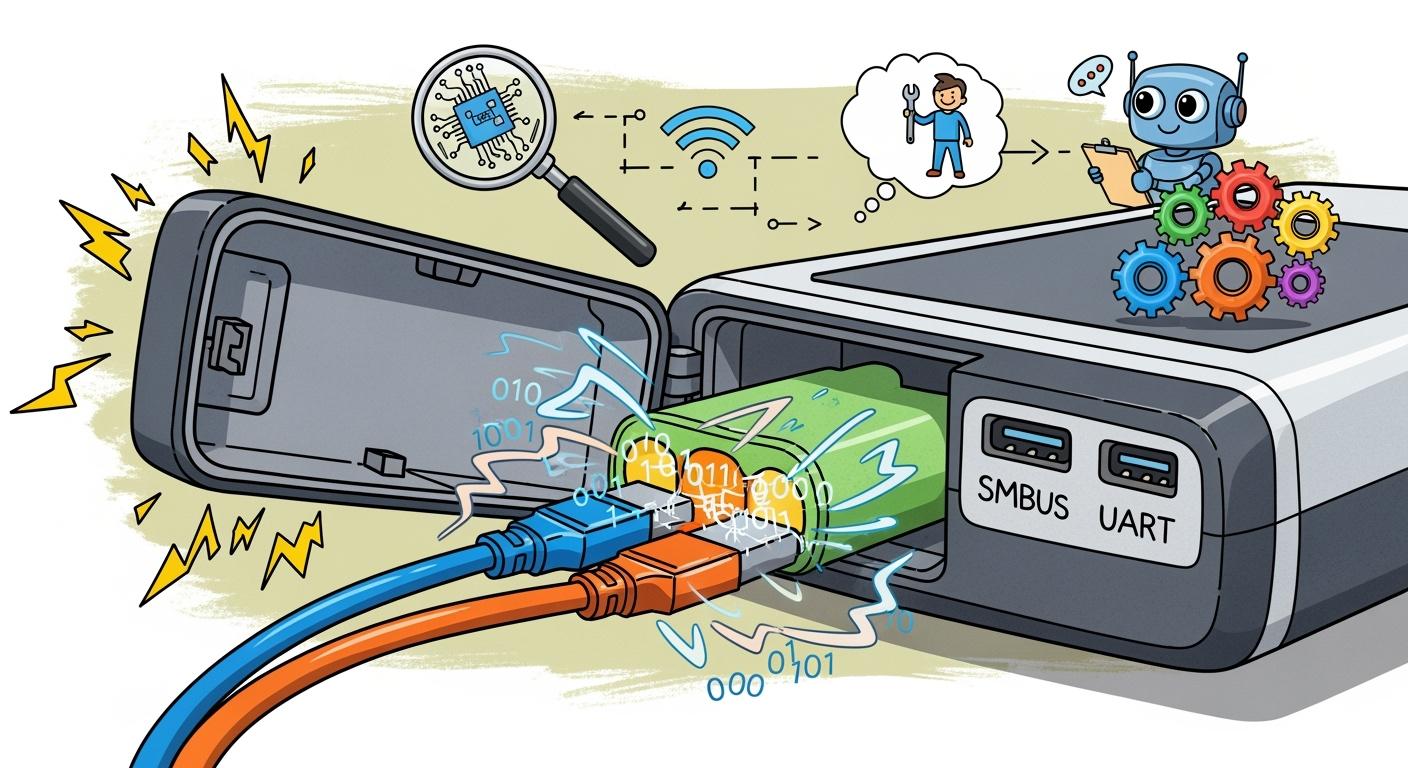

Smart inspection devices depend on battery communication interfaces to keep systems running smoothly. You use SMBus and UART to manage lithium battery packs, ensuring high reliability and efficient operation. These protocols allow your inspection technology to transmit critical battery data, which improves monitoring and diagnostics.

Communication protocols like SMBus and UART help maintain reliability and operational efficiency in lithium battery management.

Choosing the right interface directly affects the performance of your inspection device.

