Portable oxygen concentrator battery pack design shapes how you experience device performance and user independence. When you select an oxygen concentrator, the right battery pack—especially a lithium-ion solution—directly affects runtime and freedom of movement.

Battery life determines how long you can use your portable oxygen concentrator without recharging, often between 4 and 10 hours.

A well-designed pack balances size, weight, and energy capacity, supporting both portability and reliable runtime.

Extended runtime and robust safety features let you maintain oxygen therapy during travel or demanding work schedules.

Key Takeaways

Choose lithium-ion battery packs for your portable oxygen concentrator to get longer runtime and better safety compared to older battery types.

Match battery capacity to your oxygen flow needs and daily use to ensure uninterrupted therapy and greater freedom of movement.

Look for battery packs with strong safety features like Battery Management Systems and thermal controls to protect against overheating and damage.

Select lightweight, compact battery designs that fit your lifestyle and support easy transport without sacrificing power.

Follow proper charging and storage practices to extend battery life and maintain reliable performance over time.

Part 1: Portable Oxygen Concentrator Battery Pack Design

1.1 Lithium-Ion Chemistry

You rely on advanced lithium-ion chemistries for portable oxygen concentrator battery pack design because they deliver the best balance of safety, performance, and regulatory compliance. Compared to older lead-acid, NiCad, or NiMH batteries, lithium-ion chemistries offer higher energy density, longer cycle life, and lower maintenance. For critical medical devices, these advantages are key drivers of adoption.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Key Features |

|---|---|---|---|---|

NMC | 3.6–3.7 | 180–250 | 1,000–2,000 | High energy, moderate safety |

LFP (LiFePO4) | 3.2–3.3 | 90–160 | 2,000–5,000 | Excellent safety, long cycle life |

LTO | 2.3–2.4 | 50–80 | 3,000–7,000 | Superior safety, low energy, high cost |

LMO | 3.7–3.8 | 100–150 | 1,000–2,000 | Good power, moderate safety |

LCO | 3.7 | 150–200 | 500–1,000 | High energy, lower cycle life |

Lithium-ion batteries require robust Battery Management Systems (BMS) to ensure safety and reliability. For more on BMS, see BMS and PCM.

1.2 Capacity and Energy Density

Battery capacity determines how long your oxygen concentrator can operate between charges. Higher capacity means longer runtime, which is critical for business users who need uninterrupted therapy during travel or work. The energy density of lithium-ion battery packs used in portable oxygen concentrator battery pack design typically ranges from 180 to 300 Wh/kg, depending on the chemistry and form factor.

Battery Type | Energy Density Range (Wh/kg) |

|---|---|

Lithium Polymer (Li-Po) | 200–300 |

18650 Li-ion (NMC) | 180–250 |

Battery capacity options directly affect operational time:

Battery Capacity | Operational Time Range (hours) |

|---|---|

Single-battery | |

Double-battery | 5 to 13 |

You should select a battery pack with the right capacity to match your oxygen concentrator’s power needs and your operational requirements. Energy efficiency also plays a role, as efficient packs maximize usable capacity and minimize downtime.

1.3 Physical Design Factors

Portable oxygen concentrator battery pack design must balance capacity, size, and weight to ensure portability and usability. Most business-grade oxygen concentrators feature battery packs and units weighing around 5 pounds, with dimensions typically between 7 and 10 inches in length, width, or height.

Compact, ergonomic designs with adjustable straps and carrying cases improve transport and daily use.

Lightweight battery packs prevent excess bulk, supporting user comfort and mobility.

Integration with device form factor and voltage compatibility (e.g., 7.4V or 11.1V) ensures reliable operation.

Battery capacity usually ranges from 4000mAh to 8000mAh, supporting several hours of use.

Energy efficiency and the ability to recharge anywhere further enhance usability for business and clinical environments.

1.4 Safety Features

Safety is paramount in portable oxygen concentrator battery pack design. You benefit from multiple integrated features that protect against short circuits, overcharging, and thermal events:

Battery Management Systems (BMS) monitor voltage, temperature, and current in real time, preventing overheating and overcharging.

