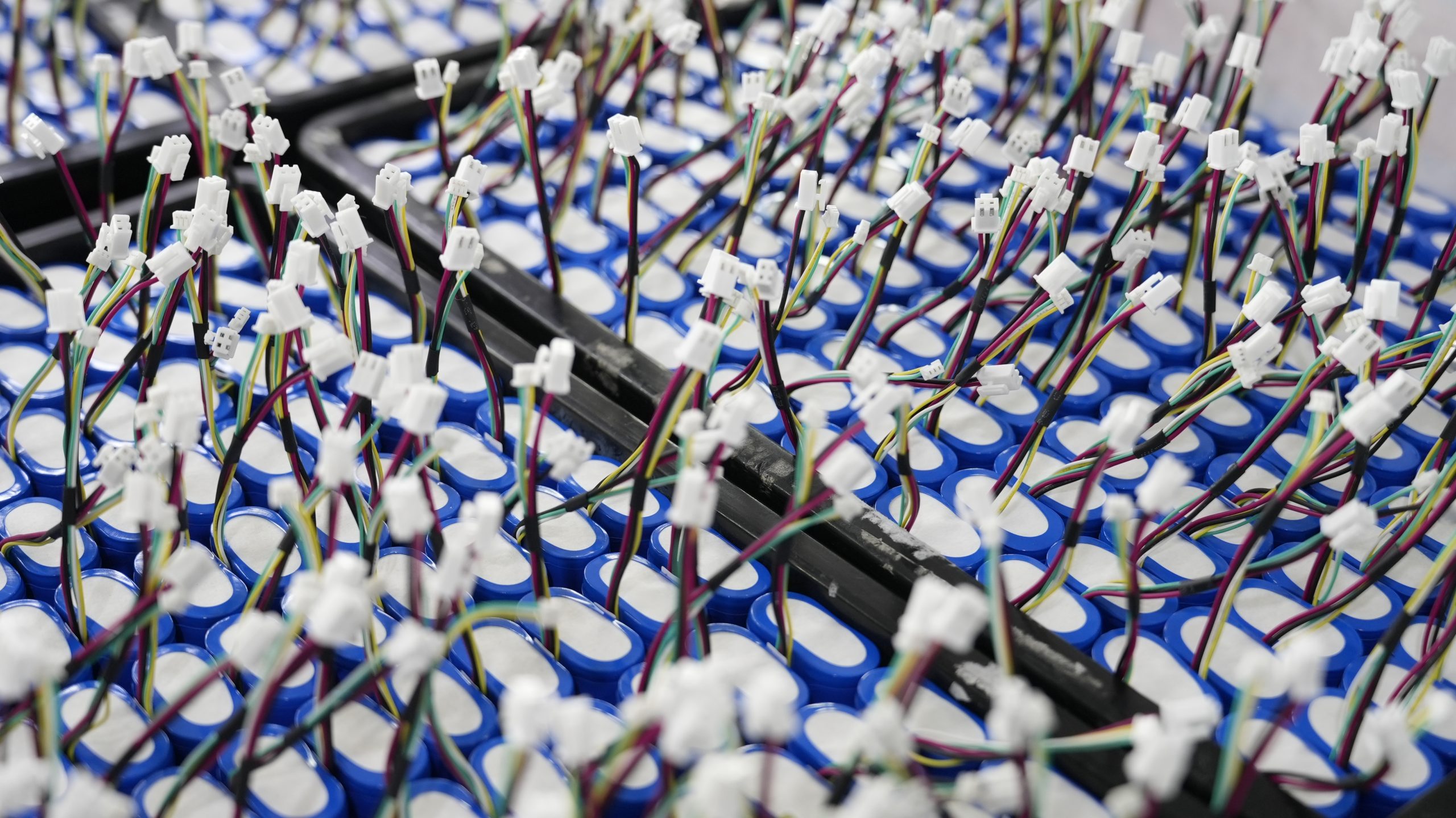

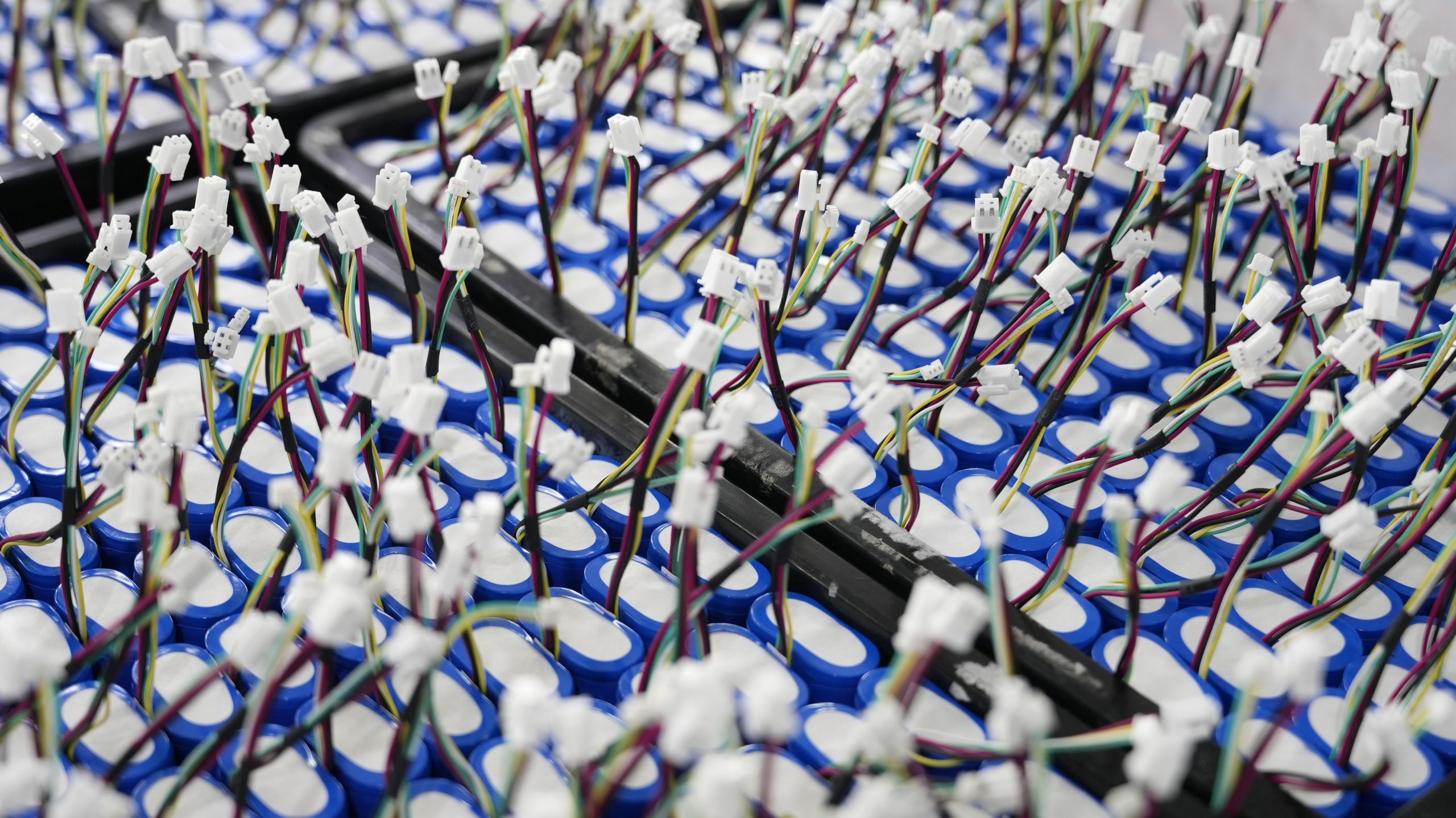

You rely on lithium battery packs to power critical equipment in demanding environments. High temperatures, freezing conditions, and exposure to water or dust create significant battery safety risk. Battery Design must address these hazards to protect your devices and the people who use them. Many sectors require high IP-rated solutions, including:

Agricultural machinery

Marine applications

A robust approach to safety allows your batteries to perform reliably, even in the harshest conditions.

