Effective lithium battery temperature management protects your battery packs from dangerous failures and costly downtime. Poor temperature management can trigger thermal runaway or rapid capacity loss in lithium-ion battery systems. Review the table below to see how temperature extremes affect battery safety, performance, and lifespan.

Temperature Condition | Impact on Safety | Impact on Performance | Impact on Lifespan |

|---|---|---|---|

High Temperature | Accelerates reactions, degrades SEI, increases thermal runaway risk | Initially boosts efficiency, later raises internal resistance | Speeds aging up to 14x, reduces longevity |

Low Temperature | Raises short circuit risk, causes capacity loss | Reduces conductivity and efficiency, forms “dead lithium” | Accelerates aging, causes faster fade |

Rapid Temperature Fluctuations | Induces material stress, worsens degradation | Damages structure, increases resistance | Accelerates degradation, raises failure risk |

Maintaining optimal lithium battery temperature management ensures consistent performance and long-term reliability in your systems.

Key Takeaways

Keep lithium batteries within the ideal temperature range of 15°C to 40°C to ensure safety, maintain performance, and extend lifespan.

Use a battery management system (BMS) to monitor temperatures in real time and control cooling or heating to prevent damage and thermal runaway.

Apply proper ventilation and cooling methods, such as passive airflow or liquid cooling, to manage heat and protect battery health in demanding environments.

Part 1: Importance

1.1 Battery Safety

You must prioritize battery safety when managing lithium-ion battery packs. Poor lithium battery temperature management can lead to severe incidents, especially in sectors like medical devices, robotics, and industrial infrastructure. Common safety incidents include:

Thermal runaway, which can cause fires or explosions due to rapid temperature increases.

Overheating from electrical faults, such as overcharging or short circuits, destabilizing battery materials.

Mechanical abuse during transport, like collisions or vibrations, which may trigger short circuits.

Environmental factors, such as high humidity, that promote corrosion and increase accident risk.

Regulatory standards, including UL 1642, UL 2580, and IEC 62133, require rigorous temperature control and safety considerations for lithium-ion battery systems. These standards help you ensure safe operation during transportation, storage, and use.

Tip: Always use specialized test environments and monitoring systems to detect abnormal temperature changes early and prevent safety incidents.

1.2 Performance Impact

The effects of temperature on lithium-ion battery performance are significant. You will notice that low temperatures reduce capacity and increase internal resistance, which slows down lithium ion movement. For example, at -10°C, capacity drops to about 70%, while at 0°C, it reaches only 85%. Charging below 0°C risks lithium dendrite formation, leading to permanent damage. High temperatures may initially boost capacity but accelerate aging and chemical instability, reducing overall efficiency. Uneven temperatures within battery packs cause inconsistent impedance and faster capacity decay, which directly impacts performance and efficiency in demanding applications like security systems and consumer electronics.

1.3 Lifespan Effects

You must understand the effects of temperature on battery lifespan to maximize return on investment. Higher operating temperatures speed up chemical reactions, causing faster aging and capacity loss. Low temperatures increase internal resistance and risk lithium plating, which leads to permanent capacity loss and safety hazards. Manufacturers specify optimal temperature ranges—typically 0°C to 45°C for charging and -20°C to 60°C for discharging—to protect battery lifespan. Operating outside these ranges accelerates degradation. For example, storing lithium-ion batteries at 55°C for six months can reduce capacity by 10%, while storage at 15°C retains 95% capacity after one year. Effective temperature control and thermal management systems are essential to maintain battery lifespan and reliability across all sectors.

Part 2: Temperature Extremes

2.1 High Heat Risks

You face significant safety risks of temperature mismanagement when lithium battery packs operate above the optimal temperature range. High temperatures accelerate chemical reactions inside lithium-ion battery cells, degrading electrodes and electrolytes. At temperatures above 45°C, you see rapid capacity loss and shortened battery lifespan. When temperatures reach 60°C, gas formation, swelling, and pressure buildup can occur, increasing the risk of venting or fire. If the temperature climbs above 130°C, thermal runaway becomes likely, which can result in combustion or explosion.

Always implement robust temperature control and thermal management strategies to prevent overheating in critical sectors like medical devices, robotics, and industrial infrastructure.