Key Takeaways

Use SMBus and UART to monitor battery health in real-time. This helps ensure your smart inspection devices operate safely and efficiently.

Choose the right communication interface based on your device needs. SMBus is ideal for master-slave setups, while UART offers flexible point-to-point connections.

Regularly check and configure key parameters like baud rate and data format. Proper setup reduces errors and enhances communication reliability.

Implement error-checking methods like checksums and parity. These practices help maintain data consistency and prevent communication issues.

Stay informed about emerging technologies in battery communication. Adopting new protocols can improve the performance and reliability of your smart inspection devices.

Part1: Applications of Battery Communication Interfaces

1.1 Battery Monitoring

You rely on battery communication interfaces to monitor the health and performance of lithium battery packs in smart inspection devices. These applications extend across industries such as medical equipment, robotics, infrastructure inspection, and industrial automation. When you use SMBus or UART, you gain access to real-time data about voltage, current, temperature, and state of charge. This information helps you maintain the safety and reliability of your devices, especially in large drone battery systems and smart bms platforms.

For example, in drone operations, battery monitoring ensures that your UAV can complete its mission without unexpected power loss. Smart bms solutions in drones and robotics use SMBus to communicate with controllers, providing accurate energy status and alerts for remote monitoring. You see similar applications in medical devices, where battery communication interfaces help maintain uninterrupted operation for critical equipment.

Tip: Regular battery monitoring using SMBus or UART can extend the cycle life of lithium battery packs and reduce downtime in your inspection devices.

Here is a table showing common applications of SMBus and UART interfaces in battery monitoring for smart inspection devices:

Interface | Application Examples |

|---|---|

SMBus | DJI smart batteries, Ardupilot flight controllers |

UART | Custom smart bms modules for industrial robots, security drones |

1.2 Diagnostics and Control

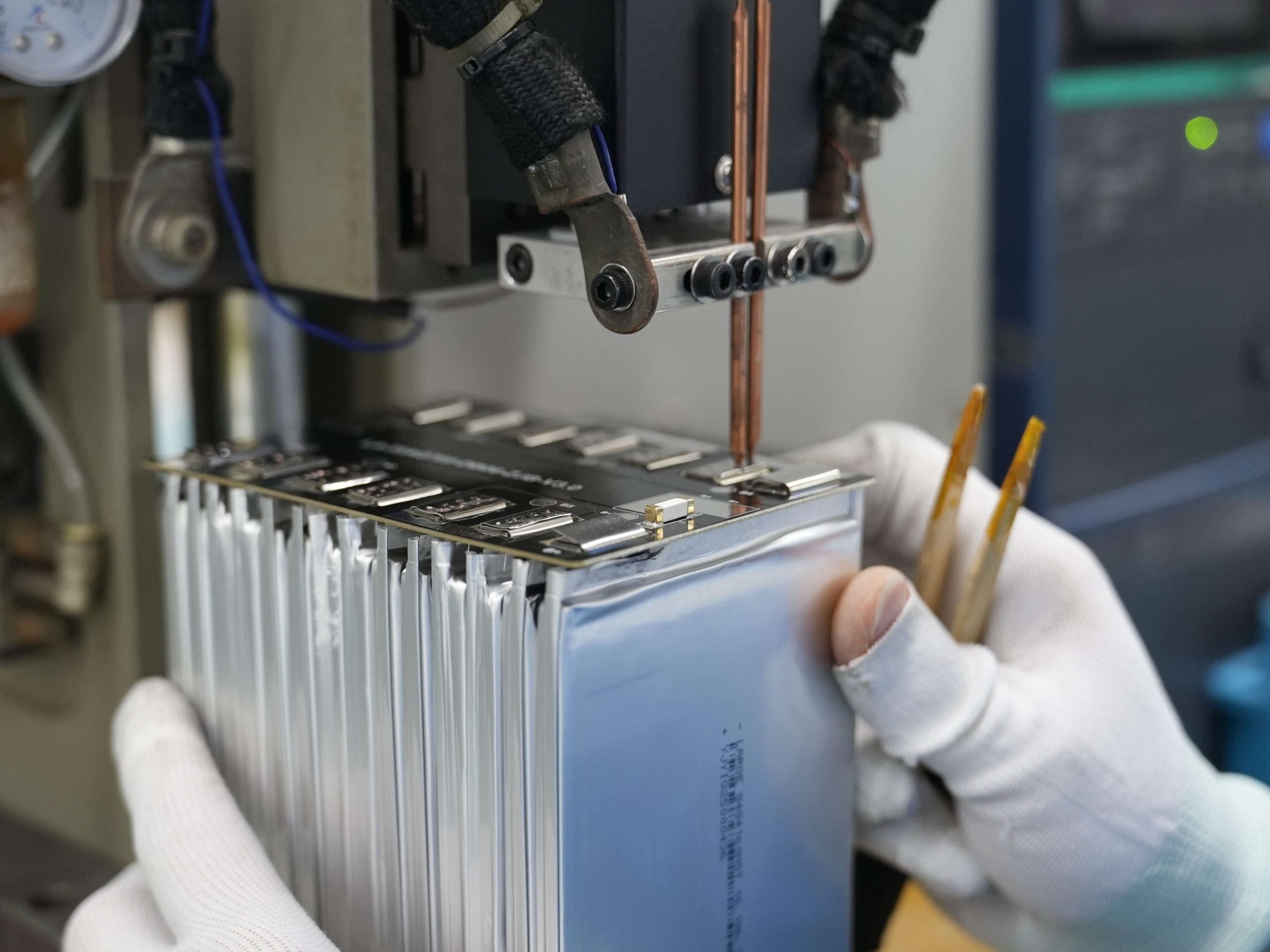

You use battery communication interfaces for diagnostics and control to keep your smart inspection devices running efficiently. These applications allow you to detect faults, balance cell voltages, and manage energy flow in lithium battery packs. In large drone battery systems, diagnostics help you identify weak cells and prevent failures during flight. Smart bms platforms use SMBus and UART to support advanced features like cell balancing and protection for LiFePO4, NMC, and LCO chemistries.

Remote monitoring becomes possible when you integrate these communication interfaces, allowing you to track battery health from a central location. You can also control charging and discharging processes, which is essential for maintaining the safety of UAVs and industrial robots.

The following table highlights how SMBus and UART interfaces facilitate diagnostics and control in lithium battery packs:

Feature | Description |

|---|---|

Protection for battery pack | Provides protection for 16 series LiFePO4 battery pack |

Cell voltage acquisition | Cell voltage acquisition and balancing function |

Protocol support | Support RS485, CAN, and Bluetooth protocols |

Note: You should always verify that your smart bms supports the required protocols for diagnostics and control, especially when working with large drone battery systems.