Key Takeaways

Monitor battery temperatures during charging and discharging to prevent thermal runaway and ensure safety.

Select batteries with high IP ratings to protect against dust and water, enhancing reliability in harsh environments.

Implement effective thermal management systems to maintain safe operating temperatures and prevent capacity loss.

Regularly inspect and maintain battery enclosures and seals to prevent water ingress and extend battery lifespan.

Choose the right battery chemistry for your application to maximize performance and safety in extreme conditions.

Part 1: Battery Safety Risk in Harsh Environments

1.1 Temperature Effects

You face significant safety risks when operating high-capacity batteries in environments with extreme temperatures. Lithium-ion battery reactions rely on complex chemical processes. High temperatures can accelerate these reactions, sometimes causing thermal runaway events that lead to fires or explosions. Cold temperatures create different challenges. Charging batteries below 0°C can cause lithium plating, which permanently reduces capacity and increases the risk of internal short circuits.

Tip: Always monitor battery temperature during charging and discharging cycles to prevent thermal runaway.

Safety Risk | Description |

|---|---|

Thermal Runaway | Heat generation exceeds dissipation, leading to fires and explosions. |

Overheating | High temperatures trigger exothermic reactions, risking battery destruction. |

Low Temperatures | Cold weather causes lithium plating, reducing capacity and causing stress. |

Temperature fluctuations also impact battery performance and lifespan. For every 1°C rise, capacity increases by 0.8%, but a 6-10°C increase can cut battery life in half. At -10°C, available capacity drops to 70%. At 0°C, it falls to 85%. These changes increase internal resistance and can cause irreversible capacity loss. The optimal operating range for lithium-ion batteries is 15°C to 35°C. Exposing batteries to temperatures above 35°C increases the risk of overheating and reduces battery health. In some cases, internal temperatures can reach dangerous levels, especially in vehicles or outdoor enclosures exposed to direct sunlight.

1.2 Environmental Hazards

Environmental conditions such as dust, water, and pressure present additional safety risks for battery packs. Dust can enter enclosures and cause internal short circuits or corrosion. Water ingress can trigger thermal runaway or electrical faults. High humidity and condensation also threaten battery safety by increasing the risk of corrosion and internal damage.

IP Rating | Dust Protection | Water Protection |

|---|---|---|

IP20/IP22 | Basic dust/drip | Minimal |

IP54/IP65 | Partial dust/splashing | Low-pressure water jets |

IP67 | Total dust-tight | 30-minute submersion in 1 meter of water |

IP68 | Total dust-tight | Prolonged or deeper immersion |

IP69K | Total dust-tight | High-pressure, high-temperature water jets |

The IP (Ingress Protection) rating system, defined by IEC 60529, classifies batteries based on their resistance to dust and water. For example, IP67-rated batteries can survive 30 minutes of submersion at 1 meter, making them suitable for marine, medical, and industrial applications. IP69K batteries withstand high-pressure, high-temperature water jets, which is essential for food processing or hygiene-sensitive environments.

Improper storage or exposure to severe weather conditions can cause fires that burn at extremely high temperatures. These fires emit toxic gases like hydrogen and carbon monoxide, posing health risks to people and damaging local ecosystems. Fires can spread quickly, damaging nearby equipment and infrastructure. In some cases, battery fires may reignite hours or days later, making them difficult to control.

1.3 Risk Mitigation

You can reduce safety risks by following best practices in battery design and installation. Start by selecting battery chemistries and pack assemblies that match your environmental conditions. Use high ingress protection ratings to safeguard against dust and water. Enclosure design should focus on material selection, shape, and placement to optimize heat transfer and prevent water intrusion.

