You need to detect voltage drop in LFP batteries to maintain optimal performance and extend lifespan. Voltage drop in LFP batteries causes rapid capacity fading and higher internal resistance in lithium iron phosphate battery systems. The table below shows how voltage drop affects battery performance and safety, especially in medical and industrial sectors.

Condition | Capacity Retention | Internal Resistance | Lifespan Impact |

|---|---|---|---|

Overcharge | Increases | Shortened | |

Normal Charge | 80% after 2300 cycles | Stable | Longer |

You improve battery lifespan and optimal performance by identifying voltage drop early in each LFP battery.

Key Takeaways

Detect voltage drop early by regularly measuring battery voltage and internal resistance using proper tools like multimeters and battery analyzers to keep your LFP batteries safe and efficient.

Prevent voltage drop by matching cells, using a battery management system to balance voltages, controlling charging and temperature, and avoiding overcharging or deep discharging to extend battery life.

Maintain your battery pack with regular inspections of terminals and connections, proper storage, and following manufacturer charging guidelines to ensure long-term performance and reliability.

Part 1: Detecting Voltage Drop in LFP Batteries

1.1 What Is Voltage Drop

Voltage drop in LFP batteries refers to the reduction in voltage that occurs when current flows through the battery. You need to monitor this parameter because it signals changes in internal resistance and cell imbalance. These changes can reduce energy efficiency and usable capacity. If you ignore voltage drop, you risk overcharging or over-discharging cells, which can lead to thermal runaway and safety hazards. Voltage consistency supports stable battery operation and prevents uneven cell aging. The battery management system (BMS) plays a key role in monitoring voltage drop, balancing cell voltages, and extending battery lifespan.

Monitoring voltage drop in LFP batteries is essential for optimal performance, safety, and long-term reliability in sectors like medical devices, robotics, and industrial systems.

1.2 Detection Methods

You can detect voltage drop using several methods:

Terminal voltage measurement under load (DC load method) gives accurate, repeatable results for large stationary batteries.

Impedance testing (AC impedance) captures both resistive and reactive components, reflecting battery performance under digital loads.

Internal resistance analysis provides insight into battery health but requires baseline data for meaningful interpretation.

