Battery cell balancing plays a critical role in maximizing performance, safety, and lifespan across lithium ion batteries used in electric vehicles, medical devices, robotics, and industrial infrastructure. Imbalanced cells can reduce battery pack lifespan by up to 30%, especially in chemistries like LiFePO4 or NMC. Proper balancing prevents dangerous conditions such as overheating and fire. Many in the industry mistakenly believe that balancing alone solves all battery issues, but frequent balancing cycles and poor cell quality can still accelerate degradation. Reliable battery cell balancing ensures efficient operation, superior safety margins, and durable lithium ion batteries for demanding applications.

Key Takeaways

Battery cell balancing keeps all cells in a lithium battery pack at similar charge levels, which helps the battery work better and last longer.

Active balancing moves energy between cells to save power and reduce heat, making batteries safer and extending their lifespan compared to passive balancing.

Proper balancing prevents dangerous problems like overheating, fires, and sudden battery failures, especially in electric vehicles and medical devices.

Imbalanced cells cause efficiency loss and faster wear, reducing battery capacity and increasing maintenance costs.

Battery management systems monitor cells continuously and use smart balancing methods to improve battery safety, performance, and reliability.

Part 1: Battery Cell Balancing

1.1 Definition and Purpose

Battery cell balancing refers to the process of equalizing the voltage or state of charge (SoC) among all cells in a lithium ion battery pack. This process ensures that each cell operates within safe limits, preventing overcharge or deep discharge. In scientific literature, battery cell balancing is recognized as a critical function within any battery management system. The main objectives include:

Preventing overcharge and overdischarge of individual cells, which can lead to capacity loss or battery failure.

Maximizing the overall capacity and performance of the battery pack by ensuring all cells contribute fully.

Extending the lifespan of lithium ion batteries by protecting cells from damaging charge conditions.

Ensuring uniform performance across all cells for reliable power delivery in real-world applications.

Battery cell balancing is essential for lithium ion batteries used in electric vehicles, medical devices, robotics, security systems, and industrial infrastructure. Regulatory standards such as UN 38.3 and IEC 62619 require battery management systems to monitor and manage cell voltages, making balancing a mandatory safety feature.

1.2 How It Works

Battery management systems employ two main types of balancing: passive and active cell balancing. Passive balancing, also called the shunt method, uses resistors to dissipate excess energy from higher charged cells as heat. This method is simple and cost-effective but wastes energy and can cause thermal issues. Active cell balancing transfers energy from higher charged cells to lower charged cells using components like capacitors, inductors, or DC-DC converters. This approach improves efficiency, reduces energy waste, and extends battery life, but it requires more complex circuitry.

Mechanism | Function | Key Features |

|---|---|---|

Passive Balancing | Dissipates excess energy as heat through resistors | Simple, low cost, energy wasted as heat, slower balancing |

Active Cell Balancing | Transfers energy between cells using advanced circuits | Complex, higher efficiency, faster balancing, extends battery life |

Battery management systems continuously monitor cell voltages and activate the appropriate balancing mechanism to maintain uniform SoC across all cells. This process is vital for lithium ion batteries in high-demand applications such as electric vehicles and energy storage systems.

1.3 Key Applications

Battery cell balancing plays a crucial role in a wide range of industries. Electric vehicles, including those using LiFePO4, NMC, LCO, LMO, and LTO chemistries, rely on advanced active cell balancing to maintain safety and performance during rapid charging and discharging cycles. In renewable energy storage and energy storage systems, passive balancing often suffices due to slower charge rates and longer cycles. Industrial automation, robotics, medical devices, security systems, and consumer electronics all depend on battery management systems with robust balancing features to ensure reliability and safety. For example, automated guided vehicles, drones, and healthcare equipment require precise control of cell voltages to prevent unexpected shutdowns or hazards. Battery cell balancing supports the long-term performance and safety of lithium ion batteries across these real-world applications.

