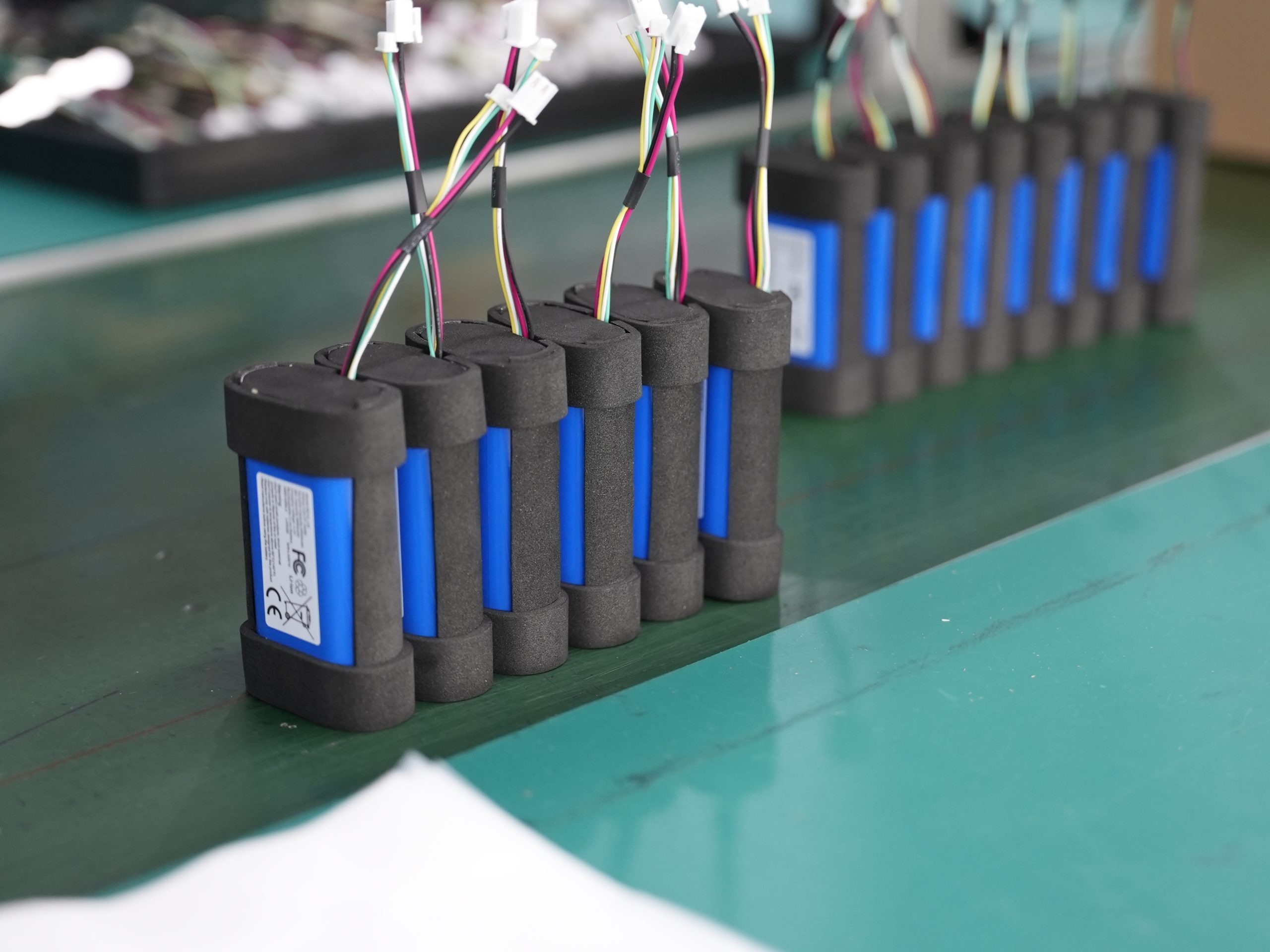

Outdoor patrol robots face battery challenges every day. You must ensure that lithium battery packs perform safely and reliably when exposed to high or low temperatures, dust, humidity, and rain. Battery management systems (BMS) help protect the cells and electronics during harsh conditions. In security, infrastructure, and industrial applications, you need robust solutions to keep robots running in unpredictable environments.

Key Takeaways

Outdoor patrol robots face battery challenges from extreme temperatures, dust, and moisture. Understanding these factors is crucial for reliable operation.

Use advanced battery management systems (BMS) to monitor temperature and protect lithium battery packs from overheating or overcooling.

Select the right battery chemistry for the environment. Advanced solid-state batteries perform better in extreme cold compared to conventional lithium-ion batteries.