Strategy | Description |

|---|---|

Battery Pack Assembly | Protects cells from severe weather conditions and reduces thermal runaway risk. |

Enclosure Design | Optimizes heat transfer and mitigates water ingress. |

High Ingress Protection | Improves safety in high humidity environments. |

Routine Maintenance | Regularly test enclosures and seals for integrity. |

Installation Inspections | Inspect installations to ensure safety and performance. |

Note: Routine maintenance and inspection of seals and enclosures help prevent water infiltration and maintain battery safety.

Manufacturers test and certify batteries for compliance with IP67, IP68, and IP69K standards. For IP67, batteries undergo submersion at 1 meter for 30 minutes. IP68 testing involves prolonged submersion at 1.5 meters for 24 hours. IP69K testing uses high-pressure, high-temperature water jets. These protocols ensure that batteries meet the demands of your application, whether in robotics, security systems, infrastructure, or consumer electronics.

International standards like IEC 60529 provide consistent ratings for battery protection. Manufacturers must design batteries to meet specific IP ratings based on the intended environment, such as marine or outdoor use. These requirements are not optional; industry standards mandate them across regions and sectors.

Part 2: Battery Design Strategies for Extreme Conditions

2.1 Thermal Management

You must address thermal management when designing high-capacity batteries for harsh environments. Effective thermal management protects battery safety and ensures reliable battery performance. Without proper temperature control, you risk thermal runaway, capacity loss, and equipment failure. You can use several technologies to manage heat and cold in your battery energy storage system.

Technology Type | Description |

|---|---|

Cooling Systems | Forced ventilation, air cooling, and liquid cooling help dissipate heat from high-capacity batteries. |

Heating Systems | Electric heating elements and fluid circuits maintain optimal temperatures in cold conditions. |

Battery Management System | Monitors temperatures and activates cooling or heating to prevent damage and ensure safety. |

You can improve battery safety by continuously monitoring cell temperatures with distributed sensors. When temperatures rise, cooling systems activate to prevent overheating. In cold conditions, heating elements trigger to keep batteries above freezing. These strategies help you maintain operational temperature and humidity, which is critical for battery risk assessments in industrial, medical, and robotics applications.

High-temperature resistant housings play a key role in battery design. These housings provide structural support and enhance durability under severe weather conditions. They protect against water, dust, and vibrations, reducing the risk of damage. Pressure equalization valves prevent explosions by managing internal pressure during thermal events. Continuous temperature monitoring allows early detection of overheating, so you can intervene before safety protocols are breached.

Evidence Description | Impact on Safety |

|---|---|

High-temperature resistant housings | Enhances durability and integrity of battery packs under extreme conditions |

Protection against external influences | Reduces risk of damage and failure due to environmental factors |

Pressure equalization valves | Prevents explosions by managing internal pressure during thermal events |

Continuous temperature monitoring | Ensures early detection of overheating, allowing for timely intervention |

Controlled battery temperatures | Minimizes risk of fire and ensures safety for users and equipment |

Tip: You should always include protection circuits and embedded temperature sensors in your battery design to maximize safety and battery performance.

2.2 Battery Chemistry Selection

Selecting the right battery chemistry is essential for reliable operation in extreme temperatures. You need to consider platform voltage, energy density, cycle life, and safety features. Some lithium battery chemistries offer better performance in cold or hot environments.

Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) | Cold Temperature Performance | High Temperature Performance | |

|---|---|---|---|---|---|

Sodium-ion | 2.3 V | 100-150 | 2,000+ | 70-80% capacity at -40°C, 6C discharge at -20°C | No thermal runaway at -40°C |

Solid-State | 2.5-3.7 V | 200-400 | 5,000+ | Operates from -40°C to 80°C | |

Lithium Iron Phosphate (LFP) | 3.2 V | 90-160 | 2,000+ | 85% capacity at -20°C, optimal between 0°C and 45°C | 92% capacity at 60°C over 1000 cycles |

Vanadium Redox Flow Batteries | 1.26 V | 20-40 | 10,000+ | Operates from -40°C to 80°C | Non-flammable across the temperature range |

You can also choose lithium titanate and TADIRAN TLH Series batteries for extreme temperature performance. These batteries deliver high energy density, low self-discharge rates, and rugged construction. You can use them in medical equipment, security systems, and industrial sensors where battery safety and reliability are critical.

Characteristic | TLH Series Batteries |

|---|---|

Voltage | 3.6 V |

Energy Density | 730 Wh/kg |

Temperature Range | -55°C to 125°C |

Self-Discharge Rate | Very low |

Construction | Hermetically sealed can for leak prevention |

High Temperature Capability | Proven performance in extreme temperatures |

High Energy Density | 1,420 Wh/l |

Extreme Temperature Range | -80°C to +125°C |

Safety Features | Protection against temperature, pressure, etc. |

High energy density (1,420 Wh/l)

High capacity for long runtimes

Low self-discharge rate for extended shelf life

Ruggedized for severe weather conditions and vibration

Added safety against temperature, pressure, puncture, shock, and vibration

You can deploy these high-capacity batteries in robotics, infrastructure, and consumer electronics where operational temperature and humidity fluctuate. You should always match battery chemistry to your application and environment to maximize battery performance and safety.

2.3 High IP Protection Enclosures

You need robust enclosure design to achieve high IP ratings like IP67, IP68, and IP69K. These ratings guarantee battery protection against dust, water, and other environmental hazards. You must use sealed connectors, pressure relief valves, and corrosion-resistant materials to ensure durability and long-term reliability.

Design Feature | Description |

|---|---|

Sealed Connectors | Prevents water and dust ingress, ensuring reliable electrical connections. |

Pressure Relief Valves | Allows for pressure equalization, preventing enclosure damage during use. |

Corrosion-Resistant Materials | Ensures durability and longevity in harsh environments, protecting the battery. |

IP67 requires immersion in a meter of water for 30 minutes.

IP68 offers higher protection against water submersion.

IP69K involves high-pressure washdowns, so you need robust sealing designs.

You should use leak-proof O-rings and elastomeric seals to create airtight and liquid-tight barriers. These sealing compounds prevent fluid seepage and contain liquid coolants, reducing the risk of short circuits and thermal imbalances. Chemical-resistant materials withstand exposure to aggressive chemicals, ensuring long-term durability. Sealing solutions block humidity ingress and road debris, protecting battery components from corrosion and contaminants.

Note: Proper sealing helps your battery enclosures meet IP67 or IP68 standards, extending the lifespan of sensitive components and maintaining battery safety.

Advanced encapsulation methods, custom casing, and anti-vibration housing increase tooling, material, and manufacturing costs. You must balance cost with the need for high IP-rated enclosures and advanced thermal management. Passive air cooling, active cooling, fire-retardant insulation, and embedded temperature sensors add complexity but improve safety and battery performance.

You can deploy these high-capacity batteries in medical, robotics, security systems, infrastructure, and consumer electronics. You must always consider battery risk assessments and safety protocols when selecting enclosure designs for your battery energy storage system.

Part 3: Battery Installation and Maintenance

3.1 Installation Guidelines

You need to follow strict installation guidelines when deploying high-capacity batteries in harsh environments. Proper battery design helps prevent water ingress and dust contamination, which can cause failures. Always select enclosures with the right ingress protection level for your application. The table below shows how different IP levels protect against dust:

Level | Protection Against | Description |

|---|---|---|

IP0X | None | No protection against contact or object ingress |

IP5X | Dust Protected | Dust may enter but not enough to interfere with operation |

IP6X | Dust-tight | Complete dust protection; no ingress permitted |

You should use corrosion-resistant materials and hydrophobic surface treatments to reduce the risk of water ingress. Integrate sealing technologies like compression seals and O-rings. Precision manufacturing ensures tight tolerances, which keeps your battery safe from dust and water. In medical, robotics, and industrial sectors, these steps help maintain reliable operation.

