Monitoring your battery charger amp meter ensures you protect lithium battery packs from overcharging, deep discharging, and overheating. Accurate amp meter readings help you optimize battery performance, extend operational life, and maintain safety. By tracking amp and charge flow, you support reliable battery charger function and consistent charger performance in demanding environments.

Key Takeaways

Always monitor your battery charger amp meter to prevent overcharging, overheating, and deep discharging, which protects battery life and safety.

Use the correct type of amp meter and follow safety steps before charging, including inspecting batteries and using proper protective gear.

Regularly check amp readings and voltage to know when to stop charging and perform load tests to ensure your battery stays healthy and performs well.

Part 1: Battery Charger Amp Meter Basics

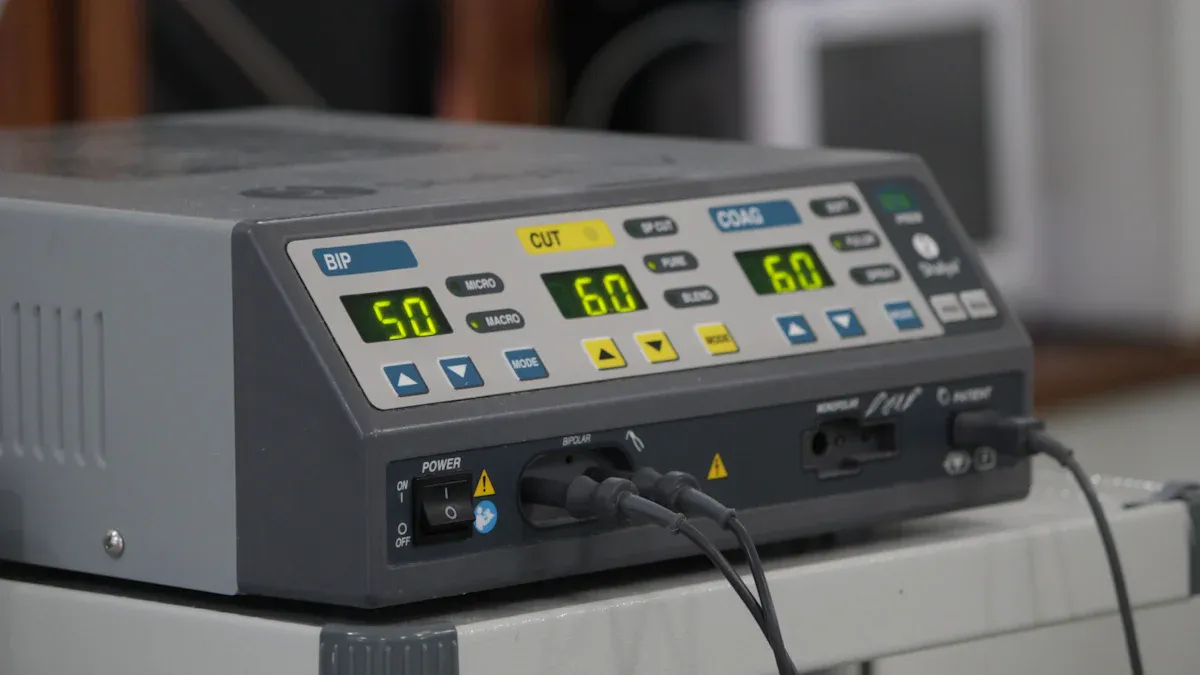

A battery charger amp meter measures the current flowing from the charger into the battery. You rely on this reading to monitor the state of charge and ensure safe, effective charging for lithium battery packs, including LiFePO4, NMC, LCO, LMO, and LTO chemistries. Accurate amp readings help you prevent overcharging, overheating, and deep discharging, which are critical for battery health in medical, robotics, security system, and industrial applications.

