You see agricultural robots reshaping agriculture at a rapid pace. The global market reached nearly USD 15 billion in 2024, with projections soaring past USD 88 billion by 2032. High-capacity lithium battery packs deliver longer lifespan, fast charging, and low maintenance, making all-day operation possible.

Advantage | Description |

|---|---|

Higher Energy Density | More power in a lighter package, boosting efficiency in agriculture. |

Longer Lifespan | Fewer replacements, lower downtime for your operations. |

Fast Charging | Rapid charging keeps your agricultural robots in the field. |

Low Maintenance | Minimal upkeep fits busy agriculture schedules. |

Environmental Benefits | Eco-friendly batteries support sustainable agriculture. |

Solar-powered solutions further drive sustainability, reducing reliance on traditional energy and cutting operating costs. |

Key Takeaways

High-capacity lithium batteries enhance agricultural robot efficiency by providing longer operation times and faster charging, reducing downtime.

Choosing the right battery chemistry, like NCA or LFP, can significantly improve the performance and lifespan of agricultural robots, ensuring reliable operation in various conditions.

Solar-powered robotics not only reduce reliance on fossil fuels but also lower operational costs, allowing for sustainable farming practices.

Advanced battery management systems monitor performance and health, extending battery life and ensuring safe operation for agricultural automation.

Investing in high-capacity batteries and solar integration can lead to significant cost savings and increased productivity in agricultural operations.

All-Day Power for Agricultural Robots

1.1 Energy Demands

You face a wide range of energy demands when deploying agricultural robots across different tasks in agriculture. Planting robots often rely on solar energy and advanced navigation systems to cover large fields efficiently. Harvesting robots require robust machine learning hardware and high-performance motors to handle crops quickly and accurately. Monitoring robots, especially drones, depend on battery technology and sensor integration for continuous data collection. Each task places unique demands on the agriculture battery system, making energy management a critical factor in automation. You must select the right cusotm lithium battery to match the operational profile of your autonomous systems and robotic automation needs.

1.2 Lithium Battery Advantage

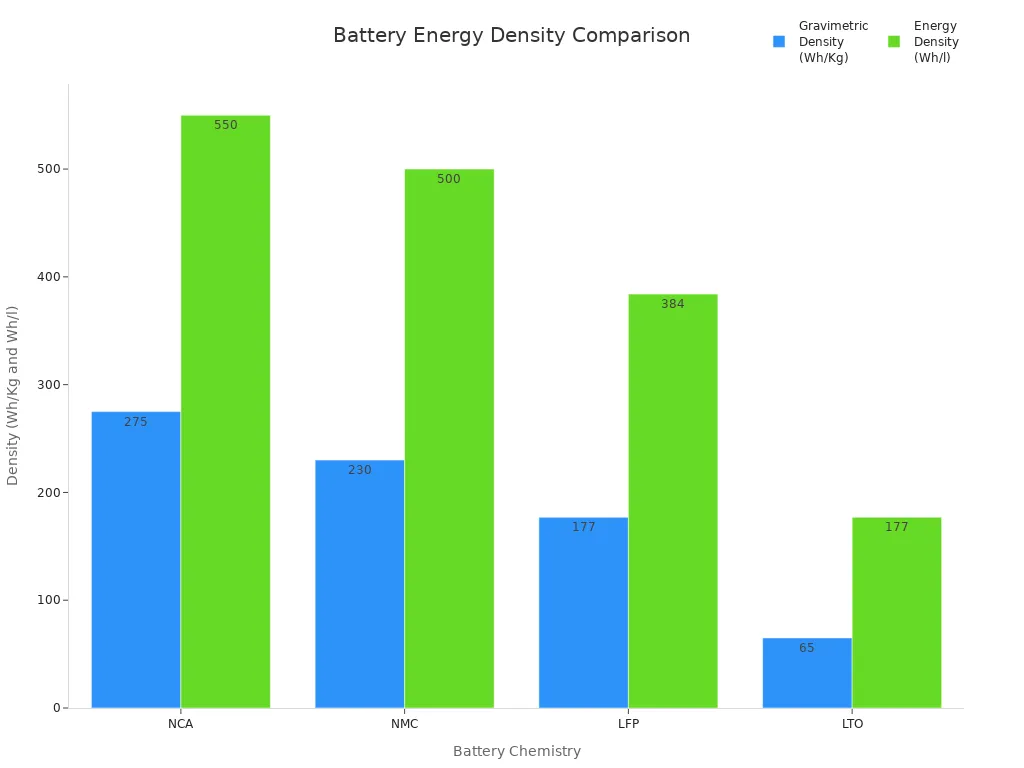

Lithium agriculture battery packs deliver superior performance for agricultural robots. You benefit from high energy density, which means more power in a compact package. This advantage allows your autonomous systems to operate longer without frequent recharging, boosting efficiency and productivity in agriculture. The following table compares standardized lithium battery chemistries used in robotic systems and automation:

