Battery selection for medical equipment involves complex cost-benefit analysis that extends beyond initial purchase price. Standard disposable AA batteries with typical retail costs of $8-$10 per pack create recurring expenses that can reach $100-$120 annually when powering high-consumption devices such as hearing aids or portable monitoring equipment. These frequent replacement cycles contrast sharply with rechargeable battery systems, where a complete starter configuration including four AA cells and charging unit requires approximately $20 initial investment but provides substantially lower operational costs over extended use periods.

Rechargeable batteries vs disposable options present distinct technical advantages in medical applications. Rechargeable cells achieve 300-1,000 reuse cycles before capacity degradation requires replacement, while disposable batteries contribute to significant waste streams through single-use consumption patterns. Millions of spent disposable batteries enter landfill systems annually, where electrolyte compounds and heavy metals can migrate into groundwater systems. Rechargeable battery construction typically incorporates enhanced corrosion-resistant materials and protective circuitry designed for repeated charge-discharge cycles, providing improved durability characteristics essential for critical medical equipment applications.

The selection criteria for medical device power sources requires evaluation of multiple performance parameters including reliability specifications, total cost of ownership, and regulatory compliance requirements. Battery technology directly affects device functionality, maintenance schedules, and environmental impact throughout the product lifecycle. This technical guide examines power source selection for specific medical applications, from daily-use hearing assistance devices to emergency backup power systems, providing the technical foundation necessary for informed procurement decisions that balance operational requirements with cost-effectiveness and regulatory compliance.

Understanding Battery Needs in Medical Equipment

Medical device power requirements are determined by specific operational parameters including voltage specifications, current demand, duty cycle characteristics, and environmental operating conditions. Battery selection affects three critical performance areas: device reliability, operational safety, and regulatory compliance.

Power source requirements vary significantly across medical device categories. Hearing aids operate at low power consumption levels with compact form factor constraints, while patient monitoring systems require continuous operation with higher current demands and backup power capabilities. Life-sustaining equipment such as ventilators and infusion pumps mandate uninterrupted power delivery with fail-safe protection mechanisms to ensure patient safety under all operating conditions.

Power Requirements of Hearing Aids, Monitors, and Pumps

Medical device power specifications vary significantly based on operational demands and regulatory safety requirements. Hearing aid systems operate within stringent size constraints, requiring specialized battery chemistries that deliver 1.4V nominal voltage while accommodating miniaturized form factors. Battery selection follows standardized size classifications denoted by numerical codes and color-coding systems: size 10 (yellow), 312 (brown), 13 (orange), and 675 (blue) configurations. These dimensional specifications directly correlate with capacity ratings and discharge characteristics essential for consistent amplification performance.

Patient monitoring systems require continuous operation capabilities with enhanced reliability specifications due to critical patient safety functions. Blood pressure monitoring, oxygen saturation measurement, and pulse rate tracking demand uninterrupted power delivery through lithium-ion battery configurations featuring 7.2V nominal voltage and 13.2Ah rated capacity specifications. The energy density characteristics of lithium-ion batteries reach 270 Wh/kg, enabling their deployment in over 70% of current medical device manufacturing applications.

Infusion pump systems present the most demanding power consistency requirements within medical equipment applications. Medication delivery precision depends on stable voltage regulation and current control parameters—voltage fluctuations can cause dosing errors with potentially life-threatening consequences. Protection against power interruption requires dual power architecture incorporating primary AC supply connections with integrated battery backup systems to maintain therapeutic delivery protocols during power disruptions.

Battery system reliability represents the fundamental requirement for medical equipment safety certification. Power supply failures and battery-related malfunctions constitute primary factors affecting overall system reliability performance, with battery-related user errors accounting for 47.1% of documented incidents in telemetry monitoring applications. These reliability statistics underscore the critical importance of proper battery selection and maintenance protocols in medical device deployment.

Which Is Better: Hearing Aid with Battery or Rechargeable?

Hearing aid power source selection requires evaluation of individual usage patterns and lifestyle requirements. The industry has experienced significant adoption of rechargeable technology, though both power solutions offer distinct operational characteristics suited to different user profiles.