1.1 Types of Amp Meters

You will encounter two main types of amp meters: analog and digital. Analog battery charger amp meters use a needle and scale to show current. These meters are durable and affordable, but they offer lower accuracy and can suffer from parallax errors. Digital amp meters provide precise, easy-to-read numerical displays. They require a battery to operate and may be more sensitive to physical impact. The table below highlights key differences:

Feature | Analog Amp Meter | Digital Amp Meter |

|---|---|---|

Accuracy | Lower; prone to parallax errors | Higher; precise numeric readings |

Readability | Needle on scale | Digital numeric display |

Durability | Rugged, less sensitive to drops | Sensitive to impact |

Power Source | No battery required | Requires battery |

Cost | More affordable | More expensive |

Extra Features | Limited | Auto-ranging, continuity tests, etc. |

1.2 Safety Before Charging

Before connecting your battery charger, you must follow strict safety steps:

Use chargers designed for your lithium battery pack and follow manufacturer instructions.

Prepare your workspace by removing conductive items and working on non-conductive surfaces.

Wear PPE, including electrical hazard-rated gloves and safety glasses.

Inspect the battery for damage, swelling, heat, or smoke.

Store batteries in original packaging and protect terminals.

Charge and store batteries in fire-retardant containers when possible.

Avoid overheating by keeping batteries in cool, dry, ventilated areas.

Tip: Electrical abuse, such as using incompatible chargers or overcharging, is a leading cause of battery failures and safety incidents.

1.3 How to Read the Battery Charger Amp Meter

To read an analog battery charger amp meter:

Observe the needle position on the scale.

0-2 amps means the battery is fully charged or in maintenance mode.

2-10 amps indicates moderate charging.

10-30 amps signals rapid charging.

Monitor needle movement; a stable needle shows ongoing charging, while no movement may indicate a problem.

For digital amp meters, simply read the numeric display. The current will decrease as the battery approaches full charge. Both meter types show the charger’s set current at the start, then a gradual drop as charging progresses. You may need to take a voltage reading to confirm the battery’s state of charge.

Part 2: Interpreting Battery Charger Readings

2.1 Understanding Battery Charger Readings

You rely on amp meter readings to assess the charging cycle of your lithium battery pack. During the initial phase, the battery charger delivers a higher charging rate, and the amp meter shows a strong current flow. As the battery approaches full charge, the amp reading drops. This decrease signals that the battery is nearing its optimal state of charge. The charger typically starts in the constant current (CC) phase, then transitions to constant voltage (CV) as the battery fills.

Charging Phase | Typical C Rate Range | Corresponding Current Range (Amps) |

|---|---|---|

Life Cycle Testing | 0.5C to several C | Tens to hundreds of amps (cell size dependent) |

Formation Charging | C/20 to C/5 | A few amps up to tens of amps |

For example, a LiFePO4 battery used in medical or robotics applications may begin charging at 0.5C, then taper off as it reaches full charge. You should expect positive amp readings during charging, which gradually decrease as the battery nears completion. When the amp meter shows a low current and the voltage is high, the charger may switch to float mode, confirming the battery is fully charged.

Tip: Always compare amp readings with voltage measurements to accurately determine the battery’s state of charge and avoid battery troubles.

Normal amp readings reflect the battery’s ability to hold a charge and indicate healthy performance. Abnormal readings, such as sudden drops or erratic fluctuations, may signal a bad battery or charger malfunction. New lithium battery packs display stable, predictable amp readings, while aged packs show slower current acceptance and fluctuating amp values due to increased internal resistance.

2.2 When to Stop Charging the Battery

You must recognize when to stop charging to prevent overcharging and extend battery life. For LiFePO4 batteries, limit the charging rate to approximately 0.2C. For a 100Ah battery, this means stopping or reducing the current at around 20 amps. Chargers with multi-stage charging and automatic cut-off features help you avoid excessive current spikes.