Overcharge and over-discharge circuits cut off power at safe voltage limits.

Multi-layer safety casings and pressure relief valves reduce risks from impact and gas buildup.

Advanced separators and stable cathode materials like LiFePO4 enhance safety.

Thermal management systems maintain optimal temperatures, preventing thermal runaway and extending battery life.

Compliance with standards such as UL 1642, UL 2054, IEC 62133, and ANSI/AAMI ES 60601-1 ensures your battery packs meet strict regulatory and safety requirements.

Tip: Always verify that your battery packs are certified and manufactured in UL-certified facilities to guarantee safety and traceability.

Part 2: Performance Impact

2.1 Runtime and Power Delivery

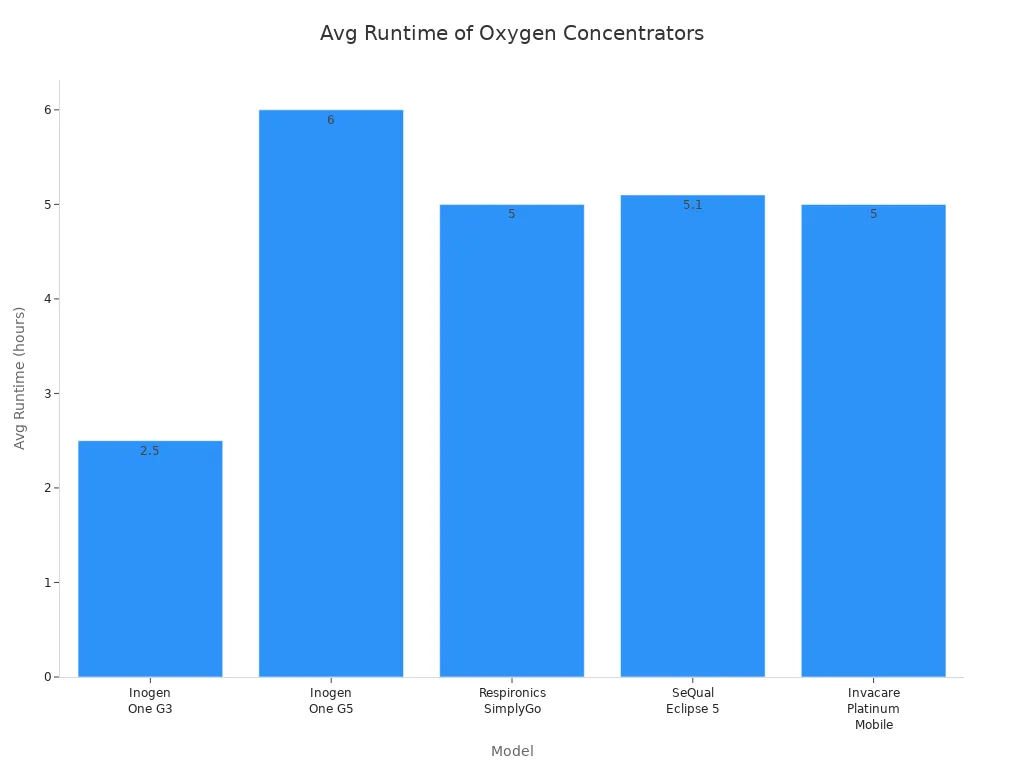

Battery pack design directly shapes the runtime and power delivery of your oxygen concentrator. You need to consider how battery capacity, chemistry, and device efficiency interact with oxygen flow rate settings. Higher flow rates demand more energy, which reduces runtime. For example, at a flow setting of 2, different models show significant variation in runtime based on battery design:

Model | Flow Setting | Average Runtime (hours) | Battery Pack Design Notes |

|---|---|---|---|

Inogen One G3 | 2 | Up to 2.5 | Standard lithium-ion battery |

Inogen One G5 | 2 | Up to 6 | Extended lithium-ion battery |

Respironics SimplyGo | 2 (Pulse) | Up to 5 | Lithium-ion battery, pulse flow mode |