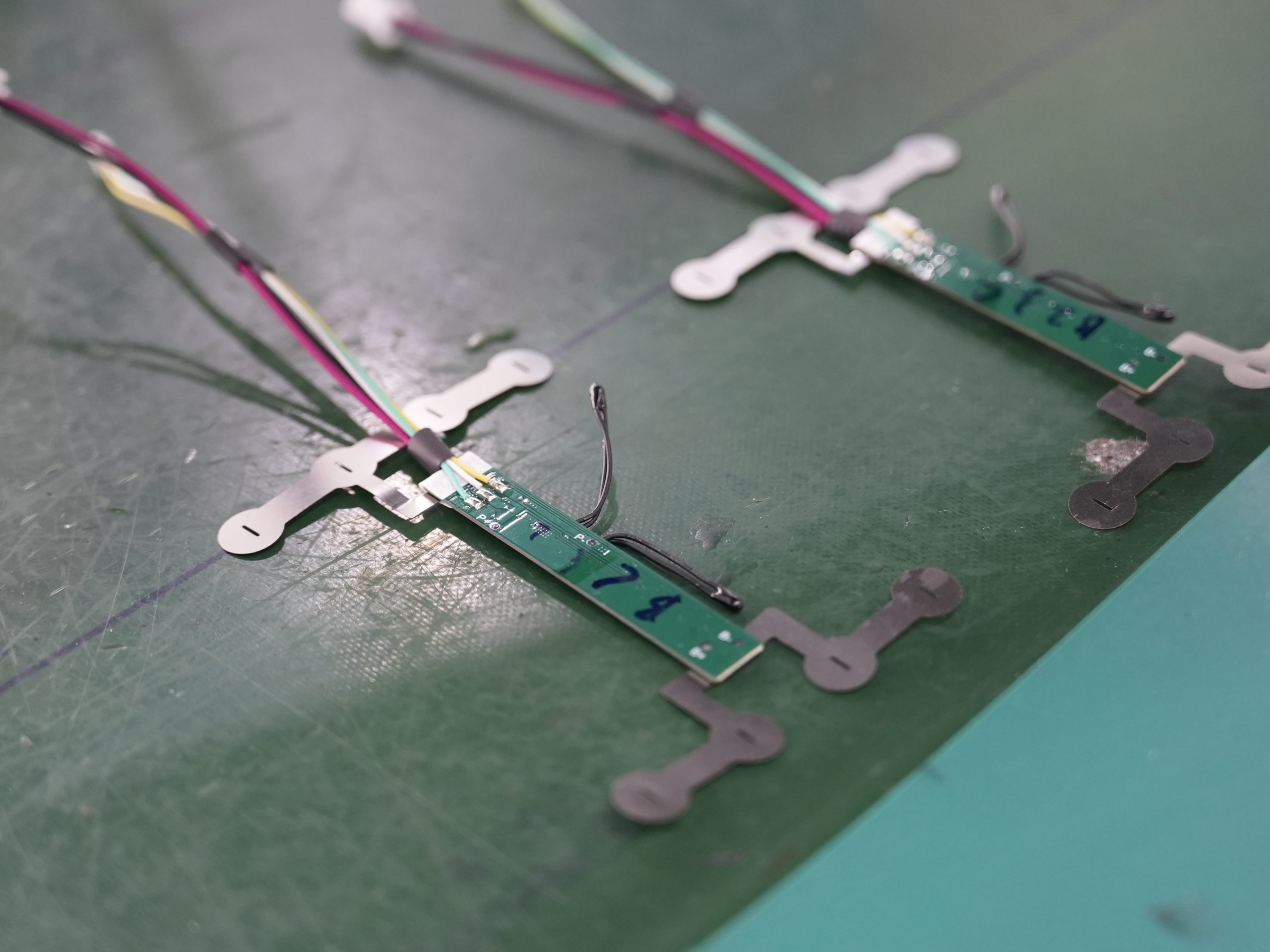

1.3 Lithium Battery Pack Integration

Integrating lithium battery packs with SMBus or UART interfaces presents unique challenges and opportunities for your smart inspection devices. You must consider communication reliability, especially in environments with high electrical noise. UART and I2C may not perform well for external links unless you add extra protections. The complexity of smart bms systems can make integration difficult, but successful implementation enables real-world applications in drones, robotics, and industrial inspection.

You need to select the right communication interface based on your device requirements. SMBus offers a master-slave architecture, which simplifies integration with system components. UART provides point-to-point communication, making it versatile for connecting sensors and displays in smart bms platforms.

Here is a comparison table of SMBus and UART features for battery communication in smart inspection devices:

Feature | SMBus | UART |

|---|---|---|

Protocol Type | System Management Bus (based on I2C) | General-purpose asynchronous transceiver |

Structure | Master-slave architecture | Point-to-point communication |

Data Transfer | Includes data, address, commands, and checksums | Supports multiple transmission rates and data bit counts |

Special Features | Battery capacity metering, thermal management, power management | Hardware flow control for smooth data transmission |

Integration | Simple, low cost, easy integration with system components | Versatile, used for various external devices like sensors and displays |

You should also follow industry standards when integrating lithium battery packs with communication interfaces. The SMBus standard provides guidelines for smart batteries, including data on voltage, current, temperature, state of charge, and alarms. PMBus extends SMBus for power systems, while UART and I2C are suitable for short-distance or internal board communications. For more details, you can refer to the SMBus 3.3.1 specification (2024).

