Battery challenges often limit how long your service robots can operate, how far they travel, and how reliably they perform in shopping malls, restaurants, and healthcare. You rely on lithium battery packs to power robots for inventory management, customer service, and patient care. These packs offer stable energy output, smart battery management systems for safety, and a lightweight design for wearable robotics. Optimized battery systems help your robots run longer with fewer charge cycles, less downtime, and lower total cost of ownership. When you overcome battery limitations, you maximize robot utility and boost ROI across your organization.

Key Takeaways

Choose lithium battery chemistries like LiFePO4 for long-lasting performance and reliability in service robots.

Implement smart charging solutions to minimize downtime and enhance robot availability during peak operational hours.

Adopt modular battery designs for flexibility and easy maintenance, allowing quick replacements without significant interruptions.

Utilize advanced battery management systems to monitor health, optimize charge cycles, and extend battery lifespan.

Stay informed about emerging battery technologies like solid-state batteries to improve efficiency and reduce operational costs.

Part 1: Service Robots and Battery Needs

1.1 Shopping Malls

You depend on service robots in shopping malls to handle inventory tracking, security patrols, and customer assistance. These robots need reliable lithium battery packs, such as LiFePO4 or NMC, to support long hours of operation and frequent movement across large spaces. High energy density and stable platform voltage help your robots cover more ground without frequent recharging. You face battery challenges when robots must operate during peak shopping hours or navigate multiple floors. Modular battery designs and smart battery management systems can help you extend operational time and reduce downtime.

Tip: Choose lithium battery chemistries with high cycle life, like LiFePO4, to minimize replacement costs and improve robot reliability.

1.2 Restaurants

In restaurants, you use service robots for food delivery, table cleaning, and guest interaction. These robots require lightweight lithium battery packs, such as LCO or LMO, to move quickly and safely in crowded environments. Fast-charging solutions allow you to keep robots running during busy meal periods. You must balance battery size with energy needs to avoid frequent interruptions. Smart charging stations and battery management systems help you optimize charge cycles and prevent overcharging, which extends battery lifespan.

Common restaurant robot tasks:

Delivering food and drinks

Clearing tables

Guiding guests to seats

1.3 Healthcare

Healthcare robots assist you with patient monitoring, medication delivery, and sanitation. You rely on advanced lithium battery packs, such as NMC or solid-state, for high energy efficiency and safety. Battery challenges in healthcare settings can impact reliability and operational time. The following table shows how battery technologies affect robot performance in hospitals and clinics:

Aspect | Impact on Service Robots in Healthcare |

|---|---|

Energy Efficiency | Minimizes power consumption and extends battery life |

Power Conversion Technologies | Reduces energy loss, enhancing effective power usage |

Battery Management Systems | Regulates charge cycles and prevents overcharging, extending battery lifespan |

Fast-Charging Solutions | Minimizes downtime, ensuring longer operational periods |

You benefit from battery management systems that regulate charge cycles and prevent overcharging. Fast-charging solutions minimize downtime, so your robots can serve patients and staff more effectively. You improve safety and reliability by choosing lithium chemistries with stable voltage and long cycle life.

Part 2: Battery Challenges

2.1 Limited Battery Life

You face significant battery challenges when deploying service robots in shopping malls, restaurants, and healthcare facilities. Limited battery life restricts how long your robots can operate and how far they can travel, especially during energy-intensive tasks like security patrols, food delivery, or patient monitoring. Robots often require frequent charging, which leads to downtime and reduced productivity.

Note: Battery life varies by robot type and application. Longer battery life means fewer interruptions and higher efficiency.

Here is a comparison of average battery life for popular service robots:

Robot | Battery Life |

|---|---|

HolaBot | Up to 12 hours |

PuduBot | 10-24 hours |

Hospitality | Minimum 8 hours |

Energy-intensive tasks drain batteries faster, forcing you to schedule more frequent charging sessions. The table below shows how limited battery life and charging time impact operational efficiency:

Evidence Type | Description |

|---|---|

Limited Battery Life | Battery-powered robots often require frequent charging, leading to downtime and reduced productivity. |

Charging Time | Recharging batteries can be time-consuming, further impacting operational efficiency. |