Method | Reliability | Key Use Case |

|---|---|---|

Terminal Voltage Measurement | High | DC-powered battery systems |

Impedance Testing | Moderate | Digital load environments |

Internal Resistance Analysis | Variable | Health diagnostics |

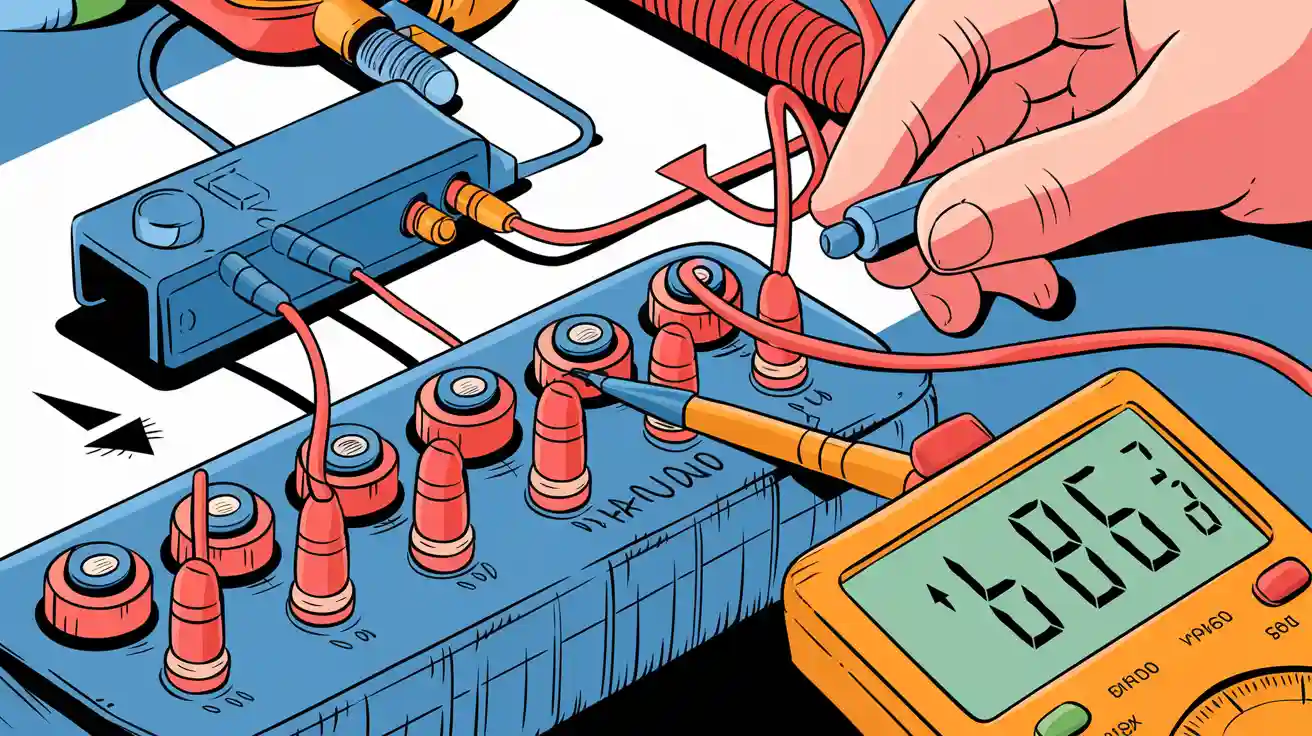

1.3 Tools for Testing

You should use industry-standard tools for accurate voltage drop measurement:

Multimeters deliver precise voltage readings and are fundamental for testing.

Battery analyzers simulate real-world usage and provide detailed performance data.

Capacity testers measure charge/discharge cycles and track voltage drop in LFP batteries.

To ensure accuracy, prepare the battery at a specific state of charge, allow it to rest, and use a four-wire connection to minimize contact resistance. Always control environmental factors like temperature and electromagnetic interference during testing.

Part 2: Causes and Prevention Strategies

2.1 Causes of Voltage Drop

You encounter voltage drop in lithium iron phosphate battery packs due to several technical and operational factors. Understanding the common causes of voltage drop helps you maintain efficiency and extend the lifespan of your battery systems.

Overcharging: Charging above the recommended voltage threshold (typically 3.65V per cell) leads to gas generation, swelling, and rapid voltage instability. Overcharging damages electrodes and causes permanent capacity loss.

Cell imbalance: When individual cells in a series-connected battery pack operate at different voltage levels, the battery management system may terminate charging or discharging early to protect weaker cells. This reduces usable capacity and causes overall voltage drop.

Corrosion: Corrosion on battery terminals and connections increases resistance, leading to voltage drop and reduced charging and discharging efficiency.

Faulty charger: Using incompatible or malfunctioning chargers can cause overvoltage, undervoltage, or irregular charging profiles, resulting in voltage drop and shortened lifespan.

Excessive discharge: Discharging below the safe threshold (around 2.0V per cell) damages the electrode structure, increases internal resistance, and causes voltage instability.

Low capacity: Aging or damaged cells lose capacity, forcing the battery pack to operate at the level of the weakest cell, which accelerates voltage drop.

High temperatures: Operating or storing batteries at elevated temperatures accelerates internal degradation, increases resistance, and leads to voltage drop.

Cable shorts: Short circuits in battery connections or cables cause sudden voltage drops and can damage the entire battery pack.

Poor connections: Loose or corroded connections between cells, terminals, or wires increase resistance and contribute to voltage drop.

Tip: Regularly inspect battery connections and terminals for corrosion or damage to prevent voltage drops and maintain optimal efficiency.

Cause | Impact on Battery Performance | Prevention Focus |

|---|---|---|

Overcharging | Capacity loss, voltage instability | Overcharging prevention |

Cell imbalance | Reduced usable capacity, early cutoff | Cell balancing, BMS |

Corrosion | Increased resistance, voltage drop | Terminal maintenance |

Faulty charger | Irregular charging, voltage drop | Charger compatibility |

Excessive discharge | Electrode damage, capacity loss | Discharge control, BMS |

Low capacity | Accelerated voltage drop | Battery replacement |

High temperatures | Degradation, resistance rise | Temperature control |

Cable shorts | Sudden voltage drop, damage | Cable inspection |

Poor connections | Increased resistance, voltage drop | Connection maintenance |

2.2 Prevention in Lithium Iron Phosphate Battery Packs

You can prevent voltage drops and maximize the lifespan of your lithium iron phosphate battery packs by implementing proven voltage management strategies and best practices.

Match cells for capacity, voltage, and internal resistance before assembling battery packs. This reduces cell imbalance and prevents localized overcharging or deep discharging.

Use low-heat welding techniques, such as ultrasonic or laser welding, to create solid, reliable connections and avoid electrical shorts.

Employ a battery management system to monitor and balance cell voltages in real time. The BMS disconnects the battery if any cell voltage drops below the safe threshold, protecting against harmful voltage drop and extending lifespan.

Control charging and discharging currents within manufacturer-recommended limits to maintain cell health and consistent voltage.

Install temperature sensors at critical points to prevent overheating and ensure safe operation.

Use dedicated chargers designed for lithium iron phosphate battery chemistry. Follow a two-stage charging protocol: constant current charging up to 3.65V per cell, then constant voltage charging until current tapers off.

Avoid overcharging and deep discharging. Charge within a temperature range of 0°C to 45°C and avoid charging beyond 90% capacity or discharging below 20% regularly.

Regularly balance cells to maintain uniform voltage and state-of-charge, preventing voltage drop caused by imbalance.

Replace aging or low-capacity cells promptly to maintain pack efficiency and prevent voltage drop.

Note: Implementing a BMS and following proper charging protocols are essential for overcharging prevention and maximizing efficiency in all application scenarios, including medical, robotics, and industrial sectors.

2.3 Maintenance Tips

Consistent maintenance routines help you prevent voltage drops and support the long-term efficiency and lifespan of your lithium iron phosphate battery packs.

Inspect battery terminals and connections every six months for corrosion or damage. Clean terminals with a soft, dry cloth and apply a spray-on protectant to prevent corrosion.

Store batteries in a cool, dry environment (10°C to 25°C) and at 50-60% state of charge to reduce cell stress and degradation.

Use only chargers recommended by the manufacturer to ensure proper charging and avoid voltage drop incidents.

Monitor charge voltage during initial and ongoing use to detect early signs of capacity loss or imbalance.

Prefer shallow charging cycles and avoid deep discharges to extend cycle life and maintain charging and discharging efficiency.

Perform regular inspections and capacity tests to verify battery health and identify potential issues before they cause voltage drop.

Avoid shorting battery terminals and ensure all cable connections are secure and insulated.

For long-term storage, periodically check voltage and recharge to 50% if necessary.

Never disassemble the battery cell compartment yourself; contact the manufacturer for repairs or replacements.

Maintenance Task | Frequency | Purpose |

|---|---|---|

Terminal inspection | Every 6 months | Prevent corrosion-related voltage drop |

Storage environment check | Ongoing | Minimize degradation, extend lifespan |

Charger compatibility | Every use | Maintain voltage stability |

Voltage monitoring | Ongoing | Early detection of voltage drop |

Shallow cycling | Regular use | Maximize efficiency, extend lifespan |

Capacity testing | Annually | Verify health, prevent voltage drop |

Cable/connection check | Every inspection | Prevent resistance, voltage drop |

Regular maintenance and monitoring are key to maximizing efficiency and ensuring the long-term reliability of your lithium iron phosphate battery systems.

You protect every battery in your system by detecting voltage drop early and using advanced monitoring. Multi-sensor approaches—combining electric, thermal, and mechanical data—help you identify battery faults before they impact safety or performance. Regular maintenance, proper installation, and adherence to best practices extend battery lifespan and ensure reliable operation in medical, robotics, and industrial applications.

Sensor Type | Key Role in Battery Monitoring |

|---|---|

Electric Sensors | Detect voltage changes and current flow |

Thermal Sensors | Identify temperature variations |

Mechanical Sensors | Monitor pressure and strain |

Stay proactive with battery management to maximize reliability and safety.

FAQ

What causes voltage drop in lithium iron phosphate battery packs?

You often see voltage drop from cell imbalance, corrosion, poor connections, or excessive discharge. These issues reduce efficiency in medical, robotics, and industrial battery systems.

How can you prevent voltage drop in LFP batteries?

You maintain stable voltage by using a battery management system, matching cells, controlling temperature, and following proper charging protocols. Regular inspections help you avoid unexpected failures.

What is the recommended maintenance schedule for LFP battery packs?

You inspect terminals and connections every six months. You test capacity annually. You monitor voltage and temperature during daily use, especially in security and infrastructure applications.