SeQual Eclipse 5 | 2 (Pulse) | Up to 5.1 | Lithium-ion battery, pulse flow mode |

Invacare Platinum Mobile | 2 | Up to 5 | Lithium-ion battery |

You see that runtime optimization depends on both battery capacity and the efficiency of oxygen delivery. Devices with advanced lithium-ion battery packs and optimized pulse delivery can maintain longer runtime, even at higher oxygen flow rates. Consistent power delivery ensures that your oxygen concentrator provides stable oxygen output. Sensitive triggering mechanisms and precise pulse alignment with your breathing pattern help reduce oxygen waste, which extends battery life and maintains performance characteristics. If the battery cannot deliver stable power, you may experience inconsistent oxygen pulses, which can compromise therapy effectiveness.

2.2 Portability and User Experience

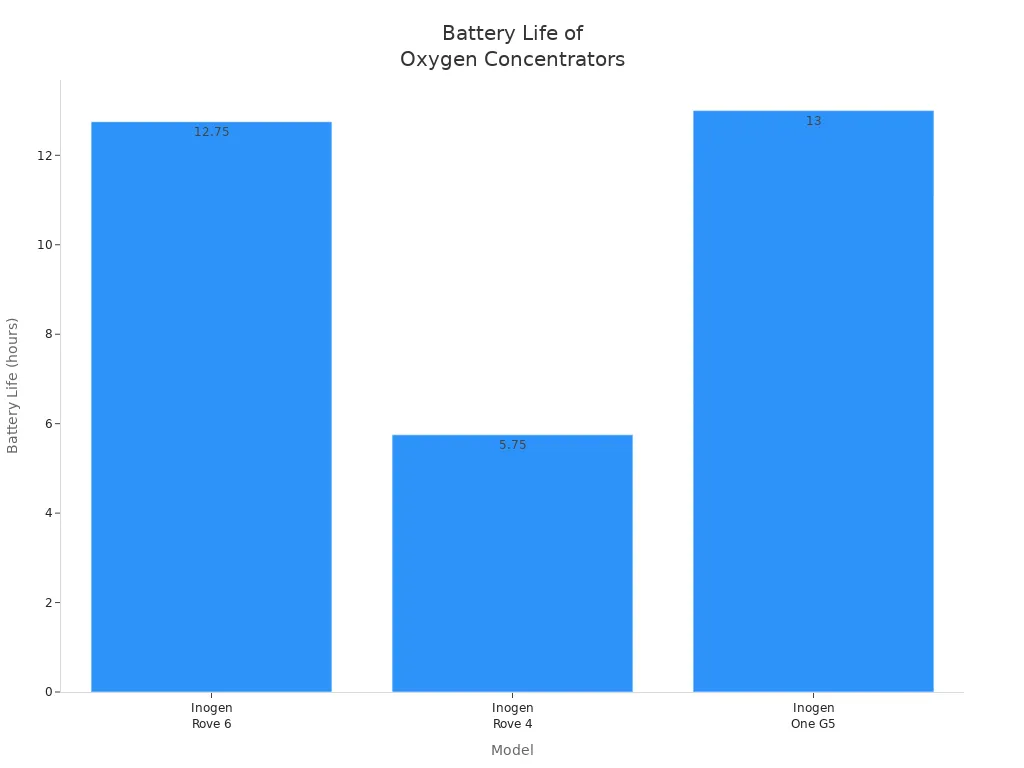

Portability and user experience depend on the physical design and battery life of your oxygen concentrator. Lightweight and compact battery packs improve daily mobility and reduce fatigue during transport. For business users, the ability to carry the device easily and operate it in various environments is essential. Battery capacity and the availability of extended or spare batteries allow you to work longer without interruption. For example, the Inogen Rove 6 offers up to 12 hours and 45 minutes of runtime at low flow settings, while the Inogen Rove 4 provides up to 5 hours and 45 minutes.