When you select lithium battery packs, you must consider chemistry and performance differences. The following table compares common lithium chemistries used in service robots:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Level | Typical Application |

|---|---|---|---|---|---|

LiFePO4 | 3.2V | 90-160 | 2000+ | High | Medical, robotics |

NMC | 3.7V | 150-220 | 1000-2000 | Medium | Security, infrastructure |

LCO | 3.7V | 150-200 | 500-1000 | Low | Consumer electronics |

LMO | 3.7V | 100-150 | 500-1000 | Medium | Industrial, robotics |

LTO | 2.4V | 70-80 | 7000+ | Very High | Medical, infrastructure |

Solid-state | 3.7V | 250+ | 2000+ | Very High | Medical, robotics |

Lithium metal | 3.7V | 300+ | 1000+ | Medium | Advanced robotics |

2.2 Charging Infrastructure

You need robust charging infrastructure to keep your service robots running reliably. In commercial and healthcare settings, IP67-rated charging stations provide waterproof and dustproof protection. These stations operate safely in wet or dusty environments, which is critical for maintaining uptime and safety in public spaces.

You must plan for dedicated charging and maintenance areas. Many restaurants and shopping malls have space constraints that limit where you can install charging stations. Reliable Wi-Fi or 5G connectivity is essential for real-time coordination and remote monitoring of battery status.

Requirement | Description |

|---|---|

Space Constraints | Many restaurants may not have the layout to support robot navigation. |

Connectivity Dependence | Reliable Wi-Fi or 5G connectivity is essential for real-time coordination. |

Charging and Maintenance Stations | Dedicated areas are required for charging and performing maintenance on robots. |

Tip: Choose charging stations with rugged designs and smart features to minimize downtime and maximize safety.

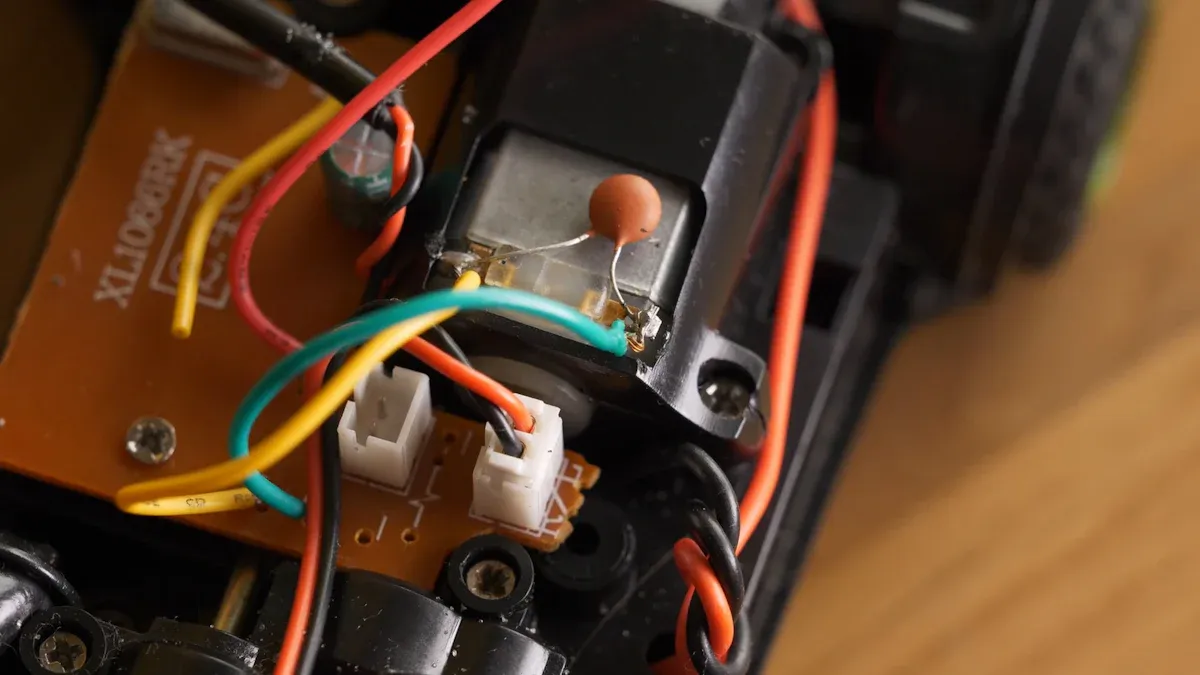

2.3 Maintenance

Battery maintenance presents ongoing challenges for your robot fleet. You must address issues like battery degradation, inaccurate state of charge estimation, uneven cell balancing, overheating, and safety risks. Environmental stress, such as dust or extreme temperatures, can accelerate battery aging and reduce reliability.