Tip: Always inspect seals and connectors before installation to avoid water ingress and ensure long-term safety.

3.2 Maintenance Protocols

You must maintain your battery packs to ensure ongoing safety and performance. Store batteries in a cool, dry place to prevent water ingress and temperature-related damage. For long-term storage, keep batteries at about 50% charge. This practice helps maintain battery health. Avoid exposing batteries to extreme temperatures. Control humidity to prevent corrosion and other damage.

Check stored batteries regularly and recharge if needed.

Use occasional charging cycles to keep batteries healthy.

Avoid inactivity for extended periods.

These protocols apply to batteries in security systems, infrastructure, and consumer electronics. Routine maintenance helps you detect early signs of water ingress or other hazards before they cause failures.

3.3 Monitoring Systems

You should use advanced monitoring systems to detect early signs of battery failure. A Battery Management System (BMS) learn more about BMS tracks voltage, current, and temperature in real time. This system prevents hazards like overcharging, overheating, and deep discharging. It also ensures balanced charging across all cells, which extends the operational lifespan of your battery packs.

Feature | Description |

|---|---|

Preventing Unexpected Failures | BMS continuously monitors voltage, current, temperature, and state of charge to detect early signs of degradation, allowing for proactive maintenance before failures occur. |

Enhancing Predictive Maintenance | BMS supports data-driven maintenance, alerting technicians to potential issues based on actual battery conditions, thus extending battery life and reducing costs. |

Remote Monitoring | Enables technicians to monitor battery health from anywhere, allowing for immediate action in case of issues, which is crucial in harsh environments. |

Modern BMS solutions use machine learning to analyze battery behavior. These systems identify unusual patterns, giving you early warnings for issues like thermal runaway. In industrial and medical applications, real-time monitoring improves safety and reduces downtime.

Real-time monitoring of key parameters enhances safety and extends the life of your high-capacity batteries. You can prevent water ingress, overheating, and other hazards by acting quickly on alerts.

You can achieve reliable battery performance in harsh environments by focusing on battery design strategies that prioritize safety. Key approaches include temperature management systems, sealed enclosures, pressure regulation, and advanced battery management systems. Regular maintenance and inspection help prevent dust and moisture issues, which improves long-term safety. Choose proven chemistries like LiFePO4 or LiSOCl₂ for stability in extreme conditions. When you invest in robust engineering and proactive risk mitigation, your battery solutions deliver dependable results in industrial, medical, and security applications.

FAQ

What does IP67, IP68, or IP69K mean for lithium battery packs?

IP ratings show how well your battery pack resists dust and water. IP67 means dust-tight and safe for short water immersion. IP68 allows longer or deeper immersion. IP69K protects against high-pressure, high-temperature water jets. Choose the right rating for your application.

How do you keep lithium battery packs safe in extreme temperatures?

You use thermal management systems like cooling fans, heating elements, and temperature sensors. These systems help maintain safe operating temperatures. You also select battery chemistries that perform well in hot or cold environments.

Which lithium battery chemistry works best for harsh environments?

Lithium titanate and TADIRAN TLH Series batteries offer high energy density and wide temperature ranges. You can use them in medical devices, robotics, and industrial sensors. These chemistries provide reliable performance and safety in extreme conditions.

How often should you inspect battery enclosures and seals?

You should inspect enclosures and seals every three to six months. Regular checks help you find leaks, corrosion, or damage early. This practice keeps your battery packs safe and extends their lifespan.

What role does a Battery Management System (BMS) play?

A BMS monitors voltage, current, and temperature in real time. You use it to prevent overcharging, overheating, and deep discharging. BMS helps you maintain battery health and safety, especially in critical applications like security systems and infrastructure.