Implement rugged designs with high IP ratings to protect batteries from dust and moisture. This prevents short circuits and corrosion.

Follow best practices for charging, such as slow charging and avoiding extreme temperatures, to extend battery life and ensure safe operation.

Part1: Battery Challenges

1.1 High Temperatures

You face significant battery challenges when outdoor patrol robots operate in extreme weather. High ambient temperatures accelerate the aging process of lithium battery packs. The heat increases the rate of chemical reactions inside the cells. This leads to faster degradation and can cause catastrophic failures like thermal runaway. Studies show that cycling lithium-ion batteries at 60°C, 80°C, and even 120°C changes the Solid Electrolyte Interphase (SEI), resulting in capacity loss and higher impedance. You see safety and performance issues as lithium plating becomes a main degradation mechanism. The battery’s internal resistance rises, and temperature spikes during operation shorten the battery’s life.

Temperature Range | Implication |

|---|---|

15°C – 35°C | Optimal operating range |

50°C | Harmful exposure |

Up to 80°C | Possible but causes degradation |

You must keep lithium battery packs within the optimal temperature range to avoid these battery challenges. In security and industrial robots, overheating can lead to sudden shutdowns or permanent damage. Intelligent battery management systems (BMS) monitor temperature and adjust charging rates to protect the cells.

1.2 Low Temperatures

Cold weather brings its own battery challenges. Lithium-ion batteries lose capacity and discharge rate as temperatures drop. You may notice that conventional lithium-ion batteries deliver only 66% of their rated capacity at -20°C and just 5% at -40°C. Advanced solid-state batteries (ASSBs) perform better in extreme cold. Low-temperature batteries can operate at 95-98% capacity below 0°C, but this drops to 50% at -30°C and 20% below -30°C. These batteries have low internal resistance, which helps maintain stable operation in demanding environmental conditions.

Conventional lithium-ion batteries see a capacity drop to 66% at -20°C and only 5% at -40°C.

Advanced solid-state batteries (ASSBs) maintain higher specific capacities in extreme cold.

Low-temperature batteries operate at 95-98% capacity below 0°C, reducing to 50% at -30°C and 20% below -30°C.

These batteries have low internal resistance, ensuring stable operation in demanding environments.

You need to select the right battery chemistry for outdoor patrol robots in cold climates. BMS systems help by regulating discharge rates and preventing over-drain, which protects the battery pack.

1.3 Humidity and Rain

Humidity and rain create battery challenges for outdoor patrol robots. Moisture can enter enclosures and damage batteries and electronic components. You risk short circuits and corrosion, which can lead to failures in security and infrastructure robots. Even with an IP55 rating, prolonged heavy rain may allow moisture to reach internal components.

Aspect | Description |

|---|---|

Protection Level | IP55 rating protects against limited dust ingress and low-pressure water jets. |

Limitations | Prolonged heavy rain can lead to moisture ingress, compromising internal components. |

Risk | Increased risk of battery and electronic component failures due to moisture. |

You should use rugged, IP65-rated enclosures to improve protection in harsh environmental conditions. BMS systems detect moisture and shut down the battery pack to prevent damage. In medical and industrial robots, reliable sealing is critical for uninterrupted operation.

Charging mechanisms pose significant challenges for outdoor patrol robots, especially in extreme conditions. For instance, contact-based charging can be problematic due to environmental factors like dust and mud, which can obstruct electrical contacts, leading to reduced current flow or complete failure. Additionally, water can cause short circuits, making the reliability of charging systems critical in rugged environments.

1.4 Dust Exposure

Dust exposure presents battery challenges in rugged environments. Fine particles can enter battery compartments and electronic housings. You may see connectors and contacts fail due to dust buildup. This leads to unreliable charging and increased risk of electrical faults. Dust can also block cooling vents, causing batteries to overheat.

Extreme temperatures can damage batteries if charged improperly. The use of intelligent charging systems that adjust voltage and current based on environmental conditions is crucial for maintaining battery health and longevity in harsh climates.

You should choose battery packs and enclosures with high IP ratings to prevent dust ingress. BMS systems monitor environmental conditions and alert you to potential risks. In consumer electronics and robotics, dust protection ensures longer battery life and fewer failures.

Part2: Charging Challenges

2.1 Temperature Effects

Charging lithium battery packs in extreme weather presents serious risks for outdoor patrol robots. You must understand how temperature impacts battery safety and lifespan. Charging at high temperatures can trigger dangerous chemical reactions inside the battery. Gas generation, swelling, venting, and even thermal runaway may occur. These problems threaten both the robot and its surroundings.