Traditional disposable batteries maintain specific advantages in hearing aid applications:

- Extended single-use operation period (10-16 days per battery)

- Zero charging infrastructure requirements

- Immediate power restoration capability

- Universal availability across multiple form factors

Rechargeable hearing aid systems have gained market acceptance based on several technical and operational benefits:

Rechargeable hearing aids typically deliver 24 hours of continuous operation per charge cycle and require daily charging protocols. The integrated battery systems generally maintain capacity for approximately one year before performance degradation necessitates professional service replacement.

Daily hearing aid users frequently find rechargeable systems provide optimal convenience and operational efficiency. However, users with irregular wearing patterns or frequent travel requirements may benefit from the immediate power replacement capability of disposable batteries, despite higher cumulative operational costs. The decision ultimately depends on individual usage profiles and maintenance preferences rather than universal technical superiority of either solution.

Rechargeable Battery Performance Characteristics

Image Source: Healthy Hearing

Rechargeable battery systems present distinct operational advantages for medical equipment applications, particularly with lithium-ion chemistry advancements. The technical evaluation of rechargeable versus disposable power sources requires assessment across multiple performance criteria including cycle life, energy density, and maintenance requirements.

Economic Performance and Cycle Life Analysis

Rechargeable battery economics become favorable after approximately 2 years of regular deployment, with cost recovery occurring through eliminated replacement cycles. The financial crossover point depends on usage frequency—devices requiring weekly battery changes achieve payback within 6-8 months, while monthly replacement schedules extend recovery periods to 18-24 months. Healthcare facilities processing 120 AA batteries annually achieve $70+ cost reductions in the second operational year.

Battery cycle life directly correlates with total cost of ownership. Quality rechargeable cells maintain 80% capacity through 300-500 complete discharge cycles, with premium lithium-ion technologies extending this to 1000+ cycles before replacement becomes necessary.

Environmental Impact and Material Composition

Rechargeable battery can replace hundreds of single-use cells throughout their operational lifespan, creating substantial waste reduction. Manufacturing processes increasingly incorporate recycled materials, with some battery designs utilizing 10%+ post-consumer content. However, environmental benefits only materialize after 50+ recharge cycles, making frequent-use applications essential for achieving sustainability objectives.

The environmental threshold represents a critical decision point for medical equipment with intermittent usage patterns. Devices operating less than weekly may not achieve the cycle count necessary to offset manufacturing impacts.

Operational Requirements and Maintenance Protocols

Rechargeable battery performance optimization requires specific maintenance protocols:

- Charge termination before complete depletion to extend cycle life

- Operating temperature control between 5-20°C for capacity preservation

- Regular charging before reaching 20% state-of-charge

- Overcharge protection to prevent thermal stress

Lithium-ion cells typically provide 2-3 years of service or 300-500 cycles, whichever occurs first. These maintenance requirements may present challenges in medical environments where consistent charging schedules cannot be guaranteed.

Storage Characteristics and Emergency Applications

The primary limitation of rechargeable batteries for medical applications involves self-discharge rate characteristics. NiMH chemistry experiences 3-5 year maximum storage life due to electrolyte degradation, while standard configurations lose 10% capacity daily during non-use periods. Emergency medical equipment requires battery verification every 6 months to ensure adequate capacity.

Disposable batteries maintain charge integrity for up to 10 years in storage, making them essential for emergency preparedness applications where charging infrastructure may be unavailable. This storage advantage becomes critical for backup medical devices and emergency response equipment.