The table below summarizes frequent maintenance issues and solutions:

Challenge | Problem | BMS Solution |

|---|---|---|

Battery Degradation Over Time | Aging from large current draws, deep cycles, and stress | Monitoring SoH and usage trends for optimal charging |

Inaccurate State of Charge Estimation | Unexpected shutdowns due to inaccurate readings | Voltage-based estimation with coulomb counting |

Uneven Cell Balancing | Unbalanced cells cause premature failure and decreased capacity | Active or passive balancing to equalize voltage levels |

Overheating | Heat from high-power actuators affects performance | Temperature sensors for power throttling or cooling |

Safety Risks | Fires from overcharging or short circuits | Immediate disconnect and real-time problem identification |

Communication and Data Integration | Control system cannot maximize energy use without data | SMBUS or CANBUS for real-time battery condition |

Harsh Environmental Conditions | Dust, vibration, or extreme temperatures harm the battery | Ruggedized BMS and conformal coating for reliability |

In healthcare, maintenance requirements for battery systems impact operational costs. Longer-lasting batteries reduce the need for frequent replacements, lowering labor costs. Regular preventive maintenance can cut battery-related service calls by up to 50%. Delays in obtaining parts and equipment downtime due to dead batteries can increase operational costs significantly.

Evidence Type | Description |

|---|---|

Replacement Frequency | Longer-lasting batteries reduce the need for frequent replacements, lowering labor costs. |

Service Calls | Regular preventive maintenance can reduce battery-related service calls by up to 50%. |

Hidden Costs | Delays in obtaining parts and equipment downtime due to dead batteries can increase operational costs significantly. |

2.4 Downtime

Downtime from battery challenges directly affects your productivity and service quality. When robots stop to recharge or undergo maintenance, you lose valuable operational hours. In restaurants and shopping malls, robots like Cloi Room Service, Pudu Bellabot, and OrionStar LuckiBot enhance efficiency by delivering food orders and interacting with guests. If these robots experience downtime, staff must take over tasks, which reduces overall efficiency.

Cloi Room Service Robots deliver food orders directly to tables, allowing staff to focus on customer service.

Pudu Bellabot interacts with guests and delivers multiple items, freeing staff for critical tasks.

OrionStar LuckiBot increases delivery efficiency and customer satisfaction, showing the importance of operational robots in maintaining productivity.

The OrionStar LuckiBot can be up to three times more efficient in food delivery, which reduces wait times and improves customer satisfaction. When you minimize battery downtime, you maximize the value of your robot investment.

Alert: Battery downtime can disrupt your workflow and lower customer satisfaction. Plan for backup batteries and fast-charging solutions to keep robots running.

Part 3: Solutions and Opportunities

3.1 Lithium Battery Advances

You can overcome many battery challenges by adopting the latest lithium battery technologies. Advanced cathode and anode materials increase energy density, allowing your service robots to operate longer between charges. Innovations in battery architecture improve charging efficiency, so robots spend less time docked and more time working. Solid-state electrolytes extend battery lifespan and reliability, which is critical for healthcare and security robots. AI-driven optimization enables predictive maintenance, reducing unexpected downtime and improving overall performance.

Aspect | Improvement Description |

|---|---|

Energy Density | Advanced cathode and anode materials enhance the energy storage capacity of batteries. |

Charging Efficiency | Innovations in battery architectures lead to faster charging times. |

Lifespan | Solid-state electrolytes contribute to longer battery life and reliability. |

AI Integration | AI-driven optimization improves battery performance and predictive maintenance. |

New lithium battery designs, such as custom lithium battery packs and advanced battery management systems, significantly enhance the operational time and reliability of service robots in healthcare. These innovations focus on increasing energy density while ensuring safety, which is essential for the effective operation of rehabilitation robots. Custom battery packs can be tailored to fit the specific geometry of robots, improving their functionality and portability, which is crucial for wearable rehabilitation devices. Advanced BMS technology enhances the safety and durability of these robots, ensuring they can operate efficiently over extended periods.

Tip: Choose lithium chemistries like LiFePO4 and solid-state for medical and robotics applications. These options offer high cycle life and stable voltage, which support long-term reliability.