Risk Factor | Description | Typical Onset Temperature |

|---|---|---|

Gas Generation | CO, CO₂, CH₄, C₂H₄ from electrolyte breakdown | 90 °C+ |

Swelling & Venting | Pressure buildup ruptures safety valves | 90 °C+ |

Thermal Runaway | Rapid temperature rise, fire, or explosion | 60–132 °C |

Structural Failure | Battery pack components fail under thermal stress | 45 °C+ (large packs) |

You see real-world examples of these risks. Tesla Powerwall 2 (LFP version) lost 18% capacity over five years due to high temperature and charging conditions. BYD electric bus fleets experienced 25% range loss in three years from frequent fast charging at high temperature. Charging lithium-ion batteries in cold weather also causes problems. Lithium plating and increased internal resistance damage the battery and reduce its lifespan. You achieve optimal performance when you keep batteries within the 15°C to 35°C range. Exceeding this range accelerates aging and increases safety risks.

Tip: Always monitor battery temperature during charging. Use battery management systems (BMS) to regulate charging rates and prevent overheating or overcooling.

2.2 Dust and Moisture Risks

Dust and moisture create major challenges for charging systems in outdoor patrol robots. You often operate in environments where dust, mud, and water can reach charging connectors. Dust or mud can dirty the contact and reduce the current or stop it flowing altogether. Water can get in between the contacts and short them out. Moisture causes corrosion and may short out circuitry entirely. Dust accumulation leads to overheating, arcing, or even fire hazards over time.

Electronics require protection from both water and dust ingress with a high ingress protection rating (IP rating).

Moisture protection is crucial because it can lead to corrosion and short circuits.

Corrosion caused by exposure to chemicals is common in outdoor environments.

High relative humidity coupled with salt fog can severely damage electronic components and connectors.

You must select charging systems with robust sealing and high IP ratings. These solutions help prevent dust and moisture from entering connectors and battery compartments. In medical, security, and industrial robots, reliable charging is essential for uninterrupted operation. You should inspect connectors regularly and clean them to maintain performance.

2.3 Safe Charging Practices

You need to follow best practices for safe charging in outdoor environments. Charging batteries at a slow rate minimizes stress on battery cells. Avoid overnight charging to prevent overcharging. Use chargers rated for approximately one-fourth of the battery capacity to ensure safe charging. Store batteries in cool, shaded areas to maintain performance and avoid high temperatures. Regularly check and maintain batteries, including cleaning terminals.

Keep batteries cool to improve performance and lifespan.

Avoid exposing batteries to hot environments, such as inside cars on hot days.

Store batteries in shaded or temperature-controlled areas to regulate their temperature.

Prefer slow charging over quick charging for optimal battery health.

Charge batteries up to around 80% capacity to reduce stress and extend lifespan.

You must implement these solutions to protect lithium battery packs from damage in extreme weather. In robotics, security, and infrastructure applications, these practices help you achieve reliable operation and longer battery life. You should train your team to follow safe charging protocols and use advanced BMS for monitoring. These solutions ensure that your outdoor patrol robots remain operational, even in harsh conditions.

Part3: Protection Solutions

3.1 Thermal Management

You need effective thermal management to keep lithium battery packs safe in outdoor patrol robots. High or low temperatures can damage batteries and reduce their lifespan. You can choose from several cooling techniques:

Technique | Advantages | Disadvantages |

|---|---|---|

Passive Cooling | Low cost, low energy use, simple design | Limited in high heat or heavy load |

Active Cooling | Maintains optimal temperature well | Uses more energy, may fail mechanically |

Hybrid Systems | Flexible, improves thermal performance | Complex, higher initial cost |

Passive cooling works well in mild climates. Active cooling suits robots in hot environments or heavy-duty applications. Hybrid systems combine both for better control. You should select the right system based on your robot’s operating conditions.

3.2 Sealing and Enclosures

You must protect lithium battery packs from dust, rain, and extreme temperatures. IP65-rated enclosures offer strong protective measures:

The enclosure blocks dust, rain, snow, and high-pressure water jets, preventing corrosion and electrical failures.

UV and temperature-resistant materials shield batteries from sun damage and allow operation from -30°C to +60°C.

Fire-retardant materials reduce overheating risks and meet safety standards.

Ventilation options help prevent heat buildup and extend battery life.

These features keep your robots running in medical, security, and industrial settings.

3.3 BMS and Monitoring

You need advanced battery management systems (BMS) and remote monitoring for uninterrupted operation. BMS tracks battery health, temperature, and charge cycles. Remote monitoring uses continuous data collection and AI pattern detection to spot risks early. You can automate compliance reporting and reduce manual checks.

Evidence Type | Description |

|---|---|

Continuous Data Collection | Monitors robot performance and environment for early anomaly detection |

AI Pattern Detection | Identifies risks and forecasts incidents for predictive maintenance |

Compliance Reporting | Tags events by time and location for transparency and regulatory support |

Automated patrols and early detection of overheating help you avoid downtime. Learn more about BMS and monitoring.