2.2 Low Temperature Issues

Operating lithium-ion battery packs below the ideal temperature range causes a different set of challenges. At temperatures below -20°C, the electrolyte may freeze, leading to mechanical damage and reduced capacity. Charging below 0°C risks lithium plating, which causes permanent capacity loss and internal short circuits. Low temperatures increase internal resistance, slow lithium-ion movement, and reduce available capacity—sometimes to 60% or less at -20°C.

You may notice rapid battery depletion, voltage drops, and longer charging times in cold environments.

These effects of temperature extremes can cause unexpected shutdowns and reduced performance in security, infrastructure, and outdoor industrial applications.

2.3 Thermal Runaway

Thermal runaway represents the most severe consequence of poor lithium battery temperature management. This process begins when internal heat generation exceeds dissipation, causing a rapid, uncontrollable rise in temperature. Overcharging, high ambient temperatures, and aging cells can all trigger this event.

Cause Category | Examples of Causes |

|---|---|

Thermal | Extreme temperatures, fire, thermal shock |

Mechanical | Dropping, crushing, vibration |

Electrical | Short circuits, overcharging, overdischarging |

Aging | High cycle count, degraded cells |

Thermal runaway can propagate from one cell to others, leading to fires or explosions. You must prioritize temperature control and monitoring to prevent catastrophic failures and ensure battery safety in all applications.

Part 3: Best Practices

3.1 Ventilation

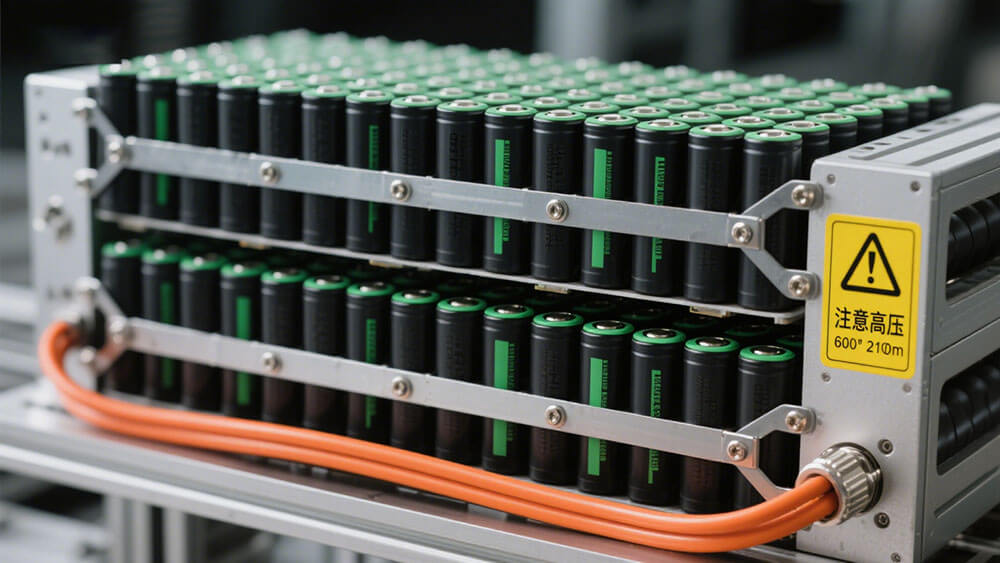

Effective ventilation forms the foundation of lithium battery temperature management in B2B applications. You must ensure adequate airflow in battery storage areas to dissipate heat and maintain stable conditions. Ventilation acts as a passive cooling technique, enabling natural convection to remove excess heat from lithium battery packs. For optimal results, store batteries away from direct sunlight and select an optimal storage location with good airflow. Use battery racks or holders to enhance safety and temperature control. Maintain a dry environment with controlled humidity to protect battery integrity.

Ensure the storage area is a well-ventilated area to prevent heat accumulation.

Combine ventilation with passive cooling methods such as heat sinks and thermal interface materials.

For large-scale installations, integrate cooling fans to improve airflow and support heat dissipation.

Monitor ambient temperature and humidity, keeping storage temperature between 15°C and 25°C (59°F to 77°F) for optimal performance and battery lifespan.

Passive ventilation, often implemented with ePTFE membranes, manages gradual pressure and temperature changes by allowing gas exchange while blocking contaminants. However, passive systems cannot handle rapid pressure buildup during thermal runaway. Active ventilation, designed to open fully under high pressure, rapidly releases gases to prevent enclosure rupture and catastrophic failure. Dual-stage venting systems combine passive and active methods, providing comprehensive protection for lithium battery packs in industrial, medical, and robotics applications.

3.2 Cooling Systems

You must select appropriate cooling systems to maintain lithium battery temperature management in demanding B2B environments. Cooling strategies fall into passive and active categories:

Passive air cooling uses fins and channels, suitable for smaller packs with lower heat output.

Forced air cooling employs fans to increase airflow and heat transfer.

Liquid cooling utilizes jackets, plates, or microchannels circulating water/glycol or dielectric fluids, ideal for packs above 5kW and high-performance applications.

Phase change materials (PCMs) absorb heat during melting, acting as thermal pads or enclosures.

Thermoelectric cooling (Peltier devices) provides solid-state temperature control.

Hybrid systems combine air, liquid, and PCM cooling to optimize efficiency and energy consumption. Battery management systems monitor cell temperatures and control cooling or heating accordingly.

Performance Aspect | Liquid Cooling | Air Cooling |

|---|---|---|

Heat Dissipation Efficiency | High | Medium |

Temperature Control Accuracy | Relatively accurate | Less accurate |

Temperature Uniformity | Even temperature distribution | Non-uniform temperature |

Energy Consumption | Lower (baseline) | 2-3 times higher |

System Complexity | High | Low |

Maintenance | High | Low |

Liquid cooling achieves approximately 3°C lower maximum battery temperatures than air cooling under similar power consumption, providing better temperature uniformity and energy efficiency. Air cooling is cost-effective and lightweight, but less effective for high-capacity packs. For industrial, infrastructure, and security systems, liquid cooling offers superior thermal management strategies, especially for high energy density batteries and fast charging methods.

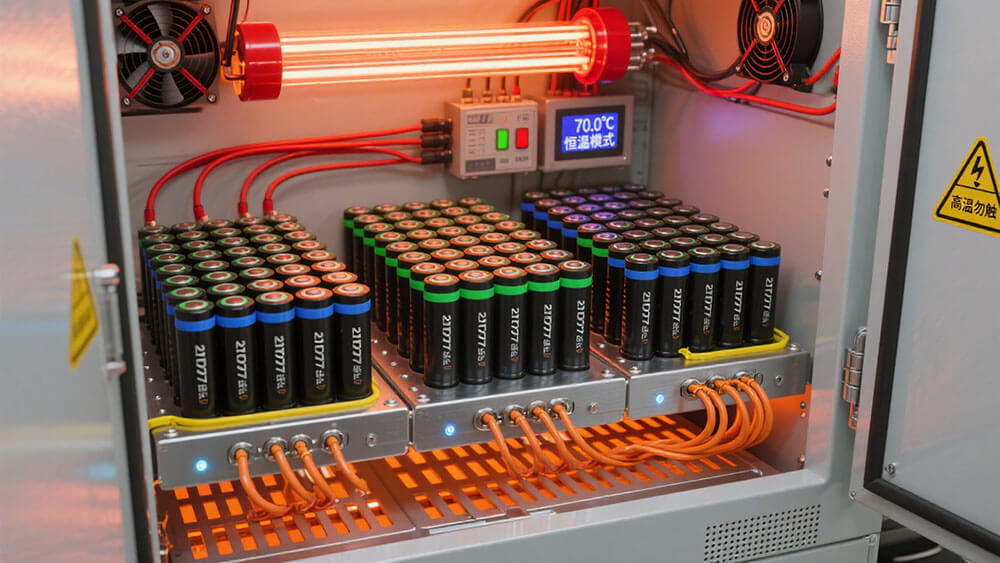

3.3 Battery Management System

A battery management system (BMS) is essential for lithium battery temperature management in B2B applications. The BMS continuously monitors cell temperatures using distributed sensors, ensuring the battery operates within a safe temperature range. When temperatures rise, the BMS activates cooling systems; in cold conditions, it triggers heating elements to prevent freezing or damage. If temperature anomalies cannot be controlled, the BMS initiates emergency shutdown to prevent damage and ensure safety.

Feature Category | Description | Purpose/Benefit |

|---|---|---|

Continuous Temperature Monitoring | Real-time monitoring of cell temperatures across the battery pack | Early detection of temperature deviations to prevent damage and optimize performance |

Active Heating and Cooling Control | Integration of heating elements and cooling systems | Maintains battery temperature within optimal range to prevent capacity loss and thermal runaway |

Heating Solutions for Cold Climates | Use of heaters or heating films to raise battery temperature before charging in low-temperature environments | Prevents lithium plating and permanent capacity loss during sub-zero charging |

Advanced Thermal Management Technologies | Use of liquid cooling, air cooling, hybrid systems, and phase change materials (PCM) | Efficient and uniform temperature regulation suitable for various applications |

Intelligent Thermal Control | AI-enhanced management and predictive analytics to dynamically optimize temperature regulation | Improves safety, prolongs battery life, and enhances performance through proactive control |

Thermal Protection Mechanisms | Activation of heaters or cooling based on real-time data, valve control in hydraulic systems | Ensures safe charging/discharging and prevents overheating or freezing under extreme conditions |

Modern BMS solutions integrate intelligent control algorithms, predictive analytics, and advanced thermal management technologies. These features improve safety, extend battery lifespan, and enhance performance in medical, consumer electronics, and industrial sectors. For more details on BMS technology, see Battery Management System.

3.4 Monitoring Tools

You must implement robust temperature monitoring tools to ensure real-time lithium battery temperature management. Data acquisition systems collect voltage, current, and temperature from lithium battery packs using A/D converters and microcontrollers. Processed data is sent to a gateway via RS485 communication, uploading it to a cloud platform for remote monitoring.

Remotely view real-time battery parameters, including temperature, and receive alarm notifications when thresholds are exceeded.

Early warning controls issue alarms for abnormal temperature or current conditions, preventing battery damage.

Hardware, software, and cloud-based platforms enable intelligent, real-time battery management.

Advanced monitoring systems use temperature sensors, environmental sensors, and gas detection technologies to provide precise and reliable temperature monitoring. These systems detect subtle changes that precede thermal runaway, such as coolant leaks or water intrusion. Gas sensors identify volatile organic compounds and gases released during early electrolyte decomposition, providing a critical early warning window to initiate mitigation strategies. Integrating these tools into your battery management system supports proactive intervention and enhances safety in B2B applications.

3.5 Storage Tips

Proper battery storage is vital for maintaining lithium battery health and preventing degradation. You must keep warehouse temperature at 20±5°C (68±9°F), with a maximum not exceeding 30°C (86°F). Relative humidity should remain below 75%. Store lithium batteries in a clean, dry, and well-ventilated area, ideally at room temperature. Avoid temperatures below -13°F (-25°C) and above 149°F (65°C) to prevent degradation and safety risks.

Store batteries in cool, dry places for safe storage and optimal battery lifespan.

Ensure the ideal storage temperature to minimize chemical reactions and capacity loss.

Avoid direct sunlight and heat sources to maintain optimal temperature.

Use battery racks and holders to improve airflow and temperature control.

Monitor storage temperature regularly to prevent overheating or freezing.

Improper storage temperature accelerates lithium-ion battery degradation, reduces battery lifespan, and increases the risk of thermal runaway. Signs of heat damage include bulging, rapid self-discharge, discoloration, and chemical odors. Maintaining battery storage conditions within recommended ranges is critical for preserving battery health and preventing hazards in B2B environments.

Tip: Always follow manufacturer guidelines for charging methods, storage temperature, and battery storage to maximize safety and performance.

You can optimize lithium battery pack safety and lifespan by:

Maintaining temperatures between 15°C and 40°C

Using a robust battery management system for real-time monitoring

Applying both passive and active cooling methods

Scheduling regular reviews of protocols

For tailored solutions, request a custom battery consultation with our experts.

FAQ

1. What is the optimal operating temperature range for lithium battery packs in industrial applications?

You should keep lithium battery packs between 15°C and 40°C. This range ensures stable performance and maximizes lifespan in industrial, medical, and robotics environments.

2. How does a battery management system (BMS) improve lithium battery safety?

A BMS monitors cell temperatures and controls cooling or heating. You prevent overheating, thermal runaway, and capacity loss by using a BMS in security and infrastructure systems.

3. Where can you get a custom lithium battery solution for your B2B project?

You can request a custom battery solution from Large Power. Their team tailors lithium battery packs for medical, industrial, and consumer electronics applications.