3.2 Smart Charging

Smart charging systems transform how you manage service robot fleets in shopping malls, restaurants, and healthcare. Dynamic charging orchestration aligns charging behavior with production pacing, optimizing energy use and reducing costs. Predictive maintenance features enable proactive battery care, which minimizes downtime and extends battery life. Enhanced uptime keeps robots available for more shifts, eliminating manual interventions.

Benefit | Description |

|---|---|

Dynamic Charging Orchestration | Aligns charging behavior with production pacing and optimizes energy use. |

Predictive Maintenance | Enables proactive maintenance and usage optimization, reducing downtime. |

Enhanced Uptime | Keeps robotic systems available for more uptime per shift, eliminating manual interventions. |

Wireless charging solutions improve safety by removing physical and electrical hazards. You create a clearer workspace without charging poles, reducing tripping risks. The absence of exposed connectors eliminates the risk of sparks or electrocution, which is vital in busy commercial and healthcare environments.

Evidence Description | Impact on Service Robots |

|---|---|

Fast-charging batteries enable continuous operation and eliminate battery swaps. | Reduces downtime by allowing robots to operate without interruptions for battery changes. |

In-process charging allows for up to 100% uptime. | Ensures that robots can work continuously without the need for mid-shift charging, enhancing productivity. |

Advanced system reliability and predictive maintenance eliminate operational disruptions. | Transforms operations into a resilient system that maintains peak performance, reducing costly downtime. |

Stable and predictable charging performance prevents degradation over time. | Improves battery longevity by maintaining charging speed and capacity, leading to increased operational efficiency. |

Note: Smart charging solutions help you address battery challenges by reducing downtime and improving battery longevity.

3.3 Energy Management

Effective energy management strategies optimize battery usage and extend the operational life of your service robots. Energy-aware orchestration maximizes the area robots can explore while minimizing energy consumption, resulting in up to 15% energy savings. Real-time feedback mechanisms adjust robot operations based on current battery levels and activity, which improves operational limits. Dynamic sensor management turns off sensors when not needed, saving energy and extending battery life.

Energy Management Strategy | Description | Energy Savings |

|---|---|---|

Energy-aware Orchestration | Maximizes explored area while minimizing energy consumption | ∼15% energy savings |

Real-time Feedback Mechanisms | Adjusts robot operations based on current battery levels and activity | Improved operational limits |

Dynamic Sensor Management | Turns off sensors when not needed to save energy | Extended battery life |

You can integrate advanced battery management systems to monitor battery health, optimize charge cycles, and prevent overcharging. These systems support predictive maintenance and real-time data integration, which are essential for maintaining high reliability in medical and industrial robots.

3.4 Modular Batteries

Modular battery designs offer you flexibility, scalability, and simplified maintenance for service robots in dynamic environments. You can customize battery modules to meet specific application needs, whether you operate in healthcare, security, or industrial sectors. Modular systems support rapid scalability by adding or rearranging modules to meet varying energy and power requirements. You simplify maintenance by replacing only the affected module, which reduces downtime and operational interruptions.

Modular batteries enhance customizability for specific application needs.

They contribute to environmental sustainability by allowing for efficient energy storage solutions.

You can expand modular systems as energy needs grow, making them suitable for dynamic environments.

Maintenance is simplified because faults can be isolated to individual modules, allowing for quick servicing.

Modular designs facilitate the integration of different cell chemistries, allowing for tailored performance and cost efficiency.

The modular approach supports design iteration with minimal disruption to manufacturing lines.

Alert: Modular battery systems help you address battery challenges by enabling rapid upgrades and minimizing downtime.

Case Study:

A hospital deployed modular lithium battery packs in its fleet of sanitation robots. When a module failed, technicians replaced only the affected unit, restoring full operation within minutes. This approach reduced maintenance costs and improved uptime, demonstrating the value of modular batteries in healthcare.

Part 4: Future Trends

4.1 Emerging Technologies

You see rapid advancements in battery technology shaping the future of service robots across shopping malls, restaurants, and healthcare. Lithium-ion batteries remain the dominant power source due to their high energy density and lightweight design. Solid-state batteries are emerging as a promising alternative, offering longer operational times and faster charging. Fuel cells and wireless charging systems also gain traction, supporting sustainable production and reducing downtime.