3.4 Maintenance Strategies

You extend battery life by following smart maintenance strategies:

Charge batteries when they drop below 50% state-of-charge.

Let chargers complete the full cycle before disconnecting.

Always use dedicated chargers for lithium batteries.

Follow manufacturer charging procedures and monitor during charging.

Store batteries in cool, dry places away from sunlight.

Keep batteries charged to at least 50% when storing.

Avoid extreme temperatures during operation and transport.

Use battery management systems to monitor health and performance.

These steps help you maintain reliable operation in robotics, consumer electronics, and infrastructure applications.

Part4: Deployment Best Practices

4.1 Battery Selection

You need to select lithium battery packs that match the demands of outdoor environments. Start by evaluating the temperature range your patrol robots will face. Choose battery chemistries that maintain high performance in both extreme heat and cold. For example, advanced solid-state batteries deliver up to 95% capacity below 0°C, while conventional lithium-ion batteries may drop to 66% at -20°C. Look for packs with low internal resistance to support stable operation during rapid discharge cycles.

Consider waterproof design and waterproof materials when choosing battery packs. These features protect against rain, humidity, and dust, which are common technical challenges in outdoor patrol scenarios. IP65-rated enclosures offer strong protection and help maintain battery performance. You should also check compatibility with your robot’s battery management system (BMS) to ensure real-time monitoring and safety.

Tip: Always review manufacturer specifications for cycle life, charge rates, and environmental ratings. This step helps you maximize adaptability and reliability in medical, security, and industrial deployments.

4.2 Real-World Examples

You can learn valuable lessons from successful outdoor patrol robot deployments. Many robots operate in harsh conditions, including medical, robotics, security systems, infrastructure, consumer electronics, and industrial sectors.

The X30 robot dog supports emergency rescue and detection missions. Its fusion perception capability allows reliable performance in low visibility and adverse weather.

Security robots from Changsha Oneway Robot Co., Ltd. feature IP55 protection. Their waterproof materials and sealed construction resist light rain and dust. Ongoing improvements enhance their adaptability to extreme weather.

DEEP Robotics X30 robot dog achieves IP67 water and dust resistance. It operates between -20°C and 55°C and carries up to 85 kilograms, showing strong performance in outdoor environments.

You can see key lessons from these deployments:

Lesson Learned | Description |

|---|---|

Robust Design | You need strong construction for wet, muddy, or freezing conditions. |

Effective Integration | Ensure your robot works with existing systems and protocols. |

Operational Efficiency | Robots maintain performance when human patrols are limited by weather. |

Public Communication | Educate the public to address privacy concerns and build acceptance. |

Clear Goals | Define specific objectives for successful deployment. |

You should apply these best practices to improve your patrol robots’ reliability and adaptability in challenging outdoor environments.

Outdoor patrol robots face battery and charging challenges from extreme temperatures, dust, and rain. You improve reliability by using lithium battery packs with robust protection and smart monitoring.

Advanced sensors and AI analyze threats and monitor safety in real time.

Weatherproof construction and strong communication systems keep robots running in harsh environments.

Proactive maintenance and regular checks extend battery life.

You achieve dependable performance in medical, security, and industrial applications by following these best practices.

FAQ

What battery challenges do outdoor patrol robots face during heavy rain?

You encounter moisture risks when patrol robots operate in heavy rain. Water can enter enclosures and damage lithium battery packs. You must use IP65-rated protection to keep security robots running. Rain can cause short circuits and corrosion, especially in outdoor environments.

How does dust exposure affect lithium battery packs in outdoor patrol robots?

Dust can enter battery compartments and block cooling vents. You see overheating and electrical faults in patrol robots. Dust buildup on connectors causes charging failures. Security robots need sealed enclosures to prevent dust ingress during outdoor patrol missions.

Why is thermal management important for outdoor patrol robots?

You need thermal management to keep lithium battery packs safe. High temperatures speed up battery aging. Low temperatures reduce capacity. Security robots use cooling systems to maintain optimal performance during outdoor patrols in rain, heat, or cold.

What are best practices for charging lithium battery packs in outdoor patrol robots?

You should charge batteries slowly and avoid overnight charging. Store batteries in cool, dry places. Clean connectors regularly. Security robots need chargers with high IP ratings to prevent damage from dust and rain during outdoor patrol operations.

How do security robots maintain reliability in heavy rain and extreme weather?

You rely on rugged designs and advanced battery management systems. Security robots use waterproof materials and sealed enclosures. These features protect lithium battery packs from heavy rain, dust, and temperature swings during outdoor patrol missions in industrial and medical sectors.