Alert: Always test your communication interface in the actual operating environment to ensure reliable data exchange and energy management.

Part2: Interface Setup and Configuration

2.1 SMBus/UART Initialization

You need to set up SMBus and UART interfaces correctly to ensure reliable communication in your smart inspection devices. Start by configuring the GPIO pins for SMBus. Assign the correct pin numbers for SCL and SDA, set the mode to alternate function open-drain, and select a high-speed frequency. Make sure the peripheral clock is enabled in the RCC registers. If you encounter issues, use STM32CubeMX to generate initialization code for your platform. For UART, select the appropriate baud rate and data format for your application. This step helps your smart bms communicate with controllers and sensors in lithium battery pack systems.

Tip: Always verify your initialization settings before deploying your device. Proper setup reduces communication errors and improves system stability.

GPIO Initialization:

Pin assignment for SCL and SDA

Mode: Alternate function open-drain

Pull: No pull-up or pull-down

Speed: Very high frequency

Alternate: I2C2 function

2.2 Hardware Requirements

You must choose hardware components that support SMBus and UART protocols for lithium battery packs. The following table lists a key controller interface IC and its voltage range:

Component Name | Description | Voltage Range |

|---|---|---|

Microchip Technology USB5906C-I/KD | I2C, SMBus, SPI, UART Controller Interface IC | 1.08V |

You also need a Universal Asynchronous Receiver & Transmitter (UART) for serial communication. Select components that match the voltage and energy density requirements of your lithium battery chemistry, such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, or lithium metal.

Note: For more details on battery management system integration, see our BMS content.

2.3 Key Parameters

You should configure several key parameters to optimize communication between your smart bms and lithium battery packs. Set the baud rate, address, and data format for UART. For SMBus, define the slave address, clock speed, and timeout values. Monitor voltage, current, and temperature readings to ensure accurate data exchange. Adjust these parameters based on your device’s operational environment and battery chemistry.

Parameter | SMBus Setting | UART Setting |

|---|---|---|

Address | Slave address | Device address |

Speed | Clock speed (100kHz+) | Baud rate (9600+) |

Data Format | 8-bit, checksum | 8/9-bit, parity |

Timeout | 25ms typical | 10-100ms configurable |

⚡ Accurate parameter configuration helps your smart bms deliver real-time diagnostics and control for lithium battery packs.

Part3: Integration Steps for Smart Devices

3.1 Protocol Implementation

You need to follow a structured approach when implementing SMBus or UART protocols in your smart inspection device firmware. Begin by initializing the hardware abstraction layer and configuring the system clock. Set up the GPIO and USART peripherals to establish communication channels. Use functions like HAL_UART_Transmit to send data between your smart bms and lithium battery pack. Manage data reception through polling or interrupts, depending on your system requirements. For higher efficiency, consider using DMA for data transfer.

Here is a table outlining the recommended steps for protocol implementation:

Step | Description |

|---|---|

1 | Initialize the HAL and configure the system clock |

2 | Initialize GPIO and USART peripherals |

3 | Use HAL_UART_Transmit for sending data |

4 | Implement data reception using polling or interrupts |

5 | Optionally, use DMA for efficient data transfer |

Tip: Test each step in your development environment to ensure reliable communication with your lithium battery pack.

3.2 Real-Time Data Exchange

You achieve real-time data exchange by integrating smart bms options that support UART, RS485, and CANBus protocols. These protocols enable your inspection device to receive real-time battery data, including state of charge, voltage, current, temperature, and fault diagnostics. The Battery Management System acts as the central control unit, facilitating intelligent communication with host devices. Smartec Battery PCM BMS supports multiple protocols, such as SMBus, RS232, and RS485, which allows you to adapt to different system architectures and lithium battery chemistries like LiFePO4, NMC, and LCO.