Model | Flow Settings | Battery Life (hours) | Notes |

|---|---|---|---|

Inogen Rove 6 | 1-6 | Up to 12 hours 45 minutes | Extended battery at low flow |

Inogen Rove 4 | 1-4 | Up to 5 hours 45 minutes | Standard battery |

Inogen One G5 | 1-6 | Up to 13 hours | Extended battery at low flow |

You benefit from features such as FAA approval for air travel, custom carrying cases, and the ability to use the device while charging. These design choices enhance user experience and support continuous use capacity in demanding business or clinical settings. Simple controls and low noise levels further improve usability, allowing you to focus on your work or travel without distraction.

Tip: Choose a model with a battery pack that matches your daily routine and operational needs. Extended batteries and quick-swap options can double your runtime and reduce downtime.

2.3 Recharge and Cycle Life

Recharge time and cycle life are critical for maintaining continuous use capacity in professional environments. Most lithium-ion battery packs for oxygen concentrators recharge in about 4 hours with an AC wall charger. Double battery configurations may require up to 8 hours. You can also use DC/car chargers or external chargers to maintain productivity during travel or fieldwork.

Charger Type | Typical Recharge Time |

|---|---|

AC wall charger | About 4 hours for a single battery; about 8 hours for double batteries |

DC/car charger | Allows charging while driving (time varies) |

External charger | Charges batteries outside the unit, enabling continuous use of the concentrator |

Lithium-ion chemistries such as NMC and LFP offer long cycle life, supporting hundreds or even thousands of charge-discharge cycles. This durability ensures that your oxygen concentrator maintains reliable performance characteristics over years of service. Proper battery management and regular maintenance extend both battery life and device longevity.

Note: Always follow manufacturer guidelines for charging and storage to maximize cycle life and maintain optimal runtime.

2.4 Reliability and Stability

You rely on the reliability and stability of your oxygen concentrator, especially in business and clinical environments. Rugged battery pack designs, such as those with rubberized shells, protect against impact and wear. Audible alerts for low battery, device malfunction, or low oxygen output help you address issues before they disrupt operations. Easy-to-read battery indicators and convenient replacement options support continuous use and minimize downtime.

Robust construction shields internal components from damage.

Intelligent alert systems enable timely maintenance and reduce repair costs.

Reliable battery packs ensure consistent oxygen delivery, even in demanding conditions.

These features are essential for maintaining long-term reliability and stable performance. In sectors such as medical, security, and industrial applications, you need devices that can withstand daily use and deliver uninterrupted therapy.

Part 3: Real-World Considerations

3.1 Integration and Customization

When you integrate lithium battery packs into portable oxygen concentrators, you face several technical challenges. You must balance energy density and power delivery to meet the high current demands of compressors, especially in medical and industrial settings. Smart Battery Management Systems (BMS) monitor cell voltage, temperature, and charge state, which prevents overcharging and ensures patient safety. You often see modular designs that divide battery packs into smaller, sealed units. This approach distributes mechanical stress and prevents moisture ingress, which is critical for reliability in security and infrastructure applications.

Advanced thermal management, such as phase-change polymers or graphene layers, dissipates heat and reduces combustion risks.

Structural integrity relies on aerospace-grade aluminum or durable polymers like PEEK for shock absorption.

User-friendly battery swapping mechanisms, including large release buttons and error-proof connectors, support users with limited dexterity.

Manufacturers use laser welding and 3D printing to create precise, strong connections, minimizing failure points. Compliance testing simulates stress scenarios, such as crush tests and altitude exposure, to ensure safety in real-world use.

3.2 Maintenance and Replacement

Proper maintenance extends the lifespan of your lithium battery packs and ensures uninterrupted performance. You should follow these best practices:

Fully discharge and recharge the battery before each use to prevent memory issues.

Store fully charged batteries in a cool, dry, and dark environment, ideally around 15°C (59°F).

For long-term storage, recharge batteries before storing and cycle them periodically.

Avoid frequent full discharges; recharge when capacity drops to about 50%.

Replace batteries after extensive recharge cycles, typically every 2 years or after 350–500 cycles.