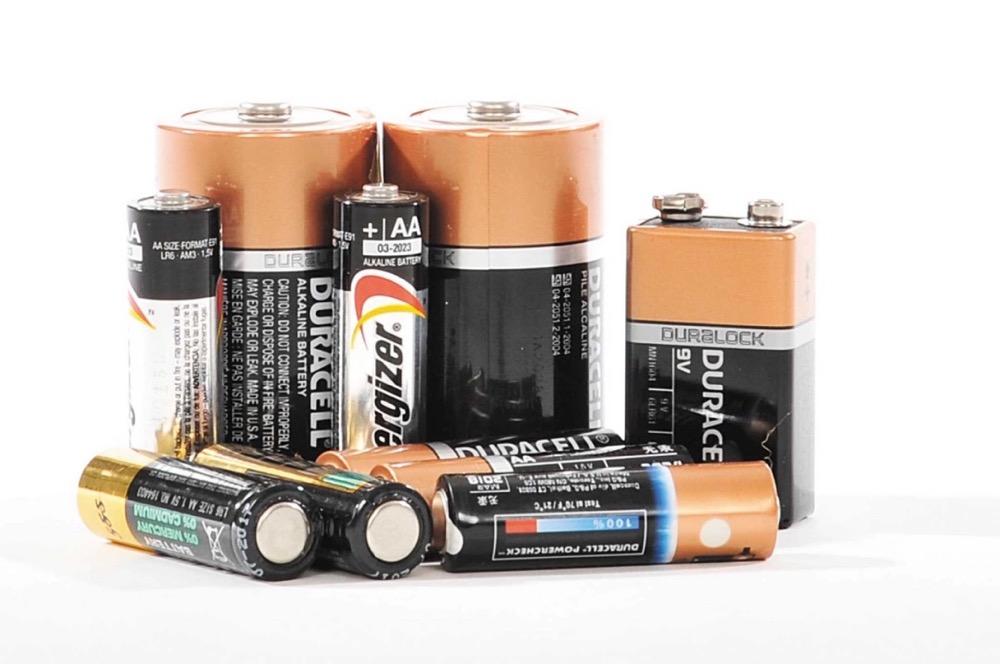

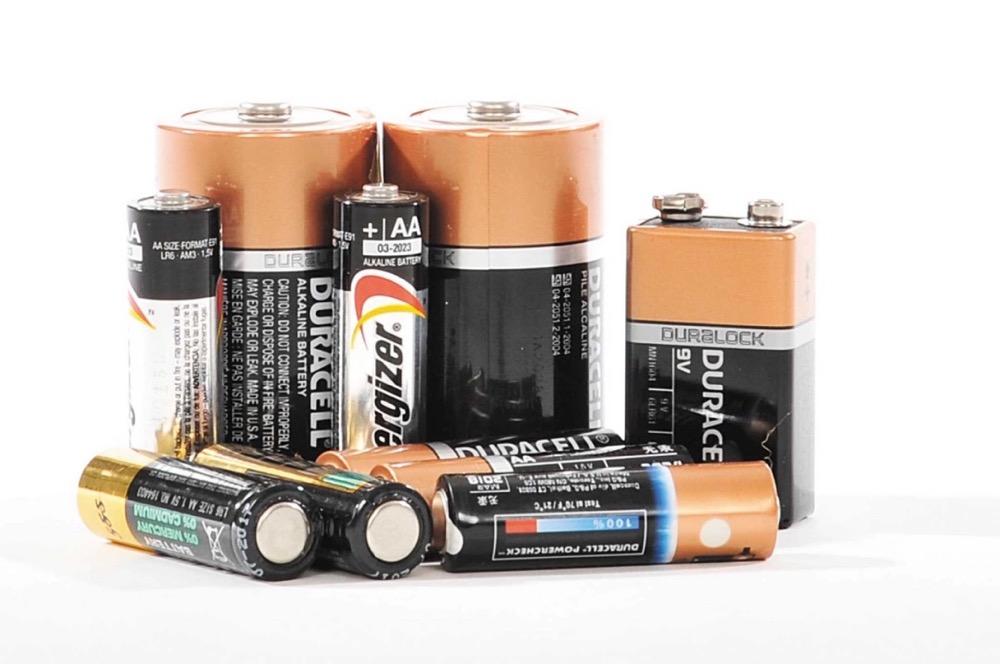

Pros and Cons of Disposable Batteries

Image Source: recoil offgrid

Image Source: recoil offgrid

Disposable batteries maintain essential roles in medical device applications where specific operational requirements favor single-use power sources. These primary cells offer distinct technical advantages in applications requiring immediate deployment and extended storage capabilities.