Note: Real-time data exchange improves system-level integration and helps you monitor the state of health of your lithium battery pack.

3.3 Software Considerations

You must address several software considerations to ensure reliable SMBus or UART communication in your smart inspection devices. Select appropriate hardware connections, including Tx and Rx pins, to match your system layout. Configure UART settings in your microcontroller software, such as baud rate, data bits, stop bits, and parity. Choose between polling and interrupt-driven methods for managing data transmission. Conduct thorough testing and debugging to verify signal integrity and correct configurations.

Select hardware connections (Tx, Rx pins)

Configure UART settings (baud rate, data bits, stop bits, parity)

Use polling or interrupts for data management

Test and debug for signal integrity

⚡ Reliable software configuration ensures accurate data exchange and extends the operational life of your smart bms and lithium battery pack.

Part4: Troubleshooting and Best Practices

4.1 Communication Issues

You often encounter communication issues when using battery communication interfaces in smart inspection devices. Problems such as corrupted data, missing bytes, and incorrect baud rates can disrupt the flow of information between your microcontroller and lithium battery pack. These issues become more frequent in large drone battery systems, where long wiring and high electromagnetic interference can affect signal integrity.

To reduce errors in UART communication, you should slow down the transmission rate, enable parity checking, and implement checksum algorithms for error checking. You also need to check the wiring between the microcontroller and the device to ensure proper connections. Verifying that both devices use the same baud rate helps you avoid garbled data. Handling unexpected events, such as buffer overflow or framing errors, keeps your system stable.

Here is a table comparing common communication issues and recommended troubleshooting actions for SMBus and UART in lithium battery management:

Issue | Troubleshooting Action |

|---|---|

Corrupted data | Enable parity checking and checksum algorithms |

Missing bytes | Slow down transmission rate |

Incorrect baud rate | Verify baud rate settings on both devices |

Buffer overflow | Increase buffer size or optimize data flow |

Wiring problems | Inspect and secure all connections |

⚠️ Always monitor alarms or fault codes on your system. These alerts help you identify potential issues before they affect your drone operations or energy management.

4.2 Data Consistency

You need to maintain data consistency to ensure reliable operation of your smart inspection devices. Inconsistent data can lead to incorrect battery status readings, which may cause unexpected shutdowns or reduced energy efficiency in large drone battery systems. You should analyze stored data in your battery management system to identify fault causes and verify that all readings match expected values.

Implementing checksum algorithms and parity checks helps you detect and correct errors during data transmission. You should also synchronize data exchange intervals between your smart bms and host controller. This practice prevents data loss and ensures accurate reporting of voltage, current, and temperature for lithium battery packs.

Tip: Regularly review your system logs and perform data analysis to catch inconsistencies early. This approach improves reliability and extends the cycle life of your lithium battery technology.

4.3 Reliable Operation

You can achieve reliable operation by following best practices for battery communication interfaces in smart inspection devices. Start by checking for alarms or fault codes displayed on your system. Use the elimination method to remove components one by one and isolate the cause of interference. Swap modules or wiring to determine if a specific module is faulty. Ensure all connections are secure and power supplies are operational. If issues arise after a software update, roll back to a previous stable version. Analyze stored data in your battery management system to identify fault causes.

Here is a checklist to help you maintain reliable operation in large drone battery and lithium battery pack systems:

Observe system alarms and fault codes

Remove components one by one to isolate interference

Swap modules or wiring to identify faulty parts

Secure all connections and verify power supplies

Roll back software if new issues appear

Analyze stored data for fault diagnosis

✅ Consistent troubleshooting and adherence to best practices ensure your drone technology delivers reliable energy management and long-term performance.

You should always use standardized lithium battery chemistries such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. These chemistries offer different platform voltages, energy densities, and cycle lives, which affect the integration and reliability of your battery communication interfaces.

Part5: Future Trends in Battery Communication

5.1 Deployment Tips

You can improve the deployment of SMBus and UART interfaces in next-generation smart inspection devices by following a clear process. When you work with drone fleets or large drone battery systems, you need to ensure reliable communication for lithium battery packs. Here are practical steps for deploying UART in your inspection technology:

Understand UART as a serial protocol for data transmission between devices in your drone.

Set up the transmitter to send data with a start bit, data bits, and stop bits. The receiver monitors the RX line for incoming data.

Match the baud rate on both transmitter and receiver to avoid communication errors in your large drone battery platform.

Write code in your main.c file to transmit messages using HAL_UART_Transmit for your energy management system.

Build your project and use the command shell console to view output and debug your drone’s battery communication.

Tip: Always verify baud rate settings and test your communication code before deploying your drone fleet. This step helps you avoid downtime and ensures stable energy delivery.

5.2 Scalability

You need to consider scalability when you deploy SMBus and UART interfaces in smart inspection devices. Large drone battery systems require robust communication to support multiple lithium battery packs. The following table compares scalability characteristics for SMBus and UART protocols:

Protocol | Characteristics | Scalability Limitations |

|---|---|---|

SMBus | Lightweight, low-speed | Limited scalability in high-demand environments |

UART | Asynchronous serial data exchange | Limitations in distance and number of devices supported |

You should evaluate the number of drones and battery packs in your inspection network. SMBus works well for small groups of lithium battery packs, but you may face challenges in large drone battery deployments. UART supports asynchronous data exchange, but distance and device count can limit its use in energy-intensive drone operations.

Note: For large drone battery fleets, consider hybrid solutions that combine SMBus, UART, and higher-level protocols like CANBus to maximize scalability and energy efficiency.

5.3 Emerging Technologies

You will see new trends in battery communication for smart inspection devices. Advanced protocols and hardware are shaping the future of drone technology and lithium battery management. Solid-state and lithium metal chemistries offer higher platform voltages, greater energy density, and longer cycle life for large drone battery systems. You can expect integration of wireless communication, cloud-based diagnostics, and AI-driven energy optimization in next-generation drones.

Wireless battery communication reduces wiring complexity in drone swarms.

Cloud platforms enable remote monitoring and predictive maintenance for large drone battery fleets.

AI algorithms optimize energy usage and extend the cycle life of lithium battery packs.

⚡ Stay updated on emerging battery communication technologies. You can improve your drone’s operational reliability and energy management by adopting new protocols and chemistries such as LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal.

You gain several advantages by using SMBus and UART interfaces in smart inspection devices with lithium battery packs.

You monitor battery parameters in real time, which helps you make informed decisions.

You optimize battery performance through accurate data collection.

You enhance safety by detecting abnormal conditions early.

You should select robust communication protocols and standardize lithium battery chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. Stay updated on new technologies to improve reliability and efficiency in future deployments.

FAQ

What are the main benefits of using SMBus or UART in lithium battery pack inspection devices?

You gain real-time battery data, improved diagnostics, and enhanced safety. SMBus and UART help you monitor voltage, current, and temperature, which supports reliable operation in smart inspection devices using LiFePO4, NMC, LCO, LMO, LTO, solid-state, or lithium metal chemistries.

How do you choose between SMBus and UART for your smart inspection device?

You select SMBus for master-slave communication and standardized battery management. You choose UART for flexible, point-to-point connections. Consider your device’s architecture, required data speed, and lithium battery chemistry before making a decision.

What steps help you ensure reliable communication in large drone battery systems?

You verify baud rate settings, use shielded wiring, and enable error-checking features like parity and checksums. Regular testing and monitoring of alarms help you maintain stable data exchange for lithium battery packs in drone fleets.

Which lithium battery chemistries work best with SMBus and UART interfaces?

You achieve reliable integration with LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal chemistries. Each chemistry offers different platform voltages, energy densities, and cycle lives. You should match your interface to your battery type for optimal performance.

Can you scale SMBus and UART communication for multiple inspection devices?

You can scale SMBus for small groups of lithium battery packs. UART supports asynchronous data exchange but may face limitations with distance and device count. For large deployments, you combine SMBus, UART, and protocols like CANBus for better scalability.