Battery Chemistry | Gravimetric Density (Wh/Kg) | Energy Density (Wh/l) | Life Cycles |

|---|---|---|---|

NCA | 250-300 | 550 | 1000 |

NMC | 220-240 | 500 | 2000 |

LFP | 177 | 384 | >4000 |

LTO | 60-70 | 177 | 15000-20000 |

You see that lithium agriculture battery chemistries such as NCA and NMC offer high energy density, making them ideal for autonomous agricultural robots that require all-day operation. LFP batteries provide longer life cycles, which is valuable for robotic systems in harsh field conditions. LTO batteries excel in durability and cycle life, supporting automation in medical, security, and infrastructure sectors where reliability is essential.

Tip: Choosing the right lithium agriculture battery chemistry can maximize efficiency and reduce downtime in your automation projects.

Lithium agriculture battery packs also improve durability and lifespan for agricultural robots. You experience minimal maintenance requirements, greater longevity, and enhanced durability. These batteries withstand environmental stress and vibrations, which are common in agriculture. You can discharge lithium agriculture battery packs to low capacity without significant performance loss, ensuring your autonomous systems remain operational throughout the day.

Minimal maintenance requirements

Greater longevity with over 2,000 cycles

Enhanced durability against field conditions

1.3 Compact Design

Compact lithium agriculture battery design plays a vital role in the maneuverability and operational efficiency of agricultural robots. You benefit from lighter robotic systems that can navigate fields with ease, reducing soil compaction and improving crop health. The following table highlights key design considerations for integrating high-capacity batteries into compact autonomous systems:

Design Consideration | Description |

|---|---|

Smart Battery Management System (BMS) | Monitors, protects, communicates, and controls the battery pack in real time. |

Safe Voltage Limits | Maintains safe voltage across each cell to prevent damage. |

Current Regulation | Ensures proper current flow during charging and discharging. |

Temperature Monitoring | Protects against overheating and thermal runaway. |

Cell Balancing | Maximizes capacity and lifespan by ensuring even aging of cells. |

State-of-Charge (SOC) and State-of-Health (SOH) | Provides estimations for battery management and maintenance. |

Efficiency Optimization | Reduces energy waste through load-matched energy supply. |

Safety and Protection | Lowers risk of fire and failure during operation. |

Extended Battery Lifespan | Increases usable lifespan by preventing excessive use of individual cells. |

Data and Diagnostics | Offers real-time diagnostics and performance logs for maintenance. |

You see that integrating smart BMS and safety features into lithium agriculture battery packs ensures reliable operation for autonomous agricultural robots. These design elements optimize efficiency, extend battery lifespan, and provide real-time diagnostics for predictive maintenance in automation.

The compact design of lithium agriculture battery packs also affects the weight and maneuverability of robotic systems. You achieve optimal balance between performance and weight, enabling longer working times and improved efficiency for agricultural tasks. Faster recharge times enhance operational readiness, allowing your autonomous systems to return to the field quickly. Compact lithium agriculture battery packs suit both large-scale and smaller, noise-sensitive farming projects, supporting a wide range of automation applications in agriculture, medical, security, and industrial sectors.

Battery Technology in Automation

2.1 Lithium-Ion and LiFePO4

You rely on lithium battery packs for agricultural automation because they deliver reliable power and long service life. When you compare lithium-ion and LiFePO4 batteries, you see clear differences in safety, energy density, and lifespan. The table below highlights these technical aspects using standardized terminology:

Feature | Lithium-Ion (NMC, LCO, LMO) | LiFePO4 |

|---|---|---|

Safety | Moderate risk of thermal runaway | Stable chemistry, high safety |

Energy Density | 45–120 Wh/lb | 40–55 Wh/lb |

Weight | Lighter | Slightly heavier |

Temperature Range | 32°F–113°F | -4°F–140°F |

Lifespan | ~500 cycles | Thousands of cycles |

Cost | Lower initial cost | Higher, but justified |

Self-Discharge Rate | Higher | 1–3% per month |

Voltage | 3.6–3.7V per cell | ~3.2V per cell |

LiFePO4 batteries stand out for their robust safety profile. You can operate them in extreme environments without worrying about overheating or fire hazards. Their stable P-O bond resists decomposition, even during overcharging or high temperatures. This makes LiFePO4 ideal for agricultural robots, medical devices, and security systems that demand reliability.

2.2 Battery Management Systems

You maximize uptime and safety in your agricultural robots by using advanced battery management systems. These systems monitor each cell, regulate temperature, and balance charge distribution. You benefit from features such as:

State of Charge (SOC) estimation for accurate runtime prediction

State of Health (SOH) monitoring to prevent failures

Thermal management to avoid overheating

Real-time diagnostics for early fault detection

Smart battery management integrates with AI and remote monitoring, enabling predictive maintenance. You can plan service schedules and avoid unexpected downtime.

Tip: Battery management helps you extend battery life and maintain safe operation in industrial, medical, and infrastructure applications.

2.3 Regenerative Braking

You improve energy efficiency in field operations by using regenerative braking. Agricultural robots equipped with BLDC motors capture braking energy and reuse it, reducing electricity consumption. The table below shows key efficiency gains:

Factor | Description |

|---|---|

Higher Efficiency Ratings | BLDC motors reach 85–90% efficiency, outperforming traditional motors |

Regenerative Capabilities | Systems recover braking energy, lowering fuel or electricity costs |

Optimized Torque Delivery | Advanced controls match torque precisely, minimizing power waste |

Reduced Idle Energy Losses | BLDC motors draw minimal current when idle, unlike combustion engines |

You see these benefits in robotics, transportation, and industrial automation. Regenerative braking not only saves energy but also extends battery life, supporting all-day operation for your agricultural robots.

Solar-Powered Robotics in Agriculture

3.1 Solar Integration

You see solar-powered robotics transforming agriculture by enabling autonomous machines to operate for extended periods. FarmDroid FD20 and Aigen Element stand out as successful examples.

FarmDroid FD20 uses solar panels to perform seeding and weeding with high accuracy.

Aigen Element operates for up to 14 hours daily, powered entirely by solar energy, and aims to minimize chemical usage.

FarmDroid FD20 features four solar panels that generate up to 1.6 kWh. These panels store enough energy for 18–24 hours of continuous operation. You benefit from robots that work autonomously, even in remote fields, without external charging. Solar-powered robotics in agriculture help you reduce reliance on fossil fuels and lower operational costs. You can deploy these robots in all seasons, maximizing productivity.

Tip: Solar-powered systems offer maintenance-free operation and reduce downtime, keeping your robots in the field longer.

3.2 Inductive Charging

You improve efficiency in solar-powered robotics by using inductive charging. This technology enables hands-free, autonomous charging, which is essential in agriculture. You avoid the hassle of manual charging and minimize wear and tear. The table below outlines key technical requirements for inductive charging in agricultural robotics:

Requirement | Description |

|---|---|

Weatherproof systems | IP 65 certification resists moisture, dust, and dirt. |

Maintenance-free operation | No regular maintenance needed, reducing downtime. |

Compatibility with battery types | Supports various batteries, especially lithium-ion packs. |

Position tolerance | 40mm tolerance in every direction for effective charging. |

Charging speed | 3 kW for efficient energy supply. |

Omnidirectional charging | Charges from any direction, no precise alignment required. |

Data transmission | Monitors charging status and performance. |

No wear and tear | No mechanical contacts, minimizing maintenance needs. |

Inductive charging systems in solar-powered robotics help you lower operational expenses. You keep your robots running efficiently, even in harsh agricultural environments.

3.3 CO2-Neutral Operation

You achieve CO2-neutral operation with solar-powered robotics in agriculture. These robots use renewable energy to reduce carbon emissions and support sustainable farming. Agrivoltaic systems can lower your farm’s carbon footprint by 25–30%. Solar panels also conserve water by reducing evaporation and improve soil health by maintaining temperature and organic carbon levels. Certain crops benefit from the shade provided by solar panels, which can increase yields.

Benefit Type | Description |

|---|---|

Economic Diversification | Generate income through power purchase agreements and renewable energy credits. |

Carbon Footprint Reduction | 25–30% reduction in carbon emissions. |

Water Conservation | Up to 30% less water evaporation, improving irrigation efficiency. |

Soil Health Improvement | Maintains soil temperature and organic carbon levels. |

Enhanced Crop Yields | Shade from panels can increase crop value. |

You support sustainability and renewable energy goals by integrating solar-powered robotics into your operations. For more on sustainability, visit Our Approach to Sustainability.

Benefits for Automation and Industry

4.1 Productivity Gains

You experience remarkable productivity gains when you deploy agricultural robots powered by advanced agriculture battery solutions. These robots help you reduce chemical use, which leads to healthier crops and a safer environment. You can weed up to 5,000 acres in a season, demonstrating significant operational efficiency. Twenty farmers now rely on these robots, showing a growing acceptance of automation in agriculture. You see how precision farming and robotics increase farming efficiency and allow you to complete more work with fewer resources.

Healthier crops due to reduced chemical use

Ability to weed thousands of acres per season

Growing adoption among professional farmers

4.2 Reduced Downtime

You minimize downtime in agriculture by using high-capacity lithium battery packs and smart agriculture battery solutions. These batteries power autonomous tractors, drones, and robotic systems, which enhance efficiency and lower labor costs. Electric tractors reach up to 80% energy conversion efficiency, compared to traditional diesel models. This improvement leads to lower fuel and maintenance costs. Autonomous tractors use AI, GPS, and machine learning to perform essential tasks without human intervention. You benefit from continuous operation and less downtime, which boosts farming efficiency.

Tip: Advanced agriculture battery solutions keep your equipment running longer and reduce the need for frequent charging or repairs.

4.3 Sustainability

You support sustainable farming by integrating lithium and solar-powered agricultural robots into your operations. Solar-powered robots assess soil conditions and manage irrigation systems, activating water delivery only when necessary. This approach conserves water and ensures continuous monitoring without extra energy expenses. You also see these sustainability benefits:

Reduced pesticide and chemical use, protecting ecosystems

Optimized water distribution and conservation

Lower carbon footprint from electric robots

Cost savings and resource optimization

Eco-friendly weed management

Sustainable soil management

Data-driven decision making for sustainability

4.4 Cost Efficiency

You achieve cost efficiency in agriculture by using high-capacity batteries and solar integration. Agriculture battery solutions help you lower energy costs and protect your business from rising utility rates. The table below highlights key cost benefits:

Benefit | Description |

|---|---|

Energy Cost Reduction | Solar battery systems can reduce farm energy costs by 30-50%, leading to predictable expenses. |

Resilience Against Power Outages | Provides farms with the ability to operate essential equipment regardless of grid conditions. |

Helps farmers avoid the impact of increasing energy costs, which have risen 5-7% annually. |

You see predictable expenses and greater resilience in your operations. Agriculture battery solutions allow you to optimize resources and maintain essential equipment, even during power outages.

Challenges and Solutions

5.1 Battery Lifespan

You face several factors that affect the lifespan of lithium battery packs in agricultural robots. The type and capacity of the battery play a major role. Lithium-ion batteries offer high energy density and lightweight properties, which make them popular in robotics, medical devices, and security systems. The capacity, measured in milliampere-hours (mAh), determines how much energy your robots can store and how long they can operate. Weather conditions also impact battery performance. Extreme temperatures, strong winds, and precipitation can shorten battery life and reduce efficiency. You must select batteries with robust chemistries and design systems that protect against harsh environments.

Type and capacity of lithium battery

Weather conditions affect battery performance

Tip: Regular monitoring and maintenance help you extend battery lifespan and ensure reliable operation in the field.

5.2 Charging Infrastructure

You need reliable charging infrastructure to support all-day operations for agricultural robots. Fast-charging stations and inductive charging pads allow you to recharge lithium battery packs quickly and efficiently. You can deploy mobile charging units in remote areas, which reduces downtime and increases productivity. Smart charging systems monitor battery health and optimize charging cycles. You must plan for scalable infrastructure that supports future expansion and integrates with renewable energy sources. This approach benefits industrial, medical, and infrastructure sectors that rely on uninterrupted power.

5.3 Safety and Recycling

You must follow strict safety and recycling protocols for lithium battery packs in agricultural automation. Proper handling and storage prevent accidents and environmental harm. The table below summarizes key safety procedures:

Safety Procedure | Description |

|---|---|

Terminal Isolation | Use tape to cover terminals and prevent short circuits. |

Damage Prevention | Handle batteries carefully to avoid breaking them. |

Proper Storage Conditions | Store batteries in dry, ventilated areas away from heat. |

Emergency Preparedness | Have a plan for emergencies and contact fire services. |

Governments now require safer disposal methods. The U.S. EPA classifies most lithium-ion batteries as hazardous waste. You must comply with these regulations to protect your business and the environment. Recycling programs track the volume of batteries collected and measure material recovery rates. These efforts help you recover valuable metals and reduce harm. You can review our company’s conflict minerals policy here.

5.4 Investment Return

You want to maximize your investment in lithium battery packs for agricultural robots. High-capacity batteries reduce operational costs and improve productivity. You see faster returns when you use batteries with longer lifespans and efficient charging systems. Recycling programs and compliance with safety standards protect your assets and reputation. You can measure success using key performance indicators such as volume of batteries collected, material recovery rate, and customer satisfaction score. These metrics help you evaluate the effectiveness of your battery management strategy and support sustainable growth in automation and industry.

Future Trends in Agricultural Robots

6.1 Next-Gen Batteries

You will see rapid progress in lithium battery technology for agriculture. Manufacturers now develop solid-state batteries that offer higher energy density and improved safety. These batteries can power agricultural robots for longer periods, even in harsh field conditions. You can expect faster charging times and greater resistance to temperature extremes. In the future, you may use lithium-sulfur and silicon-anode batteries, which promise lighter weight and longer life cycles. These advancements will help you deploy robots in agriculture, medical, and security system applications with greater reliability.

6.2 Smart Analytics

You can harness smart analytics to optimize battery performance in agriculture. Advanced sensors and AI-driven software now monitor battery health, predict failures, and suggest maintenance schedules. You receive real-time data on energy consumption and battery status. This information helps you plan operations and reduce downtime. In industrial and infrastructure sectors, smart analytics also support predictive maintenance, which extends the lifespan of lithium battery packs and improves efficiency.

6.3 Renewable Integration

You will benefit from deeper integration of renewable energy in agriculture. Solar panels and wind turbines now work together with lithium battery packs to power agricultural robots. You can store excess energy during the day and use it at night or during cloudy weather. This approach reduces your reliance on fossil fuels and supports sustainable agriculture. In the future, you may see more farms using microgrids that combine renewables and batteries for reliable, off-grid power.

6.4 Automation Expansion

You will witness the expansion of automation across agriculture and related industries. Agricultural robots will handle more complex tasks, such as precision planting, targeted spraying, and autonomous harvesting. You can expect to see robots working in medical, security, and transportation sectors as well. Lithium battery packs will remain central to these advances, providing the power and flexibility needed for continuous operation. As automation grows, you will achieve higher productivity and greater sustainability in agriculture.

You see high-capacity lithium battery packs and solar-powered robotics changing agriculture. These technologies help you boost productivity, cut costs, and support sustainability. You face challenges with battery lifespan and charging, but new solutions keep improving. You can expect more growth in agriculture as automation expands. You should invest in advanced battery systems to lead the future of agricultural robots.

FAQ

What makes lithium battery packs ideal for agricultural robots?

Lithium battery packs offer high energy density and long cycle life. You can power robots for extended periods. These batteries withstand harsh field conditions and require minimal maintenance. You gain reliable performance and reduced downtime in agricultural automation.

How do battery management systems improve safety and efficiency?

Battery management systems monitor cell voltage, temperature, and charge levels. You receive real-time diagnostics and alerts. These systems prevent overheating and extend battery lifespan. You maintain safe operation and maximize uptime for your robotic equipment.

Can you use lithium battery packs in other industries?

You can deploy lithium battery packs in medical devices, security systems, industrial automation, and transportation. These batteries deliver consistent power, fast charging, and durability. You benefit from reliable energy solutions across multiple sectors.

What are the main challenges with lithium battery recycling?

You face strict regulations for lithium battery disposal. Safe recycling requires terminal isolation, damage prevention, and proper storage. You must follow government guidelines to recover valuable materials and protect the environment.

How does solar integration support all-day robot operation?

Solar panels charge lithium battery packs throughout the day. You achieve continuous operation without relying on grid power. This approach reduces energy costs and supports sustainable farming practices.