Disposable batteries require no charging infrastructure and provide immediate power capability upon installation. The low self-discharge characteristics of primary cells enable storage periods extending multiple years without significant capacity loss. Alkaline chemistry batteries demonstrate stable performance with minimal leakage risks during extended storage under appropriate environmental conditions. Medical devices requiring sterile packaging, including surgical instruments and diagnostic equipment, benefit from disposable power sources that eliminate contamination concerns while maintaining specified voltage and capacity parameters throughout shelf life.

Higher Long-Term Cost

The cost structure of disposable batteries creates elevated operational expenses in high-consumption applications. Initial purchase pricing appears favorable compared to rechargeable alternatives, however the replacement frequency required for continuous operation results in substantially higher total cost of ownership. Medical facilities utilizing multiple battery-powered devices can experience significant budget impact when disposable cells require frequent replacement cycles.

Environmental Waste and Recycling Issues

Disposal of primary batteries creates environmental challenges requiring proper waste management protocols:

- Primary cell chemistries contain toxic chemicalsincluding mercury, lead, and lithium compounds that can migrate into soil and groundwater systems when improperly disposed

- Contamination from battery waste can enter food supply chains through affected water sources and agricultural systems

- Battery waste streams contribute to electronic waste accumulation with limited recycling infrastructure

Current recycling systems for spent batteries face technical and economic limitations, including insufficient processing capacity, elevated recovery costs, and complex material separation requirements. Advanced recycling technologies and improved collection systems remain essential for sustainable primary battery waste management.

Best for Infrequent or Emergency Use

Disposable batteries provide optimal solutions for specific medical applications requiring minimal maintenance and extended readiness periods. The extended shelf life characteristics make primary cells suitable for emergency medical kits and backup power systems. Applications with infrequent activation cycles benefit from the immediate availability of disposable power sources without charging requirements. Remote medical equipment and emergency response devices utilize disposable batteries when charging infrastructure availability cannot be guaranteed.

Real-World Scenarios in Medical Use

Image Source: Design 1st

Image Source: Design 1st

Medical device power source selection requires evaluation of specific operational contexts and usage patterns. Clinical environments present different battery performance requirements compared to home-use applications, particularly as medical equipment manufacturers continue miniaturization efforts while increasing power density demands.

Daily Use in Hearing Aids: Rechargeables Shine

Hearing assistance devices demonstrate the practical advantages of rechargeable power systems in high-frequency use applications. Lithium-ion powered hearing aids provide operational periods extending to 30 hours per charge cycle, eliminating the manipulation challenges associated with frequent battery replacement procedures. This becomes particularly critical for users with limited manual dexterity who experience difficulty accessing miniaturized battery compartments. Clinical experience demonstrates significant user acceptance improvements – one hearing instrument specialist documented a 90-year-old patient who had previously rejected hearing aid use due to battery management difficulties. Following conversion to rechargeable systems, patient compliance increased dramatically.

Rechargeable hearing aid systems establish predictable maintenance routines through overnight charging protocols similar to consumer electronics devices. The sealed construction design provides enhanced environmental protection against moisture and particulate contamination, improving operational reliability in daily use scenarios.

Hospital Monitors: Dependability of Disposables

Critical patient monitoring systems require uninterrupted power delivery with absolute reliability standards. Medical grade batteries undergo extensive validation testing protocols due to documented cases where power failures resulted in patient harm and mortality incidents. Professional monitoring equipment incorporates multiple protection mechanisms:

- Short circuit protection systems • Overcharge and over-discharge safeguards

• Integrated temperature control sensors • Real-time abnormal condition monitoring

Lithium-ion chemistry dominates current medical device applications, powering approximately 70% of newly manufactured medical devices. The high energy density characteristics support continuous monitoring requirements while integrated sensor systems provide overheating detection, pressure monitoring, and strain measurement capabilities to prevent thermal runaway conditions.

Travel and Backup: Why Disposables Still Matter

Transportation regulations create specific requirements for medical device power sources. FAA regulations permit lithium batteries for medical devices to exceed standard restrictions when “the intended destination is not serviced daily by cargo aircraft and batteries are required for medically necessary care”. Disposable battery systems provide operational flexibility when charging infrastructure becomes unavailable.

