even fire or explosion. Lithium battery packs, with their high energy density and complex chemistry, are especially vulnerable. In medical, robotics, and security system applications, a single reverse polarity event can disrupt critical operations and threaten infrastructure.

Danger | Description | Application Impact |

|---|---|---|

Fire & Explosion | Incorrect current flow causes rapid heating, gas buildup, and potential ignition. | Threatens medical devices, industrial robots, and security systems. |

Battery Failure | Internal components degrade, leading to loss of capacity and cycle life. | Reduces reliability in consumer electronics and industrial platforms. |

Equipment Damage | Sensitive electronics, such as ECUs and BMS, may fail or malfunction. | Interrupts infrastructure and automation processes. |

Chemical Leakage | Damaged battery cells may leak hazardous materials. | Risks environmental contamination and health hazards. |

Reverse polarity can cause potential damage to both the battery and connected devices. You must treat every incident as a critical safety concern.

2.2 Battery Damage Examples

You may observe several types of damage after a reverse polarity event. Lithium battery packs often show swelling, leakage, or complete failure. In industrial and consumer electronics, reverse polarity can destroy circuit boards and sensors. The following table compares typical damage across battery types:

Battery Type | Damage Symptoms | Cycle Life Impact | Energy Density Impact |

|---|---|---|---|

Lithium-ion | Swelling, venting, cell rupture | Severe reduction | Significant loss |

Lead-acid | Plate sulfation, acid leakage | Moderate reduction | Moderate loss |

Nickel-metal hydride | Cell reversal, overheating | Moderate reduction | Minor loss |

In lithium battery packs, reverse polarity often leads to irreversible damage. You may need to replace the damaged battery to restore system reliability.

2.3 Safety Prevention Tips

You can prevent reverse polarity incidents by following industry standards and implementing robust safety features. The ISO7637-2:2011 standard defines stress tests for automotive and industrial battery systems, supporting protection against reverse polarity. You should use advanced protection circuits, such as p-type MOSFETs with Zener diodes, which block reverse current and provide overvoltage protection with minimal losses. Simulation tools like PSpice confirm that MOSFET-based solutions outperform simple diode methods.

Practical Safety Steps:

Double-check terminal markings before connecting any battery.

Use color-coded cables and keyed connectors to prevent mistakes.

Select battery packs with built-in protection against reverse polarity.

Install Schottky diodes or smart diode circuits for reliable protection.

Schedule regular maintenance checks to verify correct connections and identify issues early.

Train staff on safe battery handling and emergency procedures.

Tip: Immediate disconnection and inspection are essential if you suspect reverse polarity. Regular maintenance reduces risk and protects user safety.

Protection Method | Efficiency | Voltage Drop | Current Handling | Application Suitability |

|---|---|---|---|---|

Series Diode | Good | 0.6V (standard), <0.3V (Schottky) | Low to moderate | Consumer, low-power |

MOSFET-based Circuit | Excellent | Minimal | High | Industrial, automotive |

Electromechanical Relay | Good | Minimal | High | Infrastructure |

2.4 Remedies and Replacement

If you discover a damaged battery after a reverse polarity incident, you must act quickly to minimize further risk. Some remedies may temporarily restore function, but replacement is often the safest solution.

Completely discharge the battery using a low-amperage load, such as a light bulb.

Recharge with correct polarity at the lowest current setting.

If the battery does not recover, briefly apply a higher voltage charger (e.g., 24V for a 12V battery) for a few seconds.

After initial recovery, charge at less than 1 amp for 48 hours.

Note: Modern lithium battery packs suffer severe internal damage from reverse polarity. Even if you restore polarity, cycle life and energy density decrease sharply. You should replace the battery to ensure long-term safety and reliability.

Improper disposal of damaged battery packs can harm the environment. Lithium-ion batteries may leak nickel, cobalt, and manganese, contaminating soil and water. Fires from landfill disposal release toxic gases, increasing health risks and contributing to global warming. You must follow certified recycling and circular supply chain practices to reduce environmental impact.

Always dispose of damaged battery packs through certified recycling channels. This protects ecosystems and supports responsible resource management.

You protect your business and critical systems when you prevent reverse polarity in every battery. Use sensors to monitor battery temperature, humidity, and gas emissions. Follow safety standards like UL 9540 and NFPA 855. Always select the right battery management system and replace any damaged battery to maintain reliability.

FAQ

1. What happens if you reverse the polarity of a lithium battery pack?

You risk overheating, fire, or permanent damage. Sensitive electronics in Medical, Robotics, and Security System sectors may fail. Always use Large Power packs with built-in protection.

2. How do lithium battery packs compare to lead-acid batteries in reverse polarity incidents?

Battery Type | Typical Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Reverse Polarity Risk |

|---|---|---|---|---|

Lithium-ion | 3.6V | 150–250 | 1000–3000 | High |

Lead-acid | 2.0V | 30–50 | 300–500 | Moderate |

You must select lithium packs with advanced BMS for critical applications.

3. Where can you get expert advice on safe battery pack selection?

You can contact Large Power for custom battery solutions. Their team provides guidance for Medical, Robotics, and Industrial battery solutions.