Battery Technology | Key Features | Impact on Service Robots |

|---|---|---|

Lithium-Ion Batteries | High energy density, lightweight | Dominant power source for robotics applications |

Solid-State Batteries | Higher energy density, faster charging | Longer operational times, improved safety |

Fuel Cells | Sustainable production processes | Mobile robots benefit from extended range |

Wireless Charging | Reduces downtime, improves productivity | Enhances robot availability |

Modular Battery Systems | Quick battery swaps without interrupting operations | Increases operational efficiency |

Microvast’s solid-state batteries improve safety by eliminating liquid electrolytes, which reduces risks of leaks and fires. You benefit from higher energy density and efficiency, enabling robots to operate longer and with greater reliability. Custom designs and flexible voltage configurations support advanced robotics in medical and industrial sectors.

Tip: Explore sustainable battery sourcing and recycling practices to future-proof your operations. Learn more about sustainability.

4.2 Integration with Facilities

You can enhance the efficiency and reliability of your robot fleets by integrating battery systems with facility infrastructure. Hospitals and shopping malls require uninterrupted power to avoid downtime and safety hazards. Reliable battery backup systems provide resilience during outages and support critical operations.

Battery backup power ensures continuous operation using stored energy from renewable sources.

Frequency regulation and voltage stability protect equipment and contribute to grid independence.

Integration with renewable energy sources promotes sustainability and reduces reliance on fossil fuels.

Fleet management software enables mission planning, scheduling, and real-time alerts. Autonomous inspection robots collect data and identify issues before they escalate, allowing technicians to focus on complex tasks. AI-powered predictive maintenance systems analyze data to forecast failures, improving reliability and reducing costs.

4.3 Business Models

You see new business models emerging around battery leasing and management for service robots. Battery-as-a-service (BaaS) allows you to lease batteries separately from robots, reducing initial capital expenditure and making fleet expansion more affordable. This model appeals to operators in healthcare and commercial sectors who want to lower upfront costs and improve flexibility.

Evidence Type | Details |

|---|---|

Initial Capital Expenditure | High initial costs for procurement and integration hinder market growth. |

Maintenance Costs | Ongoing maintenance averages around USD 10,000 per robot annually. |

Software and Sensor Upgrades | Additional expenses for upgrades increase total ownership costs. |

Innovative leasing and rental models help you manage costs and improve accessibility, especially for small and medium-sized enterprises. You can focus on operational efficiency and reliability while reducing financial risk.

You unlock the full potential of service robots in healthcare, shopping malls, and restaurants by addressing battery challenges. Investing in advanced lithium battery solutions increases performance and reliability, as shown below:

Evidence Description | Impact on Service Robots |

|---|---|

Solid-state lithium-air batteries can store three to four times more energy per unit weight than conventional lithium-ion batteries. | Increases energy density, allowing robots to carry less weight and perform more tasks. |

Multifunctional structural batteries can serve as both energy storage and structural components of robots. | Enhances design efficiency and functionality, improving overall robot performance and reliability. |

Ongoing battery innovations drive growth and efficiency in your operations. You benefit from longer operational periods, fast-charging, and eco-friendly technologies. As demand rises in sectors like healthcare and security, smart battery systems will shape the future of service robotics.

FAQ

What lithium battery chemistry works best for service robots in healthcare?

You should choose LiFePO4 or NMC batteries. These chemistries offer high cycle life, stable voltage, and strong safety. Hospitals benefit from longer operational periods and reduced maintenance.

Tip: LiFePO4 batteries provide over 2,000 cycles and 3.2V platform voltage.

How can you reduce downtime caused by battery charging?

You can use smart charging stations and modular battery packs. These solutions allow for quick swaps and fast charging.

Modular systems let you replace only the faulty module.

Smart charging reduces manual intervention.

Why is battery management important for robots in shopping malls?

Battery management systems (BMS) help you monitor charge cycles, prevent overcharging, and balance cells. This improves safety and extends battery life.

BMS ensures robots operate reliably during peak shopping hours.

What challenges do you face with battery maintenance in restaurants?

You often deal with battery degradation, inaccurate charge readings, and overheating. Regular preventive maintenance and advanced BMS help you avoid unexpected shutdowns and reduce service calls.

Challenge | Solution |

|---|---|

Degradation | Preventive checks |

Overheating | BMS monitoring |

Can you upgrade battery systems as your robot fleet grows?

Yes, modular lithium battery packs support easy upgrades. You can add or rearrange modules to meet new energy needs in security or industrial robots.

Note: Modular designs help you scale operations without major downtime.