Emergency medical equipment relies on disposable power sources specifically for their extended shelf life characteristics. Battery backup systems for medical carts, ventilators, and portable X-ray equipment frequently specify disposable options as secondary power sources. The immediate readiness without charging requirements makes disposable batteries ideal for infrequently used but mission-critical equipment applications.

Cost and Environmental Comparison

Financial analysis of medical device power systems requires evaluation of total cost of ownership rather than initial purchase price alone. The economic model for battery selection involves multiple variables including replacement frequency, disposal costs, and operational efficiency over extended service periods.

Rechargeable Batteries vs Disposable Cost Breakdown

Rechargeable batteries deliver significant savings through reduced replacement cycles and extended operational life. The initial investment of approximately $20 for four rechargeable AA batteries with charging infrastructure becomes cost-effective after 5-6 recharge cycles compared to $5 for equivalent disposable batteries . A single rechargeable cell achieves up to 1,000 reuse cycles throughout its operational lifespan , representing a potential cost differential of $1,000 versus $2 per disposable replacement .

Large-scale medical facilities experience accelerated return on investment. Military operational data demonstrates that battalions consuming approximately $14,000 in disposable batteries daily recover the rechargeable system investment within 19 days of implementation . Healthcare organizations can redirect these cost savings toward critical equipment upgrades and facility improvements.

Rechargeable Batteries vs Disposable Environment Impact

Environmental impact assessments demonstrate quantifiable advantages for rechargeable battery systems across multiple performance metrics. Comparative lifecycle analysis studies indicate rechargeable options produce:

Rechargeable batteries consume 23 times fewer non-renewable resources during manufacturing and operational phases compared to disposable alternatives . Environmental benefits become measurable after 50 charge cycles, where rechargeable systems demonstrate superior performance in nearly all environmental impact categories .

Best USB Rechargeable Batteries for Medical Use

Advanced USB rechargeable batteries meet stringent medical device requirements through enhanced protection mechanisms and regulatory compliance. Leading specifications include 1.5V output voltage, 1,000+ charge cycle capability, and 2300mWh energy capacity . Critical safety features include short-circuit protection, overcharge prevention, and thermal management systems essential for medical equipment reliability.

Regulatory compliance remains paramount for medical applications. Manufacturing certifications from CE, FCC, and RoHS standards ensure compatibility with medical environment safety requirements and operational protocols.

Technical Specifications Comparison

| Performance Parameter |

Rechargeable Battery Systems |

Disposable Battery Systems |

| Initial Investment Cost |

$20 (complete starter configuration: 4 AA cells + charging unit) |

$8-10 (standard multi-pack) |

| Annual Operating Cost Reduction |

Up to $77.44 cost savings after initial 24-month period |

None (baseline operational cost) |

| Service Life Specifications |

300-500 charge cycles or 2-3 years operational lifespan |

10-16 days continuous operation per cell |

| Environmental Impact Assessment |

– Replacement ratio: ~100 disposable units annually

– Environmental advantage threshold: 50 recharge cycles |

– Direct contribution to solid waste streams

– Potential electrolyte compound leaching |

| Self-Discharge Characteristics |

Up to 10% capacity loss per day (NiMH chemistry) |

Minimal discharge rate (decade-level storage capability) |

| Maintenance Protocol Requirements |

– Regular charging cycles required

– Optimal charge range: 20-80% capacity

– Storage temperature: 5-20°C |

No maintenance protocols required |

| Optimal Application Categories |

– Daily operation devices (hearing assistance)

– High-frequency use monitors

– Applications with charging infrastructure access |

– Emergency medical equipment

– Intermittent operation devices

– Sterile environment applications |

| Primary Technical Advantages |

– Long-term cost-effectiveness

– Reduced environmental impact

– Superior performance for frequent use |

– Immediate operational capability

– Extended shelf life specifications

– No charging infrastructure requirements |

| Technical Limitations |

– Higher initial capital requirement

– Regular charging cycle dependency

– Limited storage life (3-5 years) |

– Higher cumulative operational costs

– Environmental disposal considerations

– Frequent replacement cycle requirements |

Conclusion

Technical analysis demonstrates that rechargeable batteries provide measurable cost advantages for medical equipment with regular usage patterns. The break-even point occurs within 5-6 recharge cycles, establishing clear economic justification for facilities with consistent power consumption requirements. Healthcare organizations operating high-volume battery-dependent equipment can achieve annual cost reductions exceeding $100 per device through strategic implementation of rechargeable systems.