Recommended charging rates for lithium battery packs:

0.5C for standard charging (e.g., 50A for a 100Ah battery)

0.2C for gentle charging (e.g., 20A for a 100Ah battery)

Always follow manufacturer guidelines for maximum charging rate

Battery Capacity (Ah) | Typical Maximum Discharge Current (Amps) | Recommended Charging Voltage Range (V per cell) |

|---|---|---|

5 – 35 Ah | 15A (5Ah) up to 105A (35Ah) | 3.5 – 3.65 V per cell |

If the amp meter reading drops below the recommended threshold and the voltage reaches the specified setpoint, disconnect the charger or allow it to switch to float mode. Overcharging can cause overheating, gas formation, and internal damage, especially in industrial and infrastructure applications. Battery Management Systems (BMS) provide essential protection by monitoring amp readings and cutting off the charger if unsafe conditions arise.

Charging tips: Use only compatible battery chargers and avoid exceeding the recommended charging rate to maintain battery performance and safety.

2.3 Load Test the Battery

You should regularly load test the battery to confirm its ability to hold a charge and deliver rated performance. To perform a load test:

Measure the battery voltage with a multimeter. A healthy, fully charged lithium battery should read about 4.2V per cell.

Connect a known load, such as a resistor or device, to discharge the battery in a controlled manner.

Monitor the voltage during discharge. Lithium batteries typically cut off between 2.5V and 3.0V per cell.

Record the current drawn and discharge time. Calculate capacity using Capacity (Ah) = Current (A) × Time (h).

Observe amp readings throughout the test. A healthy battery delivers close to its rated capacity before reaching cutoff voltage.

Load testing helps you identify battery troubles, such as rapid voltage drops or heat buildup. If the battery fails to deliver expected amp hours or shows significant voltage instability, you should replace the battery to avoid operational disruptions in security systems or consumer electronics.

Note: Use a constant load for accuracy and ensure the load does not exceed the battery’s maximum discharge rate.

2.4 Best Practices for Battery Health

You can maximize battery life and performance by following industry-recommended best practices:

Avoid deep discharges below 20% capacity to prevent premature degradation.

Charge fully after each use to maintain optimal battery performance.

Prevent overcharging by disconnecting the charger after full charge, even if automatic shutoff is present.

Use only manufacturer-approved battery chargers for your lithium battery pack.

Power off batteries when not in use to avoid parasitic drain.

Store batteries at moderate temperatures (40°F to 80°F) and maintain charge levels during long-term storage.

Use smart charging ICs and apps to monitor state of charge, temperature, voltage, amperage, and cell balance.

Prefer partial charging cycles (keep battery charge between 20-80%) rather than full charge-discharge cycles.

Avoid charging in thermal extremes (ideal range 68-77ºF) to prevent degradation.

Regularly monitor battery health parameters and perform diagnostic checks to catch issues early.

Charging lithium batteries slowly at about one-quarter of their capacity reduces degradation.

Avoid regular charging to 100%; charging to around 80% prolongs battery life.

Prevent deep discharges below 25% to minimize capacity loss and internal resistance increase.

Store batteries in cool, dry, and shaded environments to reduce corrosion and degradation.

Avoid frequent fast charging and high drain rates to reduce thermal and mechanical stress on cells.

Proactive monitoring and adherence to best practices help you maintain optimal amp readings, prevent battery troubles, and extend battery life in demanding medical, industrial, and robotics applications.

You ensure safe and effective charging by monitoring amp readings throughout every battery charging cycle. Start with a low current if the battery voltage is low, then use the amp meter to track the charger’s output and prevent overcurrent. Ongoing monitoring helps you detect imbalances, maintain battery health, and avoid failures in industrial, medical, and robotics applications.

FAQ

1.How often should you inspect the battery during charging?

You should inspect the battery every charging cycle. Look for swelling, heat, or smoke. This helps prevent battery troubles and ensures safety in medical and industrial applications.

Charging tips: Always take a voltage reading and check amp meter readings to confirm the state of charge.

2.What does a bad battery charger amp meter reading mean?

A bad battery charger amp meter reading may show erratic fluctuations or sudden drops. This can signal a bad battery, charger malfunction, or overcharging. Replace the battery if performance drops.

3.How do you load test the battery for optimal battery life?

Connect a known load.

Monitor voltage and amp readings.

Record discharge time.

Replace the battery if it cannot hold a charge or fails the test.