Part 2: Battery Performance and Safety

2.1 Impact on Performance

Balancing directly influences battery performance in lithium ion batteries by ensuring each cell operates at optimal capacity. When cells remain balanced, the battery pack delivers consistent voltage and current, which supports stable operation in electric vehicles, medical devices, and industrial automation systems. In lithium ion batteries, balancing the capacity between the cathode and anode, often measured as the N/P ratio, plays a critical role in optimizing energy density and cycle stability. An N/P ratio close to one reduces early capacity loss caused by lithium depletion from the cathode. Maintaining an N/P ratio above one helps prevent lithium plating on the anode during charging, which otherwise accelerates aging and reduces battery lifespan.

Quantitative improvements in battery performance and capacity result from balancing the coulombic consumption ratio between the positive and negative electrodes. This balance minimizes uncompensated lithium inventory loss, a key factor in capacity fading. A global charge inventory compensation mechanism, enabled by balanced coulombic consumption, allows lithium lost at one electrode to be compensated by the other. This process sustains reversible capacity and extends cycle life. Experimental validation using Gr||NMC532 and silicon-based cells confirms that optimizing the i_p/i_n ratio reduces capacity fading. However, simply increasing i_p to match i_n can accelerate electrolyte depletion, so reducing i_n is a more practical approach. In summary, balancing quantitatively improves battery capacity retention and cycle life by minimizing lithium inventory loss through a self-regulating global compensation mechanism.

Note: In high-demand applications such as robotics and security systems, consistent battery performance ensures reliable operation and reduces the risk of unexpected shutdowns.

2.2 Extending Lifespan

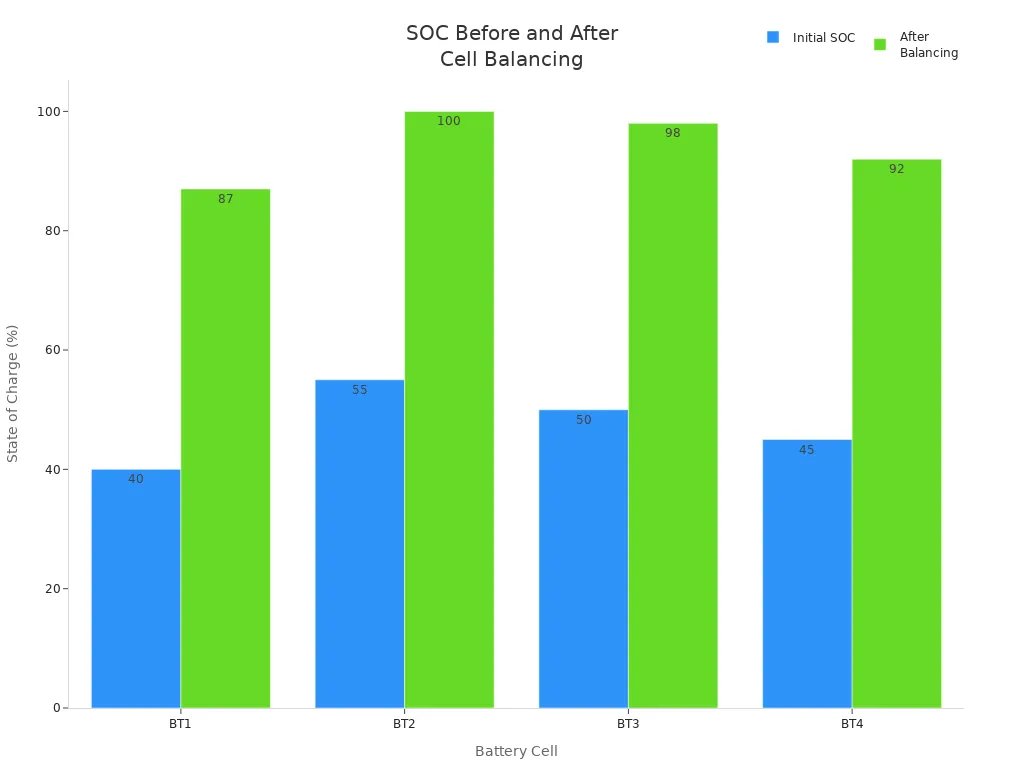

Active cell balancing significantly extends battery lifespan by improving the uniformity of state of charge (SOC) across all cells. When SOC disparities decrease, stress on individual cells reduces, which slows degradation and supports longer operational life. The following table presents simulation data that demonstrates the improvement in SOC after active cell balancing:

Battery Cell | Initial SOC (%) | SOC After Active Balancing (%) | SOC Improvement |

|---|---|---|---|

BT1 | 40 | 87 | +47 |

BT2 | 55 | 100 | +45 |

BT3 | 50 | 98 | +48 |

BT4 | 45 | 92 | +47 |

This data shows that active cell balancing improves SOC uniformity, which minimizes uneven aging and enhances battery health over time. Experimental studies on lithium ion batteries confirm that optimization-driven active cell balancing increases operational time by 3.2% under real current profiles. This improvement supports longer battery lifespan in electric vehicles, renewable energy storage, and industrial infrastructure. In medical and consumer electronics, extended lifespan reduces maintenance costs and increases device reliability.

2.3 Ensuring Safety

Balancing plays a vital role in maintaining safety in lithium ion batteries. Poor cell balancing can lead to several safety hazards, including:

Thermal runaway when one cell in a series enters a bad state and affects others, causing uncontrollable heating.

Battery damage and sudden fires resulting from instability caused by improper balancing.

Overcharge and overdischarge conditions that reduce battery life and increase safety risks.

Incorrect balancing, such as applying excessive balancing current or using an improper balancing mode, can cause overcurrent and irregular aging of cells. These issues may trigger thermal events, including thermal runaway. Since balancing often occurs when the battery is at rest, an overcharge event caused by poor balancing may not be detected in time by the battery management system, resulting in fires or explosions. Overcharged cells may trigger thermal runaway, a dangerous condition where the battery uncontrollably heats up and can catch fire or explode. Over-discharged cells can experience voltage reversal, which also poses safety hazards. Therefore, proper balancing directly reduces the risk of fires, explosions, and other safety incidents in lithium ion battery packs.

Tip: In sectors such as medical devices, robotics, and security systems, robust balancing strategies are essential to prevent catastrophic failures and ensure user safety.

Part 3: Risks of Cell Imbalance

3.1 Efficiency Loss

Cell imbalance in lithium ion batteries leads to significant efficiency loss across battery packs. When cells within a pack have different states of charge, the battery management system must limit the overall charge and discharge cycles to protect the weakest cell. This restriction reduces the usable capacity of the entire battery, impacting performance in electric vehicles, medical devices, and industrial automation. Even minor voltage differences between cells can cause the system to stop charging or discharging early, which lowers runtime and increases operational costs. In sectors such as robotics and security systems, this inefficiency can result in unexpected downtime and reduced productivity.

3.2 Accelerated Wear

Recent research demonstrates that cell imbalance accelerates wear in lithium ion batteries. Cells degrade at different rates due to manufacturing variabilities, temperature gradients, and self-discharge currents. Some cells reach minimum charge thresholds sooner, forcing the battery management system to intervene and limit usage. This process not only reduces usable capacity but also increases thermal wear. Repeated balancing operations, necessary to correct these imbalances, generate heat and further accelerate aging—much like repeated writing wears out memory storage. Industry experts note that even small voltage mismatches can trigger premature safety cutoffs, leading to early battery failure if left uncorrected. Optimized balancing strategies, such as wear leveling-aware active balancing, help minimize unnecessary balancing and reduce accelerated aging.

3.3 Safety Hazards

Cell imbalance introduces serious safety risks in lithium ion batteries, especially in large-scale applications like energy storage systems and industrial infrastructure. Safety standards such as NFPA 855 and UL 9540A highlight the dangers of thermal runaway and fire linked to imbalance. Key hazards include:

Variations in cell capacity and impedance generate heat and temperature gradients within the battery pack.

Uneven heat distribution accelerates degradation in hotter cells, increasing internal resistance differences.

These conditions raise the risk of thermal runaway, fire, and explosion.

Physical signs such as swelling, leaks, or overheating indicate imminent safety hazards requiring immediate battery pack retirement.

Cell imbalance causes uneven charge and discharge states, leading to overcharge or over-discharge.

Failures in battery energy storage systems can result in thermal risks including fire or explosion.

Proper thermal management and advanced balancing are essential to maintain safety and prevent hazardous failures in lithium ion batteries. Effective battery management systems monitor and regulate cell charge levels, improving reliability in medical, robotics, and security applications.

Part 4: Balancing Methods

4.1 Passive Balancing

Passive balancing remains a common method for managing lithium battery packs, especially in cost-sensitive applications. This technique uses resistors to dissipate excess energy from higher voltage cells as heat, equalizing the state of charge across all cells. The process is simple and cost-effective, making it suitable for systems where budget and simplicity take priority. However, passive balancing wastes energy, as the excess charge does not transfer to lower voltage cells but instead converts to heat. This inefficiency can lead to increased thermal management needs, especially in large battery systems for industrial or infrastructure use. Passive balancing typically operates during charging cycles and only balances the top 95% of cell capacity, which limits its impact on overall battery runtime. For lithium chemistries like LiFePO4, NMC, LCO, LMO, and LTO, passive balancing does not improve battery lifespan or runtime, but it can correct long-term mismatches in state of charge.

4.2 Active Balancing

Active cell balancing offers a more advanced approach for lithium battery packs in demanding sectors such as electric vehicles, renewable energy storage, robotics, and medical devices. This method transfers surplus charge from higher voltage cells to lower voltage cells using inductive or capacitive circuits. By redistributing energy instead of wasting it as heat, active cell balancing improves battery efficiency and extends cell life expectancy. The technique supports higher balancing currents, up to 6A, enabling faster and more effective balancing. Active cell balancing operates during both charging and discharging cycles, maximizing usable battery capacity and reducing cell stress. Although the method requires complex control algorithms and higher production costs due to additional power electronics, it delivers significant benefits for high-capacity and high-power battery systems. Reduced heat generation also lowers cooling requirements and fire risk, which is critical for safety in medical, security, and industrial applications.

Aspect | Passive Balancing | Active Cell Balancing |

|---|---|---|

Principle | Dissipates excess energy as heat via resistors | Transfers energy between cells using inductive/capacitive methods |

Energy Efficiency | Low (energy wasted as heat) | High (energy redistributed, improving efficiency) |

Complexity | Simple, low cost | Complex, higher cost due to additional power electronics |

Balancing Current | Typically low (~0.25A) | Higher (up to 6A), enabling faster balancing |

Operation Cycle | Usually only during charging | Can operate during both charging and discharging |

Thermal Management | Poor, generates heat | Better, less heat generated |

Impact on Battery Life | No improvement | Extends battery life by better balancing |

Speed of Balancing | Slower | Faster balancing |

Hardware Implementation | Uses resistors and bypass transistors | Uses charge shuttles, inductive converters, capacitors |

Application Suitability | Suitable for consistent cells, low-cost systems | Suitable for large capacity, high power, or cells with discrepancies |

4.3 Application Suitability

Selecting the right balancing method depends on the battery chemistry, application requirements, and system scale. Passive balancing fits low-cost, small-scale lithium battery packs with consistent cell quality, such as those in consumer electronics or basic security systems. It also works for chemistries that tolerate energy dissipation, like lead acid, but proves less effective for lithium-ion chemistries, which demand precise energy management. Active cell balancing is essential for high-capacity, high-power lithium battery packs used in grid storage, electric vehicles, and industrial automation. This method maximizes energy efficiency, extends battery lifespan, and enhances safety—key factors for sectors like medical, robotics, and infrastructure. Lithium-ion chemistries, including LiFePO4, NMC, LCO, LMO, and LTO, benefit most from active cell balancing due to their sensitivity to overcharge and the need for efficient energy use. For organizations prioritizing sustainability and responsible sourcing, advanced balancing supports longer battery life, reducing waste and the demand for conflict minerals. Learn more about sustainable battery practices and conflict minerals in the supply chain.

Part 5: Battery Management Systems

5.1 Monitoring and Control

Battery management systems serve as the central intelligence for lithium battery packs. They monitor each cell’s voltage, current, and temperature in real time. The system estimates state of charge (SOC) and state of health (SOH) to assess battery condition. Balancing occurs when the battery management system detects voltage or SOC differences among cells. The system moves charge from higher-voltage cells to lower-voltage cells, maintaining uniformity and preventing overcharge or deep discharge. This process maximizes usable battery capacity and extends battery lifespan. The battery management system also protects against thermal issues and electrical faults.

Key monitoring and control functions include:

Continuous cell voltage, current, and temperature tracking

SOC and SOH estimation for battery health

Passive and active balancing to equalize cell charge

Protection against overcharging, over-discharging, and overheating

5.2 Predictive Functions

Modern battery management systems use predictive analytics to enhance balancing effectiveness. These systems analyze battery usage, charging cycles, and environmental data to forecast cell behavior. Machine learning models predict SOC and SOH, allowing the battery management system to optimize balancing actions. Model Predictive Control (MPC) anticipates future cell states and adjusts balancing dynamically. Cloud-based analytics support anomaly detection and trend analysis, enabling early identification of cell imbalances. This proactive approach reduces unexpected failures and maximizes battery lifespan. Predictive maintenance powered by AI further extends battery life and lowers operational costs, especially in industrial and infrastructure applications.

Note: Predictive functions in battery management systems improve reliability in medical devices, robotics, and security systems by preventing downtime and supporting safe operation.

5.3 Use in Key Applications

Battery management systems play a vital role in electric vehicles and renewable energy storage. In electric vehicles, the system assures safety by preventing thermal runaway, fire, and explosions. It optimizes performance by balancing cells and monitoring SOC and SOH, which maximizes power output and efficiency. The battery management system extends battery life by managing charge cycles and temperature, reducing replacement costs.

Safety assurance

Optimization of battery performance

Extension of battery life

Enhanced energy efficiency

Fault diagnosis and proactive maintenance

Thermal management

Integration with vehicle systems

In renewable energy storage, battery management systems optimize longevity, safety, and efficiency. They actively manage charging, discharging, and balancing cell utilization. The system protects batteries from hazardous conditions and provides accurate SOC and SOH estimations. Advanced battery management systems use AI and machine learning to predict battery behavior and enhance performance. Real-world examples such as Tesla’s Powerwall and Hornsdale Power Reserve demonstrate fast response to outages and grid stabilization.

Circuit breakers, transfer switches, and fire suppression systems further enhance reliability.

Intelligent monitoring and predictive maintenance support grid stability and wider renewable energy adoption.

Battery management systems are essential for lithium battery packs in medical, robotics, security, consumer electronics, and industrial sectors. They ensure safe, efficient, and reliable operation across all major lithium chemistries, including LiFePO4, NMC, LCO, LMO, and LTO.

Effective cell balancing remains essential for extending battery lifespan, improving performance, and ensuring safety in lithium battery packs. Recent advancements include:

Active balancing methods that optimize energy transfer and reduce heat, supporting applications in electric vehicles, industrial infrastructure, and medical devices.

Battery management system innovations that enable real-time monitoring, predictive maintenance, and early anomaly detection, which minimize costly downtime.

B2B clients benefit from robust balancing strategies by reducing maintenance costs, enhancing operational reliability, and meeting the demands of evolving lithium chemistries such as LiFePO4 and NMC. Prioritizing advanced battery management system integration ensures long-term value and safety across critical sectors.

FAQ

What is the main benefit of cell balancing in lithium battery packs?

Cell balancing maximizes usable capacity and extends battery lifespan. It ensures each cell operates within safe voltage limits. Industries such as robotics, medical devices, and infrastructure rely on balanced packs for reliable performance and safety.

Which lithium chemistries require cell balancing?

Cell balancing is essential for LiFePO4, NMC, LCO, LMO, and LTO chemistries. These types show sensitivity to overcharge and deep discharge. Industrial and medical sectors use balancing to maintain safety and efficiency.

How does active balancing differ from passive balancing?

Feature | Passive Balancing | Active Balancing |

|---|---|---|

Energy Efficiency | Low | High |

Application | Consumer electronics | Electric vehicles, robotics |

Active balancing transfers energy between cells, improving efficiency and lifespan.

Can cell imbalance cause safety hazards?

Cell imbalance increases the risk of overheating, fire, and thermal runaway. Security systems and industrial infrastructure require robust battery management systems to prevent these hazards and maintain operational safety.

How do battery management systems support predictive maintenance?

Battery management systems use real-time monitoring and predictive analytics. They forecast cell behavior and detect anomalies early. This approach reduces downtime and supports reliability in medical, robotics, and industrial applications.