Application-specific requirements determine optimal battery selection. Daily-use medical devices including hearing aids and portable monitors benefit from rechargeable technology due to consistent usage patterns that exceed the 50-cycle environmental threshold and provide sustained cost benefits. Emergency medical equipment requires disposable batteries to meet shelf-life requirements and ensure immediate availability without charging infrastructure dependencies.

The environmental impact differential becomes significant at scale. Rechargeable batteries reduce waste streams by replacing hundreds of disposable units throughout their operational lifespan. However, this environmental benefit materializes only after surpassing the 50-cycle threshold, making usage frequency a critical selection parameter.

Medical device reliability standards necessitate careful evaluation of power source characteristics. Modern lithium-ion rechargeable batteries incorporate protection circuit modules with over-voltage, under-voltage, and temperature monitoring capabilities essential for critical applications. Disposable batteries maintain advantages in sterile environments and backup power systems where charging infrastructure presents contamination risks or operational complexity.

Battery selection strategy should be based on specific operational parameters:

- High-frequency use devices: Rechargeable batteries for cost-effectiveness and environmental benefits

- Emergency and backup systems: Disposable batteries for extended shelf life and immediate readiness

- Sterile applications: Disposable batteries to eliminate charging infrastructure requirements

- Mixed-use environments: Hybrid approach optimizing each application independently

The objective for medical facility battery management is to minimize operational costs while maintaining safety and reliability standards. This requires systematic evaluation of usage patterns, environmental requirements, and regulatory compliance parameters for each device category rather than universal adoption of either technology.

Key Takeaways

Understanding the financial and environmental implications of battery choices in medical equipment can lead to significant savings and better sustainability practices.

- Rechargeable batteries save up to $100 annually after initial investment, becoming cost-effective after just 5-6 recharge cycles compared to disposables

- For daily-use medical devices like hearing aids, rechargeable options eliminate frequent battery changes while providing 24-30 hours of continuous power

- Emergency medical equipment still requires disposable batteries due to their 10-year shelf life versus rechargeable batteries’ 3-5 year storage limit

- Each rechargeable battery replaces approximately 100-1,000 disposable batteries, reducing environmental waste by 28 times less global warming impact

- Healthcare facilities should adopt a hybrid approach: rechargeable batteries for high-use devices, disposables for emergency and sterile equipment

The optimal battery strategy balances immediate convenience with long-term economics, ensuring both cost savings and reliable medical device operation while minimizing environmental impact.

FAQs

Q1. Are rechargeable batteries more cost-effective for medical devices? Rechargeable batteries can save up to $100 annually after the initial investment. They become cost-effective after just 5-6 recharge cycles compared to disposables, making them more economical for frequently used medical devices.

Q2. How do rechargeable batteries compare to disposables in terms of environmental impact? Rechargeable batteries have a significantly lower environmental impact. Each rechargeable battery can replace 100-1,000 disposable batteries, reducing waste and environmental contamination. They produce 28 times less impact on global warming compared to disposables.

Q3. Which type of battery is better for emergency medical equipment? Disposable batteries are generally better for emergency medical equipment due to their long shelf life of up to 10 years. They provide immediate power without the need for charging, making them ideal for infrequently used but critical devices.

Q4. How long do rechargeable batteries last in medical devices like hearing aids? Rechargeable batteries in hearing aids typically provide 24-30 hours of continuous power on a single charge. They can last for about 300-500 charge cycles or 2-3 years before needing replacement.

Q5. What’s the best approach for battery management in healthcare settings? The optimal approach involves a balanced strategy—using rechargeable batteries for high-use devices while maintaining disposable options for emergency and specialized applications. This maximizes cost savings, minimizes environmental impact, and ensures reliable operation of essential medical equipment.

Image Source:

Image Source:  Image Source:

Image Source: