Battery innovations are redefining how you manage AEDs in healthcare. Reliable batteries power automated external defibrillators and advanced defibrillation technology during medical emergencies. You see high-capacity batteries and lithium-ion technology improve device readiness. Healthcare facilities depend on smart battery monitoring to minimize failures.

Equipment failures cause 23.5% of surgical technology errors, while 8.5% of ICU incidents relate to device issues.

Healthcare leaders now prioritize technology-driven solutions for emergency medical services and life-saving devices.

Key Takeaways

Modern lithium-ion batteries enhance the reliability and readiness of emergency medical equipment, reducing the risk of device failures during critical moments.

Adopting rechargeable battery solutions lowers operational costs and extends device lifespan, ensuring that emergency medical equipment remains functional when needed.

Smart monitoring technology provides real-time insights into battery health, helping healthcare providers prevent unexpected failures and improve patient outcomes.

Part 1: Battery Innovations

1.1 Lithium-Ion Advances

You see rapid progress in lithium-ion battery technology transforming emergency medical equipment. Modern lithium battery packs deliver higher energy density and longer cycle life, which means your devices stay ready for critical moments. Compared to traditional alkaline batteries, lithium-ion and LiFePO4 chemistries offer significant advantages for medical applications.

Chemistry Type | Energy Density (Wh/kg) | Cycle Life (cycles) | Retained Power after 12 Months (Refrigerated) | Memory Effect | Environmental Impact |

|---|---|---|---|---|---|

Lithium-Ion | 150-250 | 500-1,500 | 90% | None | No lead acid |

LiFePO4 | 90-160 | 3,000+ | 95% | None | No lead acid |

Lithium-Polymer/LiPo | 150-200 | 500-1,000 | 90% | None | No lead acid |

Solid-State Battery | 250-350 | 2,000+ | 98% | None | No lead acid |

Alkaline | 80-100 | 1 (single-use) | 65% | Yes | Lead acid disposal |

Note: Lithium-ion and LiFePO4 batteries outperform alkaline batteries in both energy density and cycle life. You benefit from fewer replacements and more reliable operation in medical environments.

Recent advancements in lithium-ion technology include:

Improved safety certifications (IEC62133, IEC60601, ISO 10535) that protect against hazards in medical settings.

Enhanced performance metrics, such as 50% more lift cycles per charge and two-hour recharge times.

Increased reliability, which reduces service calls for dead batteries and extends device uptime.

Greener technology, eliminating lead acid disposal issues and memory effect.

Versatile applications across medical, robotics, security, infrastructure, consumer electronics, and industrial sectors.

You gain a competitive edge by choosing lithium-ion battery packs for your medical devices. These batteries comply with UN38.3 for safe handling and transport, which is essential for global medical logistics.

1.2 Rechargeable Solutions

Rechargeable battery solutions have become the standard for modern emergency medical equipment. You reduce operational costs and improve device readiness by adopting high-quality rechargeable lithium battery packs. Hospitals that switched from nickel-cadmium to lithium-ion batteries in infusion pumps reported lower maintenance costs and better device uptime.

Key benefits of rechargeable solutions for medical technology include:

Extended device lifespan, which means fewer replacements and less waste.

Lower frequency of battery changes, reducing the risk of device downtime during emergencies.

Seamless integration with medical equipment, supporting operational efficiency.

💡 Tip: Battery energy storage systems provide a steady power supply, minimizing operational hiccups in critical medical environments.

However, you must address several challenges:

Regular charging and checks are necessary to maintain optimal performance.

Higher initial costs and the need for specialized chargers require careful planning.

Proper care and storage practices prevent issues like battery corrosion, drainage, and expiration.

Despite these challenges, rechargeable batteries offer clear advantages:

Environmentally friendly and suitable for frequent use in medical technology.

Rechargeable multiple times, making them cost-effective over time.

You ensure continuous availability of emergency medical equipment by selecting the right battery type and maintaining a robust charging protocol.

1.3 Smart Monitoring

Smart monitoring technology has revolutionized battery management in medical devices. You now have access to real-time data on battery health and state of charge, which is critical for emergency readiness. Advanced BMS (Battery Management Systems) provide accurate insights, helping you prevent unexpected failures.

Source | Key Findings |

|---|---|

Performance Analysis of Battery Management Systems in Emergency Backup Systems | Accurate, real-time monitoring of battery health is essential for emergency scenarios. |

Smart Battery Voltage Monitoring: Real-Time Data for Smarter Power Management | Real-time insights ensure device operation during emergencies. |

Higher Reliability and Longer Lifetimes with Advanced Battery Management in Healthcare Energy Storage Systems | High standards for reliability and efficiency are required in medical applications. |

Smart monitoring systems, especially those using LoRa technology, offer:

Low power consumption, which extends battery life in medical devices.

Real-time monitoring capabilities, ensuring devices remain operational.

Predictive maintenance, allowing you to address issues before they impact patient care.

📊 Pro Tip: Implementing smart monitoring technology in your medical equipment reduces the risk of device failure and supports compliance with strict healthcare standards.

You improve patient outcomes and operational excellence by leveraging smart battery monitoring in your medical technology infrastructure.

Part 2: AED and Defibrillator Technology

2.1 Battery Life in AEDs

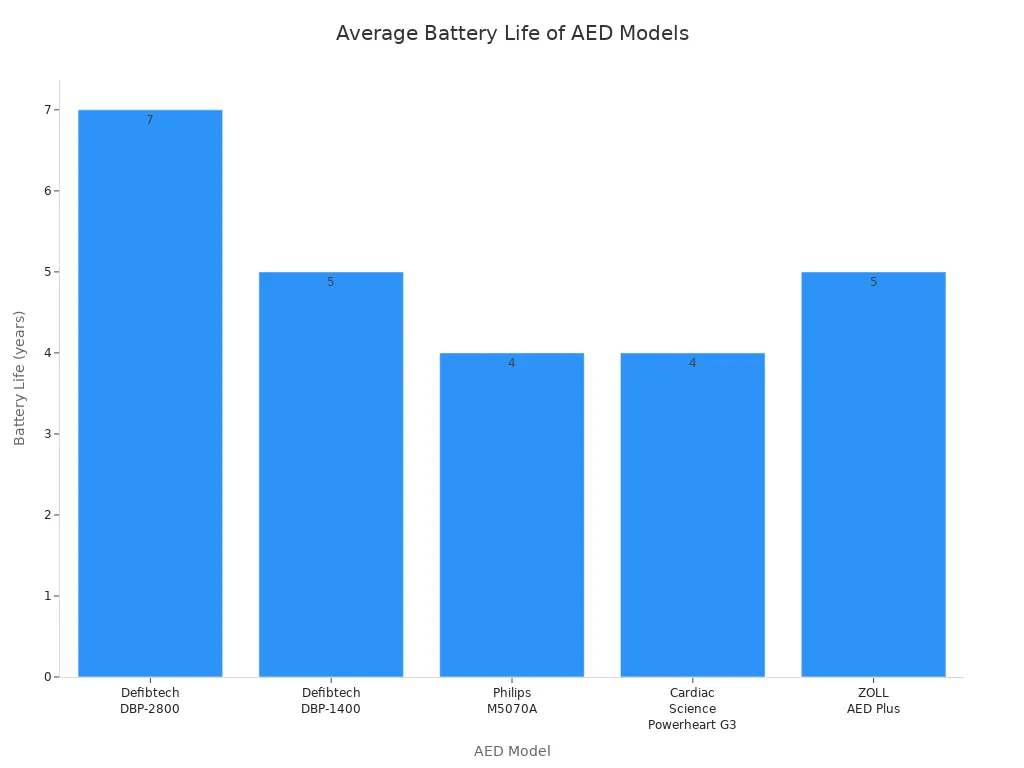

You rely on automated external defibrillators to deliver rapid, effective cardiac care during emergencies. Battery life stands as a critical factor in defibrillator technology. Modern lithium battery packs now power defibrillator models for up to 7 years, a significant improvement over previous generations. For example, the Defibtech DBP-2800 offers a battery life of up to 7 years, while older models like the Philips M5070A and Cardiac Science Powerheart G3 typically last around 4 years. This advancement in battery chemistry ensures your defibrillator remains ready for sudden cardiac arrest situations.

AED Model | Average Battery Life |

|---|---|

Defibtech DBP-2800 | Up to 7 years |

Defibtech DBP-1400 | Up to 5 years |

Philips M5070A | Typically 4 years |

Cardiac Science Powerheart G3 | Around 4 years |

ZOLL AED Plus | Up to 5 years |

You must monitor battery performance and replace batteries every 2 to 5 years, regardless of usage, to maintain reliability. Regular inspections and proactive maintenance keep your defibrillator technology operational for every cardiac emergency.

2.2 Remote Connectivity

Next-generation defibrillator technology integrates IoT connectivity and remote monitoring. You gain real-time insights into device status, battery health, and readiness. Platforms like Avive REALConnect™ provide daily self-tests and instant notifications, ensuring your automated external defibrillators remain functional for cardiac emergencies. Remote support options from leading companies enable quick troubleshooting, reducing downtime and improving reliability in medical environments.

Feature | Description |

|---|---|

IoT Connectivity | Enables remote monitoring and communication of AED status, ensuring readiness and functionality. |

Remote Support Options | Companies like Boston Scientific and Stryker offer features for rapid troubleshooting. |

Avive REALConnect™ | Provides daily self-tests and notifications for AEDs, enhancing maintenance and readiness. |

Remote monitoring delivers actionable data, allowing you to detect issues early and schedule maintenance efficiently. This approach minimizes disruptions and supports continuous cardiac care delivery.

2.3 Patient-Centric Design

You see a shift toward patient-centric design in automated external defibrillators and wearable defibrillators. Manufacturers now focus on user-friendly interfaces, clear visual cues, and intuitive instructions. These improvements help lay responders and medical professionals deliver faster, more effective cardiac care during emergencies. Studies show that better interface design reduces time to shock, which can improve outcomes in sudden cardiac arrest.

Study Title | Findings | Recommendations |

|---|---|---|

Usability of Automated External Defibrillators: A Randomized, Comparative Simulator Study | Clinically relevant differences in time to shock (TTS) due to interaction design. | Improve interface design based on user feedback and conduct further research to establish best practices. |

You benefit from standardized device appearance and enhanced auditory cues, which support rapid response in high-stress cardiac emergencies. Integrating robust battery management systems into defibrillator technology ensures stable power delivery, protects patient safety, and maintains device uptime in critical medical scenarios.

Part 3: Reliability & Outcomes

3.1 Device Uptime

You depend on uninterrupted device uptime during emergencies. Advanced lithium battery packs in medical technology deliver consistent power for critical equipment, including portable systems, powered carts, and emergency room devices. To measure uptime, you track several key metrics:

Battery runtime—ensures backup power for essential loads.

Mean Time Between Failures (MTBF)—higher values indicate reliable medical equipment.

Load percentage—maintains optimal operation, usually between 40–80% capacity.

Temperature stability—prevents overheating and extends battery life.

“Battery monitoring” means you consistently measure critical indicators, such as internal resistance and temperature, for every battery in your system. This approach lets you detect early signs of deterioration and avoid unexpected failures.

You see these standards applied across medical, robotics, security, infrastructure, and industrial sectors, where device uptime directly impacts operational efficiency.

3.2 Maintenance Reduction

Modern battery management systems (BMS) in medical technology help you reduce maintenance needs. Real-time monitoring of battery status allows you to detect early signs of failure and schedule proactive maintenance. You benefit from:

Extended battery lifespan through detailed analysis of degraded cells.

Enhanced reliability with proactive monitoring and maintenance strategies.

Optimized charge and discharge cycles, reducing the risk of sudden device failure.

Benefit | Description |

|---|---|

Reduced Downtime | Systems stay online longer, even during emergencies. |

Extended Battery Lifespan | Preventing overcharge and thermal damage increases battery cycles. |

Lower Maintenance Costs | Fewer emergency repairs and better replacement schedules save time and budget. |

Improved Device Safety | Avoiding overheating and chemical breakdowns reduces risk. |

Increased Sustainability | Better battery health reduces e-waste and supports environmental standards. |

You minimize downtime and maintenance costs, maximizing the efficiency of your medical assets.

3.3 Patient Impact

Reliable battery technology in medical equipment directly affects patient safety and outcomes. Studies show that battery failures in devices like defibrillators can lead to adverse events during emergencies. For example, a defibrillator powered by an unchecked, five-year-old battery switched off during a resuscitation attempt, highlighting the importance of regular monitoring.

A study on cardiac implantable electronic devices found that malfunctions and battery discharge during treatments can compromise patient care. You ensure better outcomes by using advanced battery technology and consistent monitoring protocols. This approach protects patients and supports high standards in medical emergencies.

Part 4: Integration & Safety

4.1 IoT & Predictive Analytics

You now see IoT and AI transforming battery maintenance for emergency medical equipment. Smart Battery Management Systems (BMS) enable continuous monitoring of device status and battery health. Real-time data from wearables and connected devices provides early warning alerts, helping you prevent complications and reduce hospitalizations. You benefit from improved collaboration among stakeholders in healthcare, security, and industrial sectors. Predictive analytics allow you to schedule maintenance before failures occur, ensuring your lithium battery packs remain ready for critical use.

Tip: Integrating IoT-enabled battery systems supports proactive care and enhances device readiness across your medical infrastructure.

Continuous monitoring delivers personalized insights.

Early alerts help you avoid downtime and improve patient safety.

Connected ecosystems foster better treatment continuity.

4.2 Regulatory Standards

You must comply with strict regulatory standards to ensure battery safety in emergency medical equipment. These standards govern the design, testing, and transport of lithium battery packs. The following table summarizes key regulations:

Standard | Description |

|---|---|

UL 2054 | Recognized by the FDA for medical devices with lithium batteries, focusing on safety and performance. |

IEC 62133 | International standard for safe operation of portable sealed lithium-ion cells and batteries in various applications. |

UN 38.3 | Required for shipping lithium cells and batteries, classifying them as a Class 9 Dangerous Good due to fire hazards. |

Manufacturers must consult and comply with standards like ANSI/AAMI ES 60601-1, IEC 60086-4, and UL 1642 before entering the U.S. market. You ensure safe transportation by passing UN 38.3 tests, including altitude simulation, thermal testing, vibration, and shock.

4.3 Safety Assurance

You rely on robust safety protocols to mitigate risks in lithium-ion and smart batteries. Manufacturers use risk assessments such as P-FMECA at both cell and device levels. Quality control inspections, including 100% outgoing and in-process checks, guarantee manufacturing excellence. Each battery cell receives a unique identifier for traceability. Transport testing ensures compliance with UN38.3 regulations. Complaint management systems follow ISO 13485 standards to address market feedback. Continuous improvement processes, like the PDCA cycle, drive ongoing enhancements.

Protocol Type | Description |

|---|---|

Risk Assessment | P-FMECA evaluates risks at battery-cell and device integration levels. |

Quality Control Inspection | 100% outgoing and in-process checks maintain manufacturing quality. |

Traceability | Unique identifiers link battery cells to devices for full traceability. |

Transport Testing | UN38.3 testing ensures safe shipment and regulatory compliance. |

Complaint Management System | ISO 13485 standards guide analysis and resolution of battery-related complaints. |

Continuous Improvement Process | PDCA cycle supports ongoing product and process improvements. |

You install lithium-ion-specific fire extinguishers and follow routine inspection protocols.

Safe charging and storage practices reduce fire risks.

Staff training and collaboration with safety experts ensure preparedness for emergencies.

Note: Adhering to these protocols protects your patients, staff, and assets in every critical scenario.

You see lithium battery innovations transform emergency response by powering lighter, longer-lasting devices.

Lithium-ion batteries support mobile oxygen concentrators and heart pumps, improving emergency response for patients.

Reliable power ensures uninterrupted emergency response and data integrity for healthcare teams.

Smart BMS and wireless charging will drive future emergency response, with eco-friendly materials supporting sustainability.

You face challenges in emergency response, including battery variety, maintenance complexity, and device life cycles. Staying ahead with advanced lithium battery packs ensures your emergency response remains effective.

FAQ

What lithium battery chemistries offer the best reliability for emergency medical equipment?

Chemistry | Cycle Life | Safety Rating | Application Scenario |

|---|---|---|---|

LiFePO4 | 3,000+ | High | Medical, Robotics |

Lithium-Ion | 1,500 | Medium | Security, Infrastructure |

Solid-State | 2,000+ | Very High | Industrial, Electronics |

How can you reduce maintenance costs for lithium battery packs in critical devices?

You implement smart monitoring and predictive analytics. These tools help you schedule maintenance, extend battery life, and minimize downtime in your medical and industrial assets.

Where can you get custom lithium battery solutions for your business?

You contact Large Power for a custom consultation.

Ready to optimize your emergency equipment? Request your custom lithium battery solution now.