Aspect | Details |

|---|---|

Battery Lifespan | |

Replacement Indicator | Faster drain from full to less than half charge |

Maintenance Recommendations | Monthly recalibration by full discharge and recharge |

Storage Advice | Store spares at 50% charge if unused for 2–3 months |

Safety Checks | Inspect for swelling, leakage, or overheating; discontinue use if issues are found |

You should always consult the user manual for model-specific instructions. Regular maintenance and timely replacement help you avoid unexpected downtime and maintain safety standards.

3.3 Compliance and Safety Standards

You must ensure that your lithium battery packs meet strict compliance and safety standards in every market. Regulatory requirements shape battery design, capacity, and labeling. For example, lithium ion batteries in portable oxygen concentrators must not exceed 100 Wh to comply with U.S. Department of Transportation and FAA regulations, allowing unrestricted use on aircraft. Devices must also avoid hazardous materials and maintain oxygen pressure below 200 kPa gauge.

Certification/Standard | Market/Region | Key Compliance Focus |

|---|---|---|

United States | Oxygen concentration accuracy, electrical safety, biocompatibility | |

CE | Europe | Mechanical safety, electromagnetic compatibility |

ISO 13485 | Global | Quality management for medical devices |

Manufacturers must apply labels certifying compliance with FAA acceptance criteria. You benefit from evolving regulations that drive innovation and improve safety features, reducing battery-related incidents and building trust in medical, robotics, and industrial sectors.

Part 4: Selection and Maintenance Tips

4.1 Choosing the Right Battery Pack

Selecting the right lithium battery pack for your portable oxygen concentrator requires a strategic approach. You must align battery capacity with your oxygen flow rate and daily operational needs. Higher flow rates drain batteries faster, so you should assess your typical usage patterns. Consider your mobility requirements—if you work in the field or travel frequently, extended battery life and modular packs that allow hot-swapping will support uninterrupted operations.

FAA regulations require lithium-ion batteries under 160 watt-hours for air travel, and you must carry enough capacity for at least 150% of your expected flight duration.

Pulse dose systems can extend battery life by activating only during inhalation, while continuous flow systems consume more power but may be necessary for specific clinical or industrial scenarios. Evaluate whether standard or extended capacity packs best fit your workflow, and weigh the trade-off between runtime and device weight. Always verify compatibility, warranty coverage, and consider custom solutions for specialized needs such as altitude performance or smart monitoring.

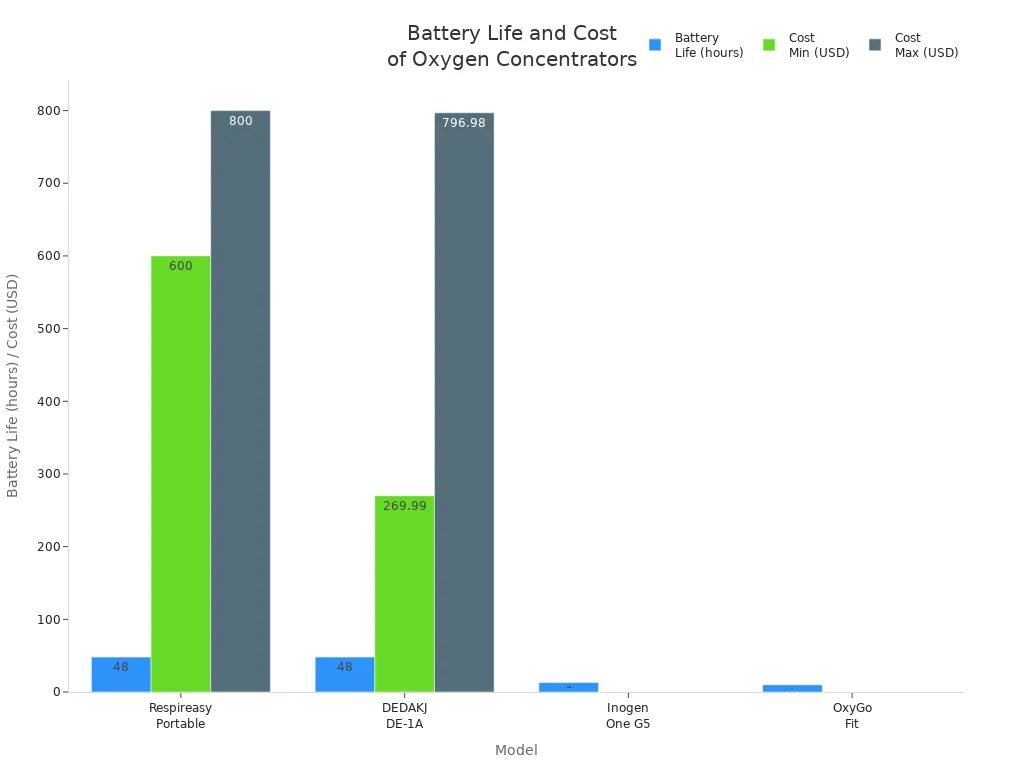

Model | Battery Life (hours) | Weight (kg) | Cost Range (USD) | Reliability Indicators |

|---|---|---|---|---|

Respireasy Portable | Up to 48 | ~2.2 | $600-$800 | Travel-ready, dependable |

Inogen One G5 | Up to 13 | ~2.2 | Premium | FAA-approved, reliable brand |

Philips SimplyGo Mini | Swappable battery | N/A | Premium | Trusted brand, energy efficient |

OxyGo Fit | Up to 10 | Mid to High | Lightweight, travel-friendly |

4.2 Best Practices for Longevity

You can maximize battery life optimization and ensure performance maintenance by following industry best practices:

Avoid overcharging to reduce heat buildup and electrode wear.

Charge and discharge batteries within recommended temperature ranges (32°F to 113°F).

Store batteries at partial charge in cool, dry locations (around 60°F).

Monitor battery health and charge levels regularly to detect issues early.

Use fast charging sparingly, as it generates excess heat.

4.3 Supplier Evaluation

When you evaluate suppliers for lithium battery packs, prioritize those with proven track records in medical, robotics, security, and industrial sectors. Look for OEM batteries with guaranteed compatibility and extended warranties. Assess cost-effectiveness, technical support, and the availability of custom solutions. Confirm that suppliers comply with all relevant safety and regulatory standards.

Advanced Battery Management Systems (BMS) are essential for safe operation and long-term reliability.

You shape device performance, reliability, and user satisfaction by choosing the right lithium-ion battery pack design. In business settings—medical, robotics, security, infrastructure, and industrial—battery chemistry, safety features, and physical design matter most.

Prioritize lithium-ion technology for high energy density and long cycle life.

Match battery capacity to your operational needs.

Your choice of battery pack determines how well your portable oxygen concentrator supports your workflow and safety standards.

FAQ

What lithium battery chemistry should you choose for portable oxygen concentrators?

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Key Benefit |

|---|---|---|---|---|

NMC | 3.6–3.7 | 180–250 | 1,000–2,000 | High energy density |

LFP | 3.2–3.3 | 90–160 | 2,000–5,000 | Long cycle life |

You should select NMC for high energy needs or LFP for maximum safety and longevity.

How does battery pack design affect device reliability in business environments?

You gain higher reliability from packs with robust BMS, thermal management, and rugged casings. These features protect against power loss and physical damage. In medical, robotics, and security sectors, you maintain continuous operation and reduce downtime.

What maintenance steps extend lithium battery pack lifespan?

Recharge when capacity drops to 20–50%

Store at partial charge in cool, dry places

Inspect monthly for swelling or leaks

Regular maintenance ensures stable performance and reduces replacement costs.

Can you use the same battery packs across different devices or sectors?

You must check voltage, connector type, and certification. Packs designed for medical use may not suit robotics or industrial equipment. Always verify compatibility and compliance with sector-specific standards.

What certifications should you require for lithium battery packs in regulated industries?

You should require certifications such as UL 1642, IEC 62133, and ISO 13485. These standards ensure safety, quality, and regulatory compliance for medical, security, and industrial applications. For custom medical device battery solutions, contact Large Power.